Patents

Literature

34results about How to "Realize energy-saving production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

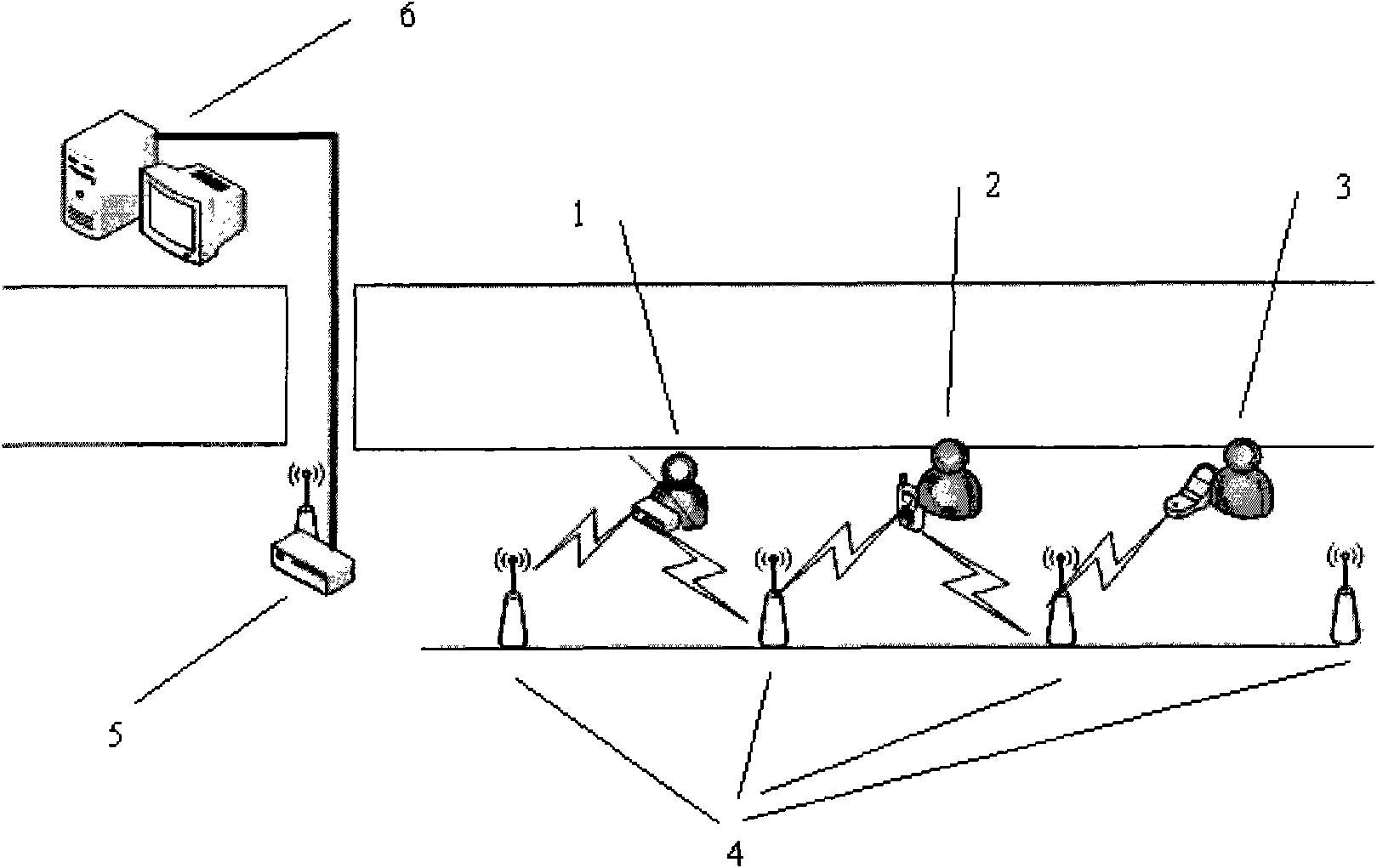

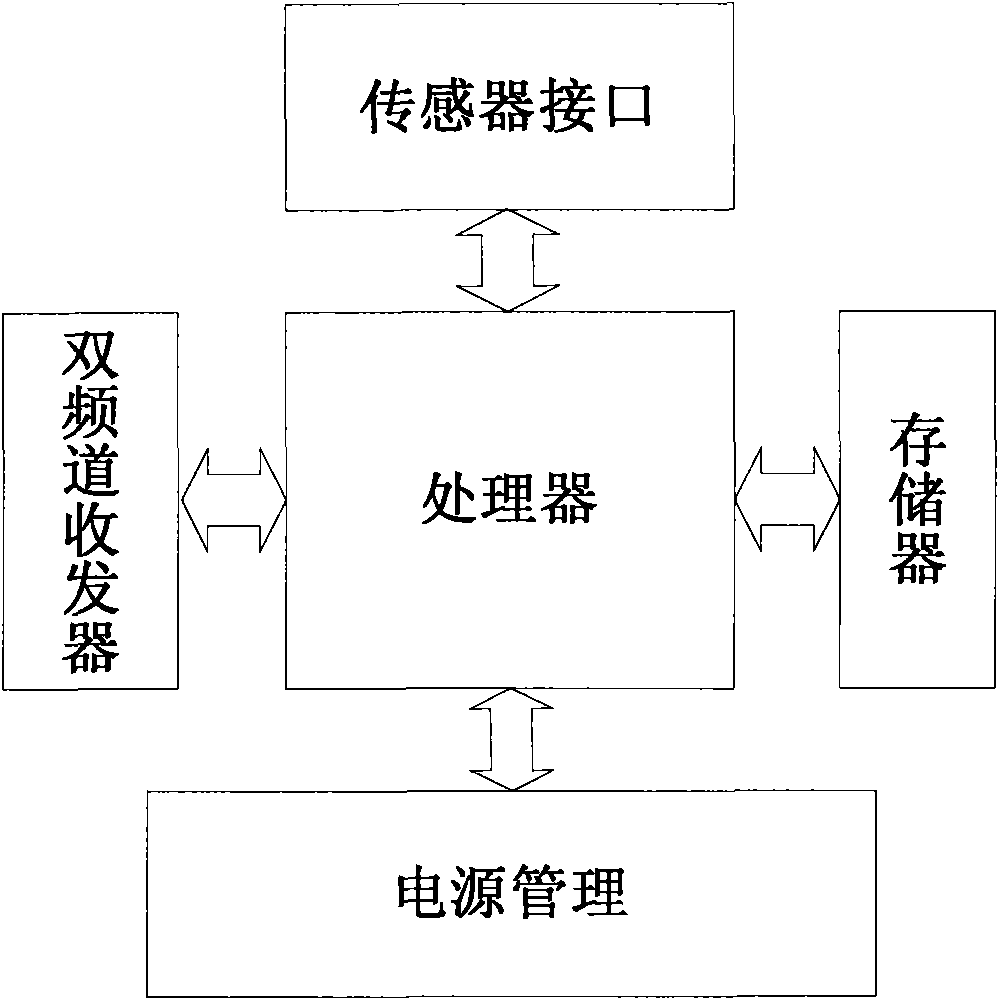

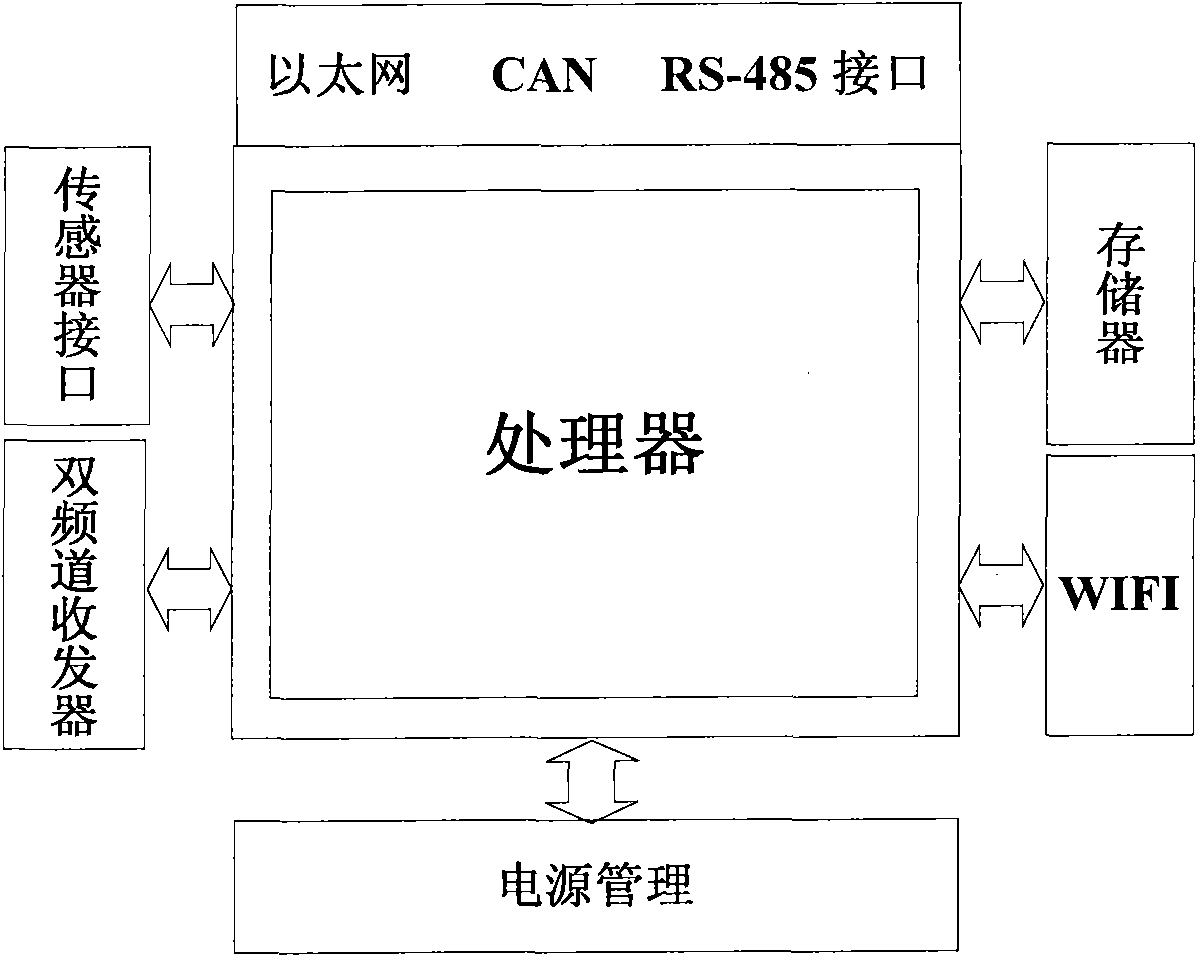

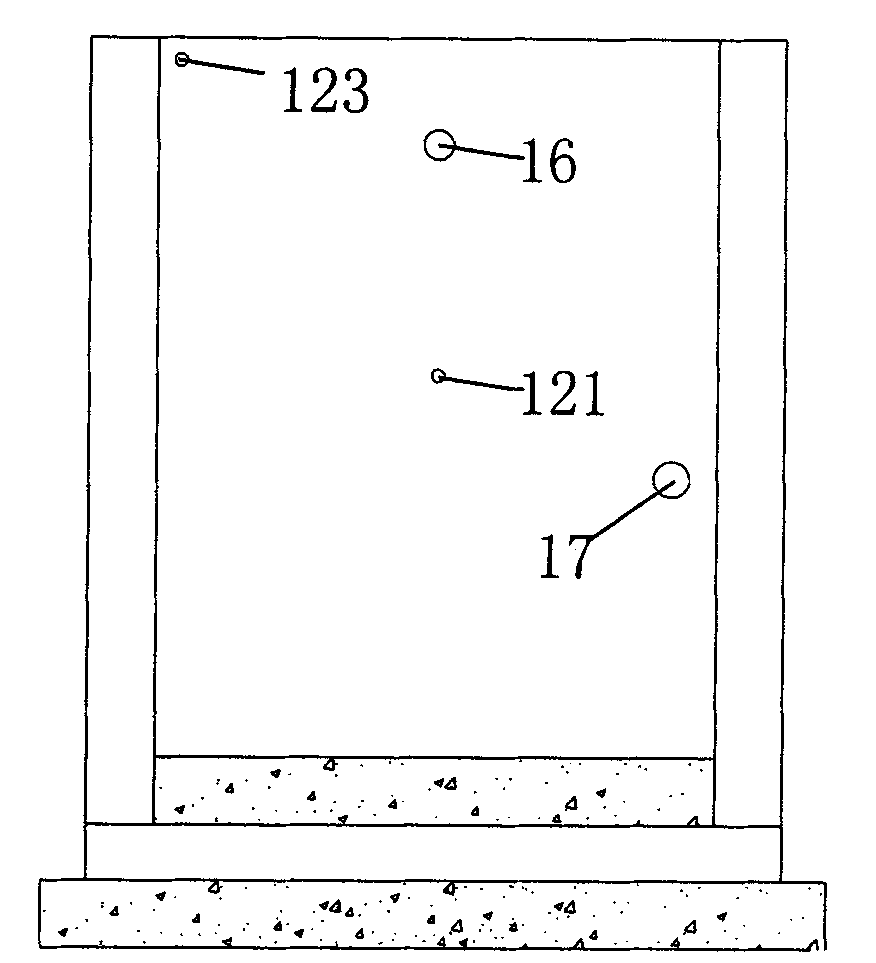

Underground positioning and safety monitoring system on basis of communication network

InactiveCN102083236AReal-time detectionFlow detectionEnergy efficient ICTMining devicesData centerVoice communication

The invention provides an underground positioning and safety monitoring system on the basis of a communication network, which comprises a ground control center, a plurality of personnel positioning terminals, a plurality of short message positioning terminals, a plurality of voice communication positioning terminals, a plurality of wireless positioning base stations and a base station gateway. The personnel positioning terminals carry out timing on broadcast signals by broadcast bands; the base station gateway or the wireless base stations receive the broadcast signals, acquire contents and the signal strengths of the broadcast signals, encapsulate information according to a protocol, transmit the information to the ground control center by the network for positioning processing, and acquire corresponding position information; meanwhile, a mobile node adopts a timing POLL mechanism to receive a downlink command of a data center so as to realize bidirectional data transmission, and a network base station controls illumination equipment to realize energy-saving production according to existence or non-existence of the mobile node in a current region. The underground positioning and safety monitoring system has the characteristics of high reliability, simplicity in construction and accuracy in position.

