A feeding device for cold heading machine

A feeding device, cold heading machine technology, applied in the direction of operating devices, forging/pressing/hammer devices, cleaning methods using gas flow, etc., can solve the problem of hard-to-move discharge plates, hard-to-remove metal shavings, nuts and other fasteners Difficult to move and other problems, to achieve the effect of stable conveying and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

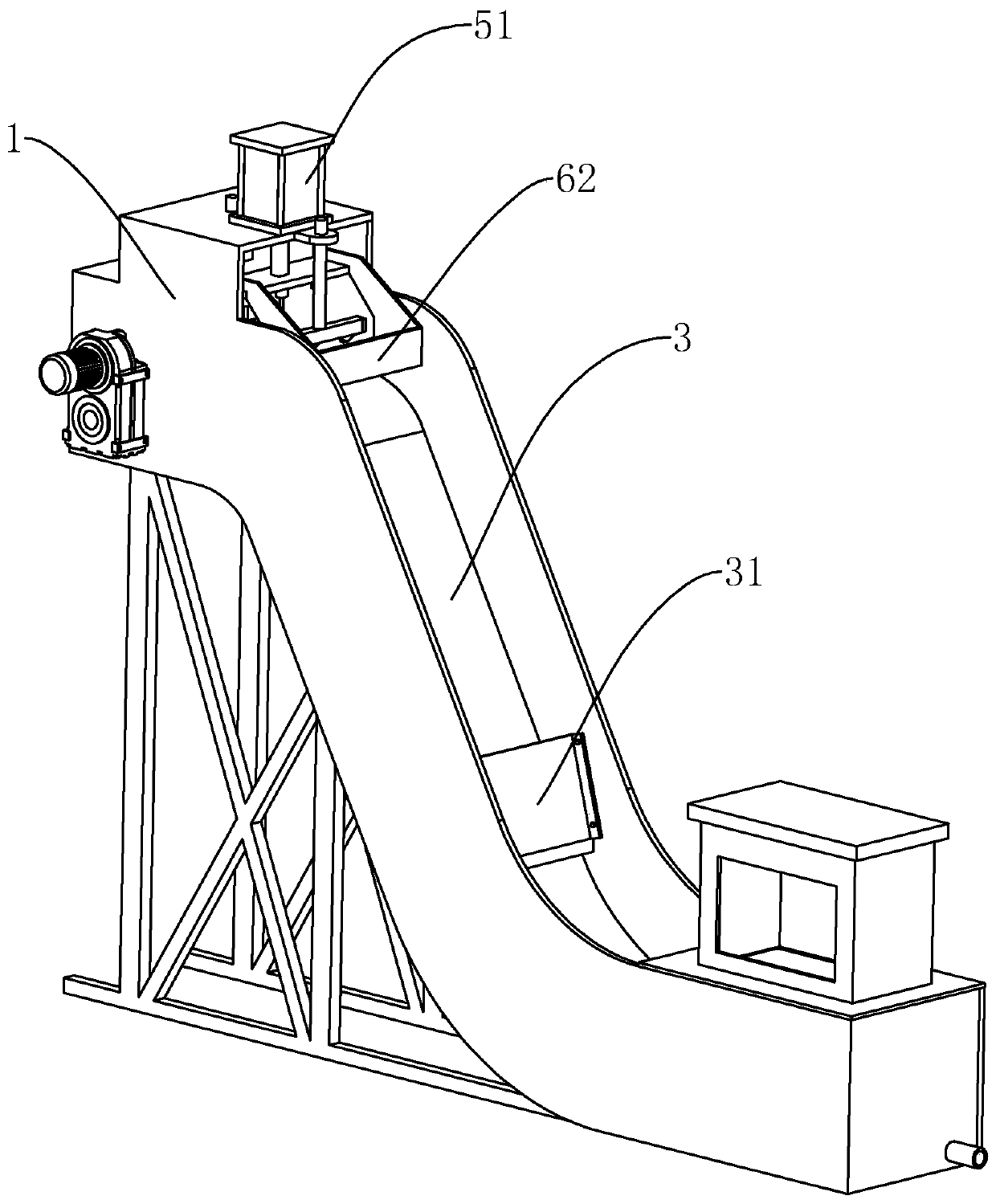

