Patents

Literature

159results about How to "Reduce intermediate process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

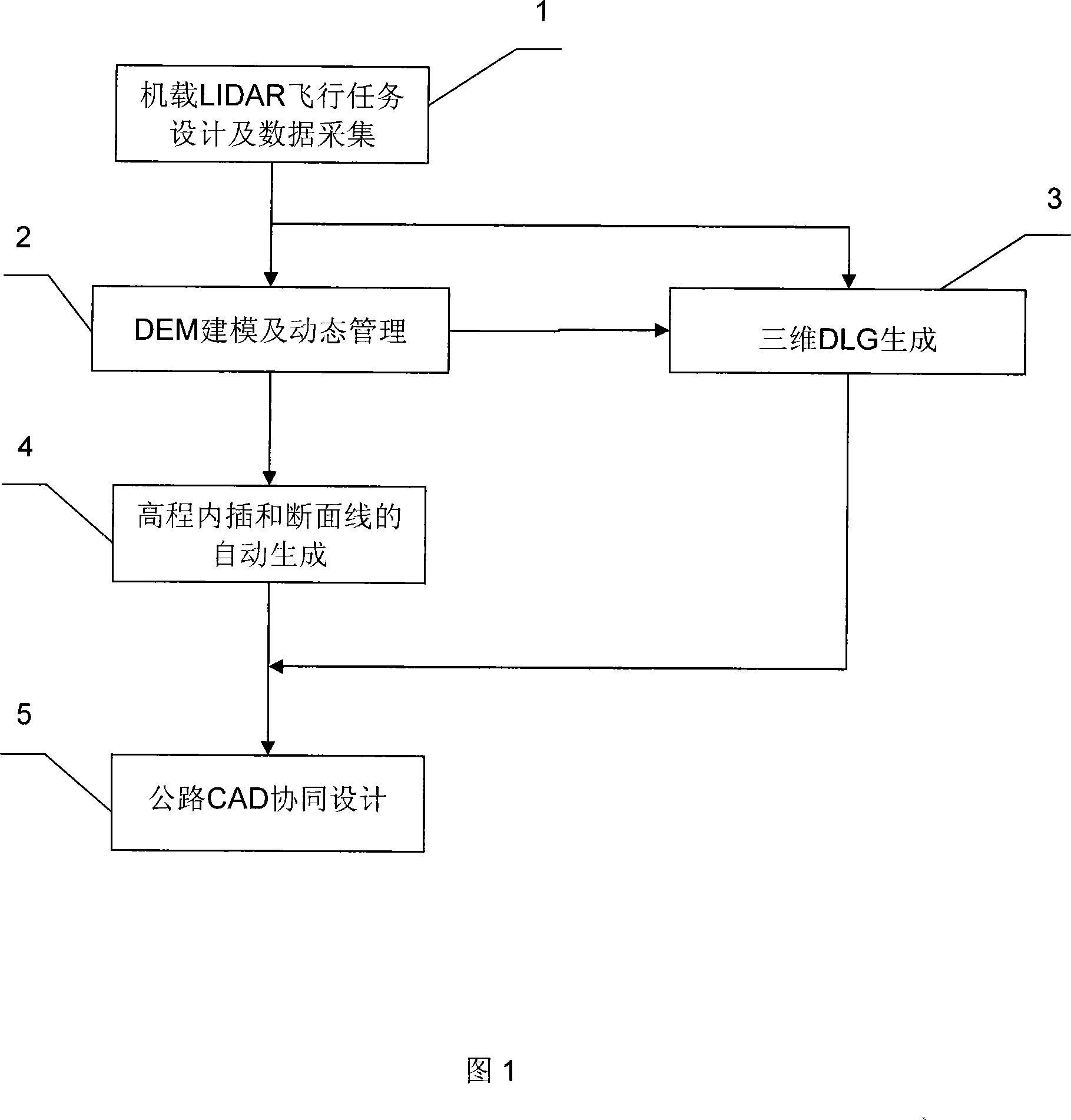

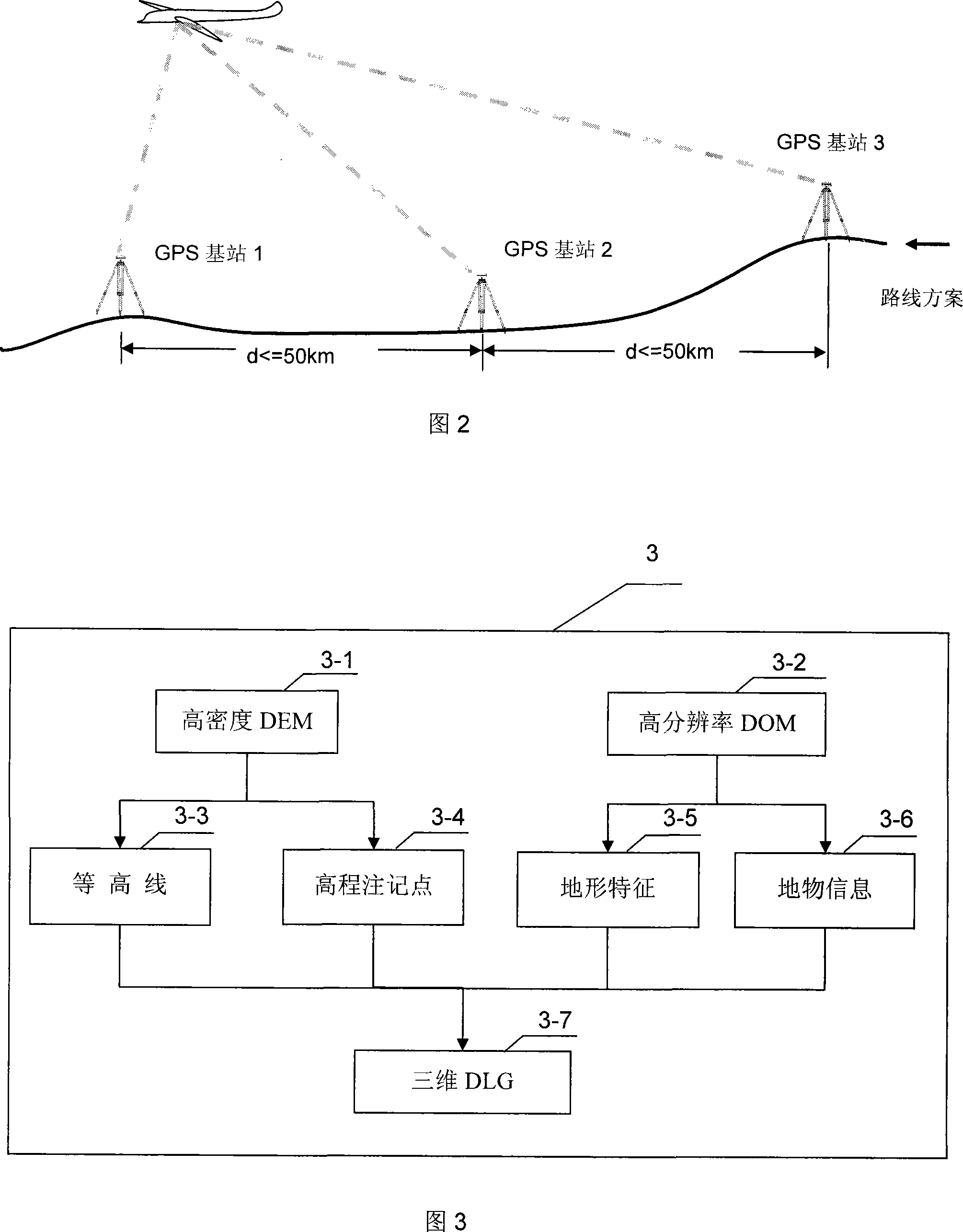

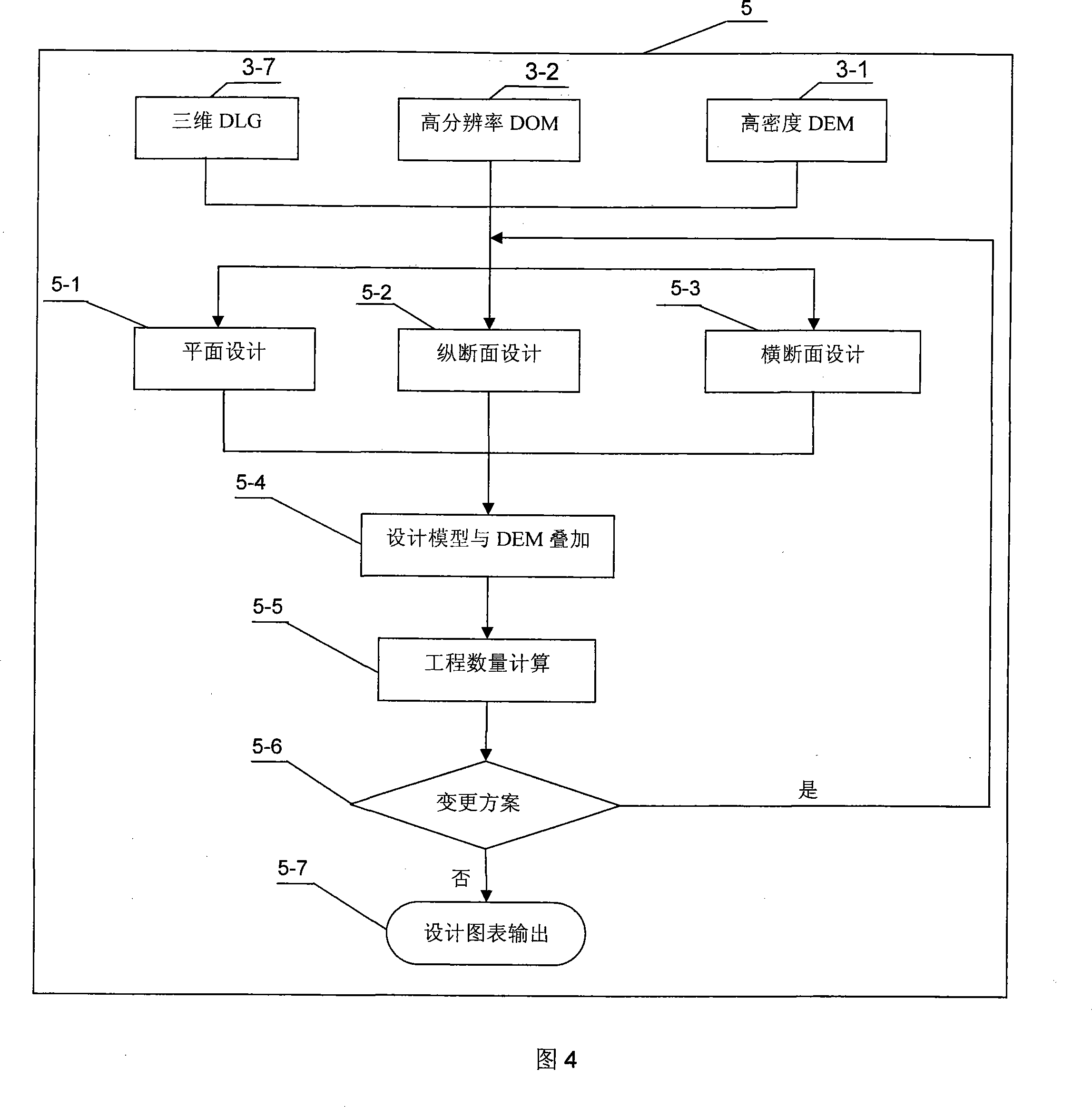

Highway measuring and setting method based on three-dimensional airborne LIDAR

ActiveCN101159066AReduce workloadReduce operating costsPhotogrammetry/videogrammetryElectromagnetic wave reradiationShop drawingWork flow

The invention discloses a road measurement method based on 3D plane-carried LIDAR. The steps include: firstly, constructing GPS base stations in a measurement area and setting technical parameters based on a road design proposal by employing a ground data collection system and taking a plane as a platform; secondly, building a database of a large amount of high density DEM data, and performing dynamic block management on the database via a range index file to satisfy rapid scheduling of required data in design procedure; thirdly, generating a 3D DLG based on DEM and DOM; fourthly, generating ground broken section data satisfying road measurement and design requirement of construction blueprint; and fifthly, realizing 3D visibility and dynamic design based on combination of plane-carried LIDAR and road CAD to automatically generate various design schemes and construction blueprints. The inventive method has the advantages of simple and convenient operation, directly-realized road measurement and construction blueprint design based on data generated by a plane-carried LIDAR, reduced external field work flow, shortened measurement and design period, and greatly increased measurement and design efficiency.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

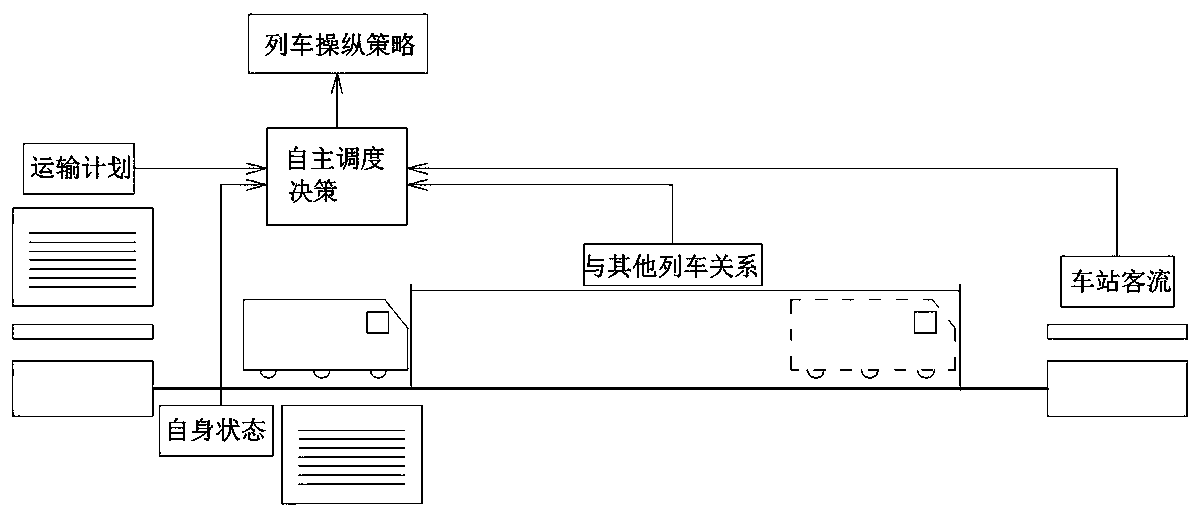

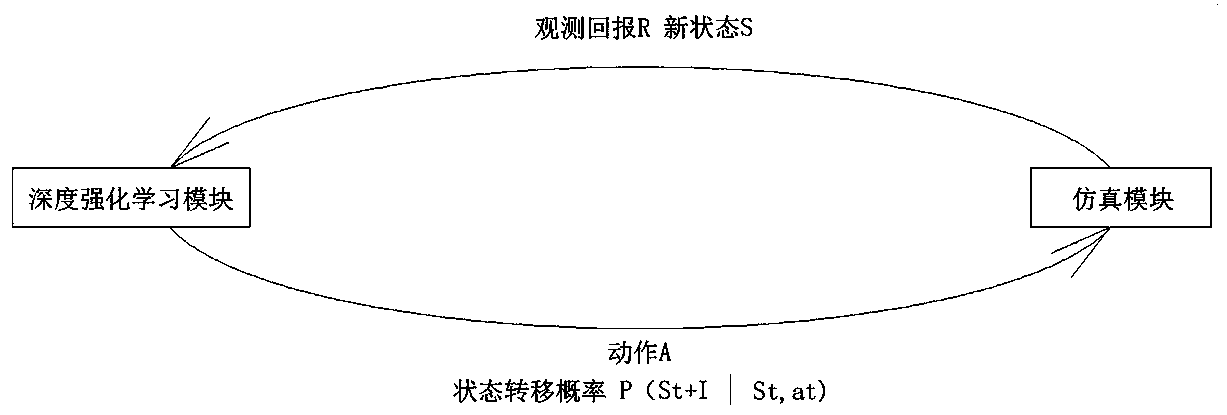

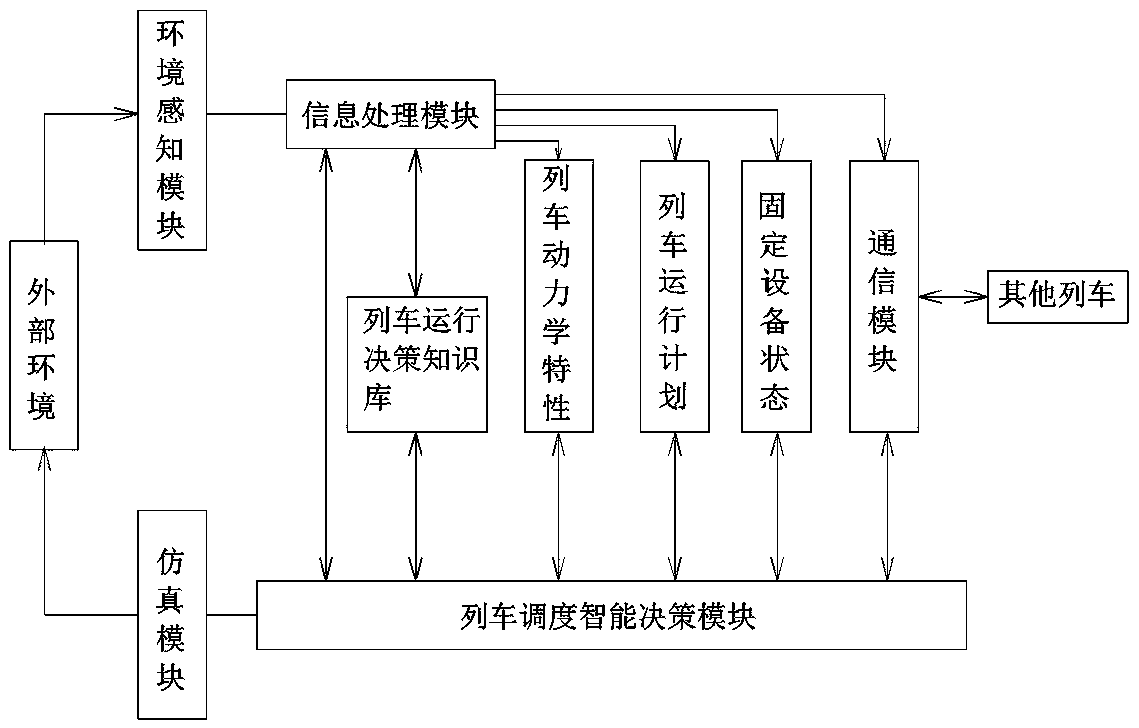

Autonomous scheduling method and system for train

ActiveCN111376954AGuaranteed operational safetyImprove reliabilityAutomatic systemsDecision modelSystems simulation

The invention provides an autonomous scheduling method and system for a train. A simulation module receives rail transit data and simulates an actual rail transit system; the simulation module and a deep reinforcement learning module perform interactive training; the deep reinforcement learning module obtains a trained scheduling decision model; the deep reinforcement learning module transmits thetrained scheduling decision model to a scheduling scheme module; the simulation module simulates a current train running state and outputs the current train running state to the scheduling scheme module; the scheduling scheme module generates a scheduling scheme based on the current train running state; and the scheduling scheme module transmits the scheduling scheme to the actual rail transit system. The actual rail transit system is simulated through the simulation module; the scheduling model is trained through the deep reinforcement learning module; the deep reinforcement learning moduletrains the scheduling model, so that each train adjusts the operation control strategy of the train according to an operation environment, and therefore, train operation energy consumption and passenger waiting time are reduced on the premise that train operation safety and punctuality are ensured; and the real-time performance and flexibility of scheduling are relatively high.

