Steelmaking equipment based on low-content carbon emission for steelmaking

A carbon emission, low content technology, applied in the manufacture of converters, etc., can solve the problems of carbon monoxide recycling, carbon monoxide pollution, carbon monoxide waste, etc., to achieve the effect of reducing carbon dioxide content, achieving low carbon emissions, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

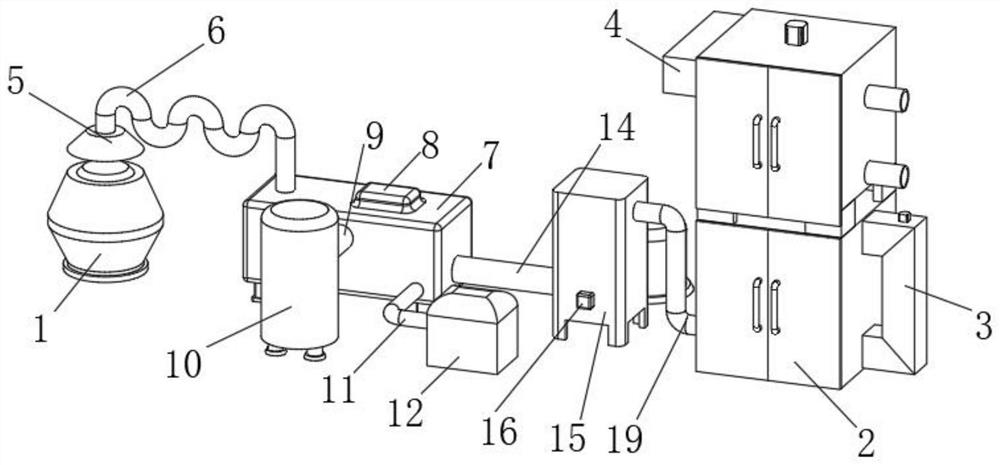

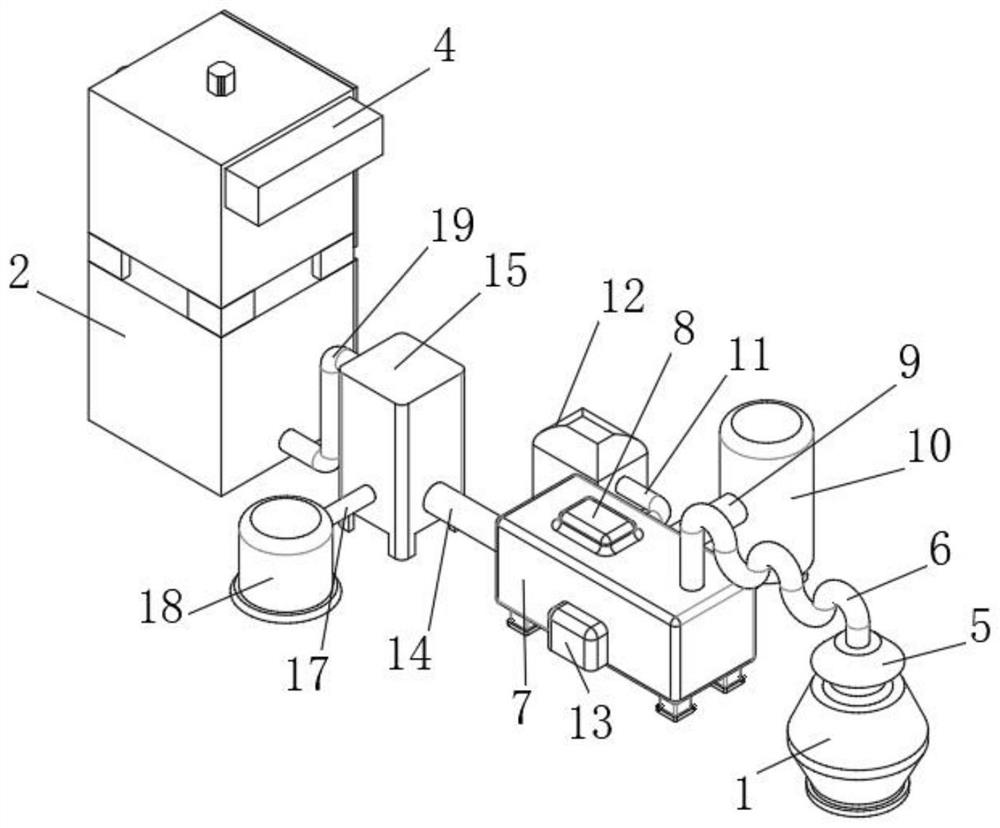

[0032] see Figure 1-9 , the present invention provides a kind of technical scheme:

[0033] A low-carbon emission steelmaking equipment for steelmaking. In this solution, a smoking port 5 is installed above the converter 1, so that the flue gas generated by the converter 1 can be absorbed by the smoking port 5, and the smoking port 5 passes through the flue gas cooling pipe. 6 and the flue gas dedusting box 7 are hollowly connected, so that the flue gas discharged from the converter 1 will flow into the flue gas dedusting box 7 through the flue gas cooling pipe 6. It takes a certain amount of time to cool the flue gas when it flows through the flue gas cooling pipe 6;

[0034] After the flue gas enters the flue gas dust removal box 7, the electromagnetic valve installed in the flue gas cooling pipe 6 seals the flue gas dust removal box 7, so that the dust removal equipment installed in the flue gas dust removal box 7 can remove the smoke air for dust removal;

[0035] After ...