Owner:中滦科技股份有限公司

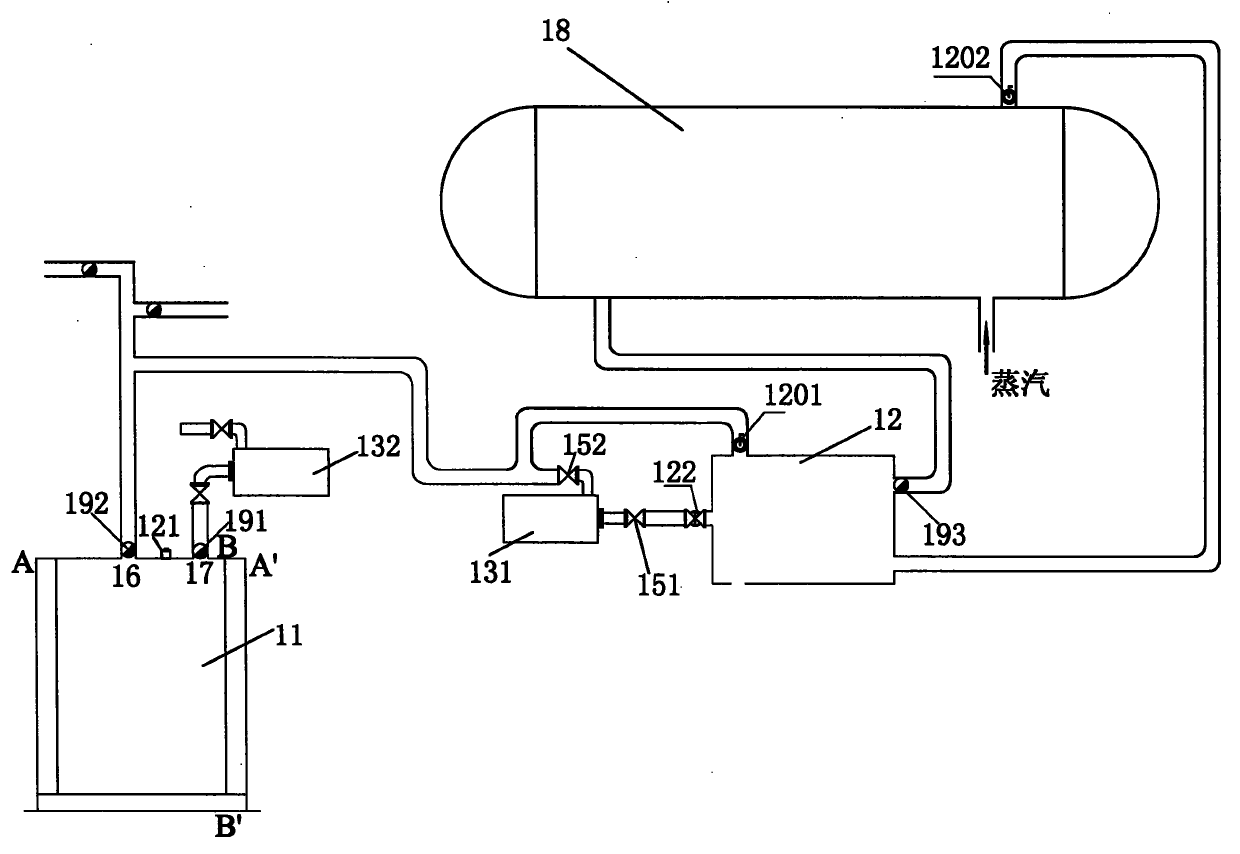

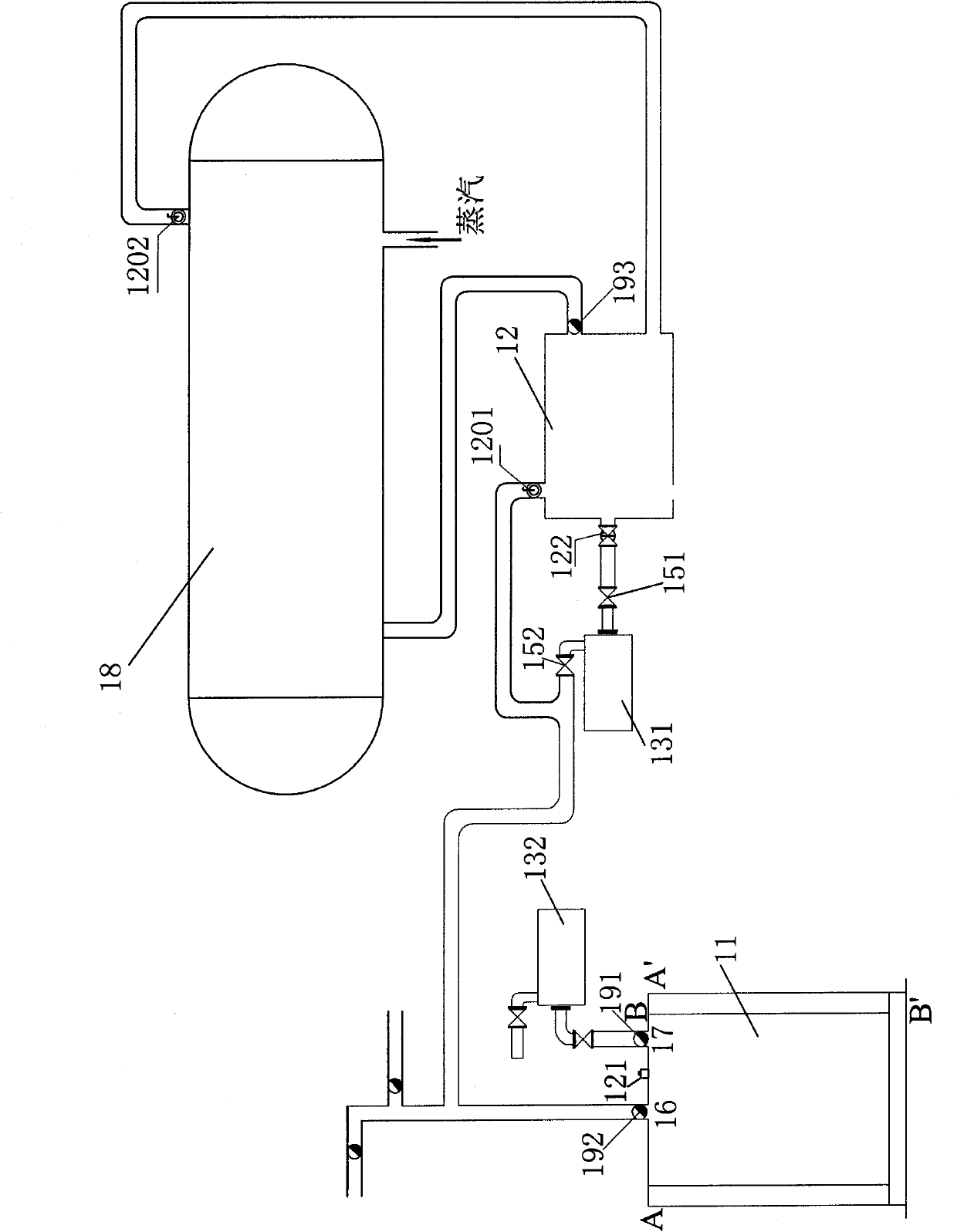

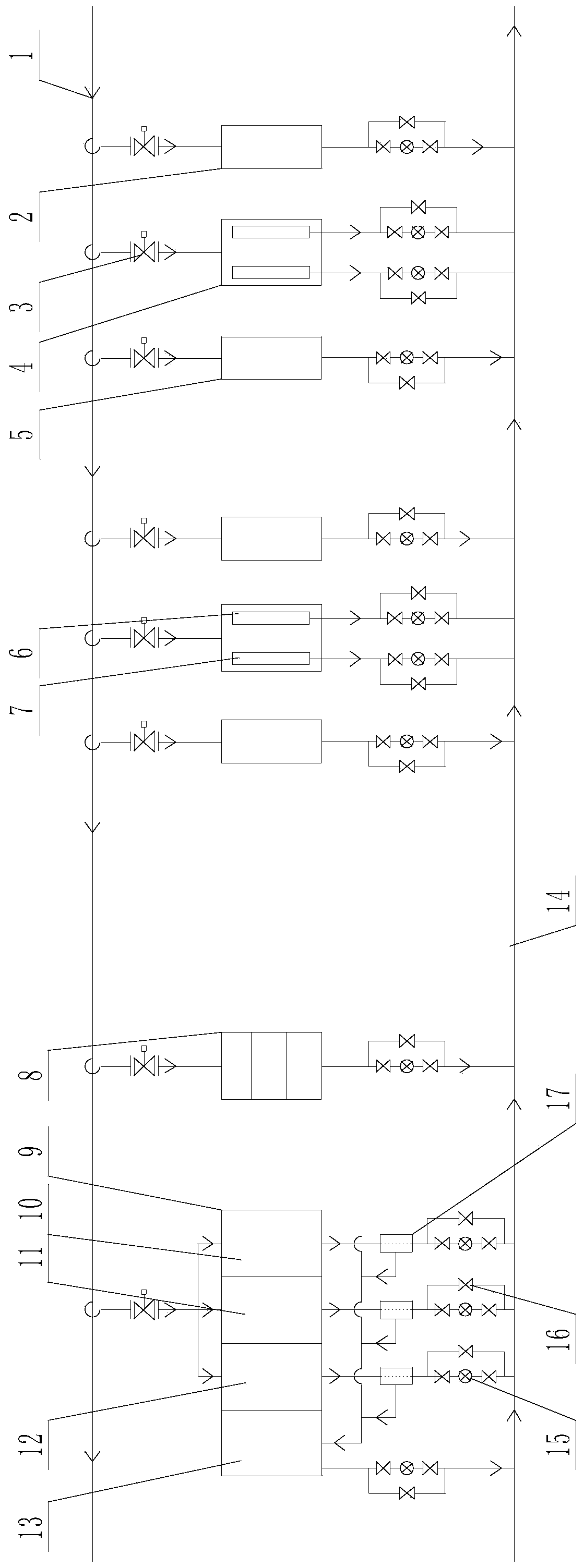

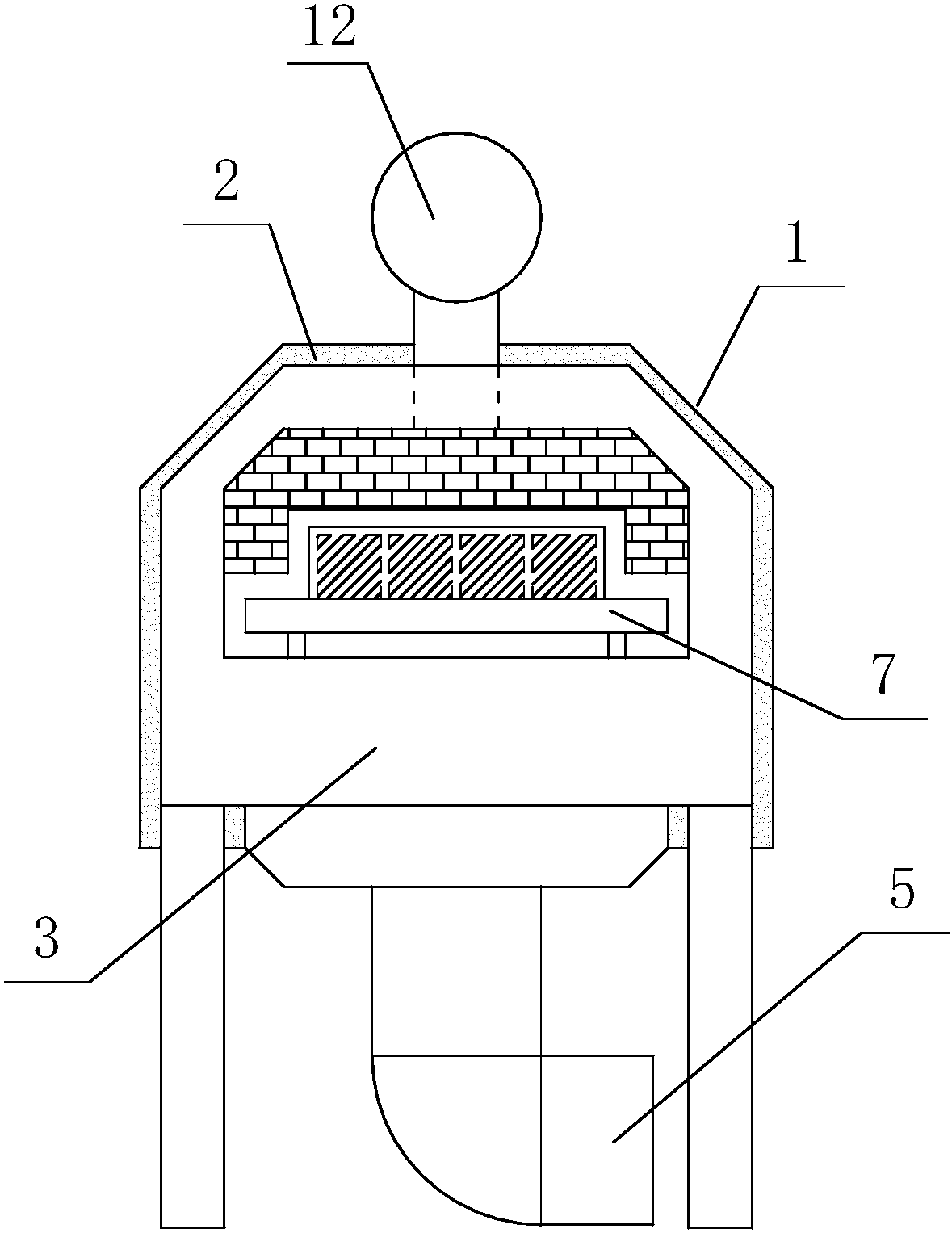

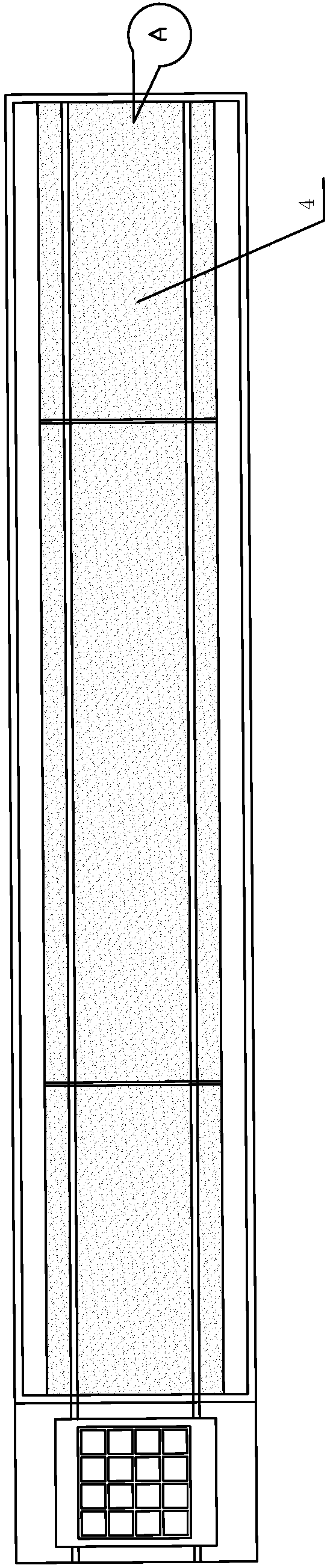

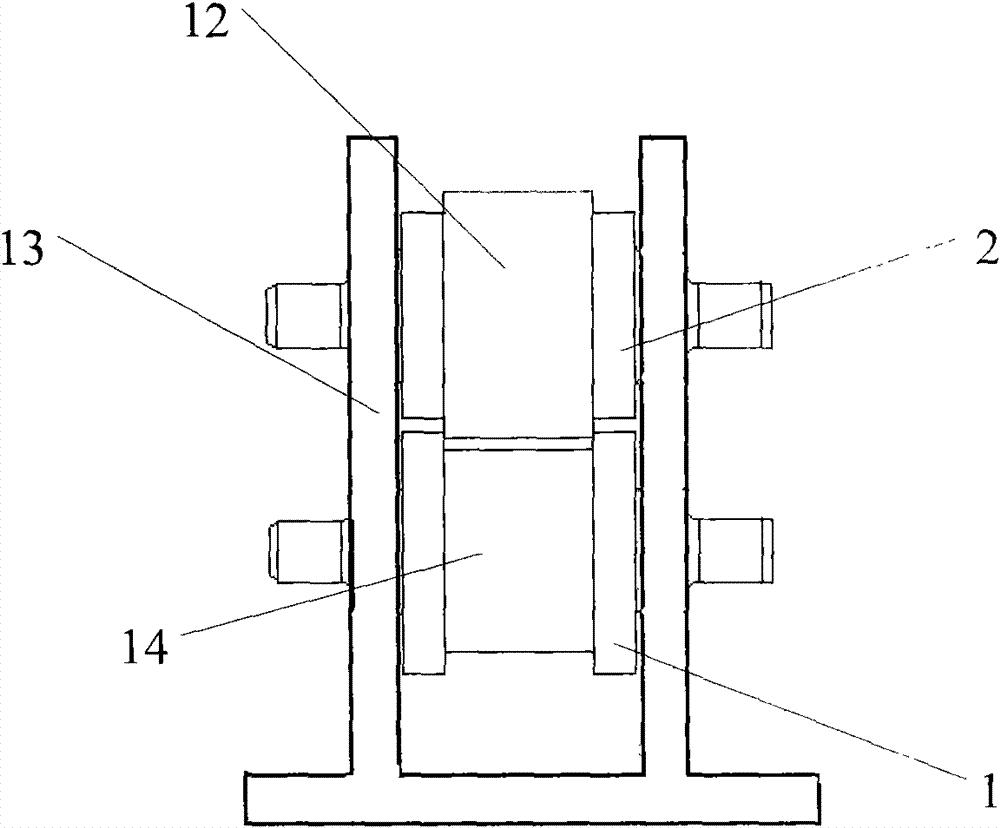

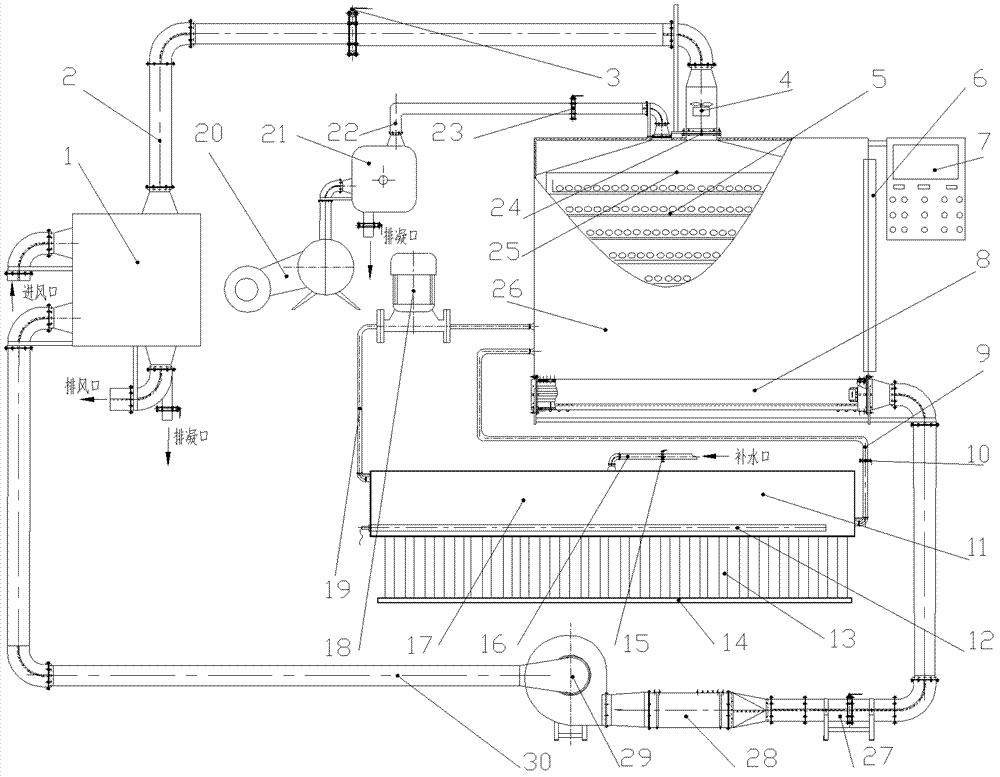

Water curing method and device for centrifuged pretensioned prestressed concrete pipe pile

ActiveCN101905486ATo overcome the lack of maintenance technologyRealize environmentally friendly productionCeramic shaping apparatusWater storage tankEngineering

The invention relates to a pipe pile water curing method. In the method, a water storage tank is arranged, and condensate water and residual steam in a still kettle are guided into the water storage tank; a pipe pile is placed in a steaming and curing pool, the condensate water in the water storage tank is guided into the steaming and curing pool, and the residual steam in water storage tank is guided into the steaming and curing pool; and steaming and curing the pipe pile in the steaming pool for 4-5 hours at 80-90 DEG C. The curing device comprises the steaming and curing pool, the water storage tank and the still kettle, wherein the steaming and curing pool is provided with a water-steam port; the water storage tank is provided with a residual steam outlet, a residual steam inlet, a condensate water outlet and a condensate water inlet; and the still kettle is provided with a steam inlet and a steam outlet. A condensate channel is arranged between the water-steam port of the steaming pool and the condensate water outlet of the water storage tank, and a steam channel is arranged between the water-steam port of the steaming pool and the residual steam outlet of the water storage tank. The condensate water inlet of the water storage tank is communicated with the condensate water outlet of the still kettle through a third electric control valve and a pipeline, and the steam inlet of the water storage tank is communicated with the steam outlet of the still kettle through a second steam valve and a pipeline.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