Owner:CRSC RESEARCH & DESIGN INSTITUTE GROUP CO LTD

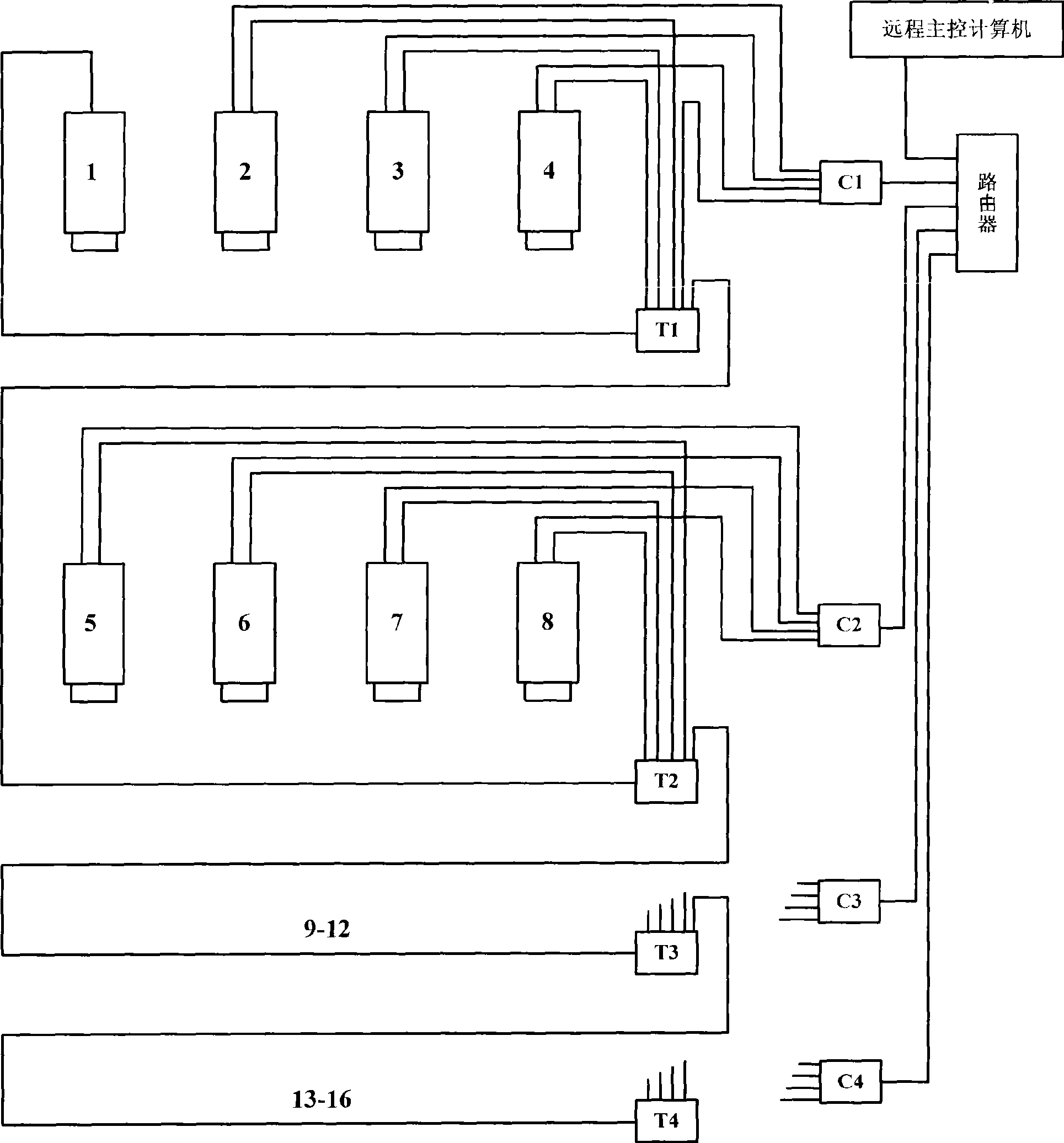

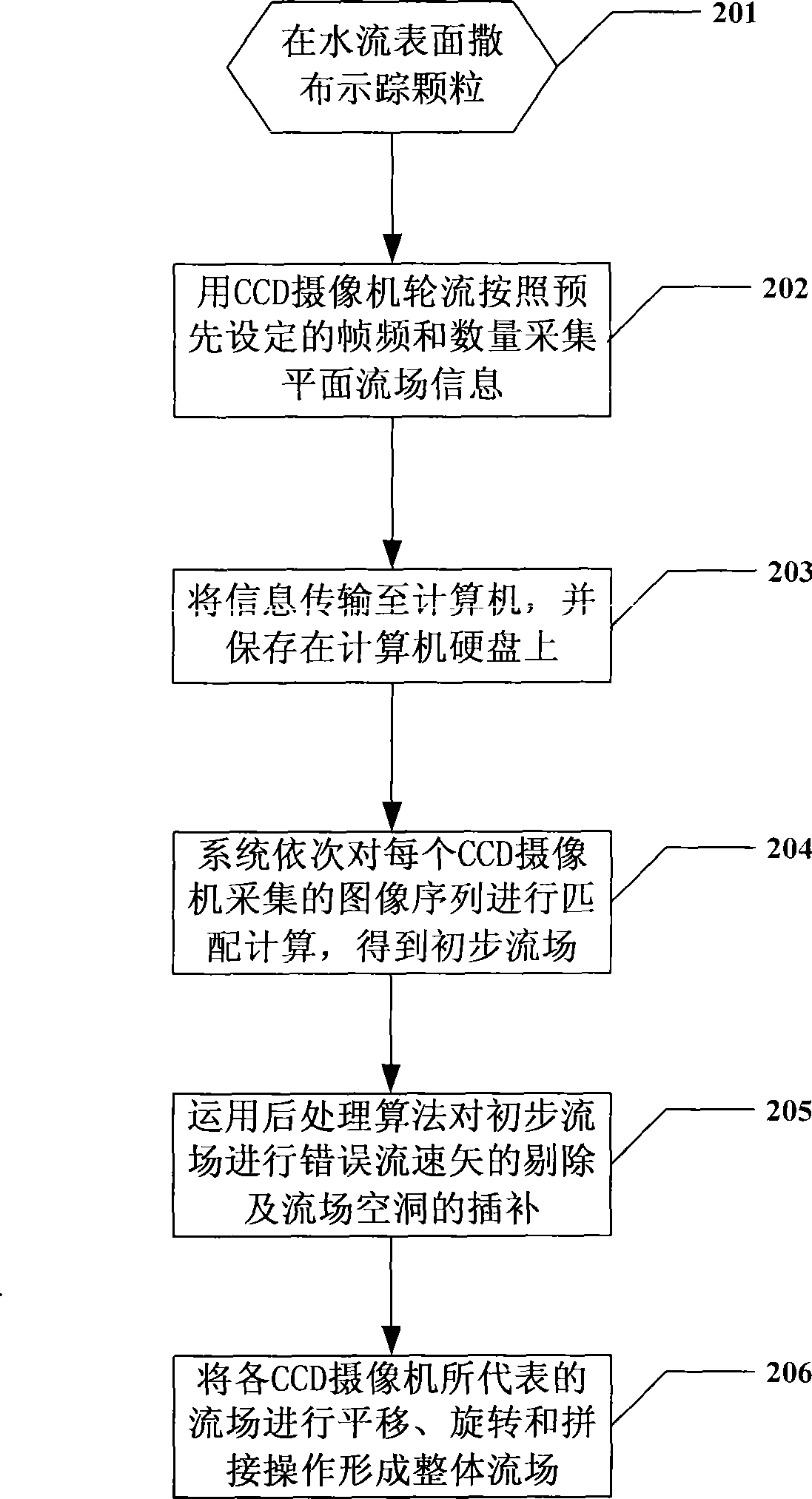

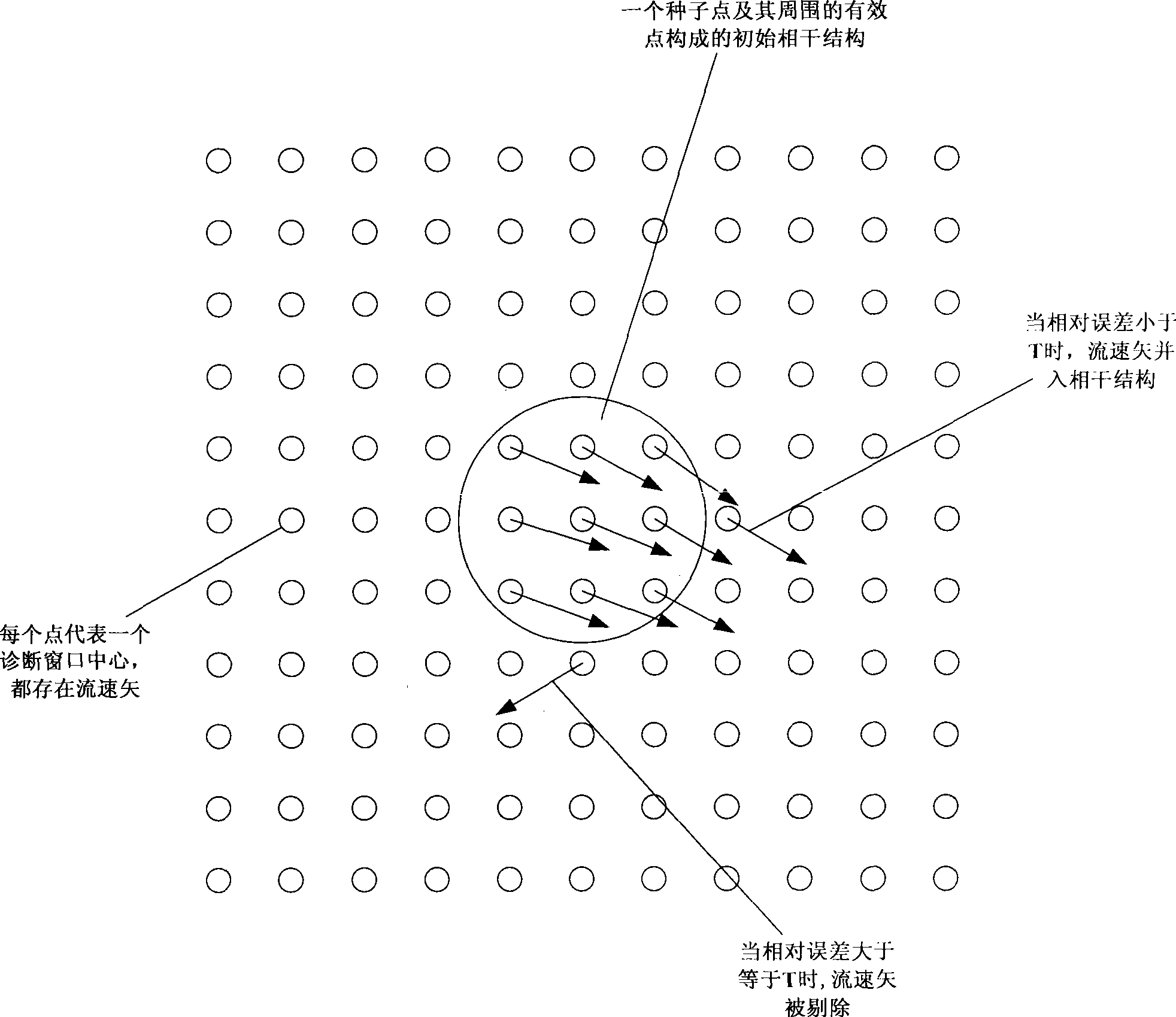

Real-time measurement system for solid model surface flow field and its reprocessing method

The invention discloses a real-time measuring system for a flood-controlling physical model testing surface flow-field in the water conservancy measuring technology field and a post-processing method thereof. The system and the method comprise technical scheme that the real-time measuring system for the flood-controlling physical model testing surface flow-field comprises an image acquiring module, an image management module, a flow-field calculating and post-processing module and a data fetching module. The post-processing method for the flood-controlling physical model testing surface flow-field comprises the steps as follows: tracer particles are evenly sprinkled on a water flow surface and are led to move along with the water flow; a vidicon is installed above the surface flow-field, and external synchronization can be realized through a videofrequency synchronizer; particle motion image signals are transmitted to a computer image grabbing card through a video line for analysis and treatment; and the flow velocity and the flow state of the flow-field are obtained. The real-time measuring system and the post-processing method thereof increase the velocity of flow velocity vector matching calculation, and lead the automation degree for removing error flow velocity vectors to be increased greatly.

Owner:TSINGHUA UNIV

Attitude angle direct resolving method based on global position system (GPS) carrier wave double-difference equation

InactiveCN102998690AReduce intermediate processReduce estimation errorSatellite radio beaconingDouble differenceCarrier signal

The invention provides an attitude angle direct resolving method based on a global position system (GPS) carrier wave double-difference equation. The attitude angle direct resolving method mainly comprises building a carrier wave double-difference equation, guiding carrier attitude information into the carrier wave double-difference equation and solving an attitude angle by utilizing nonlinear least squares. The attitude angle direct resolving method can effectively reduce or eliminate short base line public errors, achieves high-precision resolving, can directly resolve the attitude angle by leading the attitude angle information into the double-difference equation, greatly reduces intermediate evaluated errors, evaluates the attitude angle by utilizing the nonlinear least squares method, improves system resolving speed, finishes real-time resolving of the attitude information and is more suitable for real-time carrier attitude measuring.

Owner:HARBIN ENG UNIV

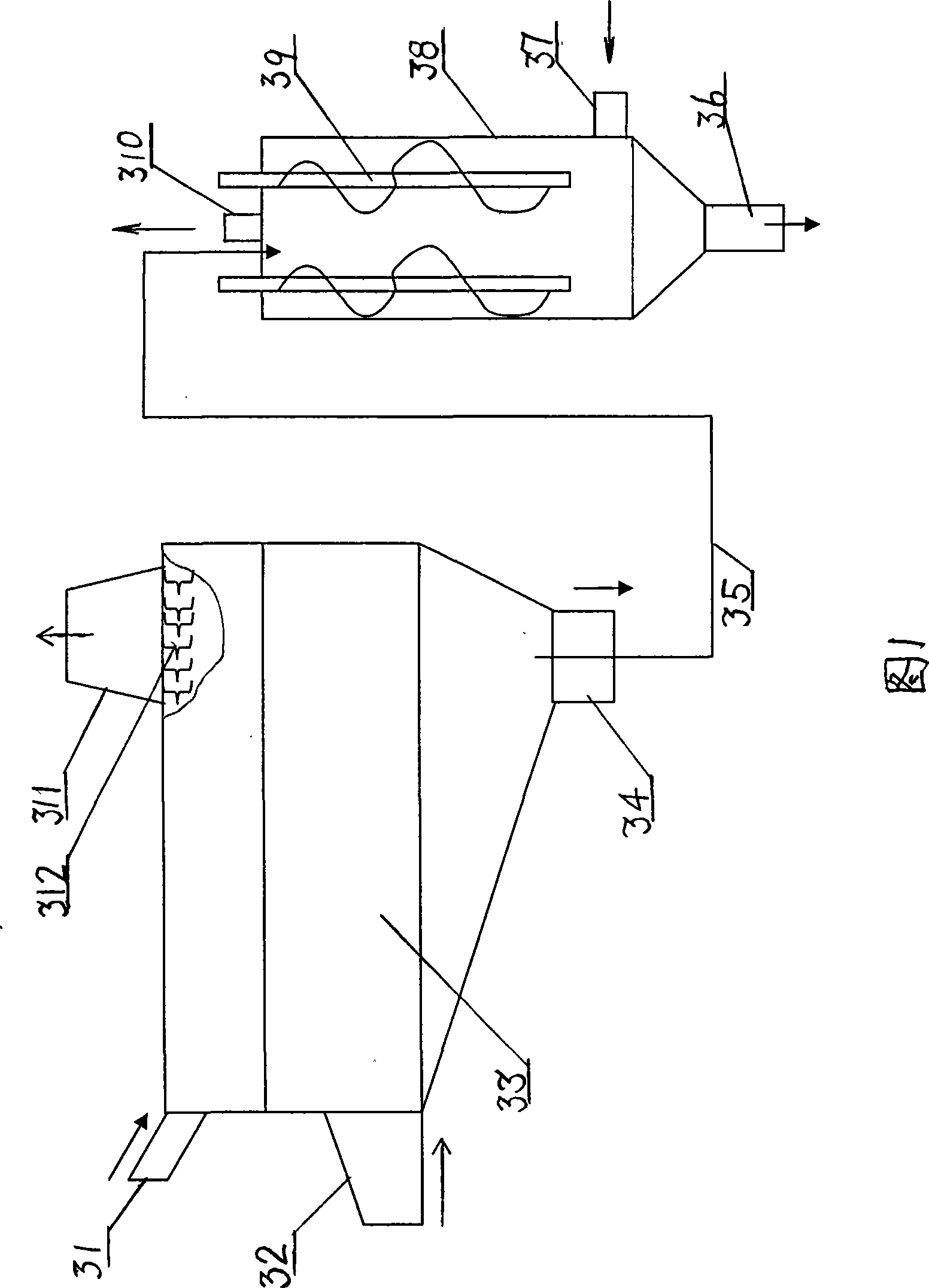

Method for producing terylene POY filament in scale by recycling PET bottle sheet material

ActiveCN101435113ASolve the problem of water content inconsistencyHigh meshSolid waste disposalMelt spinning methodsEngineeringBottle

The invention provides a method for producing polyester POY filament in scale by recycling PET bottle chip. Recycled waste PET bottles are crushed into flaky bottle chip, dried after cleaning, and then sent into a crystallizing bed body; under the action of hot air entering the crystallizing bed body, crystallization is carried out, a crystallizing layer is formed on the bottle chip surface, and then the bottle chip is sent into a drying tower for drying; the dried bottle chip enters a screw extruder for melt extrusion, and the obtained melt is sent into a two-stage filtering device for filtering and then enters a spinning box; and a high-speed spinning process is adopted for spinning to produce the polyester POY filament. The method for producing the polyester POY filament adopts a filling type drying mode, the drying is even and the operating cost is low; a screw mixer is arranged in the drying tower, which solves the problem of 'arching' that happens to the recycled PET bottle chip during the drying process; and the two-stage filtering device is adopted, which ensures the filtering quality. Therefore, the high-end product-polyester POY filament can be continuously produced in large scale.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