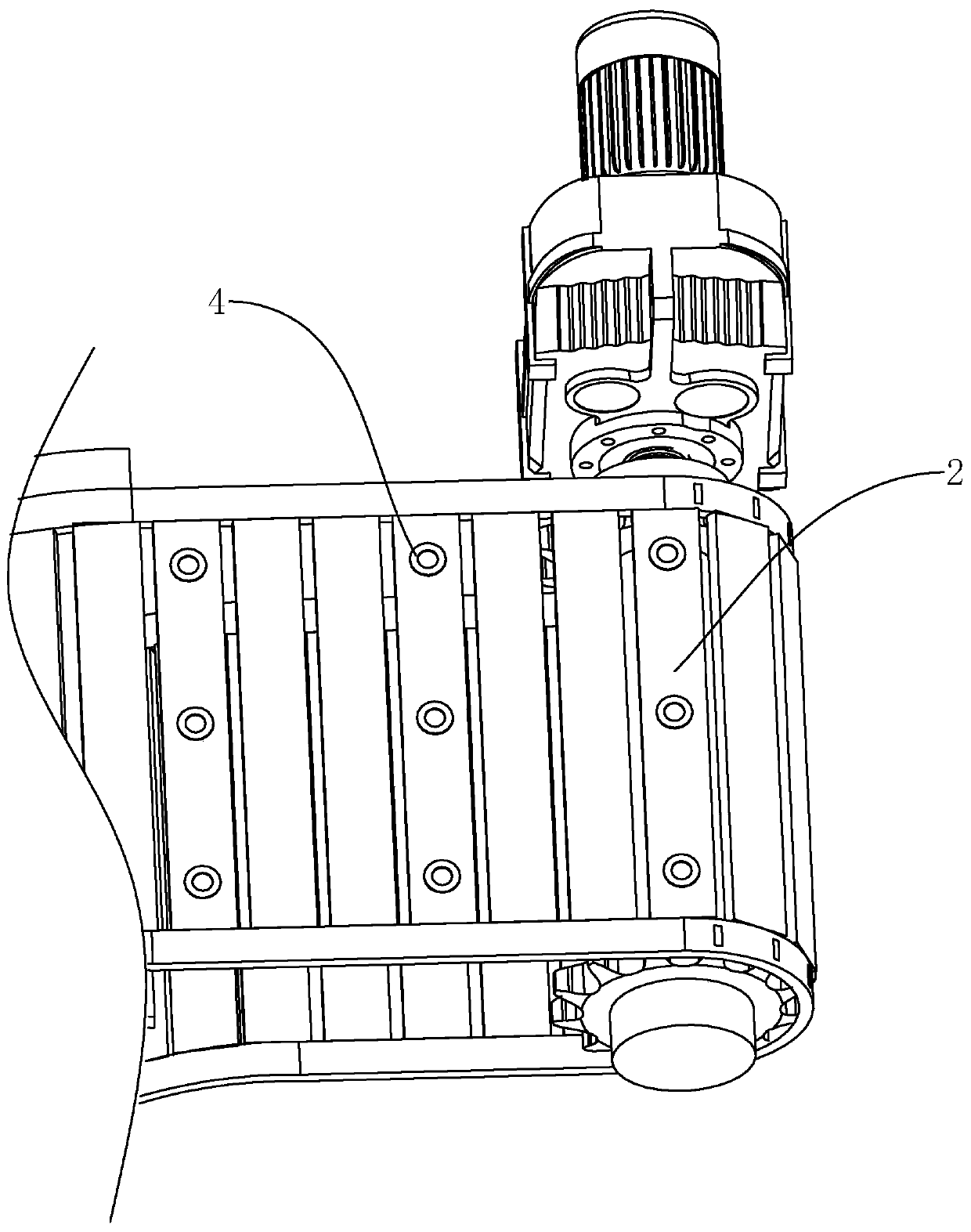

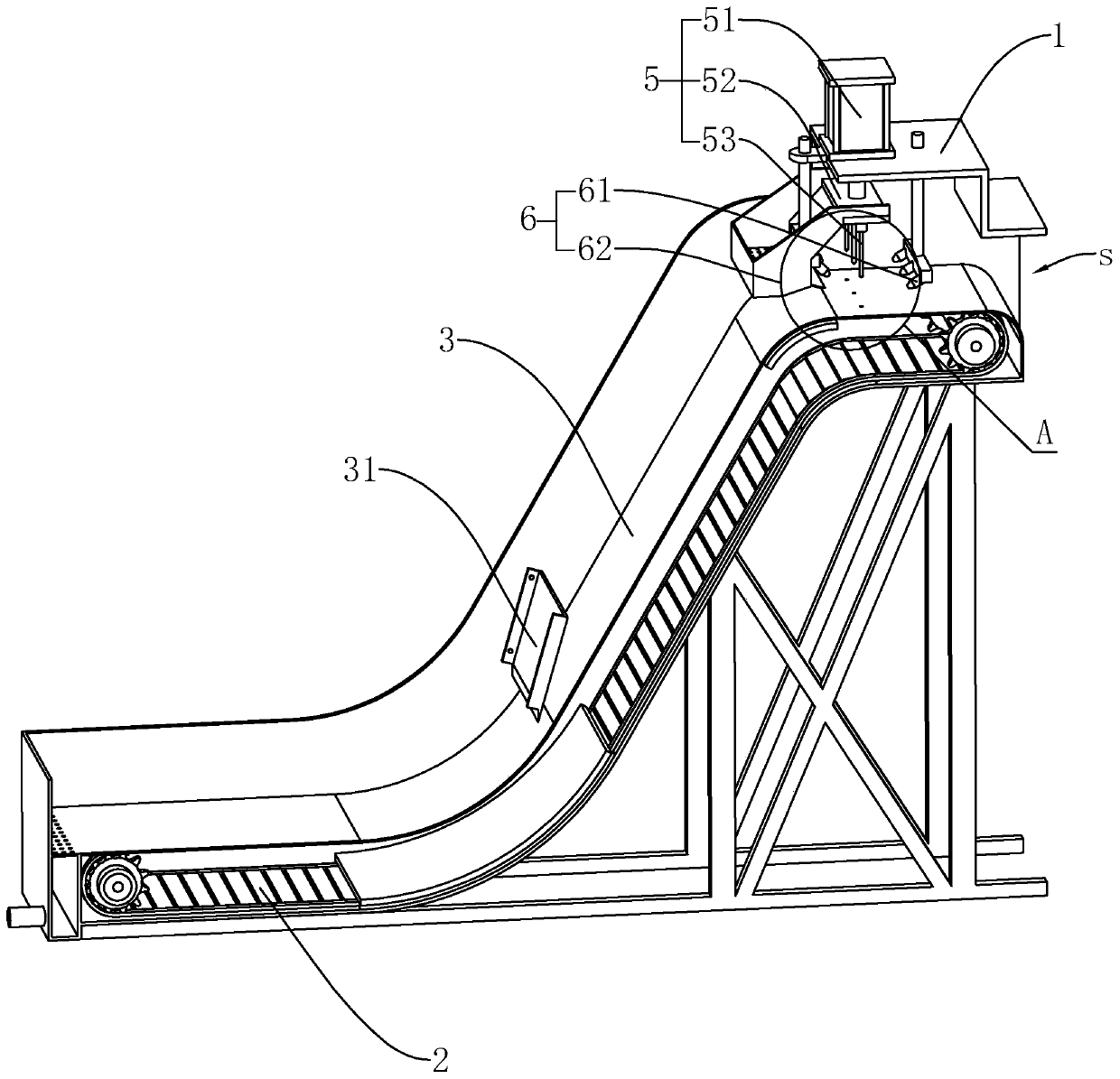

[0037] This embodiment discloses a feeding device for a cold heading machine, such as figure 1 , figure 2 As shown, it includes a frame 1 and a conveying mechanism installed on the frame 1 . The conveying mechanism includes a chain plate conveyor belt 2 driven by a geared motor and a delivery groove 3 fixed above the chain plate conveyor belt 2. A plurality of magnets 4 are fixed side by side on the chain plate of the chain plate conveyor belt 2, and the delivery groove 3 is made of stainless steel, and The bottom of the conveying trough 3 fits with the magnet 4 on the chain plate conveyor belt 2. When the nut falls into the conveying trough 3, it can be attracted by the magnet 4 and bonded to the conveying trough 3; and when the chain plate conveyor belt 2 operates , the nut can also be adsorbed and move relative to the delivery trough 3 .

[0038] Since...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com