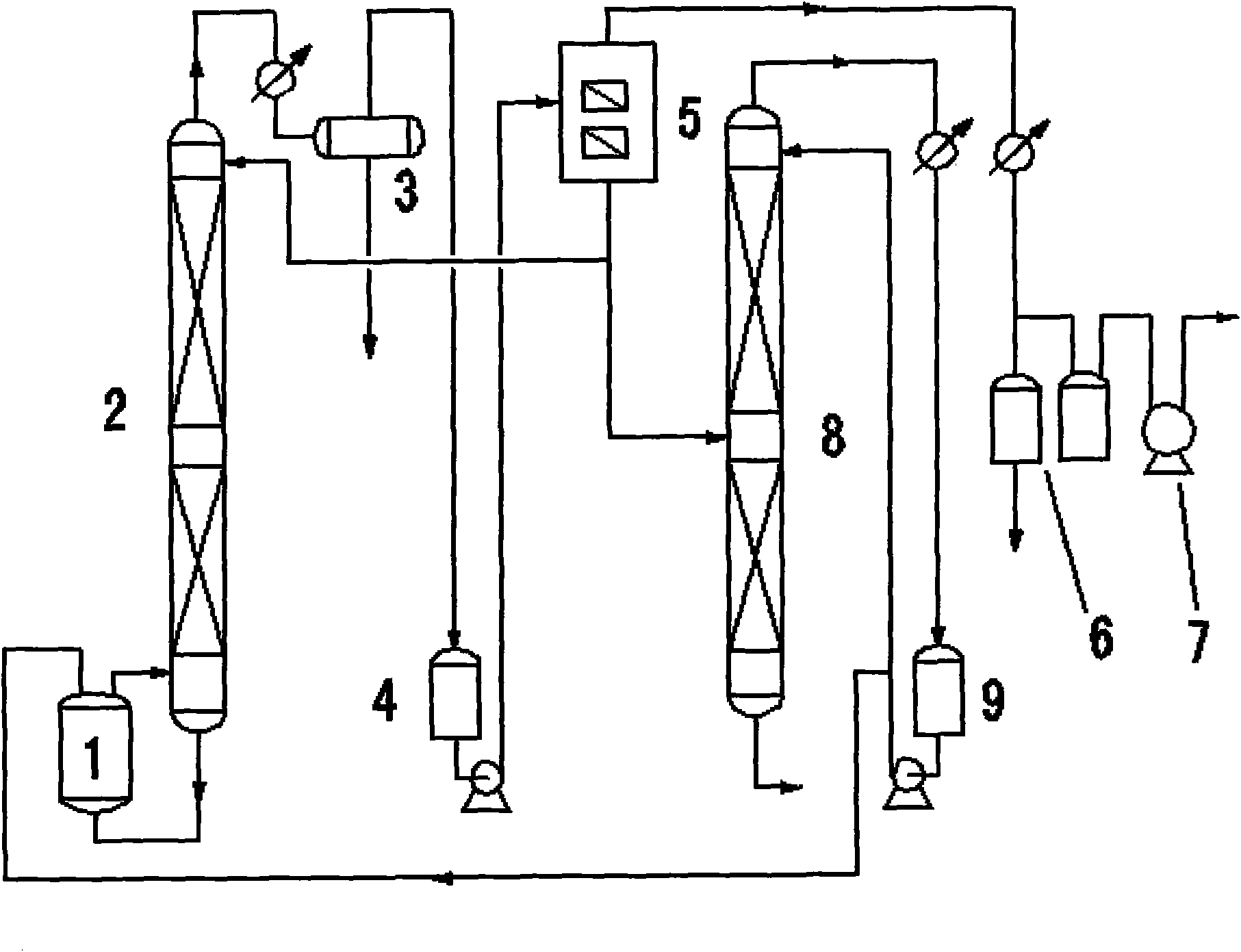

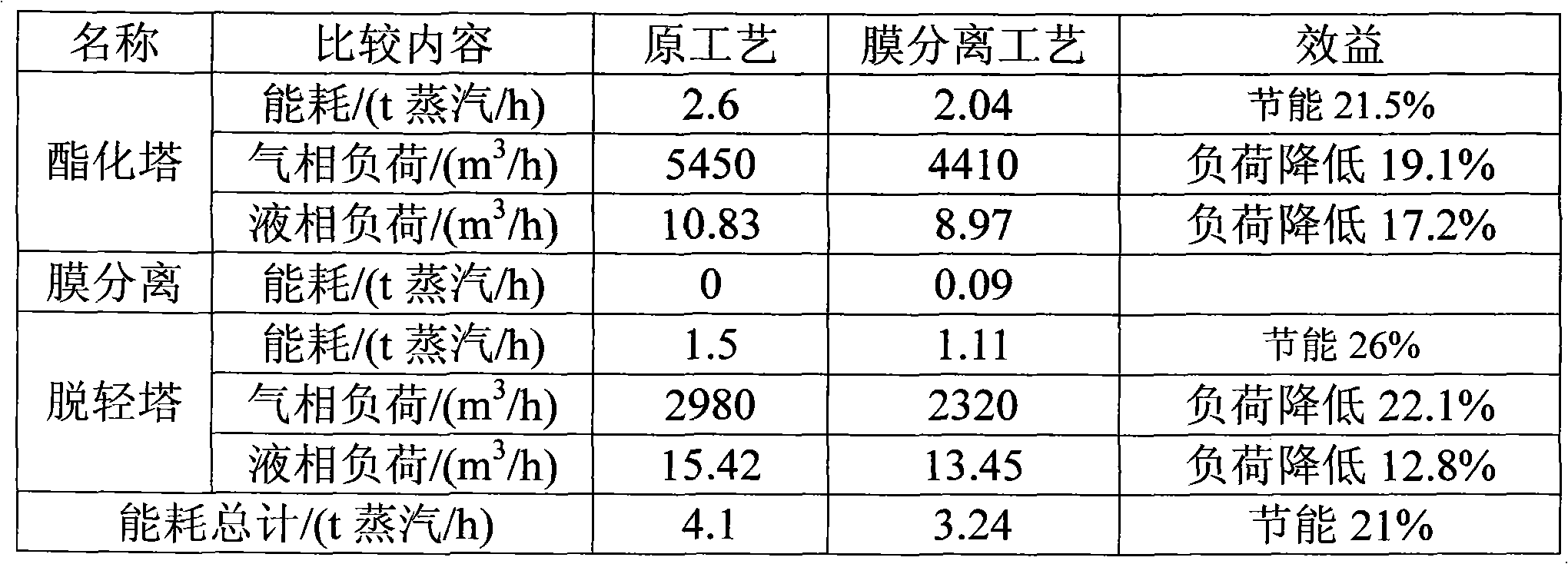

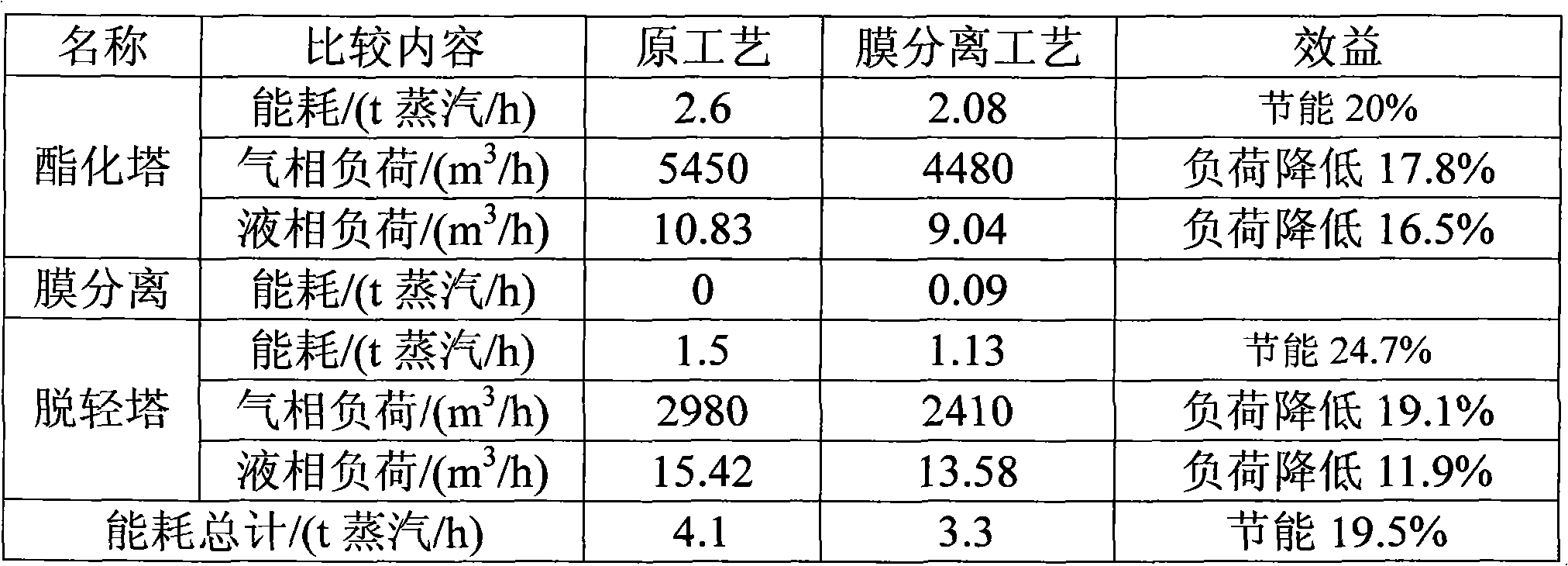

New energy-saving production process of ethyl acetate

InactiveCN102030639ARealize energy-saving productionReduce moisture contentOrganic compound preparationChemical industryAcetic acidNew energy

The invention relates to a new energy-saving production process of ethyl acetate. The process comprises the sections of esterification, light removal, refining and recovery, and the membrane separation section is added between the esterification section and the light removal section. The organic phase at the esterification tower top is subject to membrane separation to desorb most moisture, and one part of the treated organic phase returns to an esterification tower to reflow and the other part is sent to a light removal tower to be refined. The membrane separation section comprises a vacuum cover (with a membrane module inside), a condenser, a penetrating fluid tank, a buffer tank and a vacuum pump. The method provided by the invention can greatly reduce water circulating in the esterification and light removal sections, save the heating steam in the esterification tower and the light removal tower, reduce the loads of the esterification tower and the light removal tower and further improve the production capability of the esterification tower and the light removal tower.