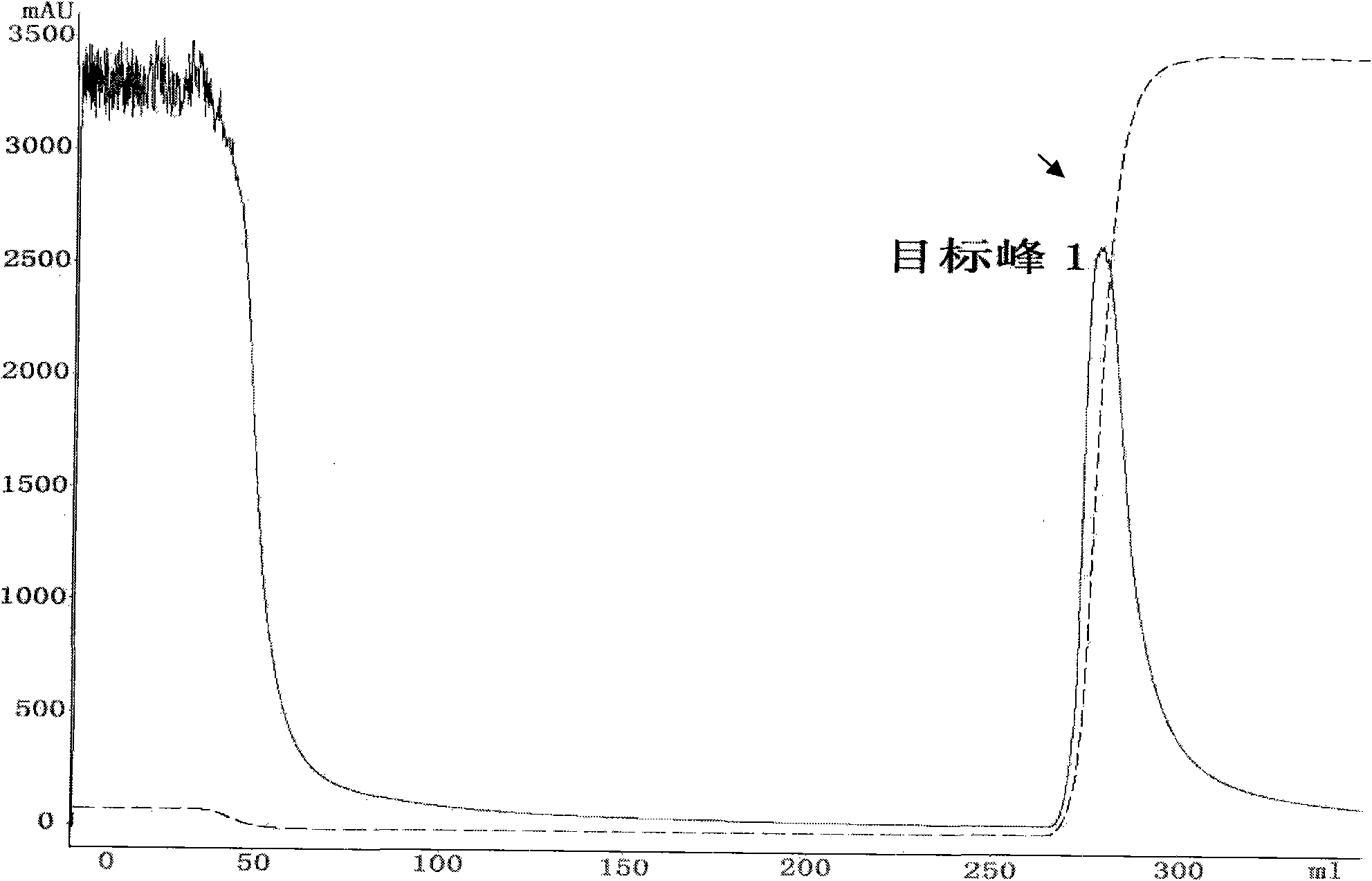

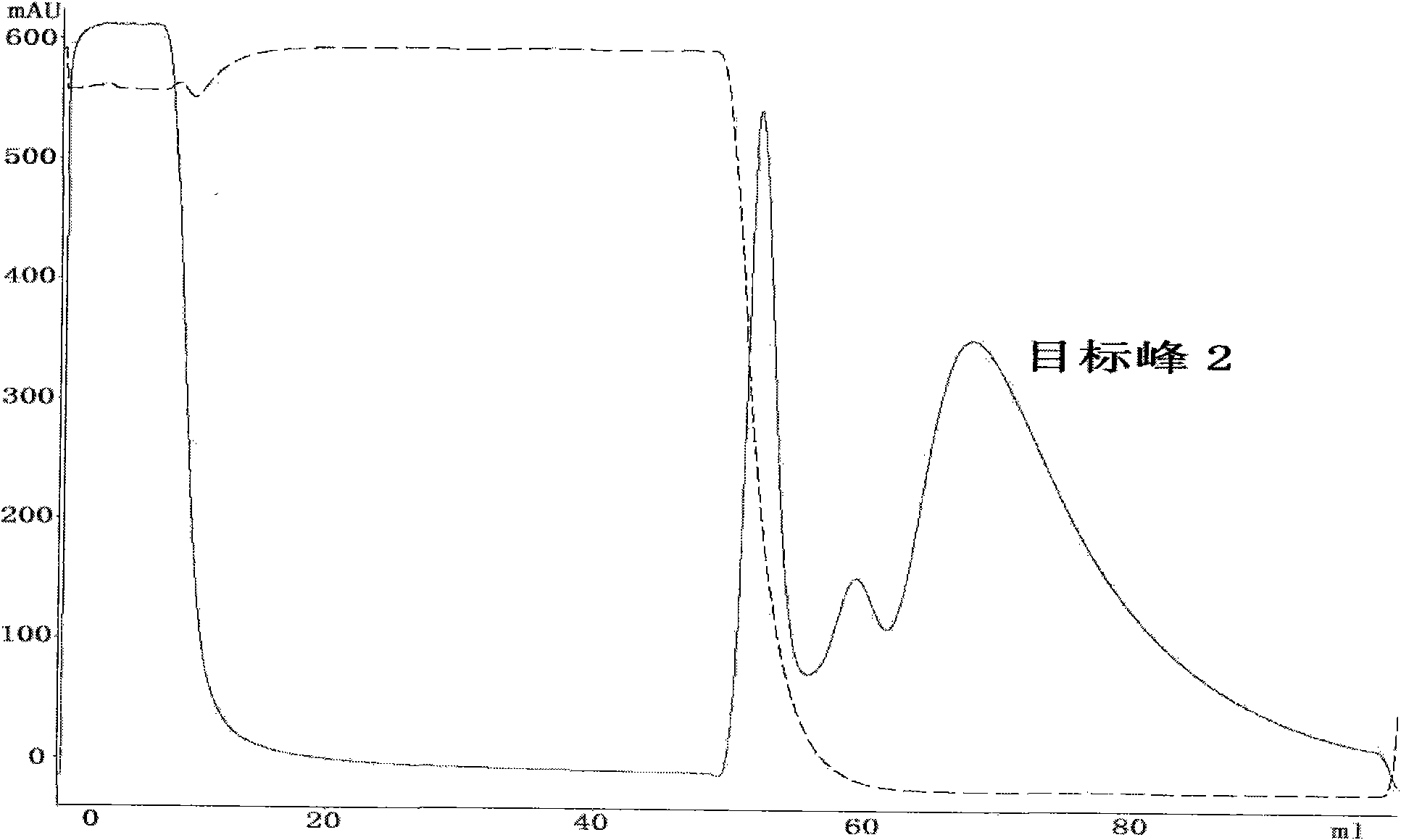

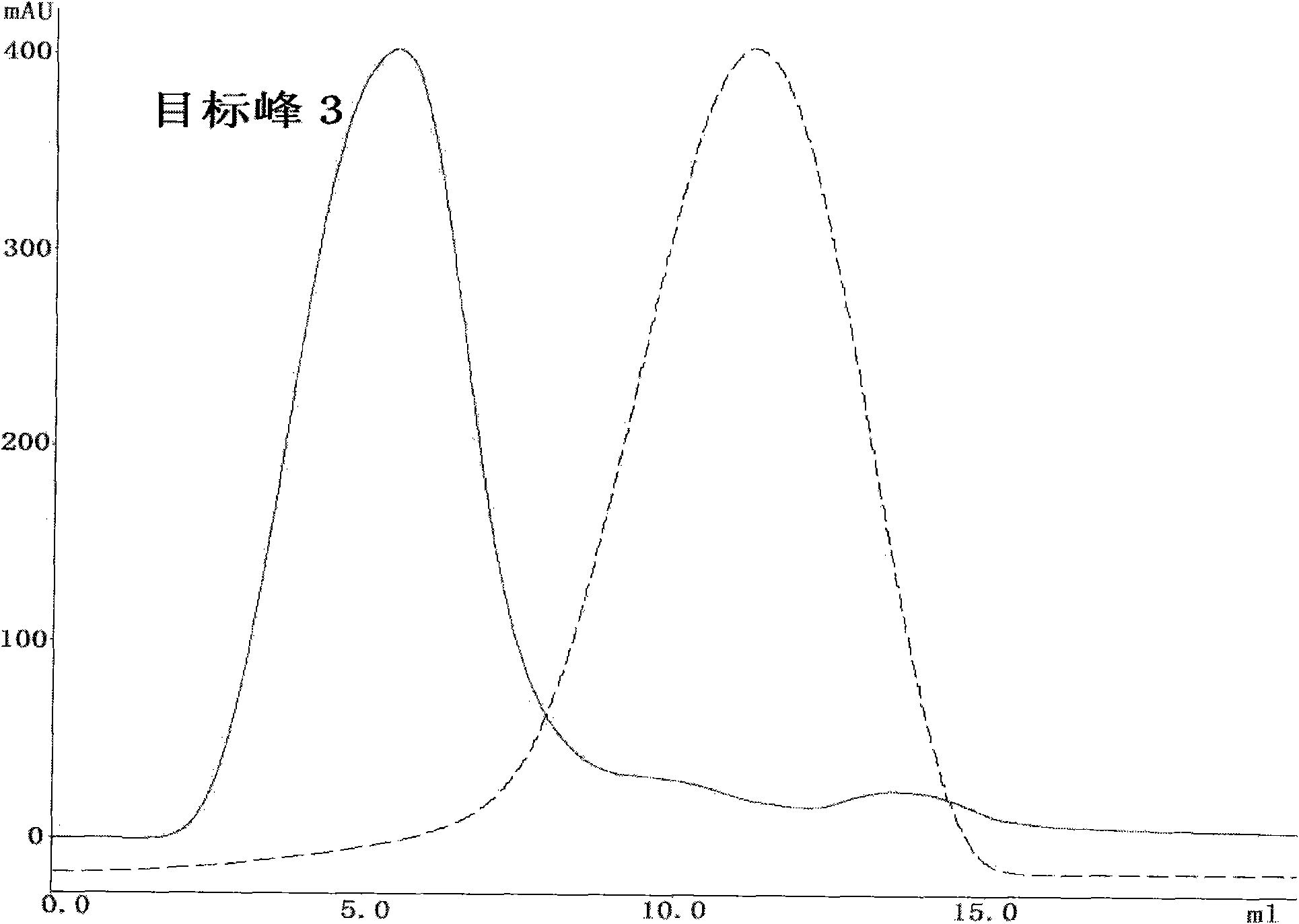

Fusion protein of Exendin-4 tandem polypeptide and human serum albumin, preparation and application thereof

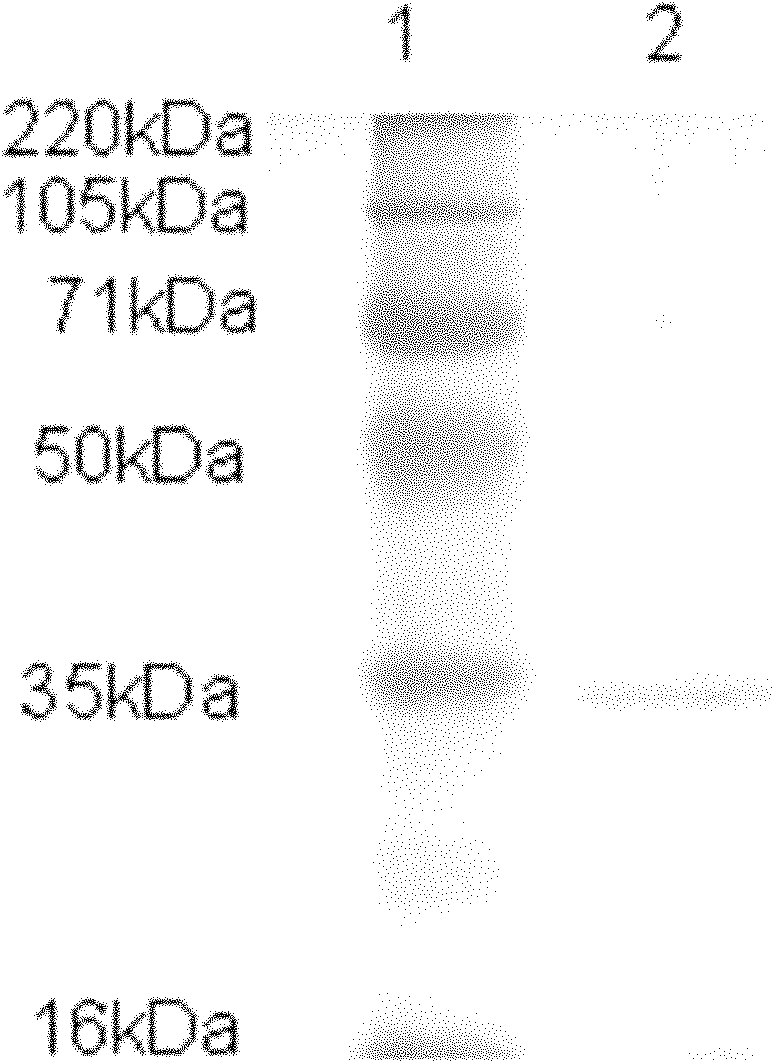

ActiveCN101525386AGenetic stabilityNot easy to losePeptide/protein ingredientsMetabolism disorderHalf-lifeSerum albumin

The invention relates to a fusion protein of Exendin-4 tandem polypeptide and human serum albumin, a preparation method and application thereof. The fusion protein of the Exendin-4 tandem polypeptide and the human serum albumin is expressed by a genetic engineering method. The fusion protein shows long-acting controlling blood sugar activity in a body, solves the problem that the half life period of the Exendin-4 tandem polypeptide in the body is short and has the advantage of convenient preparation. The fusion protein can be used for preparing diabetes medicaments and weight-losing products.

Owner:浙江昂大久力生物制药有限公司

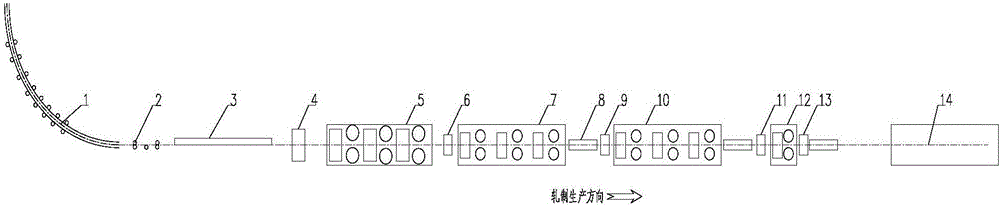

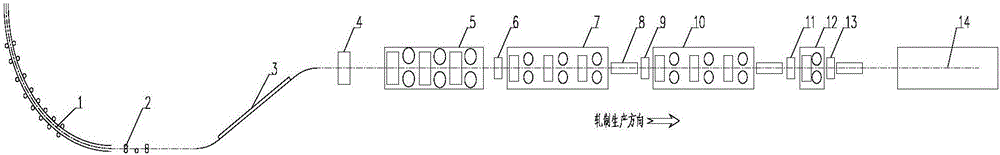

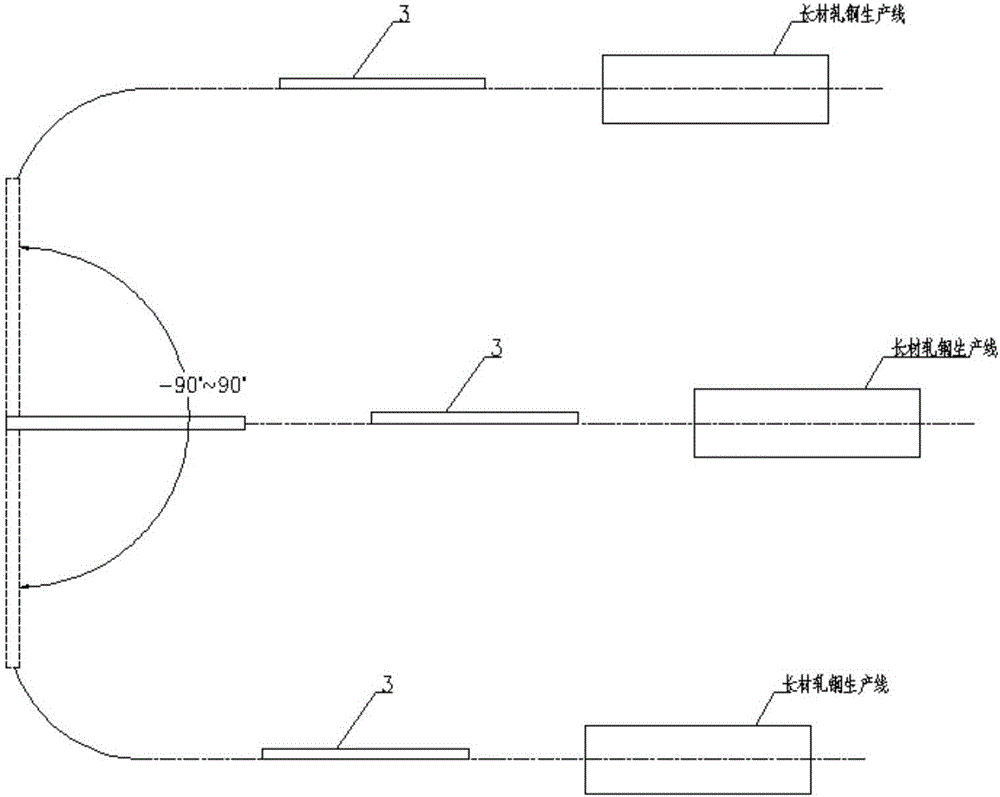

Long-bar rolling production line and production technology thereof

InactiveCN106269868AAvoid lostAvoid losses and achieve endless rollingMetal rolling arrangementsFailure rateProduction line

The invention discloses a long-bar rolling production line and a production technology thereof, and belongs to the technical field of bar rolling. The production line comprises a continuous casting machine, a withdrawal and straightening machine, a pre-rolling emergency shear, a roughing mill unit, a head cutting flying shear, an intermediate mill unit, a finishing mill unit, a reducing and sizing unit and a cooling bed which are connected by roller beds in sequence, wherein the continuous casting machine is a single-machine uniflow continuous casting machine; and the roller bed between the continuous casting machine and the roughing mill unit is a heat preservation roller bed. The production technology comprises the steps of: carrying out single-machine uniflow continuous casting, carrying out heat preservation by using the conveying roller bed, straightening by using the withdrawal and straightening machine, rolling by using the roughing mill unit, rolling by using the intermediate mill unit, rolling by using the finishing mill unit, rolling by using the reducing and sizing unit, cooling and collecting. The long-bar rolling production line and the production technology have the beneficial effects that round billets are directly rolled after the round billets are cast by using the single-machine uniflow continuous casting machine, thereby reducing middle working procedures and heat loss, realizing endless rolling, meanwhile omitting a heating surface and reducing a failure rate in a production process.

Owner:CISDI ENG CO LTD

Method for producing industrial polyester filament by recycled PET (Polyethylene Terephthalate) bottle chips on scale

ActiveCN102605454ASolve the problem of water content inconsistencyGuaranteed Filtration QualityFilament forming substance formingMonocomponent polyesters artificial filamentPolyesterPolyethylene terephthalate

The invention provides a method for producing industrial polyester filament by recycled PET (Polyethylene Terephthalate) bottle chips on a scale. The method comprises the steps of crushing the recycled PET bottles into chips, washing and drying, sending into a crystallization bed body for crystallization, forming crystallization layers on the surfaces of the bottle chips, sending the crystallizedbottle chips into a drying tower which is provided with a pair of spiral agitators, leading the dried bottle chips to enter a screw extruder for melting and extrusion, sending the obtained melt into a two-stage filtration device consisting of a coarse filter, a fine filter and a pressure pump between the coarse filter and the fine filter for filtration, leading the melt which is filtrated by two stages to enter a liquid phase tackifying kettle, conducting polycondensation reaction in the liquid phase tackifying kettle, leading the melt after being subjected to liquid phase tackifying to entera spinning box, and spinning by adopting a high-speed spinning process, thus obtaining the industrial polyester filament. In the method for producing the industrial polyester filament, the liquid phase tackifying step is added in the production process, so that the problems of low viscosity and poor stability of the PET bottle chip melts are solved.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

Method for preparing electric polypyrrole nano hollow sphere

The process of preparing composite particle of hollow nanometer conductive polypyrrole-silica ball includes the following successive steps: adding pyrrole monomer and nanometer silica ball into deionized water and dispersing ultrasonically; and introducing initiator to react at 100-180 deg.c to obtain the composite particle. Compared with available technology, the process of the present invention has the advantages of less intermediate steps, low cost, capacity of obtaining product with high size homogeneity and controllability, and other advantages.

Owner:CENT SOUTH UNIV

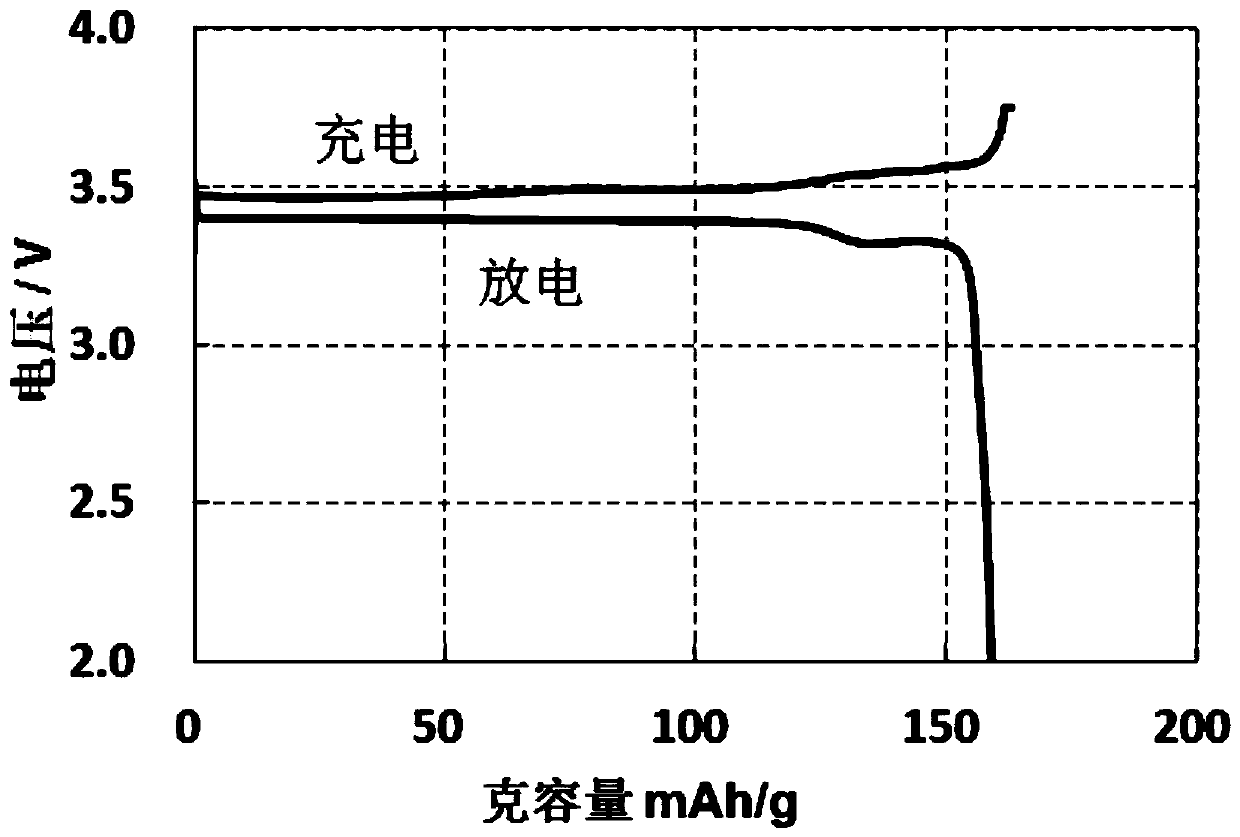

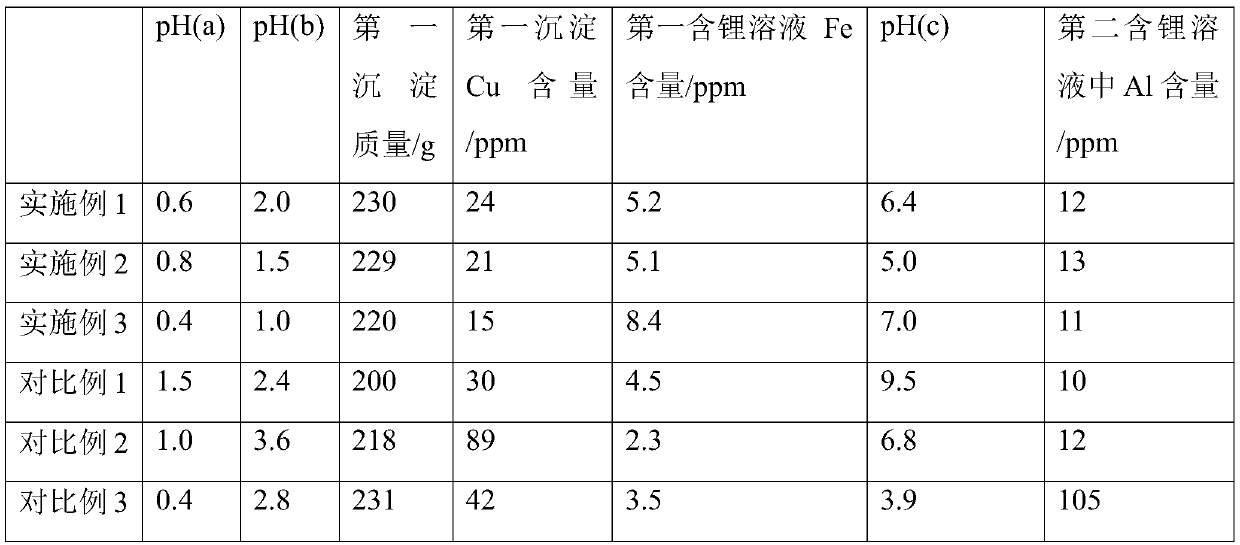

Method for recycling lithium iron phosphate positive electrode material

ActiveCN109721043AEasy to recycleImprove recycling ratesCell electrodesWaste accumulators reclaimingLithium iron phosphateSolvent

The present invention relates to the field of electrochemistry, and more particularly to a method for recycling a lithium iron phosphate positive electrode material. The method comprises the followingsteps: contacting a recycled cell material with an acid solution, and carrying out solid-liquid separation to obtain a first liquid phase and an insoluble substance; adjusting the pH value of the first liquid phase, and carrying out solid-liquid separation to obtain a first lithium-containing solution and a first precipitate; mixing the first precipitate, a second lithium-containing solution andan auxiliary agent to obtain a second liquid phase; adjusting the contents of Li element, Fe element, P element and C element in the second liquid phase to obtain a third liquid phase; removing the solvent of the third liquid phase to obtain a lithium iron phosphate precursor; and calcining the precursor in a reducing environment to obtain the lithium iron phosphate positive electrode material. The method for recycling the lithium iron phosphate positive electrode material provided by the present invention has the advantages of simple process, high recycling rate, low impurity content and thelike, and has a good industrialization prospect.