Embodiment 2

[0040] see Figure 1-9 , on the basis of Embodiment 1, the present invention provides a technical scheme:

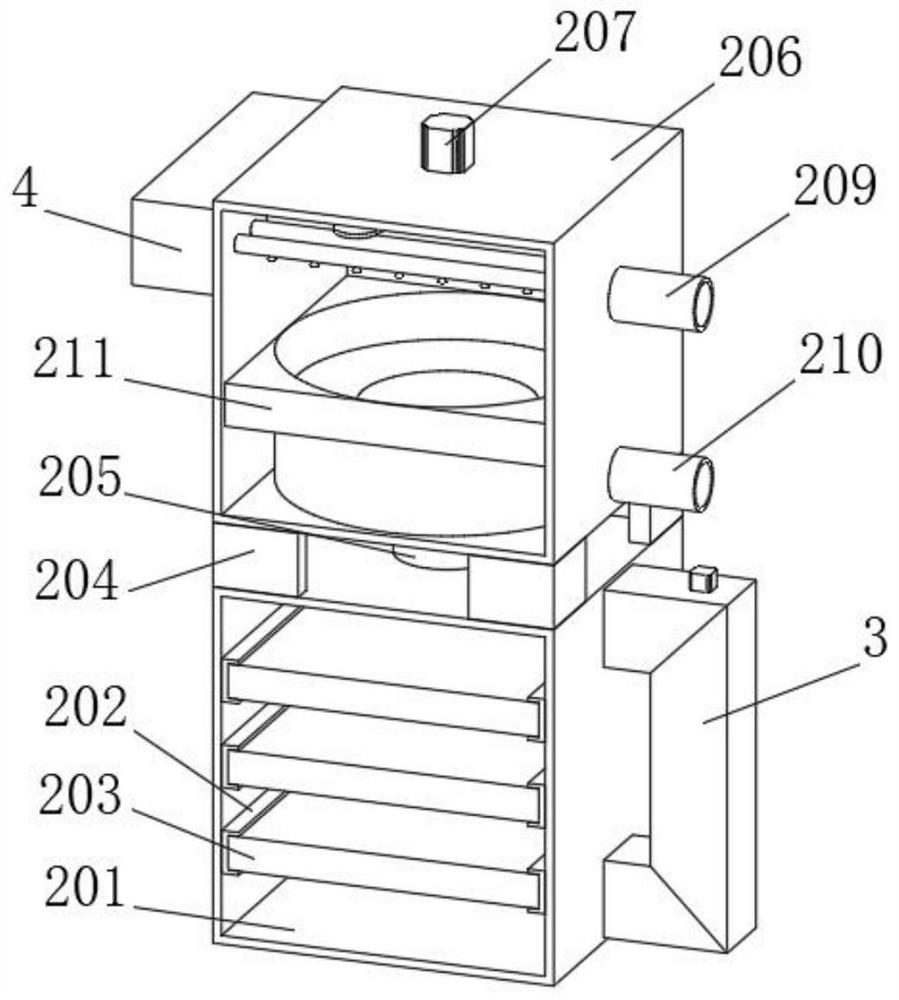

[0041] A low-carbon emission steelmaking equipment for steelmaking, the carbon dioxide treatment equipment 2 includes a lower treatment box 201 for flue gas filtration and an upper treatment box 206 for flue gas treatment. When the flue gas passes through the carbon dioxide discharge pipe 19 from After the air inlet below the lower treatment box 201 enters, three groups of installation racks 202 are fixedly connected to the inner wall of the lower treatment box 201 and are vertically distributed at equal distances. 203 can adsorb carbon dioxide in flue gas;

[0042] The filtering mechanism 203 is a porous material, and the filtering mechanism 203 is a combination of any two or more adsorbents in materials such as molecular sieve, activated carbon, silica gel and activated alumina, thereby improving the absorption effect of carbon dioxide;

[0043] And the side wall of ...

Embodiment 3

[0048] see Figure 1-9 , on the basis of embodiment two, the present invention provides a kind of technical scheme:

[0049] A low-carbon emission steelmaking equipment for steelmaking, the surface of the lower treatment box 201 is fixedly connected with the upper treatment box 206 through the installation platform 204, and the lower treatment box 201 and the upper treatment box 206 are connected through communication The pipe 205 is hollowly connected, and a solenoid valve is installed inside the communication pipe 205, so that the lower processing box 201 and the upper processing box 206 can be connected or separated;

[0050] After the flue gas in the lower treatment box 201 is filtered through multiple cycles, it is discharged into the upper treatment box 206 through the communication pipe 205. At the same time, the surface of the upper treatment box 206 is equipped with a chemical spraying mechanism 4, and the chemical spraying mechanism 4 is installed on the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com