Owner:江门天诚溶剂制品有限公司

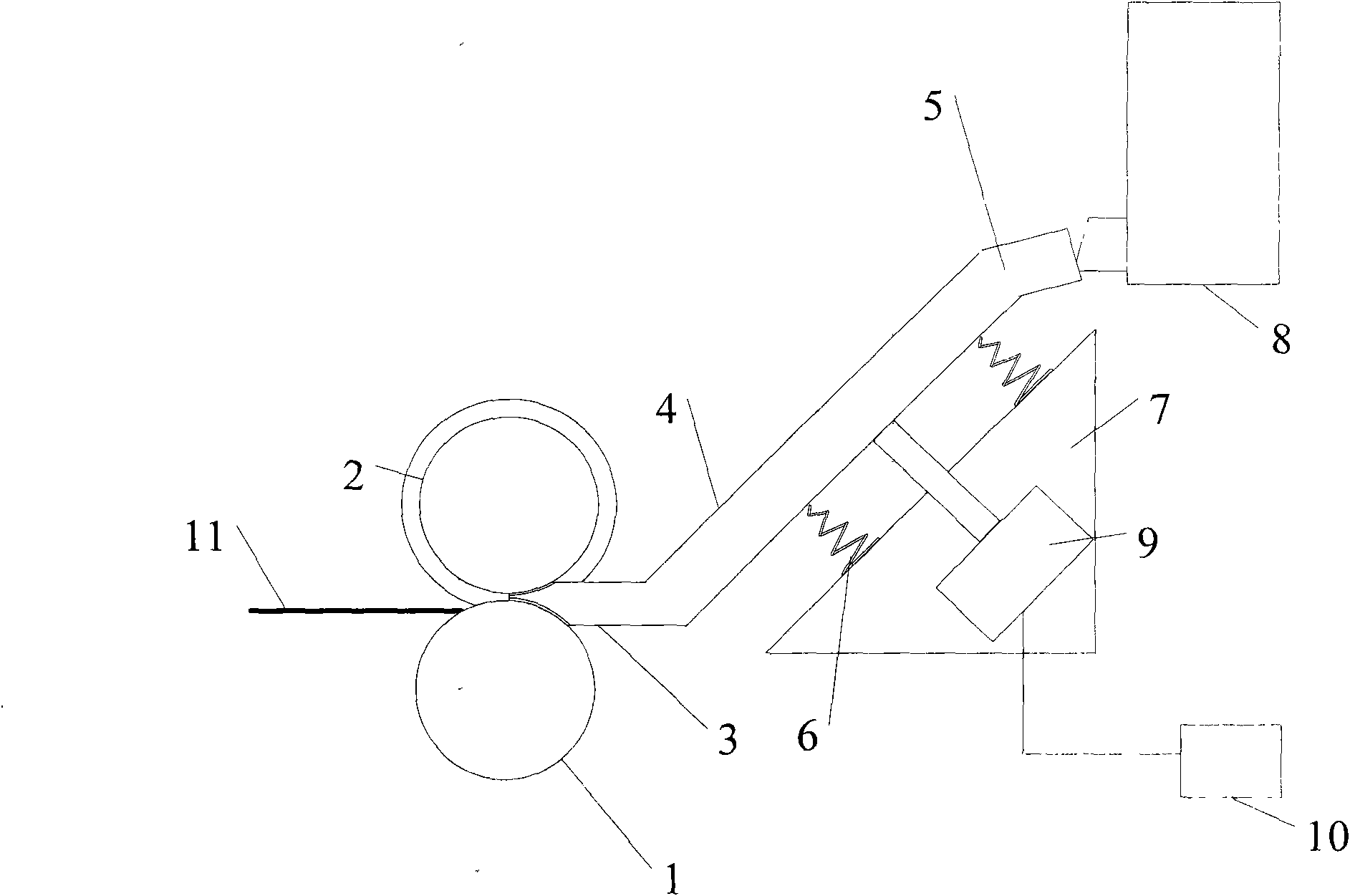

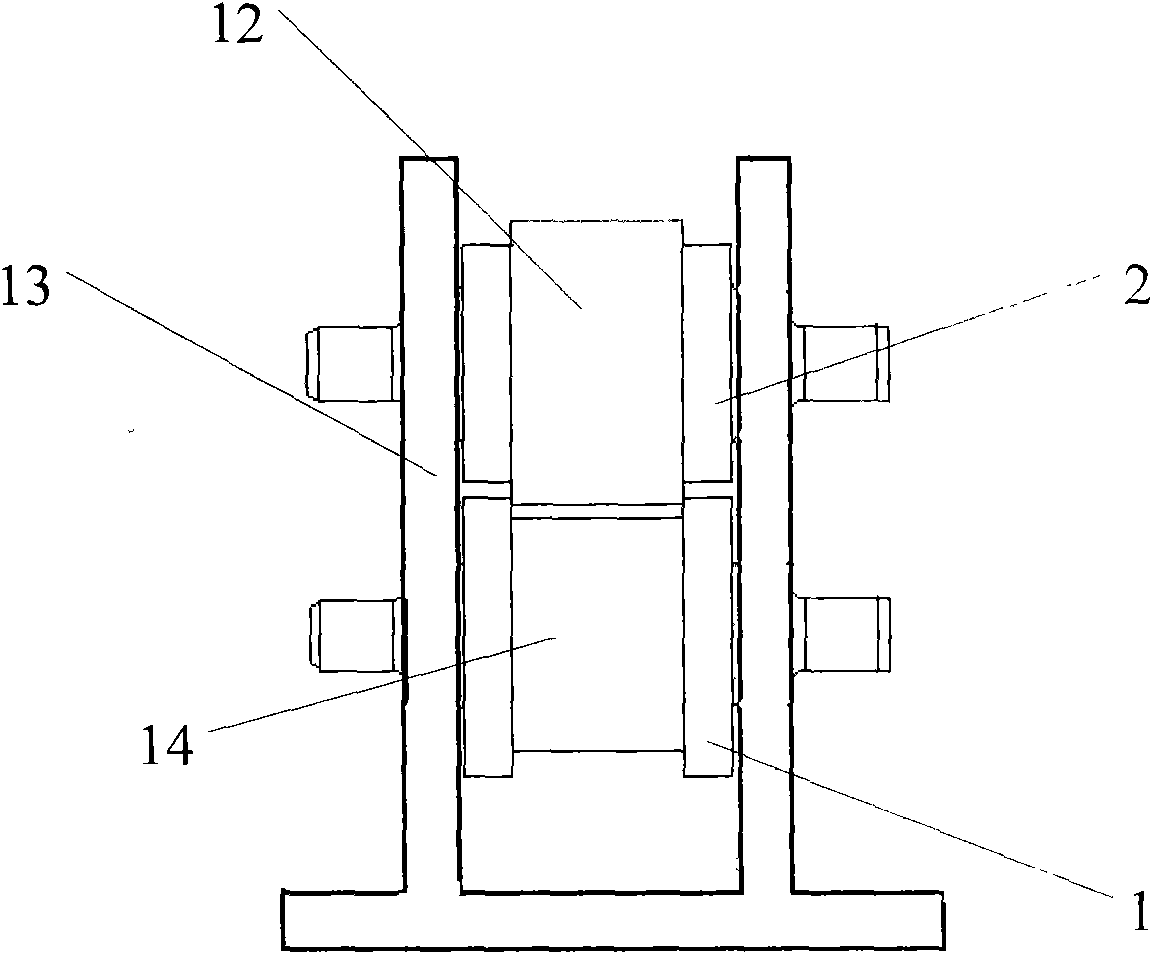