Owner:CONTEMPORARY AMPEREX TECH CO

Method for producing bronze coated iron powder

The invention relates to a method for producing bronze coated iron powder, wherein copper accounts for 18%-20% (weight percentage) of the total weight of the composite powder, while tin accounts for 1.8%-2% (weight percentage) of the total weight of the composite powder, and the rest is iron. The method comprises the following steps of: according to the predetermined components of the bronze coated iron powder, weighing appropriate cupric oxide powder, tin powder and iron powder, respectively; firstly, evenly mixing the weighed cupric oxide powder and the pure iron powder together in a ball mill or a mixer, and then, adding the tin powder for mixing; next, moving the evenly mixed powder to a reducing furnace, and performing reducing diffusion in an ammonia decomposition or ammonia combustion atmosphere, thereby obtaining the bronze coated iron powder. The method for producing the bronze coated iron powder is simple in production process, thereby reducing the production cost; the copper layer on the surface of the individual bronze coated iron particle obtained by the method is complete and compact and the quality of the bronze coated iron powder is guaranteed; and simultaneously, no harmful substance is emitted in the preparation process, thereby avoiding pollution and damage on the environment.

Owner:朱湖泽

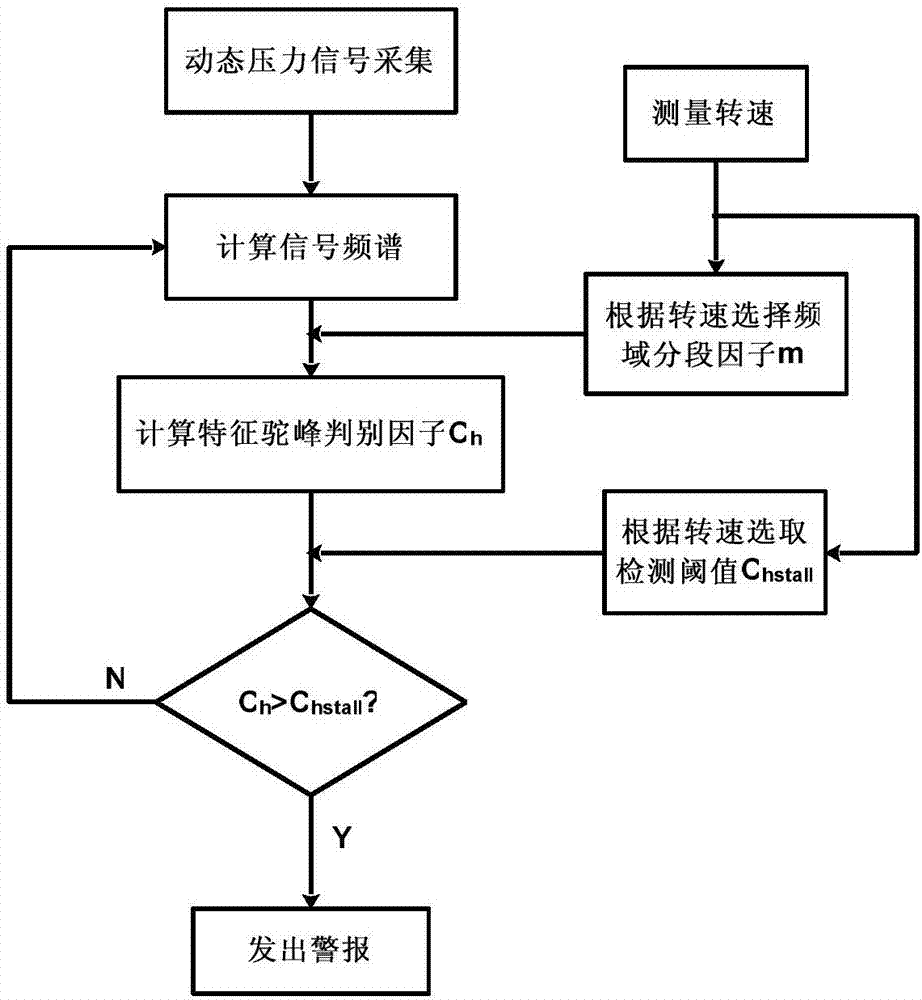

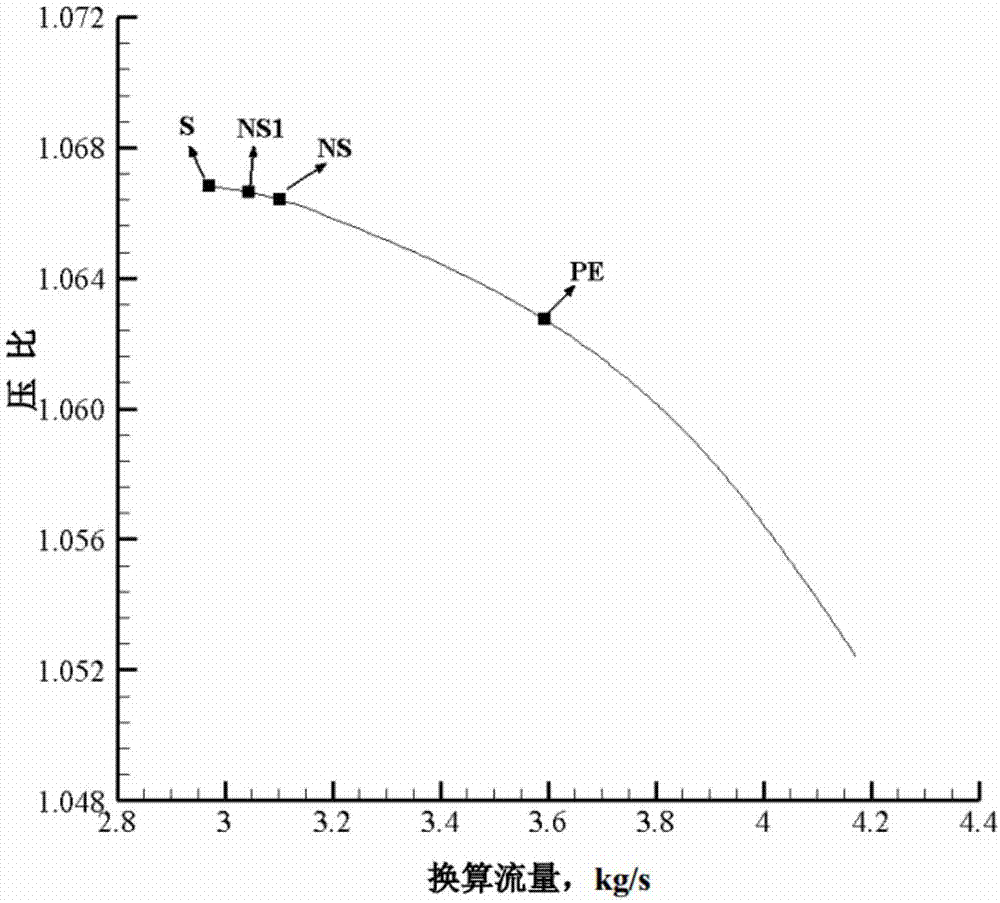

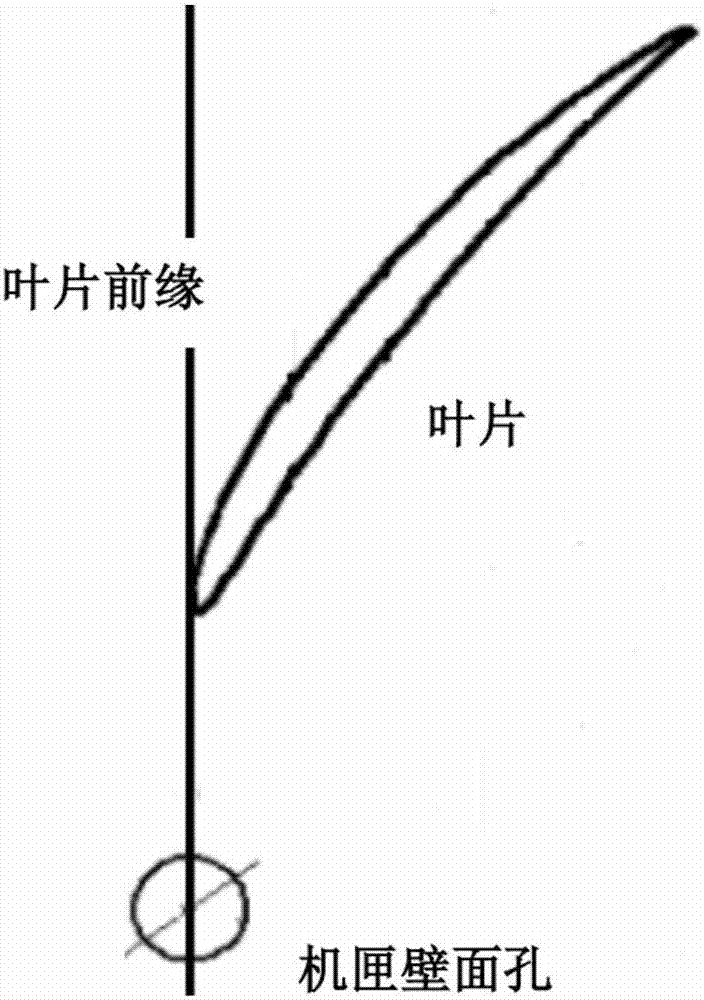

Early warning method for rotating stall of axial-flow air compressor based on frequency domain hump identification

ActiveCN107165850ACalculation speedReduce intermediate processCharacter and pattern recognitionPump controlFast Fourier transformFrequency spectrum

The invention discloses an early warning method for rotating stall of an axial-flow air compressor based on frequency domain hump identification. The method comprises the following steps: continuously and dynamically acquiring a pressure signal; continuously calculating the frequency spectrum of the pressure signal within one air compressor rotation period by utilizing fast Fourier transform; calculating a characteristic hump distinguish factor Ch corresponding to the frequency spectrum; and judging whether the air compressor is close to the rotating stall boundary by comparing the characteristic hump distinguish factor Ch with a detection threshold value Chsta11. The characteristic hump distinguish factor Ch defined by the early warning method for rotating stall of the axial-flow air compressor has definite physical significations and is used for implementing real-time on-line detection on a frequency domain hump appearing earlier than rotating stall so as to give an early warning when the work situation of the air compressor is close to the rotating stall boundary, and the early warning method is reliable. By requiring a simplex signal sensor only and adopting fast Fourier transform, the early warning method for rotating stall of the axial-flow air compressor has few middle procedures, realizes high calculation speed and provides sufficient response time for active control.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

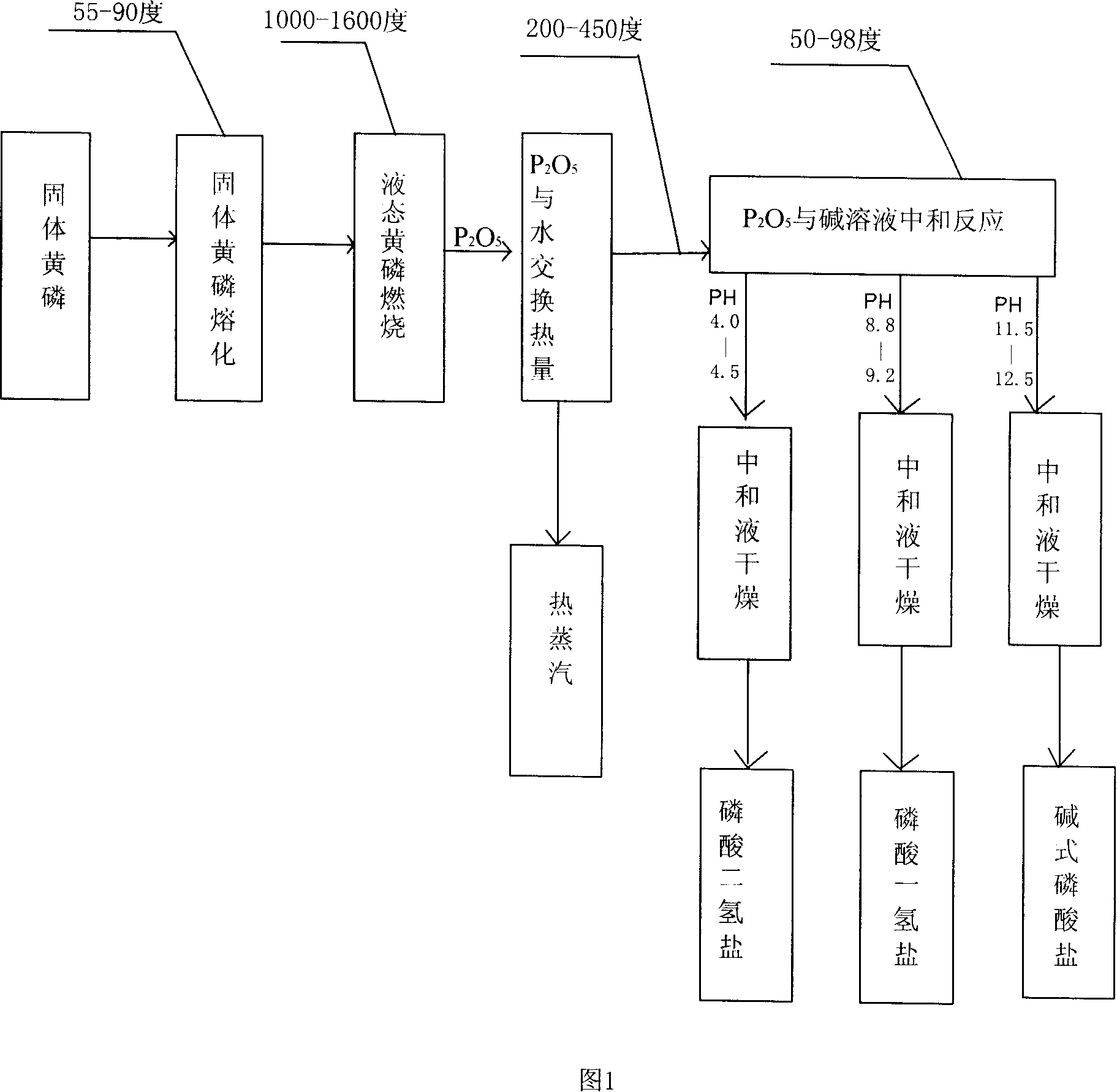

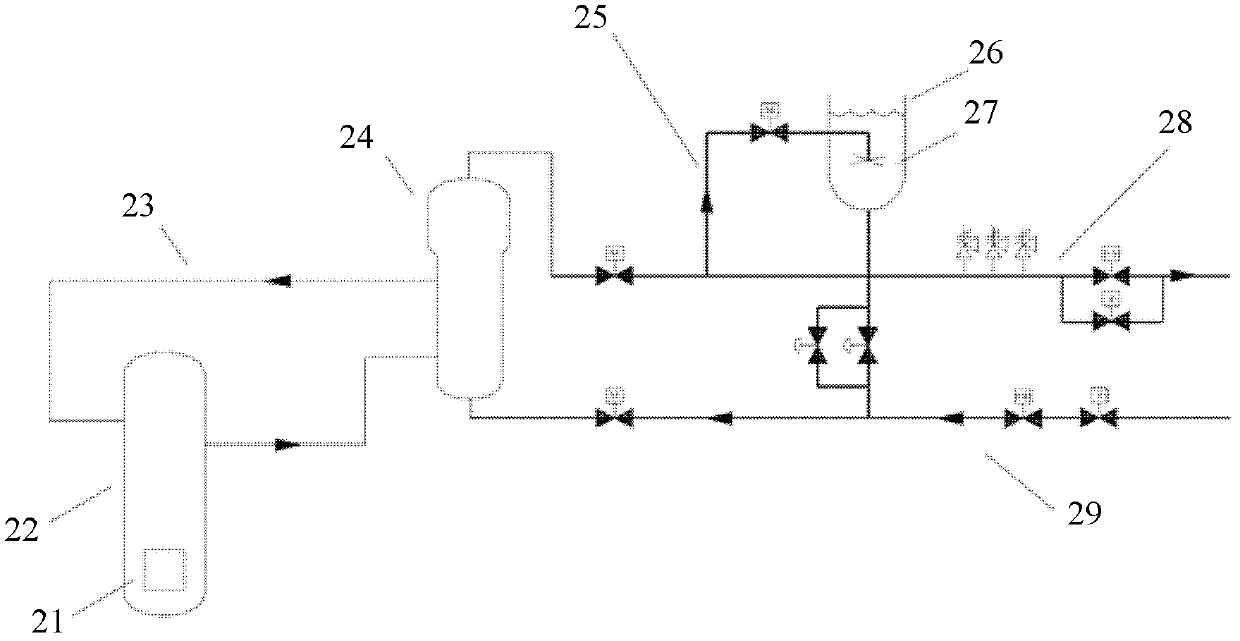

One-step method and device for production of phosphonate by yellow phosphorus

InactiveCN101117215AEliminate and reduce thermal pollutionReduce heat pollutionPhosphoric acidPhosphatePhosphoric acid

The invention discloses a method and device for producing phosphate through adopting yellow phosphorus one-step method. The technical proposal of the invention are that: solid yellow phosphorus is melted into liquid elemental phosphorus inside a phosphorus melting trough and then is pumped into a phosphorus furnace for oxidizing combustion to generate high-temperature phosphorus pentaoxide gas; then, the temperature of the high-temperature phosphorus pentaoxide gas is lowered after completing heat exchange inside an exhaust heat boiler and generate high-pressure water vapor at the same time; finally, low-temperature gas enters into an alkali absorbing tower to react with alkali solution to generate phosphate. The invention can fully reclaim the chemical heat energy generated from yellow phosphorus combustion and also reduces the three major steps adopted in phosphate production to two steps, thereby omitting the intermediate process during phosphoric acid production, saving raw materials and equipment investment, avoiding discharge of acid mist and reducing environmental pollution.

Owner:罗宗恬 +1

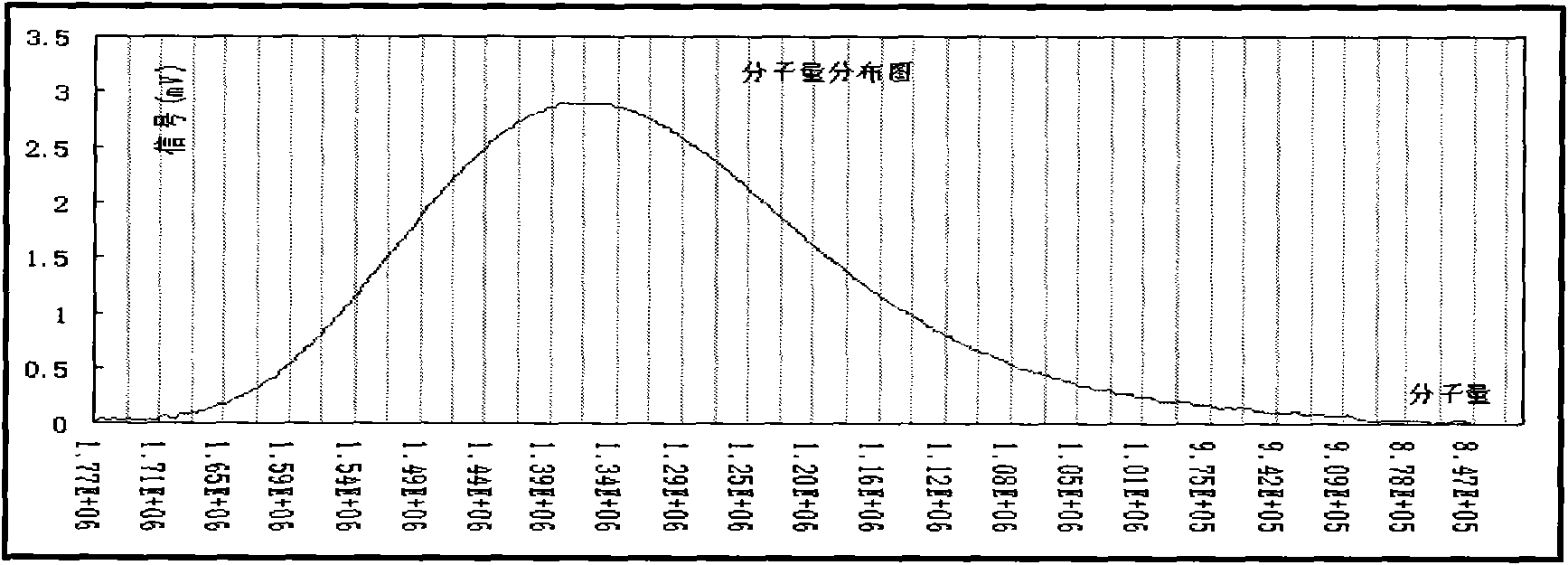

Preparation method for polysiloxane with extra high molecular weight

The invention discloses a preparation method for polysiloxane with extra high molecular weight, comprising the steps of (1) adding dimethyl siloxane or alpha, omega-dihydroxy polydimethylsiloxane intoa reactor, stirring, controlling the rotating speed being 30 to 60 revolutions per minute, heating up to 90-160 DEG C., adding catalyzer which occupies 0.001% to 0.1% by weight of raw materials and reacting for 2.0 to 6.0 hours at constant temperature, (2) at constant temperature, vacuum-pumping for 1.0 to 4.0 hours, and controlling the vacuum degree being -0.080 to -0.10 MPa, and (3) adding neutralizing agent which occupies 0 to 0.1% by weight of raw materials, heating up to 170-180 DEG C., introducing nitrogen, vacuum-pumping for 2.0 to 6.0 hours, stopping heating, stirring, discharging after cooling to room temperature to obtain the blocky or granular hydroxyl silicone oil products with extra high molecular weight. The invention can prepare the polysiloxane with molecular weight more than 1000000.

