One-step method and device for production of phosphonate by yellow phosphorus

A phosphate and yellow phosphorus technology, applied in phosphoric acid, phosphorus oxyacid, etc., can solve the problems of limiting waste heat recovery efficiency, occupying combustion space, increasing equipment investment, etc., saving raw materials and equipment investment, and avoiding the discharge of acid mist , the effect of reducing thermal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

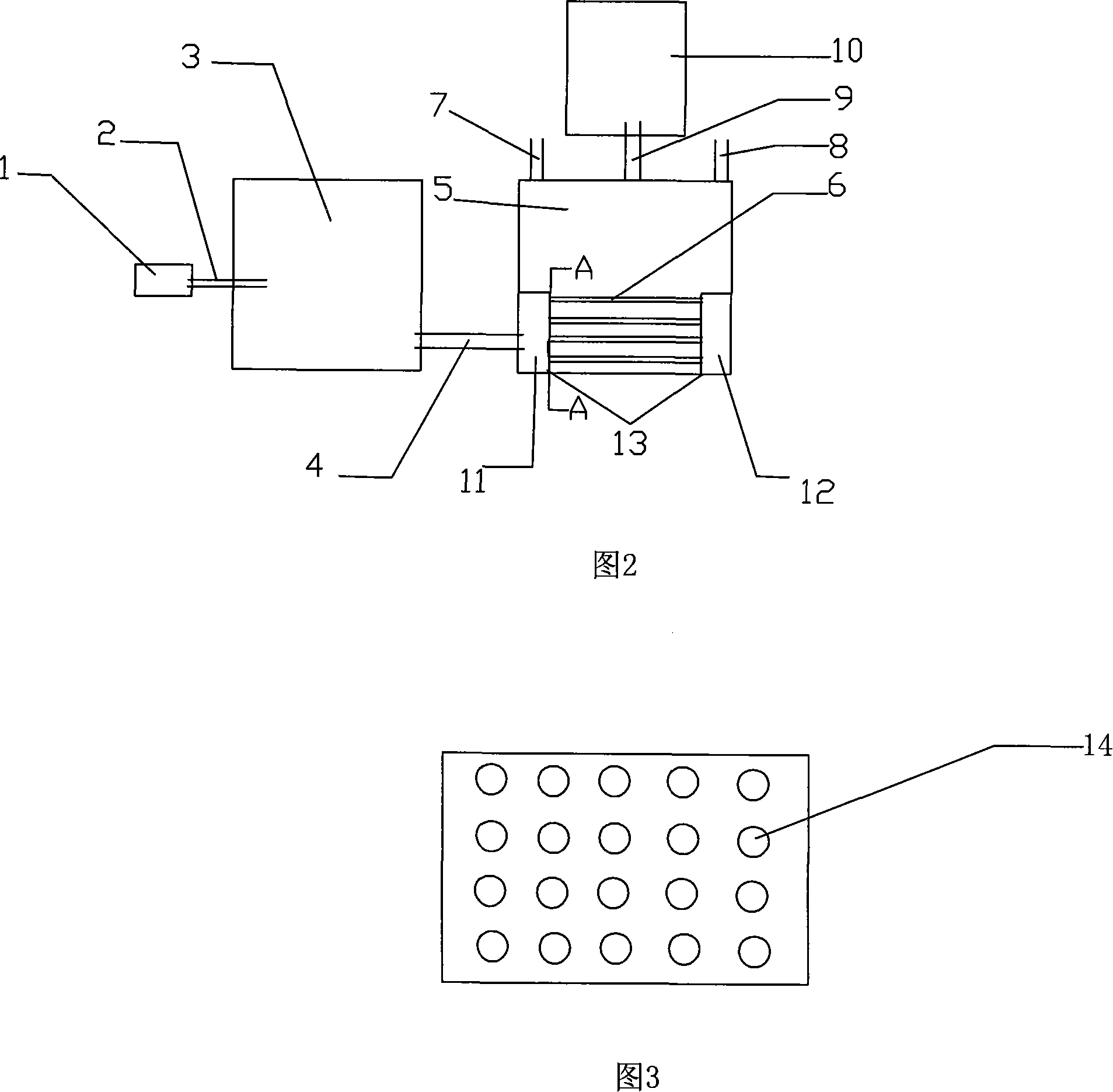

[0020] As shown in Figure 2, the yellow phosphorus one-step method production phosphate device of the present invention comprises the sequentially connected phosphorus melting tank 1, phosphorus spraying gun 2, phosphorus burning furnace 3 that is arranged on the front stage process flow, is arranged on the back stage process flow The absorption tower 10 also includes the P that is arranged between the phosphorus burning furnace 3 and the absorption tower 10, and its two ends are respectively connected with the phosphorus burning furnace 3 through the pipeline 4 and the pipeline 9. 2 o 5 The gas outlet is connected to the inlet of the absorption tower 10 to execute the waste heat boiler 5 of the middle process flow. In the cavity of the waste heat boiler 5, tube rows 6 for heat exchange with water are arranged and fixed. 13 and the inner wall of the waste heat boiler 5 separately constitute the P 2 o 5 The gas gathers delivery chambers 11 , 12 . The phosphorus furnace 3 ha...

