Method for reducing emission of thermal power generation smoke CO2 and subsidiarily producing superfine nanometer CaCO3 from thermal power generation smoke CO2

A technology of ultra-fine nano and flue gas, which is applied in the direction of nanotechnology, nanotechnology, separation methods, etc., can solve the problems of low treatment costs, achieve low carbon emissions, reduce thermal pollution, and prevent equipment fouling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

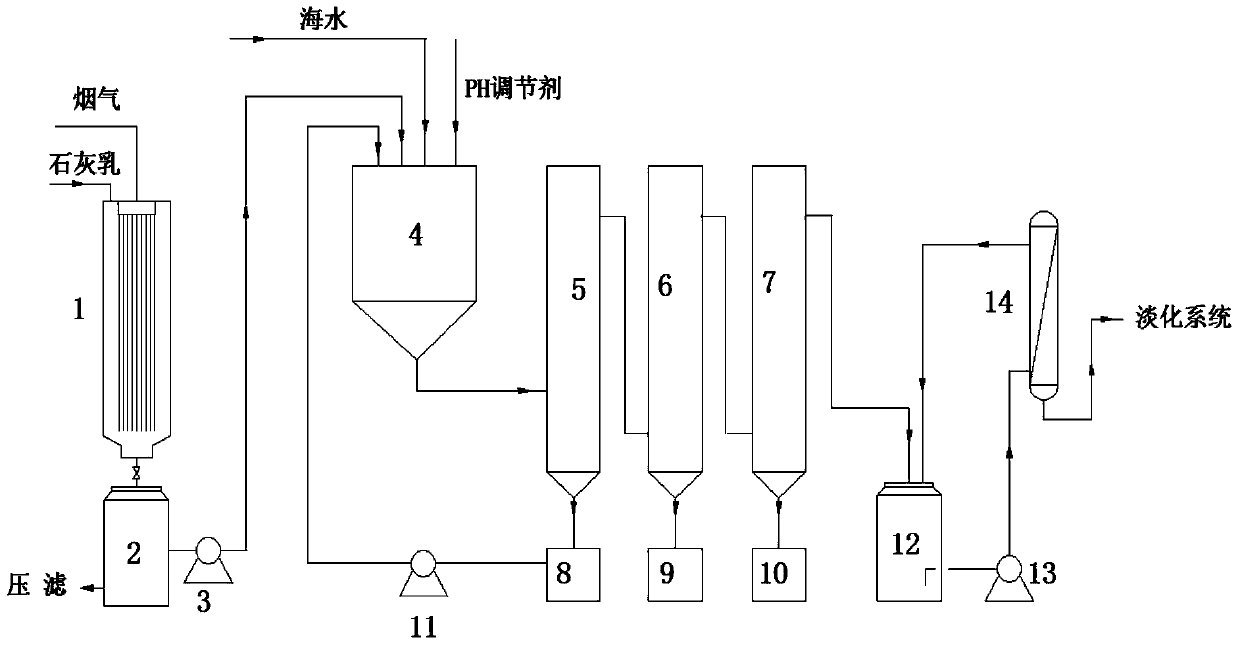

[0039] at 10m 3 / h seawater on the flue gas decarbonization process of 50kw gas-fired power generation as an example:

[0040] 1) The milk of lime with a concentration of 25% is used as a decarburizing agent to pass into the decarbonization tower 1. The temperature of the flue gas discharged after gas-fired power generation is 100°C, and the volume content of carbon dioxide is 10%. The gas reacts with milk of lime to generate calcium carbonate and calcium bicarbonate through countercurrent washing, and the pH value of the solution after the reaction is 5.5. Excess flue gas (temperature 25°C, carbon dioxide content 1%) is discharged from the top of the decarbonization tower, and the carbon dioxide absorption rate is 90%;

[0041] 2) Calcium carbonate and calcium bicarbonate are settled through the settling tank 2, and the industrial calcium carbonate product is produced after the precipitate is washed, press-filtered and dried, and the mixed solution containing calcium bicarbo...

Embodiment 2

[0048] at 150m 3 / h Seawater decarbonization process of 1000kw coal-fired flue gas (after desulfurization and denitrification) as an example:

[0049] 1) The milk of lime with a concentration of 35% is used as a decarburizing agent to pass into the decarbonization tower 1. After the flue gas after coal-fired power generation is desulfurized and denitrified, the volume content of carbon dioxide is 11.3%. Gas reacts with milk of lime to generate calcium carbonate and calcium bicarbonate through countercurrent washing, and the pH value of the solution after the reaction is 6. Excess flue gas (temperature 24°C, carbon dioxide content 1.1%) is discharged from the top of the decarbonization tower, and the carbon dioxide absorption rate is 90.2%;

[0050] 2) Calcium carbonate and calcium bicarbonate are settled through the settling tank 2, and the industrial calcium carbonate product is produced after the precipitation is washed, press-filtered and dried, and the mixed solution cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com