Owner:GUANGZHOU TINCI MATERIALS TECH

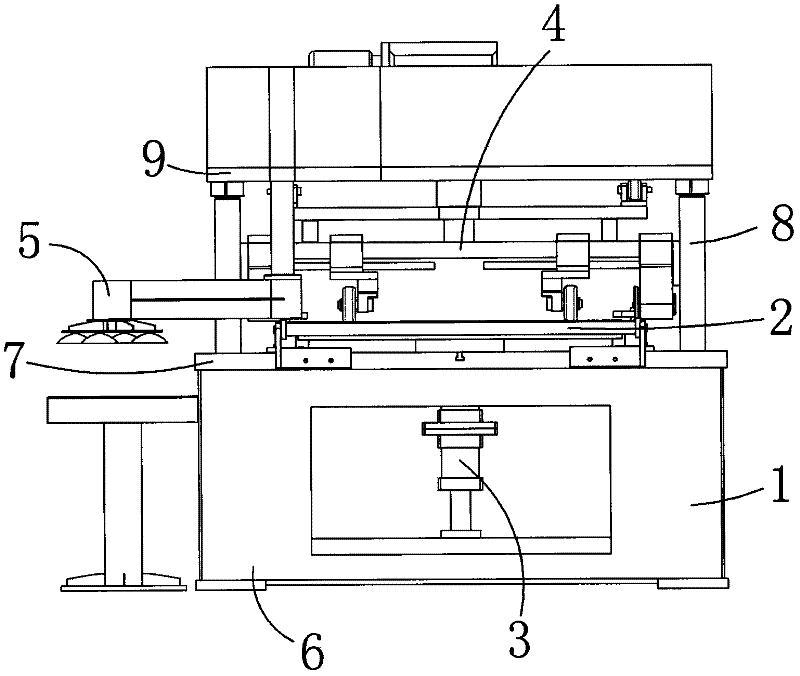

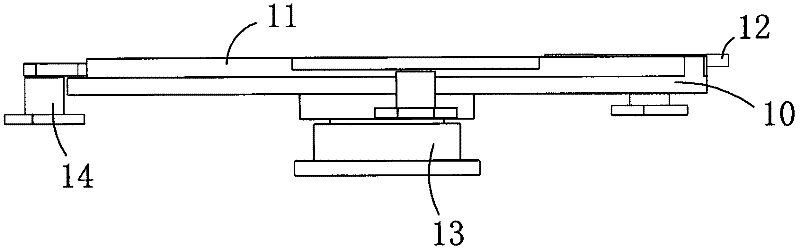

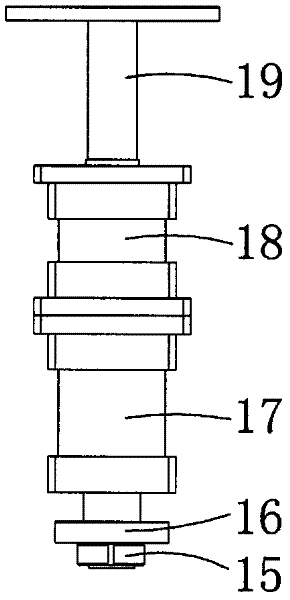

Automatic blanking and ring cutting process

InactiveCN102528152AReduce intermediate processHigh precisionMetal-working feeding devicesShearing machinesEngineeringManipulator

The invention relates to an automatic blanking and ring cutting process, which comprises steps of a), blanking for obtaining a blank; b), positioning and pressing: descending a cross beam under action of a hydraulic piston and enabling a pressing tool to press and position the blank closely; c), cutting and forming: cutting from two sides of the blank by two groups or four groups of shearers and cutting a ring or annular workpiece by rotating a tool rest by semicircle; d), resetting a shearing device: ascending the shearing device to reset for the next operation cycle under action of the hydraulic piston after the tool rest completes rotating; e) discharging: moving an ejecting rod upwards under action of a lower main cylinder so as to eject workpieces out, sucking the workpieces and moving the same to be stored outside a machine tool under action of a sucker of a manipulator, and then moving an ejecting and vertical moving device downwards to reset for the next operation cycle. The automatic blanking and ring cutting process realizes automatic production and is high in processing speed and operation efficiency and low in waste of materials. Workpieces processed by the process are high in precision and quality.

Owner:董利强

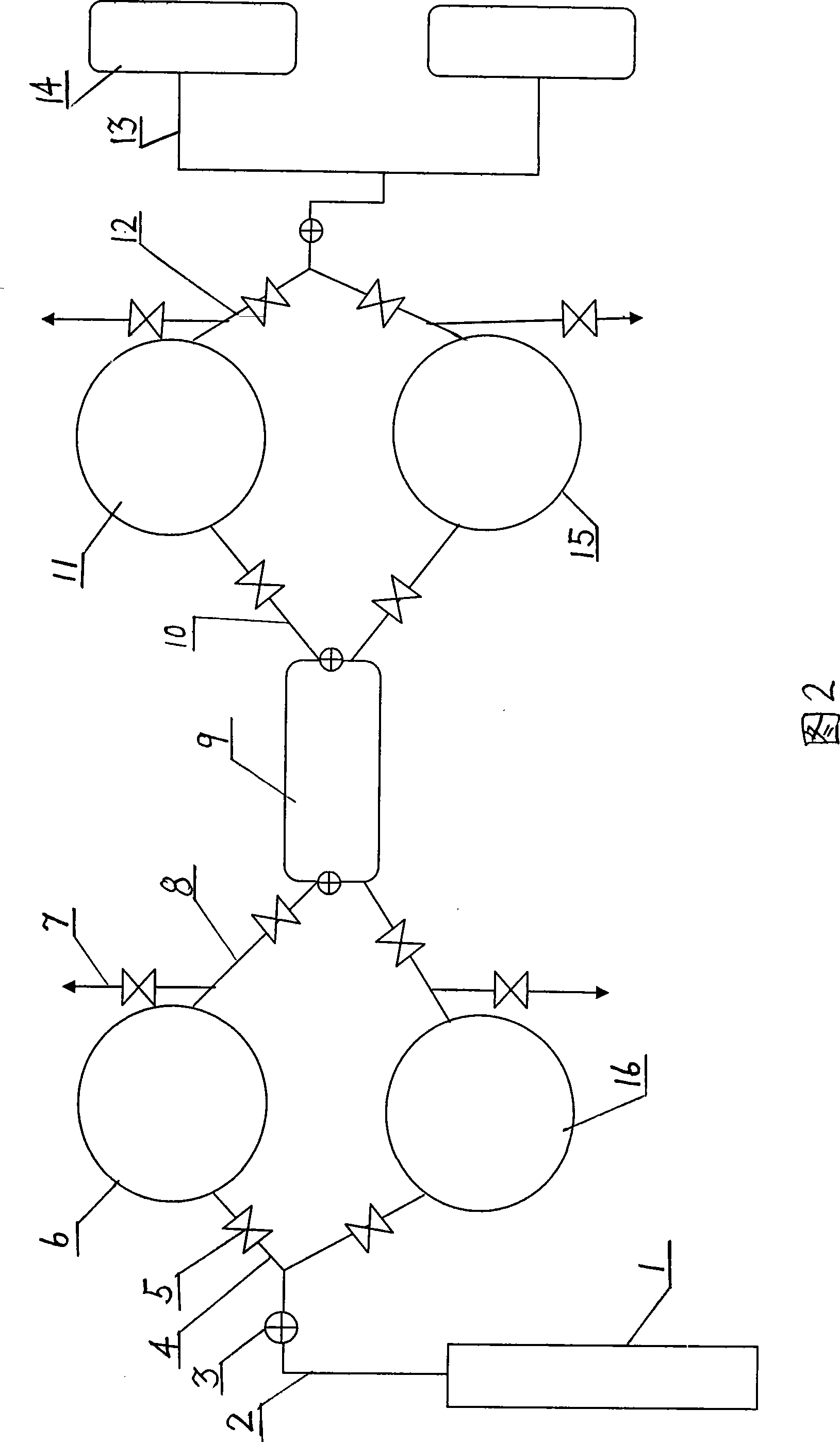

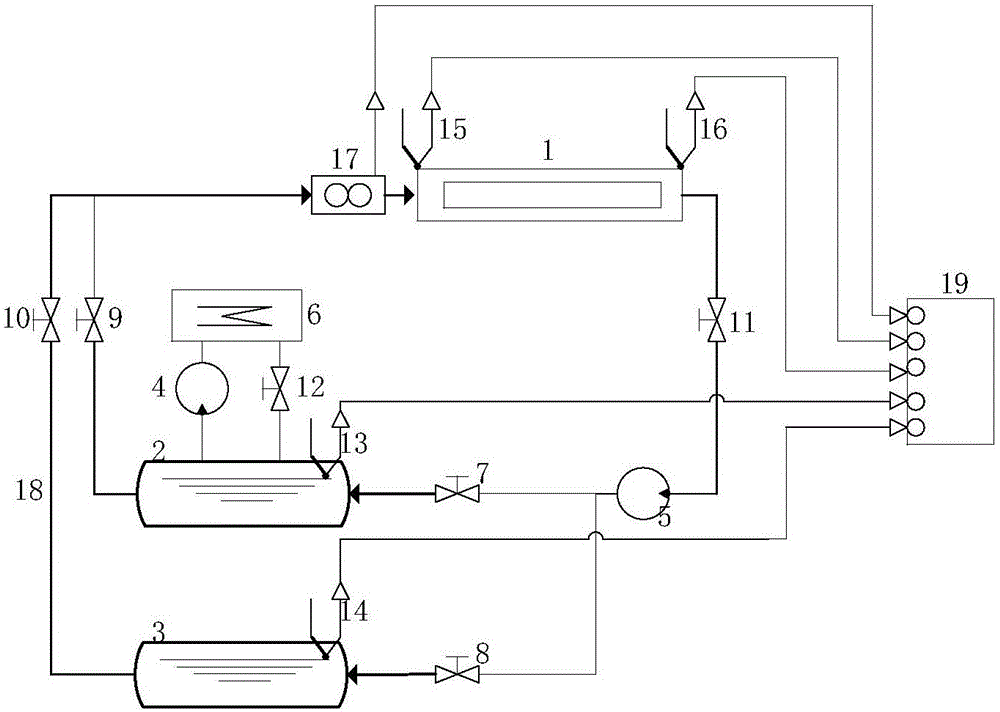

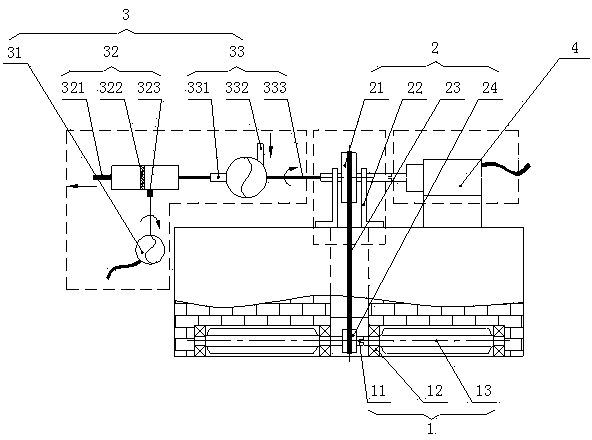

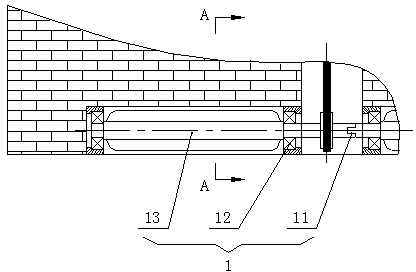

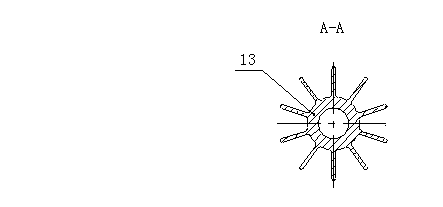

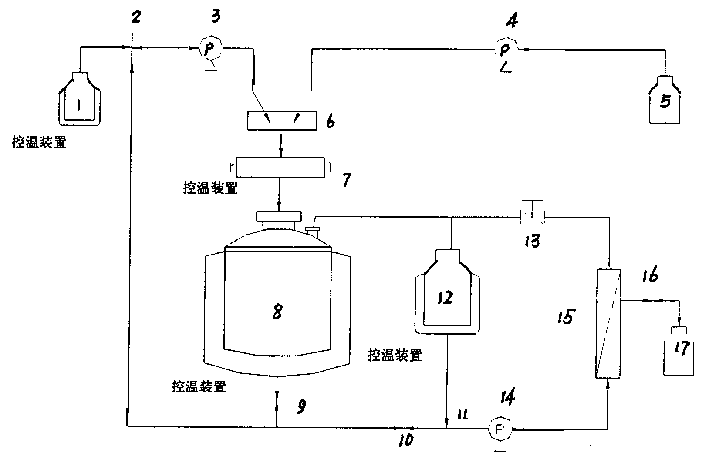

Generator stator bar hot water flow experiment simulation device and experimental method

ActiveCN106500996AEasy to operateThe experimental operation is simple and convenientEngine testingExperimental methodsWater flow

The invention discloses a generator stator bar hot water flow experiment simulation device and an experimental method. The generator stator bar hot water flow experiment simulation device comprises a stator bar, a hot water loop, a cold water loop, temperature measuring elements and a data acquisition device, wherein a water inlet end of the stator bar is connected with water outlets of the hot water loop and the cold water loop, a water outlet pipeline of the stator bar is connected with a main loop water pump, and the main loop water pump is connected water inlets of the hot water loop and the cold water loop; the water inlet end of the stator bar is provided with a flowmeter, the water inlet ends and the water outlet ends of the hot water loop, the cold water loop and the stator bar are provided with the temperature measuring elements, and the data acquisition device acquires test values of all the temperature measuring elements and the flowmeter. The generator stator bar hot water flow experiment simulation device simulates the field test completely, operates all the test processes in situ, is simple, convenient, real-time and efficient, and is of very important significance to the intensive study of test factors such as flow, environment temperature and temperature difference on test effects and stability and the formation of scientific and practical test system and criteria.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

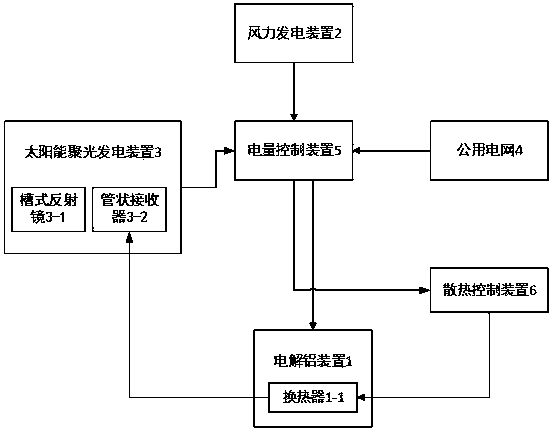

Electrolytic aluminium system adopting non-grid multi-energy collaborative power supply

The invention relates to an electrolytic aluminium system adopting non-grid multi-energy collaborative power supply, which comprises an electrolytic aluminium device, a solar condensation and power generation device, a wind power generation device, as well as an electric quantity control device and a heat dissipation control device, wherein a heat exchanger is arranged on a side wall casing of an aluminium cell; a thermal insulating layer is arranged on the outer side of the heat exchanger; the heat exchanger is connected with a tubular receiver through a pipeline; the heat dissipation control device is connected with the control output end of the electric quantity control device. During the use, the electric quantity supplied by the public grid to the electrolytic aluminium device during the daytime is the minimum electric quantity required for thermal insulation operation, electric quantity generated by the wind power generation device and the solar condensation and power generation device are as supplementary, while electric quantity supply limit of the public grid to the electrolytic aluminium device at night is canceled. The system adapts to the fluctuation of wind and solar power generation, fully utilizes time-of-use price difference of the public grid to promote the economic benefits of enterprises, and can be used for assisting the public grid in pitch peak.

Owner:顾为东

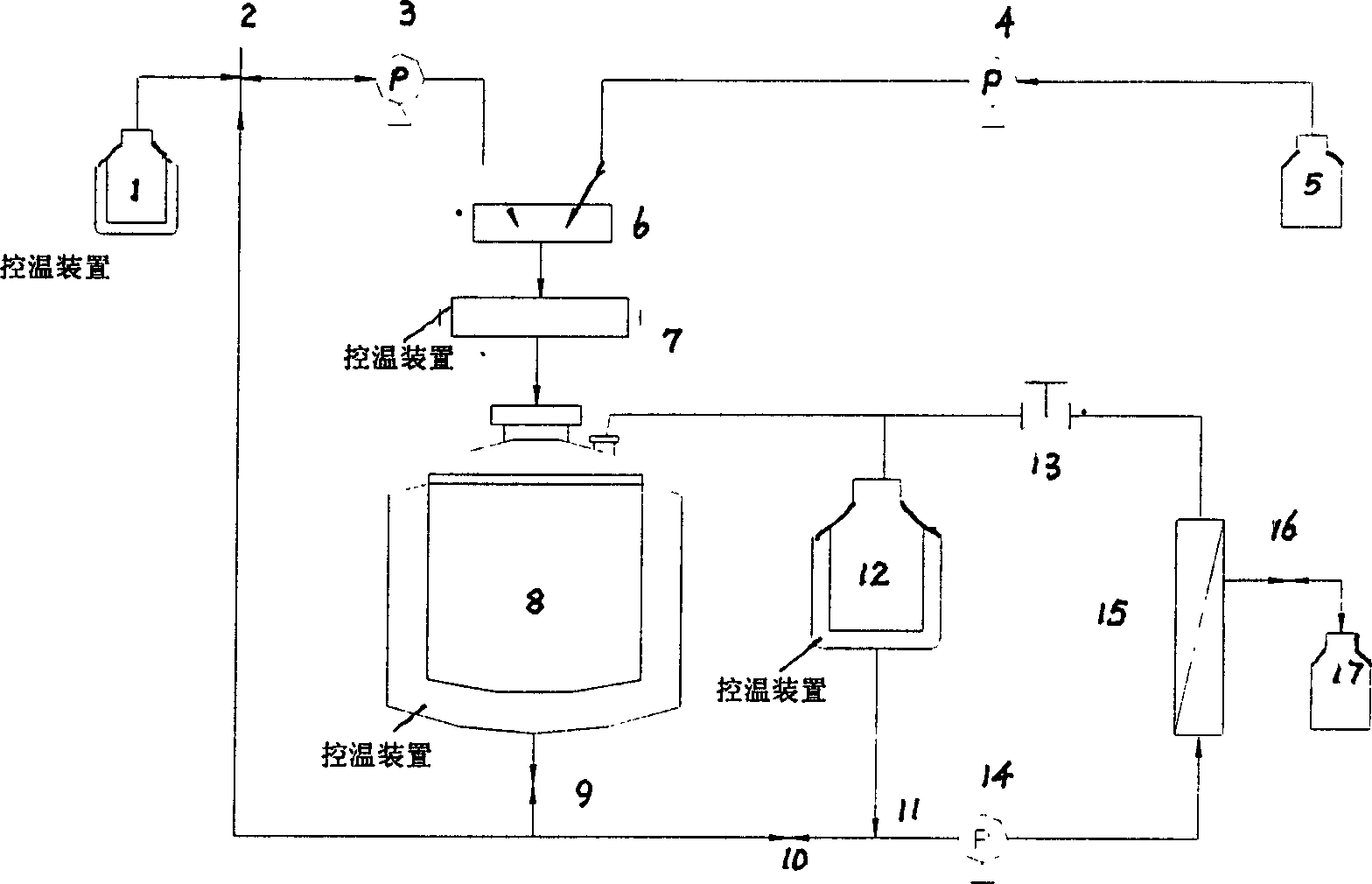

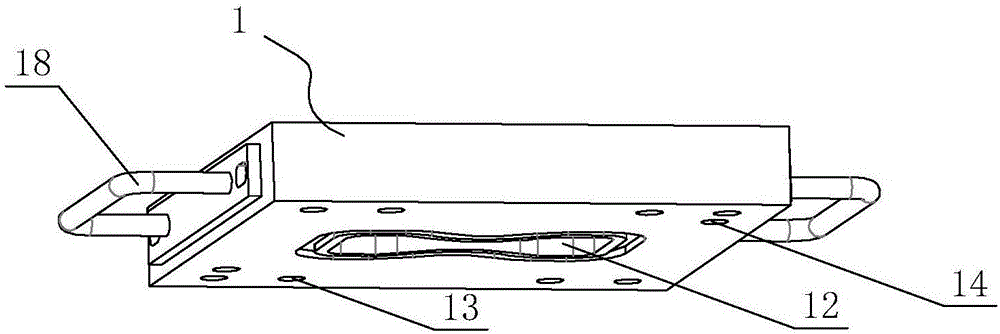

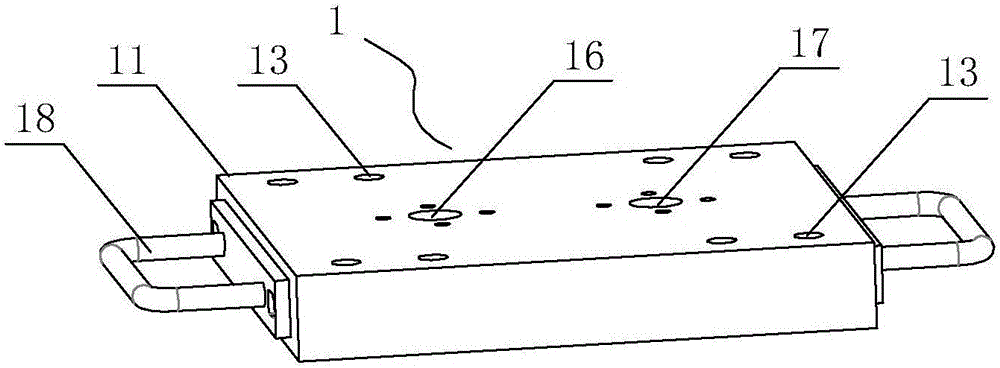

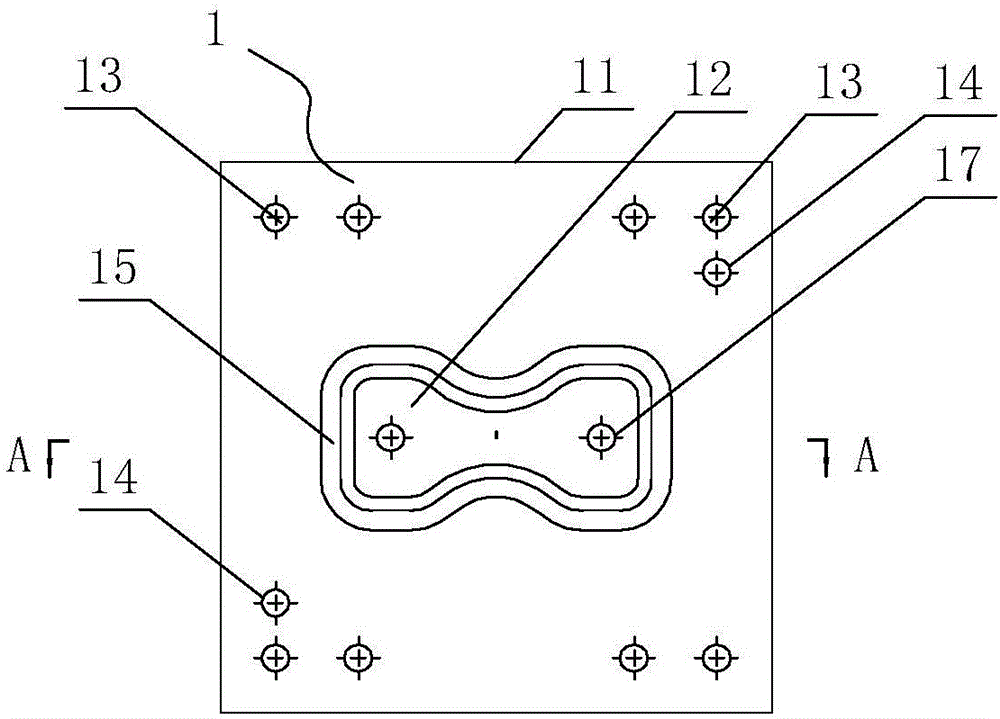

Device and method for preparing and collecting lipidosome

InactiveCN103182333AImprove production efficiencyImprove separation efficiencyLaboratory glasswaresMicrofiltration membranePharmaceutical drug