Embodiment 2

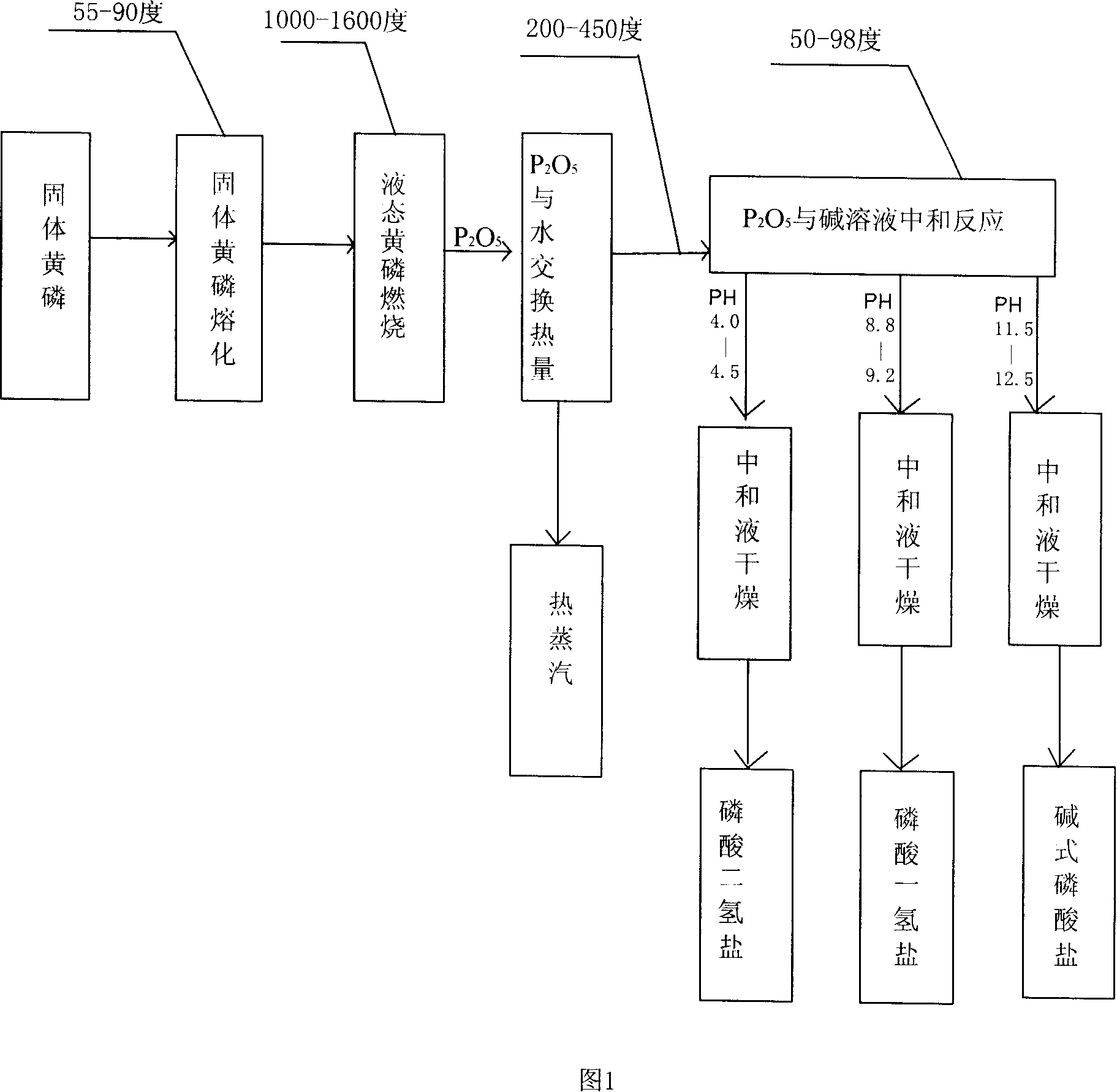

[0022] Add solid yellow phosphorus into the phosphorus melting tank 1 to make it melt into a liquid state at 55-90°C; under the action of compressed air in the phosphorus spray gun 2, the liquid yellow phosphorus is automatically sprayed into the phosphorus furnace through the phosphorus spray gun 2 Combustion in 3, release a large amount of heat energy at the same time, the generation temperature is 1000~1600℃P 2 o 5 Gas; the gas is introduced into the waste heat boiler 5 through the pipeline 4, enters the tube row 6 through the gas distributor 13, and performs heat exchange with the cooling water around the tube row 6, that is, the high-temperature gas goes through the tube side, the water goes through the shell side, and the water takes away the high temperature The thermal energy of the gas is converted into steam of 0.4-0.8 MPa, and the steam is transported to the phosphorus melting tank 1 through the pipeline 7, or transported to the external production and living needs ...

Embodiment 3

[0025] P with a temperature of 200-450°C after heat exchange 2 o 5 The gas enters the absorption tower 10 through the pipeline 9, reacts with 30-42% potassium hydroxide alkali solution at a temperature of 50-98°C, adjusts the pH value to 8.8-9.2, and adds a precipitant to remove arsenic and heavy metals. Then pass through precipitation filtration, crystallization and drying to obtain the finished dipotassium hydrogen phosphate. Burning a ton of yellow phosphorus can produce 6.5-7.0 tons of water vapor with a pressure of 0.4-0.8 MPa, and obtain 5.052 tons of dipotassium hydrogen phosphate as a finished product, with a product conversion rate of 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com