The invention discloses a device and a method for preparing and collecting lipidosome. The device comprises a signal generator and a preparation and collection chip, wherein the preparation and collection chip comprises a preparation chamber, a collection chamber and a waste fluid chamber; the preparation chamber comprises an electrode couple and a preparation cavity; the electrode couple is connected with the signal generator through electric conduction tapes; the collection chamber comprises an upper-layer collection cavity and a lower-layer collection cavity; a layer of microfiltration membrane is arranged between the two cavities; and the preparation chamber, the collection chamber and the waste fluid chamber are connected through microchannels. The device for preparing and collecting lipidosome mainly uses the method of powering up to prepare the lipidosome, and utilizes the microfiltration membrane to collect and process the lipidosome on the same chip. Compared with the prior art, the device and the method have the following technical effects: the large blank space lipidosome and the large lipidosome carried with drug, protein and particles can be effectively prepared; the preparation and collection of the lipidosome are integrated to reduce pilot process; and the required dose of reagents is less.

Owner:CHONGQING UNIV

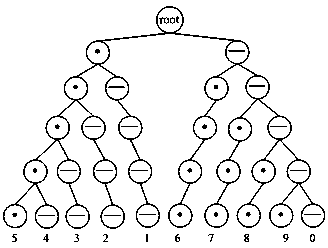

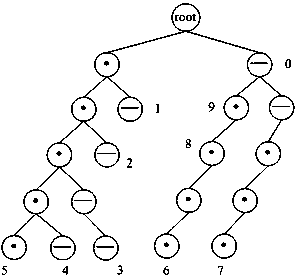

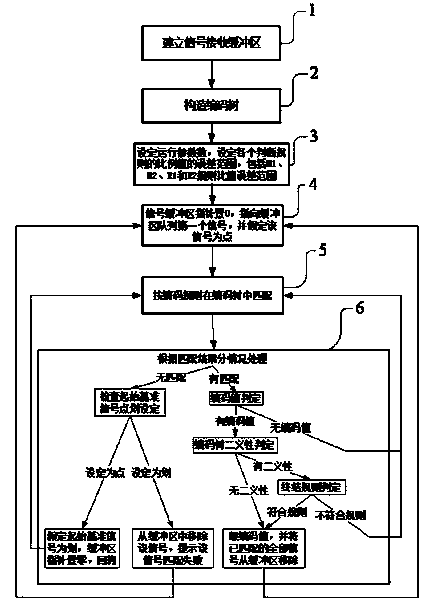

Morse signal self-adaptive recognition method based on backtracking

InactiveCN103414663AImprove adaptabilityReduce intermediate processDot-and-dash receiving apparatusTerm memorySelf adaptive

The invention relates to Morse signal recognition and belongs to the field of communication technology. The invention provides a Morse signal self-adaptive recognition method based on backtracking to solve the problem that the reference point calculation mode in the prior art is not suitable for embedded equipment. The method comprises a first step of establishing a Morse signal reception buffer; a second step of constructing an encoding tree; a third step of setting operating parameters; a fourth step of by setting mating pointer of the signal reception buffer to 0, pointing to a first signal of the reception buffer, and assuming the signal to be a point; a fifth step of matching in the encoding tree according to encoding rules; and a sixth step of handling each case according to matching results. The Morse signal self-adaptive recognition method based on backtracking is advantageous in that firstly, independent of reference point calculation, the recognition method is based on the encoding rules and therefore has a strong self-adaptive capability and a high code word recognition rate; secondly through combination of signal recognition and decoding, and signal recognition by decoding, an intermediate process is reduced, execution efficiency is improved and response speed is faster; and thirdly, the recognition method is applicable to embedded equipment having a small memory and the execution efficiency is very high.

Owner:KUNMING UNIV OF SCI & TECH

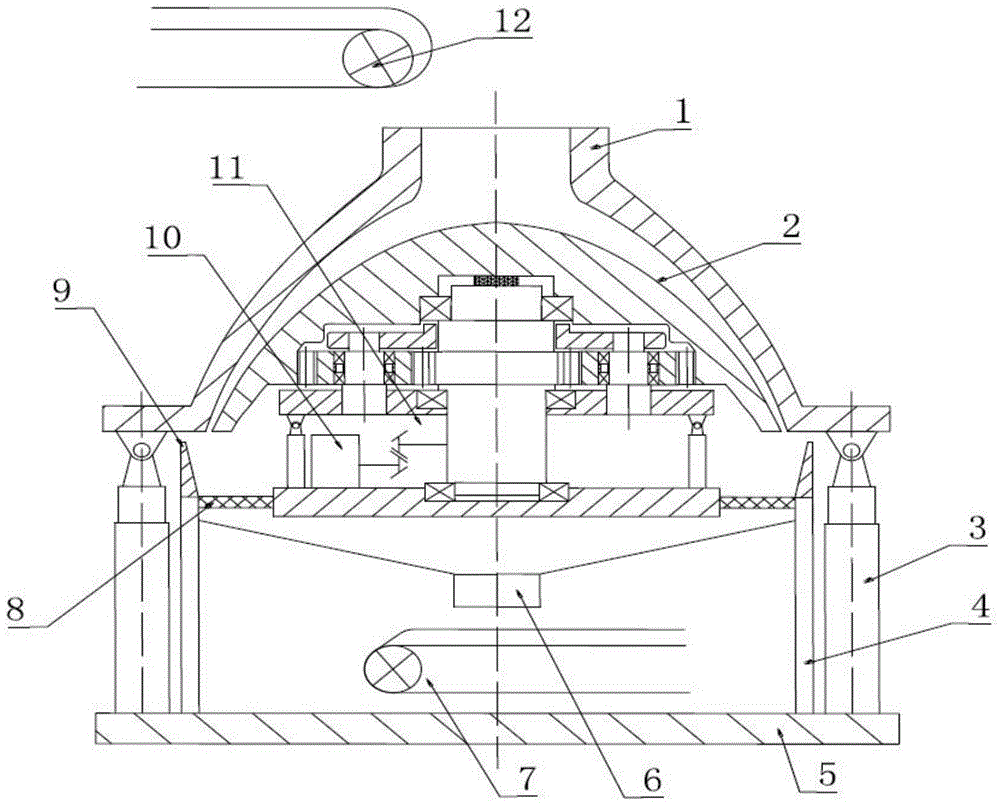

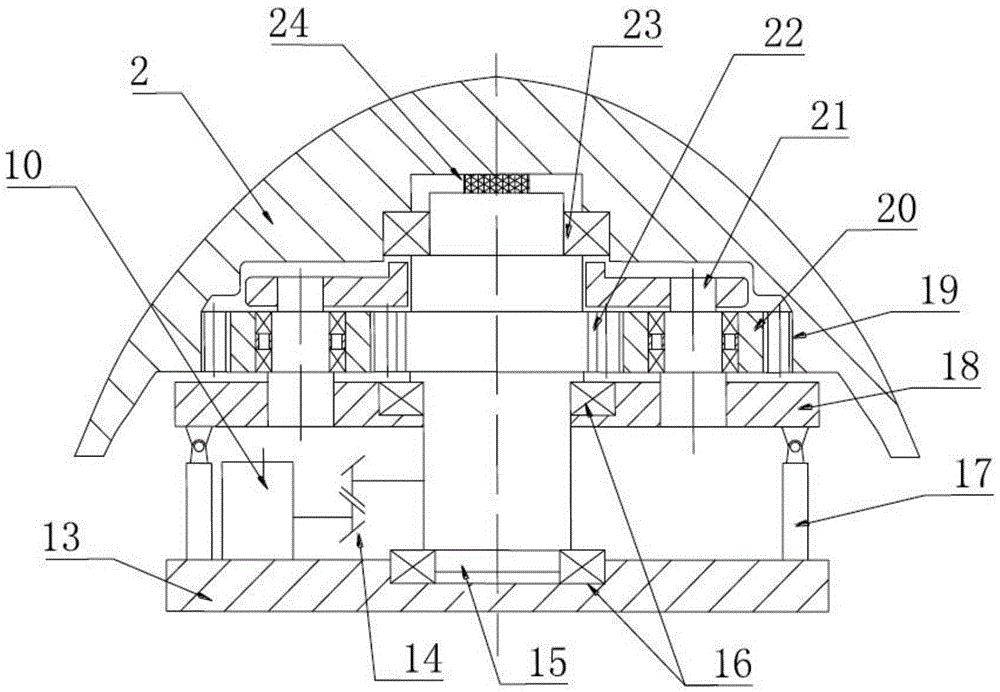

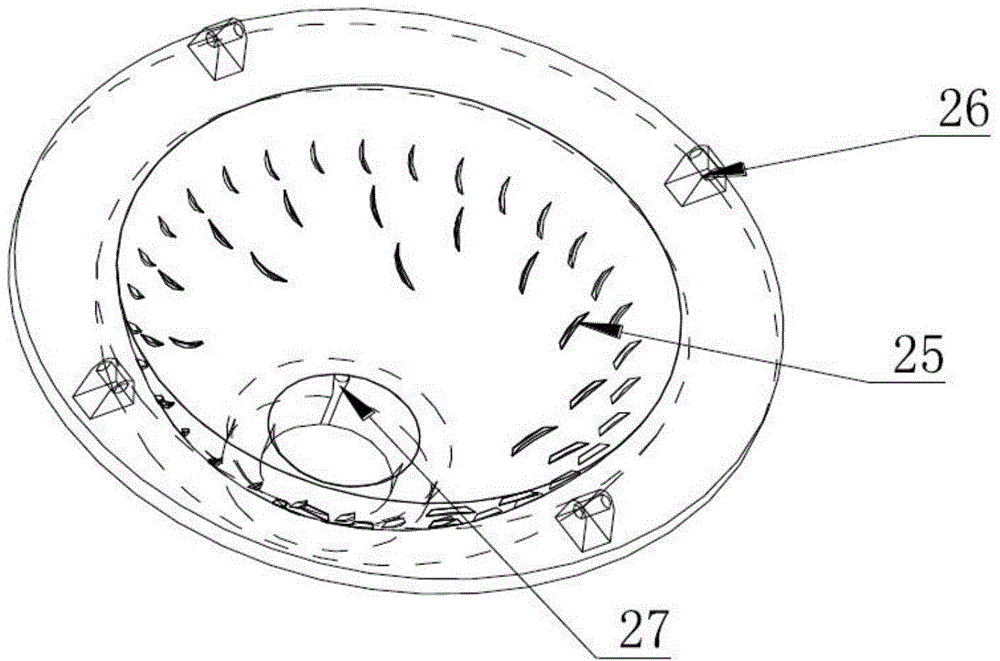

Method and equipment for simultaneously crushing and grinding ores

The invention discloses a method and equipment for simultaneously crushing and grinding ores. The method includes overlaying an upper arc-shaped grinding face on a lower arc-shaped grinding face, forming spatial regions which are gradually diminished from top to bottom between the inner surface of the upper arc-shaped grinding face and the outer surface of the lower arc-shaped grinding face, dividing the spatial regions into crushing regions and grinding regions from top to bottom, respectively arranging cutting teeth and fixing teeth on the inner surface of the upper arc-shaped grinding face and the outer surface of the lower arc-shaped grinding face in the crushing regions and arranging smooth arc faces on the outer surfaces of the upper arc-shaped grinding face and the lower arc-shaped grinding face in the grinding regions; enabling the upper arc-shaped grinding face and the lower arc-shaped grinding face to rotate relatively, feeding the ores into the crushing regions from a feed inlet in the top of the upper arc-shaped grinding face, fixing the ores by the aid of the fixing teeth, crushing the ores by the cutting teeth, enabling the crushed ores to fall into the grinding regions, grinding the ores by the smooth arc faces and enabling grains of the ores to fall via gaps at the lower ends of the upper arc-shaped grinding face and the lower arc-shaped grinding face. The method and the equipment have the advantages that the traditional crushers and ore grinding machines can be replaced, the ores can be crushed at first and then can be ground and integrally manufactured, and the equipment is high in crushing ratio.

Owner:CHINA UNIV OF MINING & TECH

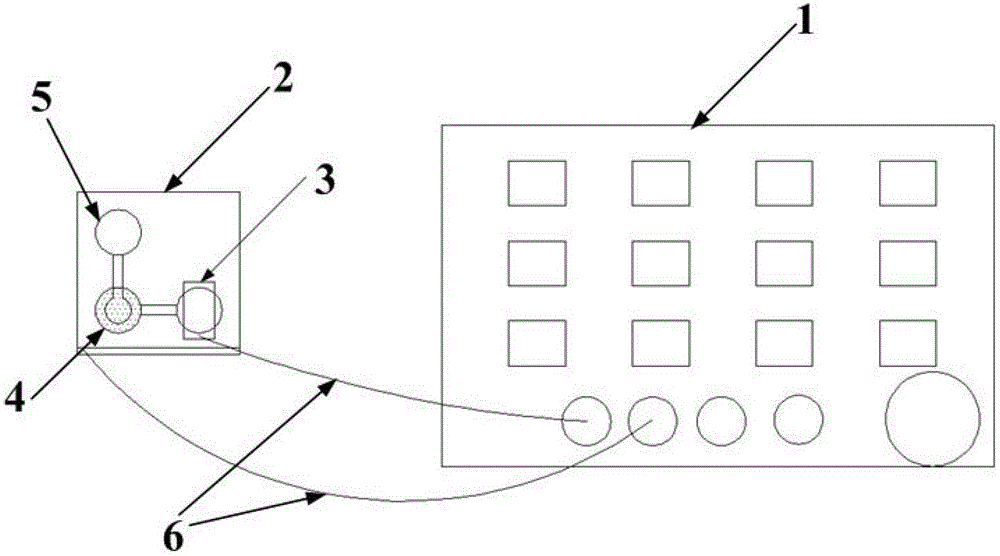

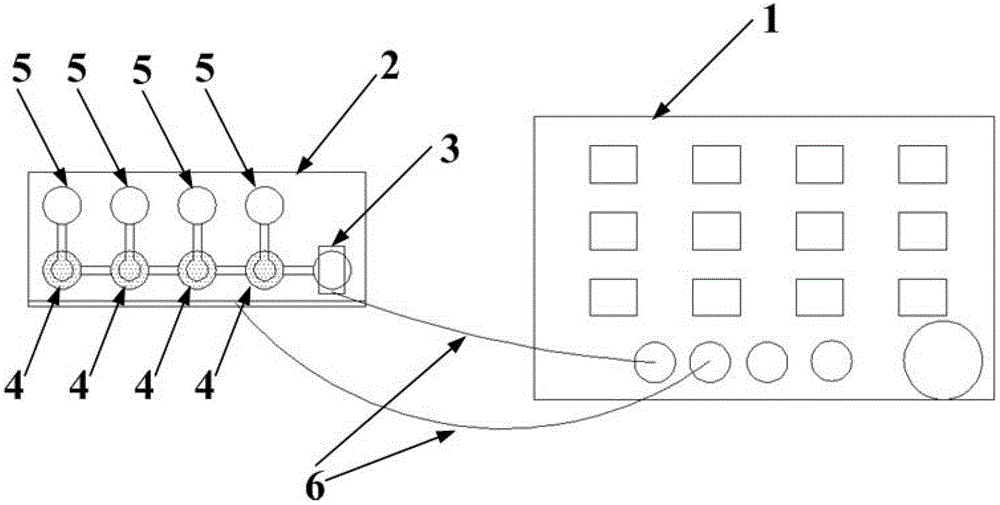

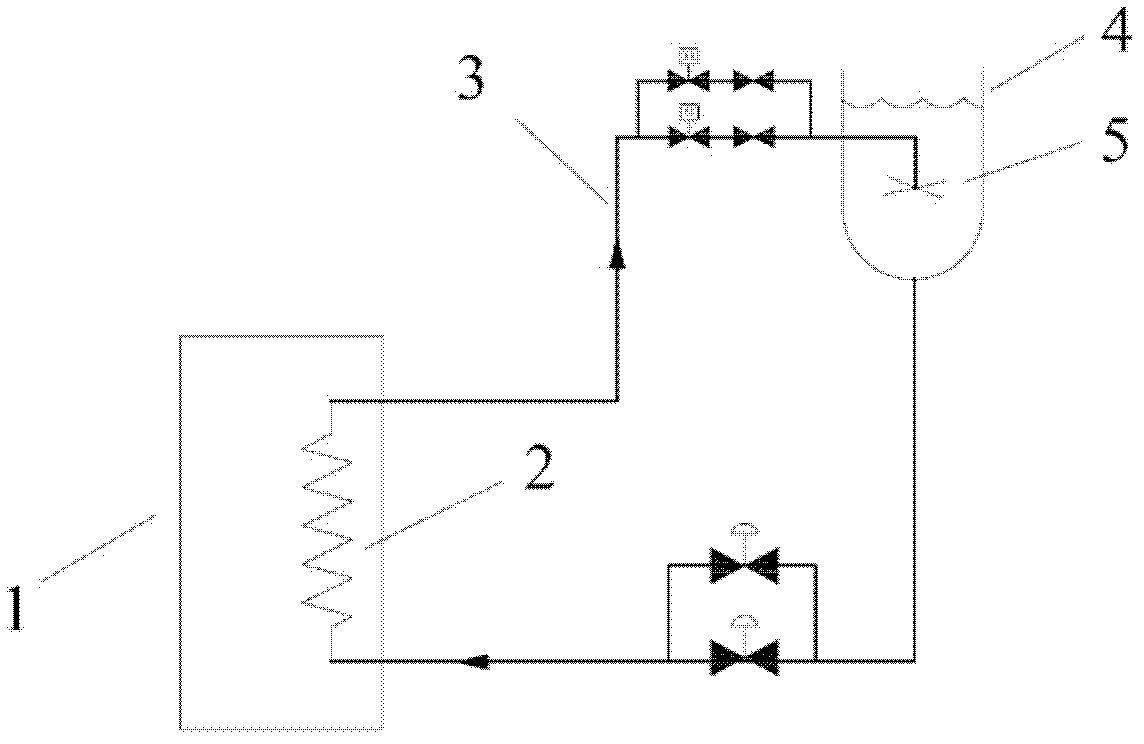

Residual heat removal system of nuclear reactor

InactiveCN103295657AImprove reliabilityReduce intermediate processNuclear energy generationCooling arrangementNuclear reactor coreNuclear reactor

The invention aims to provide a residual heat removal system of a nuclear reactor, which is used for enhancing the reliability of residual heat removal of the nuclear reactor. The residual heat removal system of the nuclear reactor comprises a main reactor cooling agent, a residual heat exchanger, a passive water feeding tank and a spraying device; a work medium flows into an inlet of the residual heat exchanger from the passive water feeding tank, and is used for absorbing heat of the main reactor cooling agent, which is transmitted by the residual heat exchanger; then, the work medium flows to the spraying device from an outlet of the residual heat exchanger and then is sprayed into the passive water feeding tank from the spraying device; the passive water feeding tank is higher than the residual heat exchanger.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

Combined device for generating power through tidal power and desalinating sea water

InactiveCN103423076AEfficient use ofNo pollution in the processGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisWater desalinationEngineering

The invention discloses a combined device for generating power through tidal power and desalinating sea water. The device is composed of a hydraulic turbine set, a transmission set, a sea water desalinating device and an electric generator, wherein the hydraulic turbine set is arranged at the bottom of a dam and formed by connecting a plurality of water wheels in series through couplings, each water wheel is a hollow cylinder, and a plurality of blades are arranged on the outer circle of each hollow cylinder. One end of the transmission set is arranged on an output shaft of the water wheels, the other end of the transmission set is arranged on a support on the dam, and linkage between the two ends is achieved through a transmission belt or a transmission chain. One end of an output shaft of the transmission set is connected with a booster pump to produce high-pressure sea water, then, fresh water is prepared by a membrane permeation assembly, and the other end of the output shaft of the transmission set is connected with the electric generator to generate electricity. The whole device integrates the tidal power and sea water desalination well, therefore, not only is the tidal power effectively utilized, but also the fresh water can be prepared, and the device is environmentally friendly, free from pollution and capable of being used in some coastal regions or islands where both water and electricity are in shortage.

Owner:厦门锐思达机电科技有限公司

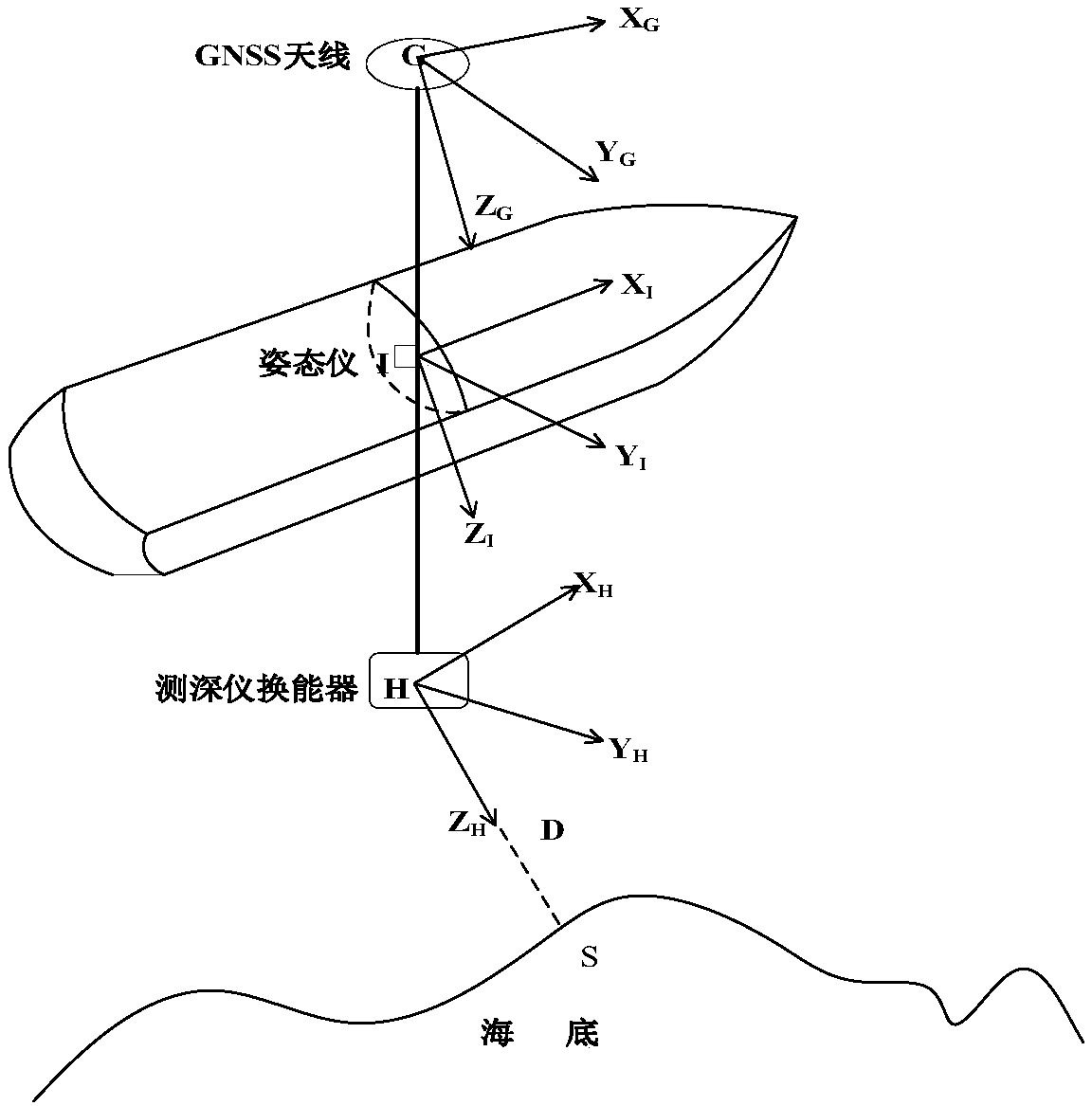

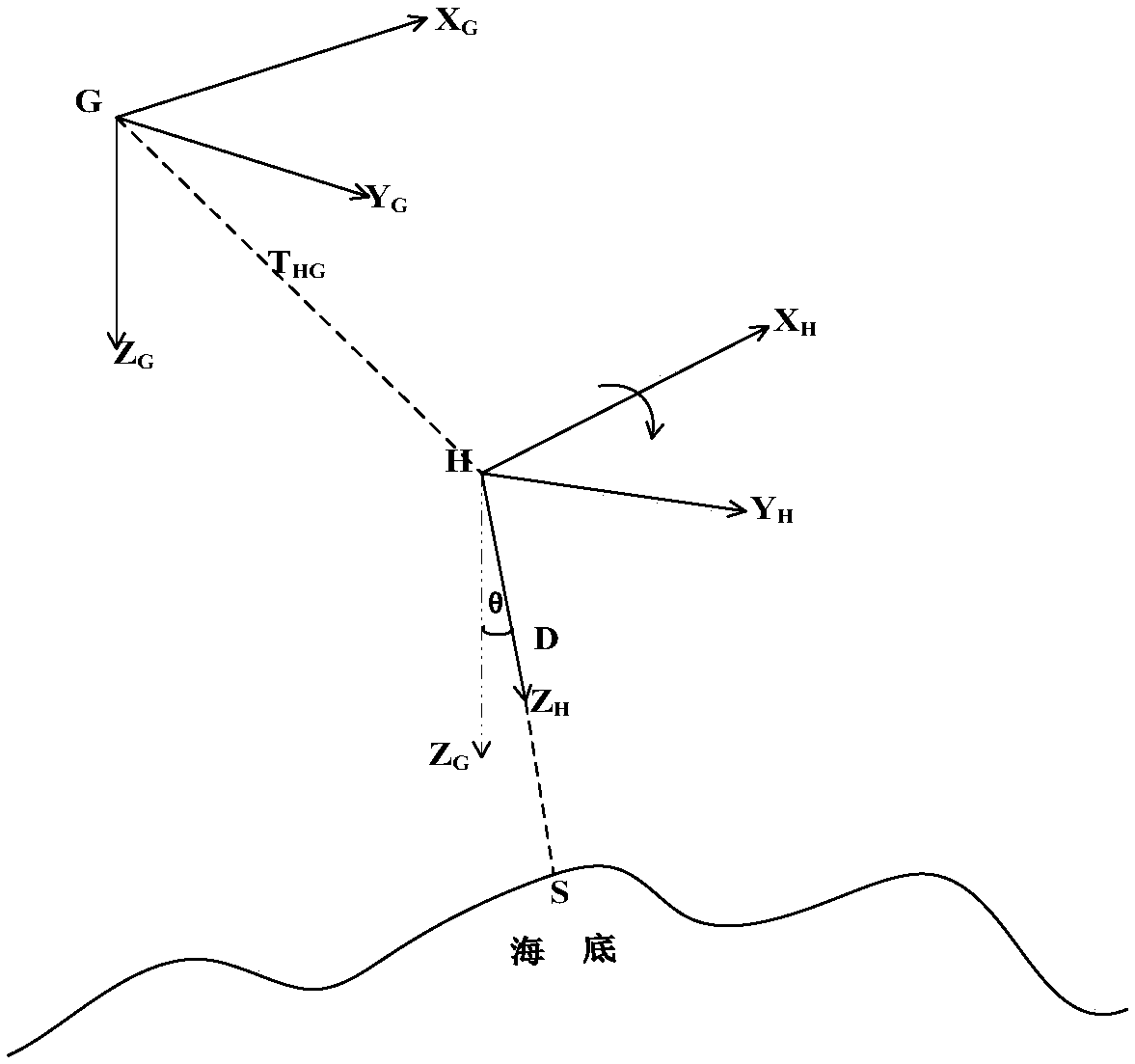

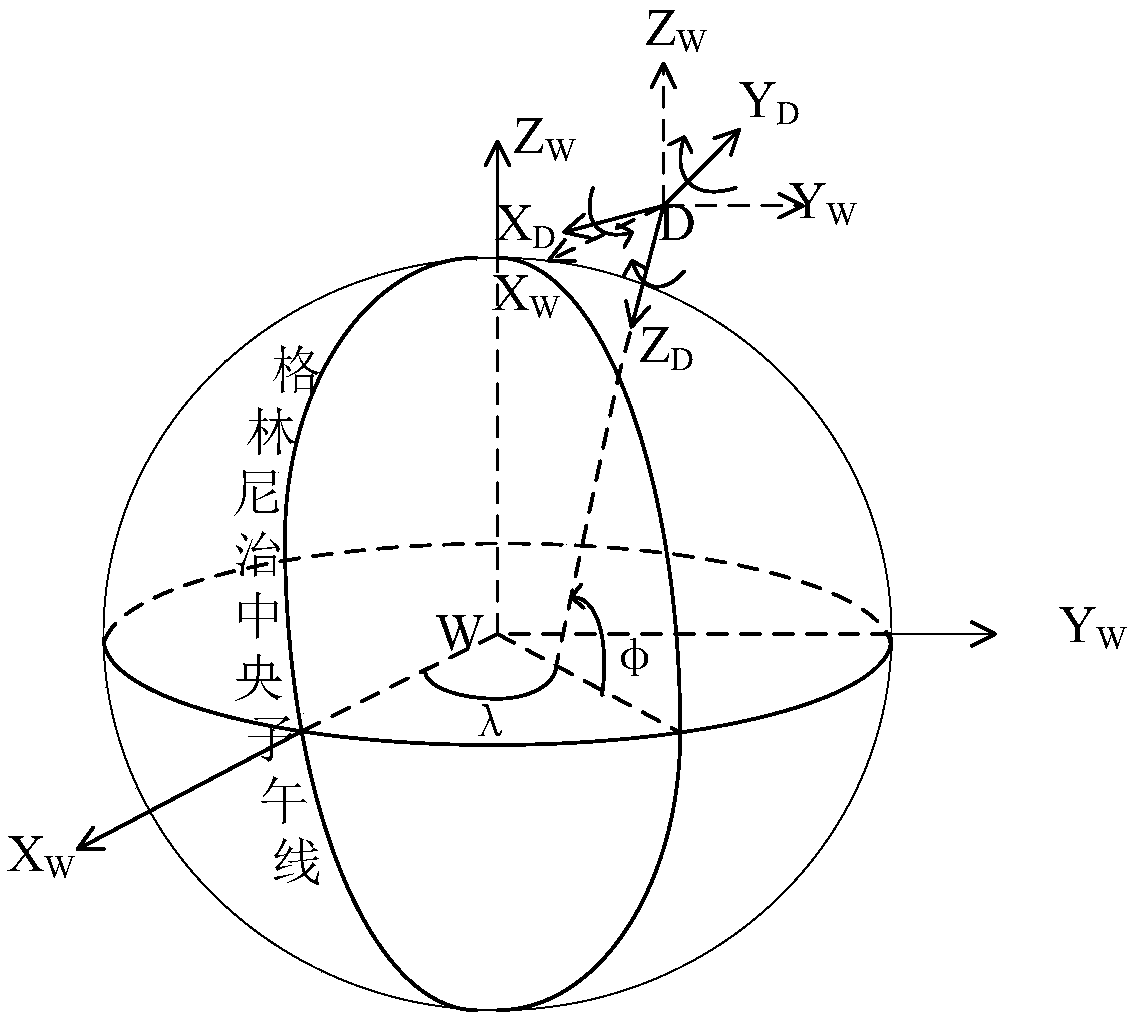

Submarine topographic measurement method based on precision POS

InactiveCN109059746AAchieve integrated expressionReduce intermediate processElectrical/magnetic solid deformation measurementSatellite radio beaconingOcean bottomReference ellipsoid

The invention relates to the technical field of submarine topographic measurement, in particular to a submarine topographic measurement method based on a precision POS. The submarine topographic measurement method aims to collect the three-dimensional coordinate information of a hull measurement system by the precision POS composed of a GNSS receiver, an attitude instrument and a depth sounding instrument based on high-precision GNSS positioning. A reference ellipsoid surface is taken as the reference when calculating three-dimensional coordinates of measuring points. A WGS-84 coordinate system is adopted uniformly to solve the problem that the accuracy of measurement results is affected by matching of the plane position and depth information, water level control, water depth reduction andthe like in traditional water depth measurement work.

Owner:TIANJIN UNIV

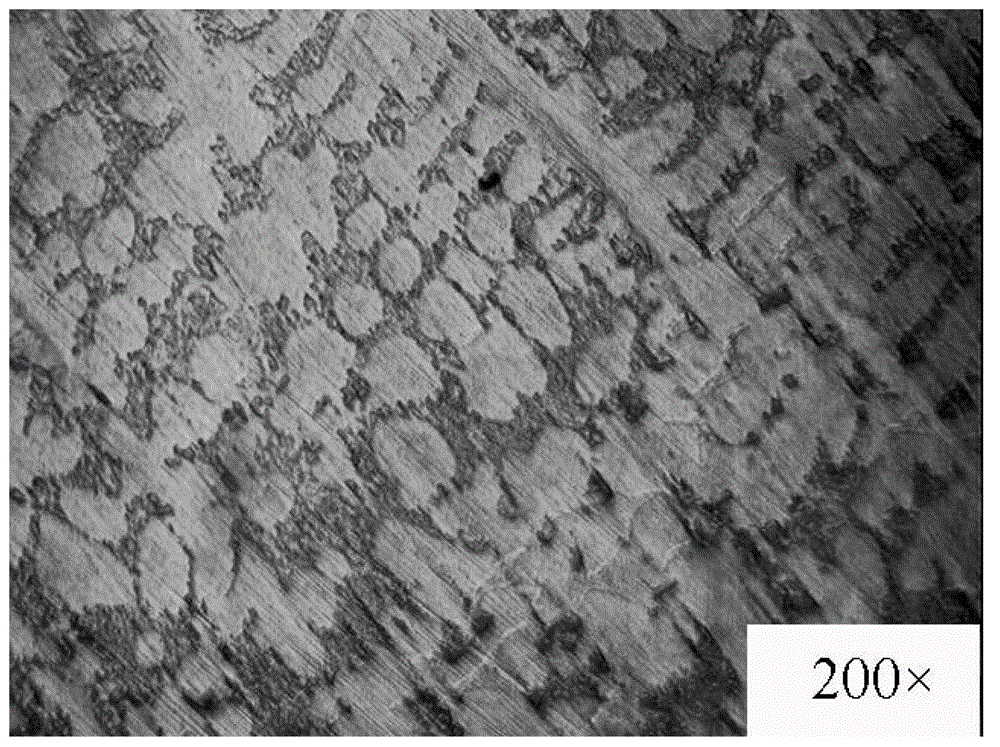

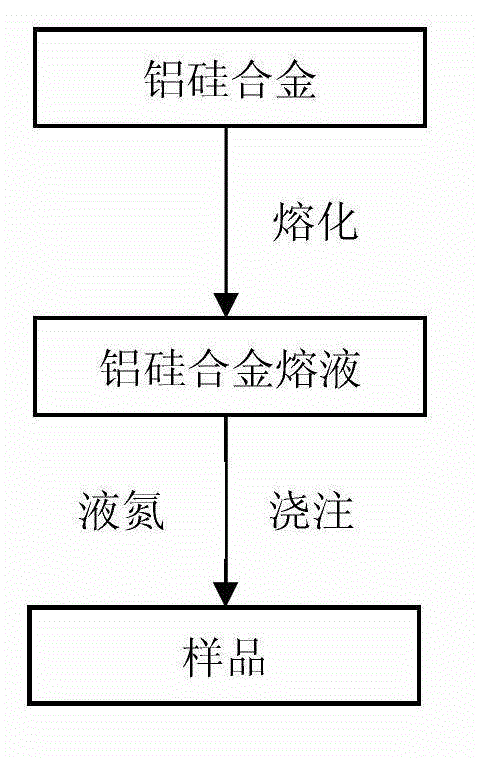

Method for refining hypo eutectic aluminum-silicon alloy structure

The invention discloses a method for refining a hypo eutectic aluminum-silicon alloy structure. The method comprises the steps of: firstly melting down an aluminum-silicon alloy; then casting rapidly, solidifying and shaping the melt aluminum-silicon alloy in a liquid nitrogen environment. The method for refining the hypo eutectic aluminum-silicon alloy structure has the advantages of being simple in operation, safe and environment-friendly, obvious in refining effects and fast to prepare. A relatively large number of eutectic structures which are distributed uniformly, have compact and fine organization and have low cutting function for a basal body can be obtained after the AC4B aluminum-silicon alloy is cooled by liquid nitrogen, so that the hardness of the aluminum alloy is up to 148 HBS. The AC4B aluminum-silicon alloy which is obtained by being cooled rapidly in the liquid nitrogen environment has a size of about 3 microns to 15 microns. The crystal particle structure is fine; and the edges and corners of the crystal particles are passivated and smooth.

Owner:ANHUI RUNXIN TAIDA INTELLIGENT SYST ENGCO

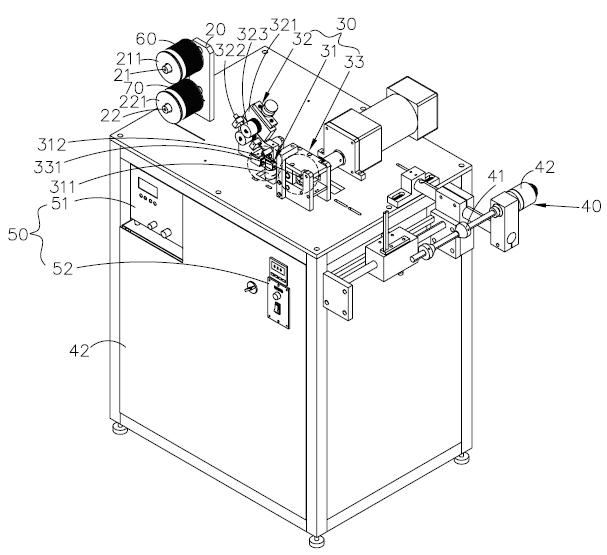

Fuse wire, device for manufacturing fuse wire and manufacturing method of fuse wire

ActiveCN102543612AReduce intermediate processesSimple processFuse device manufactureOperating temperatureWire frame

The invention discloses a fuse wire, a device for manufacturing the fuse wire and a manufacturing method of the fuse wire. The device comprises a machine body, a wire outlet frame, a hot melting device, a wire coiling frame and a controller, wherein the wire outlet frame comprises a tin wire frame and a copper wire frame; a tin wire is arranged on the tin wire frame; a copper wire is arranged on the copper wire frame; the hot melting device comprises a heating device and a clamping device; a heating column is arranged on the heating device; the copper wire is attached to the heating column; the clamping device is used for driving the tin wire to extend to the place above the heating column and to be in contact with the copper wire; the controller is arranged on the machine body and is electrically connected with the hot melting device and the wire coiling frame; and the controller is used for controlling the operating temperature of the heating device and the operating speed of the tin wire and the copper wire. Through controlling the operating speed of the tin wire and the copper wire, the hot melting device is used for melting the tin wire onto the copper wire of a laminated structure, so that the middle process is reduced, the process flow is simple, the environmental protection demand is met, the cost is lower, the production efficiency is high, the property is stable and the structure is simple.

Owner:DONGGUAN BETTER ELECTRONICS TECH

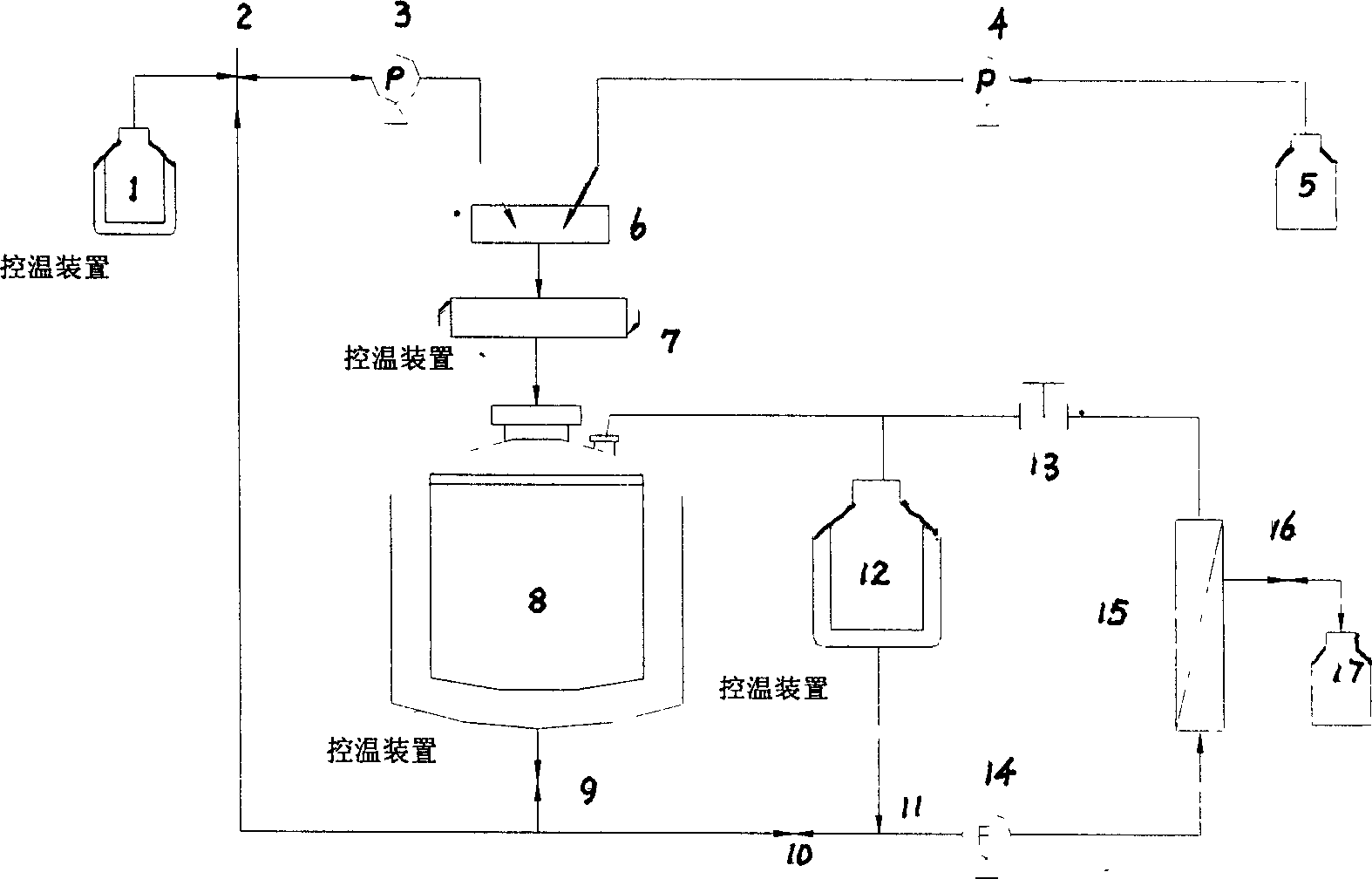

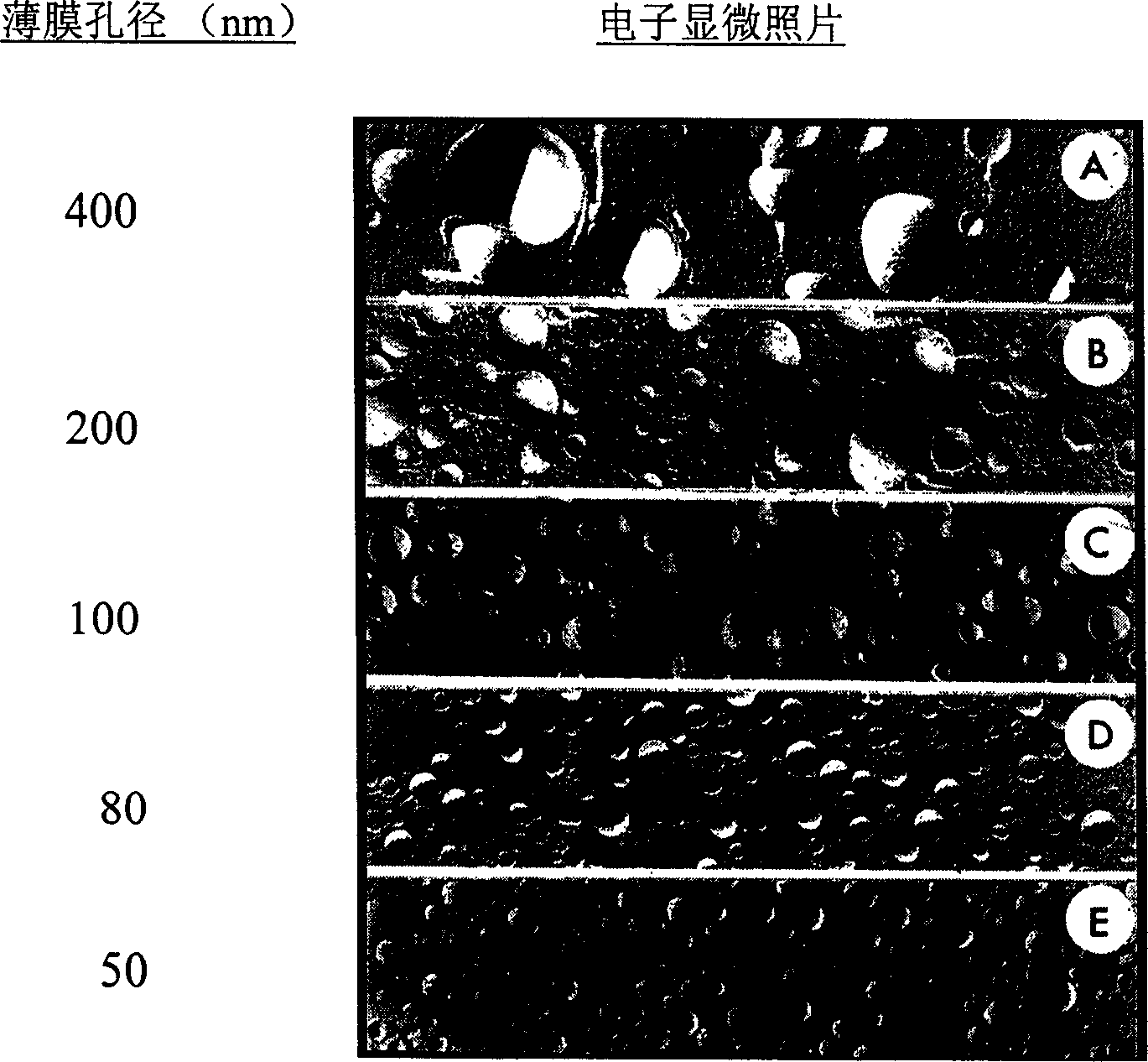

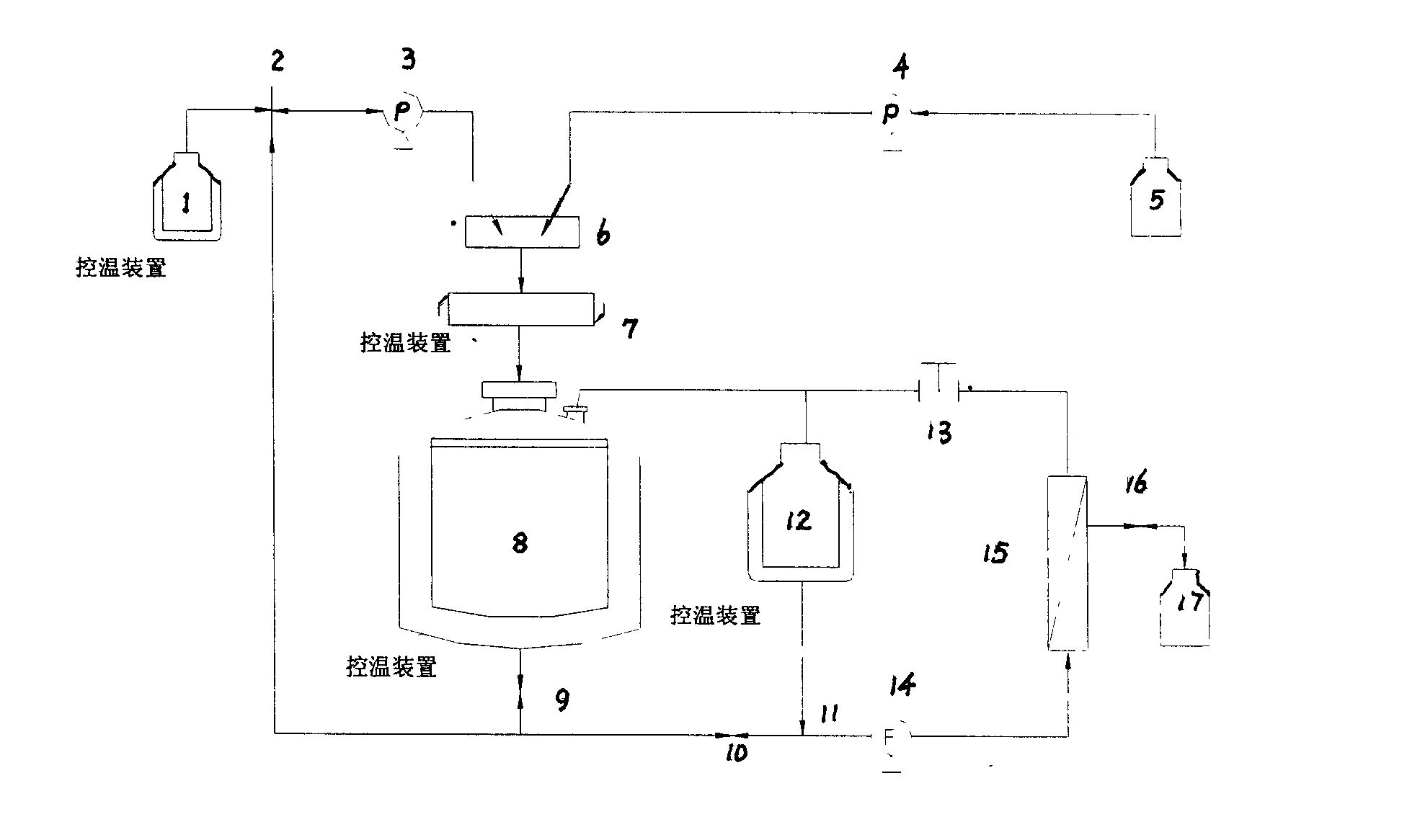

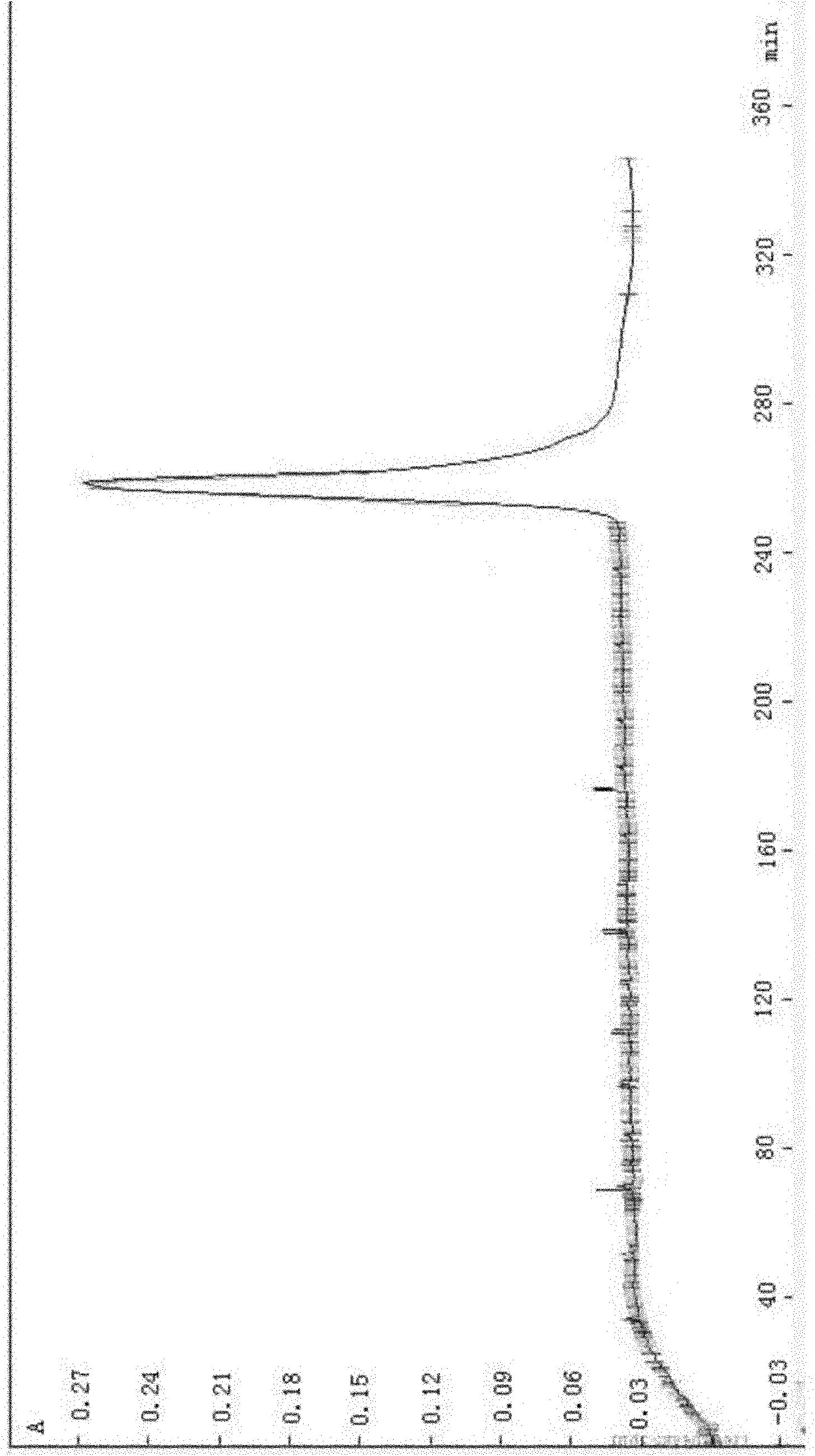

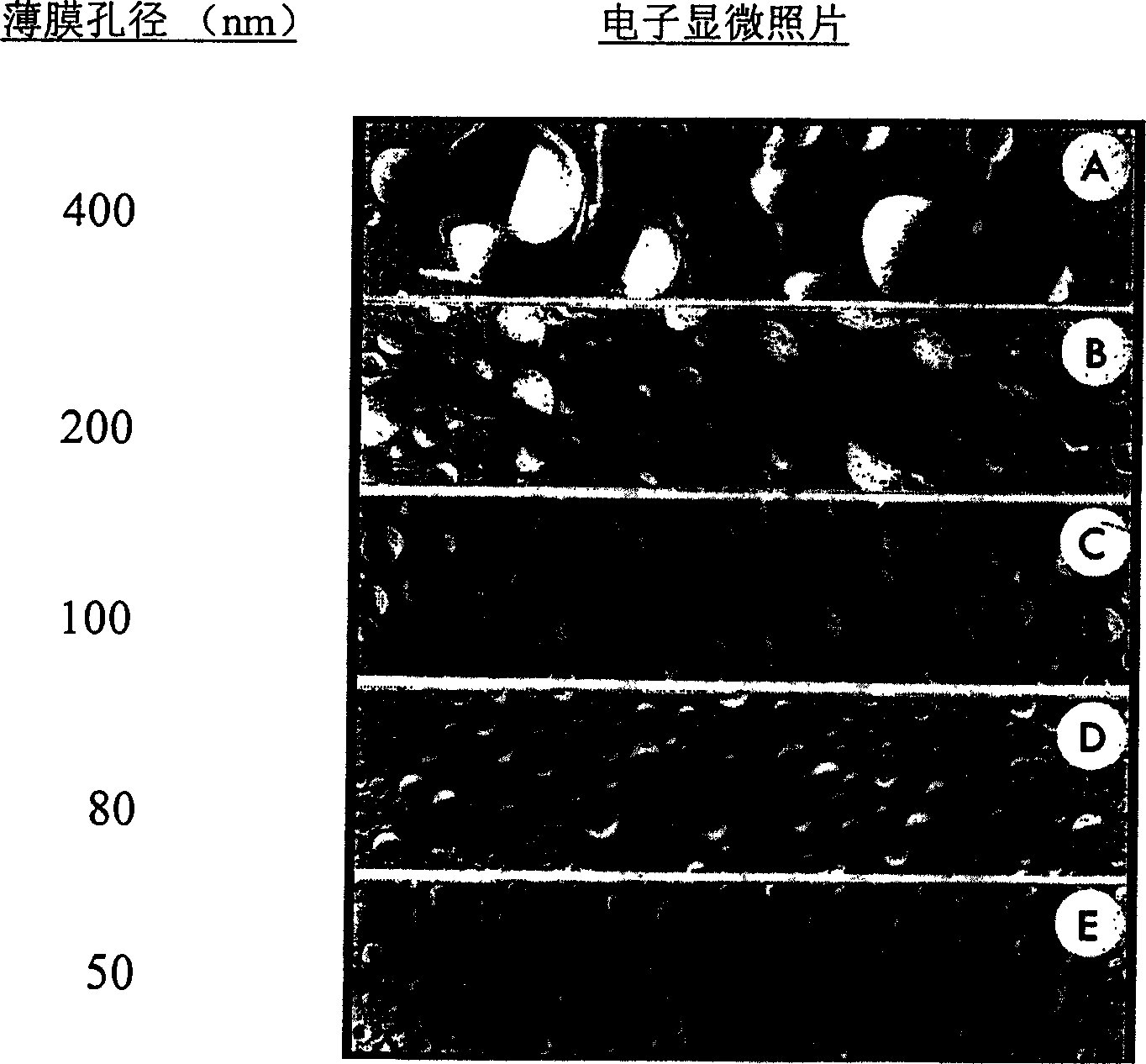

Automatic liposome preparation apparatus and method for prepaving liplsome by same

InactiveCN1483400AParticle size controllableUniform particle sizePharmaceutical product form changeLiposomal deliveryPhospholipidWater soluble drug

The present invention relates to an automatic liposome preparation equipment and method for preparing liposome by using said equipment. Said equipment includes 1). high-pressure pump; 2). solution mixer; 3). liposome grain size control device; and 4). high-pressure ultrafiltering dialysis column. Said invention uses the high-pressure pump to make the phospholipid dissolved in organic phase, liposoluble medicine and aqueous solution be quickly mixed in solution mixer to obtain multiphase multilayer liposome, then makes said multiphase multilayer liposome directly pass through liposome extruding device so as to obtain large monochamber liposome, and the medicine which is not wrapped in the liposome and organic solvent can be removed by using high-pressure ultrafiltering dialysis column.

Owner:XIAN LIBANG PHARMA TECH

Method for separating and extracting peroxidase in sweet potato peels

The invention discloses a method for separating and extracting peroxidase in sweet potato peels, comprising the following steps of: (1) taking peels after sweet potatoes are cleaned, adding a phosphate buffer with pH value of 7.0-8.0 to homogenate and extract at 0-15 DEG C, and filtering after extracting to obtain a filter liquor; (2) adding two aqueous phase extractants including solid ammonium sulfate and PEG6000 (Polyethylene Glycol 6000) into the filter liquor at the same time stirring so that the mass percentage concentration of the ammonium sulfate is 20-30% and the mass percentage concentration of the PEG6000 is 6-8%, standing for delaminating at 0-15 DEG C after dissolution under sufficient stirring, and taking a lower layer of solution which is a crude enzyme solution; (3) directly carrying out hydrophobic chromatography on the crude enzyme solution obtained in the step (2) by a Phenyl Sepharose6 fast flow, carrying out gradient elution by using an ammonium sulfate solution of 0-1 mol / L after sample application, and lyophilizing after collecting an elution solution with enzyme activity; (4) carrying out gel chromatography and ion chromatography on lyophilized powder to obtain the peroxidase. The invention preferably solves the problem on material sources and can increase the efficiency and the enzyme activity.

Owner:HANGZHOU NORMAL UNIVERSITY

Automatic liposome preparation apparatus and method for prepaving liplsome by same

InactiveCN1186011CParticle size controllableUniform particle sizePharmaceutical product form changeLiposomal deliveryPhospholipidWater soluble drug

The present invention relates to an automatic liposome preparation equipment and method for preparing liposome by using said equipment. Said equipment includes 1). high-pressure pump; 2). solution mixer; 3). liposome grain size control device; and 4). high-pressure ultrafiltering dialysis column. Said invention uses the high-pressure pump to make the phospholipid dissolved in organic phase, liposoluble medicine and aqueous solution be quickly mixed in solution mixer to obtain multiphase multilayer liposome, then makes said multiphase multilayer liposome directly pass through liposome extruding device so as to obtain large monochamber liposome, and the medicine which is not wrapped in the liposome and organic solvent can be removed by using high-pressure ultrafiltering dialysis column.

Owner:XIAN LIBANG PHARMA TECH

Hydraulic forming die and method for manufacturing complex panel component through hydraulic forming die

A hydraulic forming die comprises an upper die body and a lower die body. The lower die body is a mold die body. The upper die body is an empty die body. An exhaust hole is formed in the bottom of a lower die cavity. An upper die cavity is provided with an oil inlet hole and an oil outlet hole. A sealing ring is arranged between the upper die cavity and the lower die cavity. An upper main die body and a lower main die body are locked through a locking bolt. A method for manufacturing a complex panel component through the hydraulic forming die comprises the steps that firstly, simulated analysis is conducted; secondly, charging and die assembly pre-tightening are conducted; thirdly, press locking is conducted; fourthly, compressed liquid is injected, and pressurizing is gradually conducted; fifthly, pressure maintaining is conducted; sixthly, pressure releasing is conducted, and the compressed liquid is discharged; and seventhly, die sinking is conduced, and the component is taken out. The die is simple in structure, short in design period and low in manufacturing cost. The middle procedures for manufacturing the complex panel component through the method are few, manpower and material resources are saved, the product thinning rate is low, and the wall thickness is uniform; the material forming extremity is high, the forming quality is good, precision is high, the bearing capability is high, and residual stress is low; and the problems that the complex panel component is prone to cracking and deformation due to drawing, and wrinkling happens to the edge pressing position are solved, and the hydraulic forming die and the method are particularly suitable for complex drawing structural pieces formed at a time.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Chocolate mousse powder

The invention discloses chocolate mousse powder which consists of the following components in percentage by weight: 40-50% of white granulated sugar, 15-20% of cocoa powder, 15-18% of non-dairy creamer, 10-15% of gelatin and 5-12% of glucose and is prepared by preparing, mixing, sterilizing and packaging. The chocolate mousse powder can be used for preparing mousse as well as mousse stuffing of mousse cakes, split cakes, Swiss rolls, puff and dessert, and is suitable for bakeries, cake houses, chain stores of baking and the like. When the chocolate mousse powder is used for preparing chocolate mousse, the process is simple, convenient to operate and easy to understand; the prepared product is pure and natural in taste and delicate and cool in mouthfeel and has the characteristics of high-end frozen food; since multiple middle processes are reduced, the occurrence probability of the problems in quality, sanitation and the like is reduced, and the chocolate mousse powder has obvious advantages in production management, quality control, product standardization and the like.

Owner:HARBIN AIKEER FOOD TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com