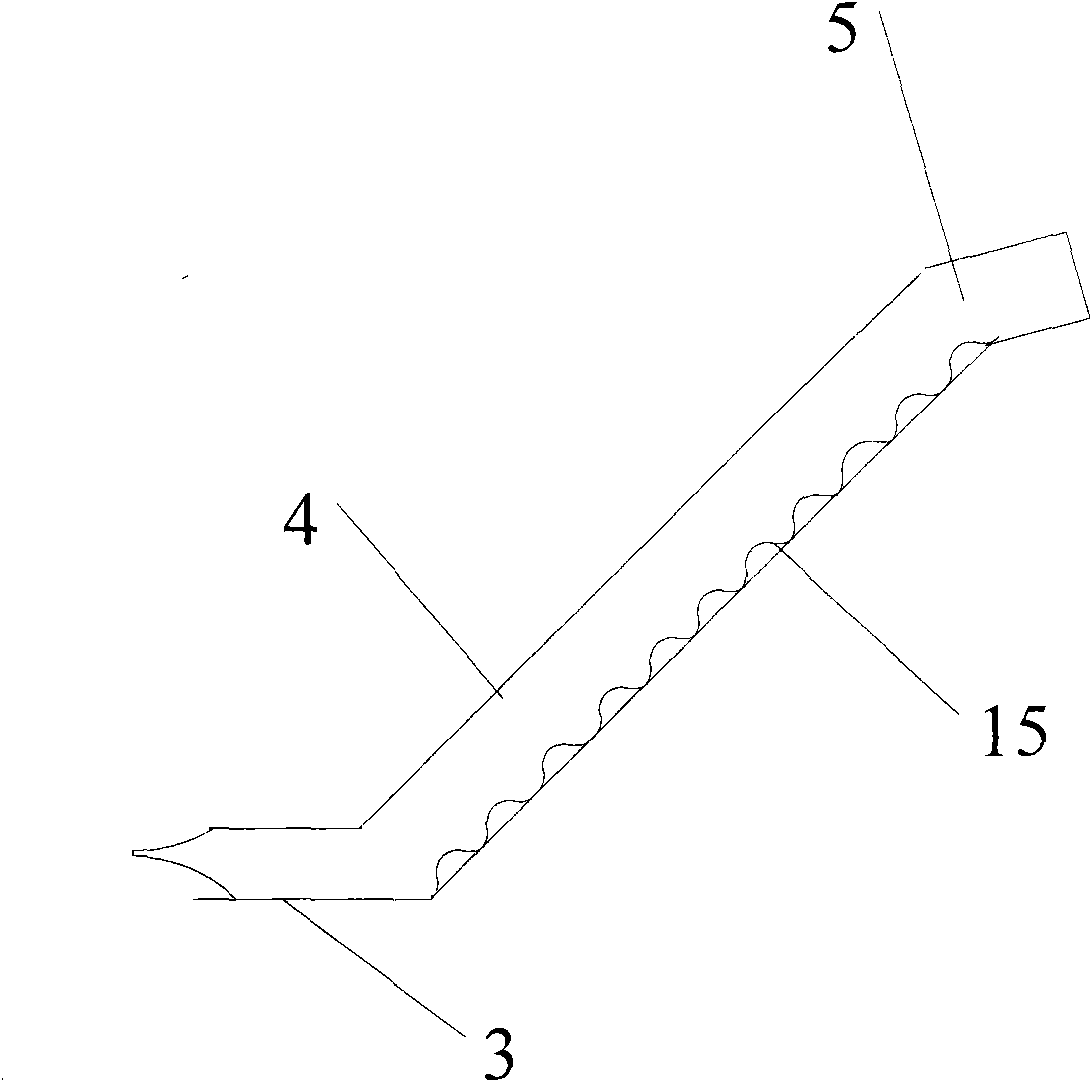

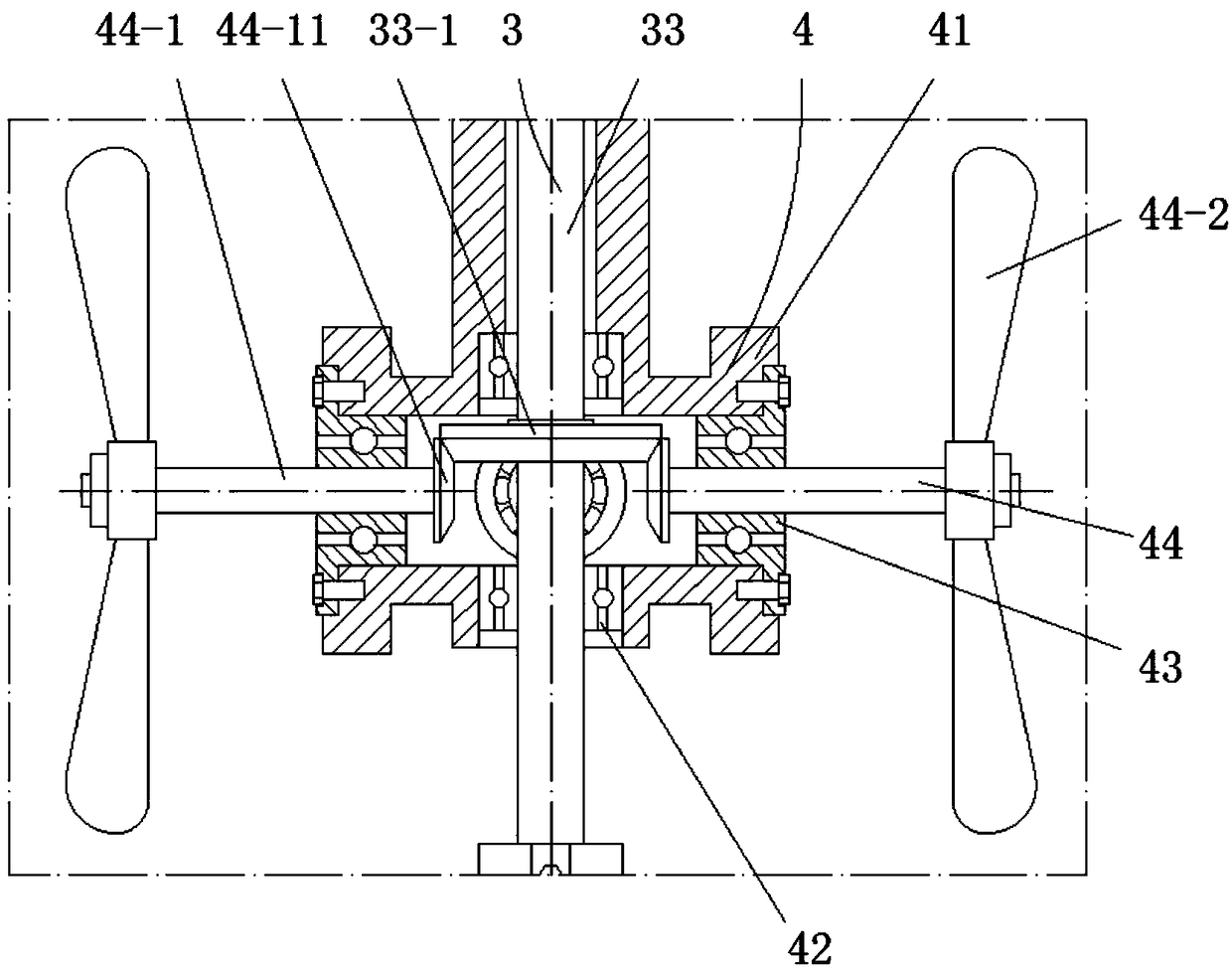

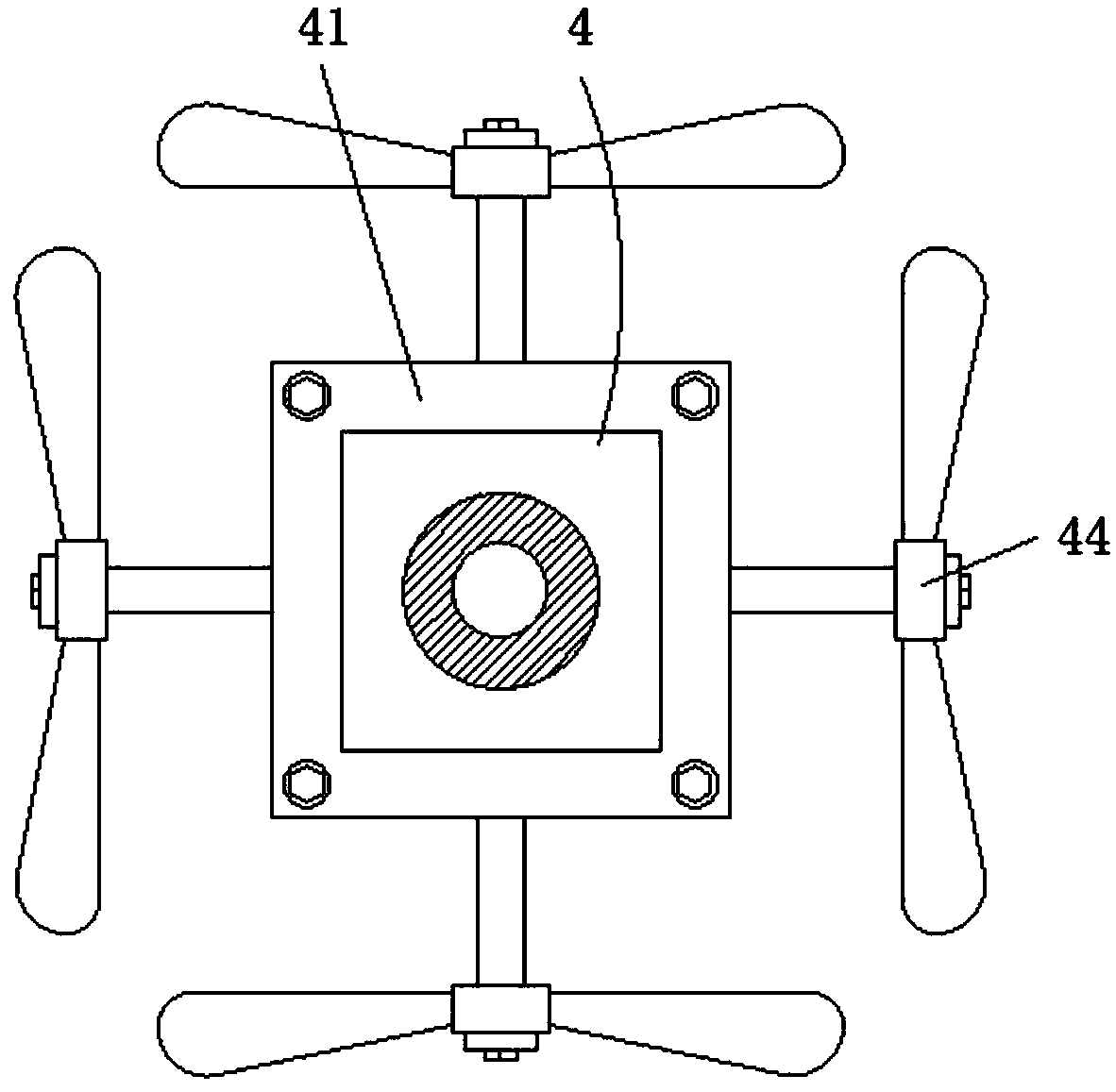

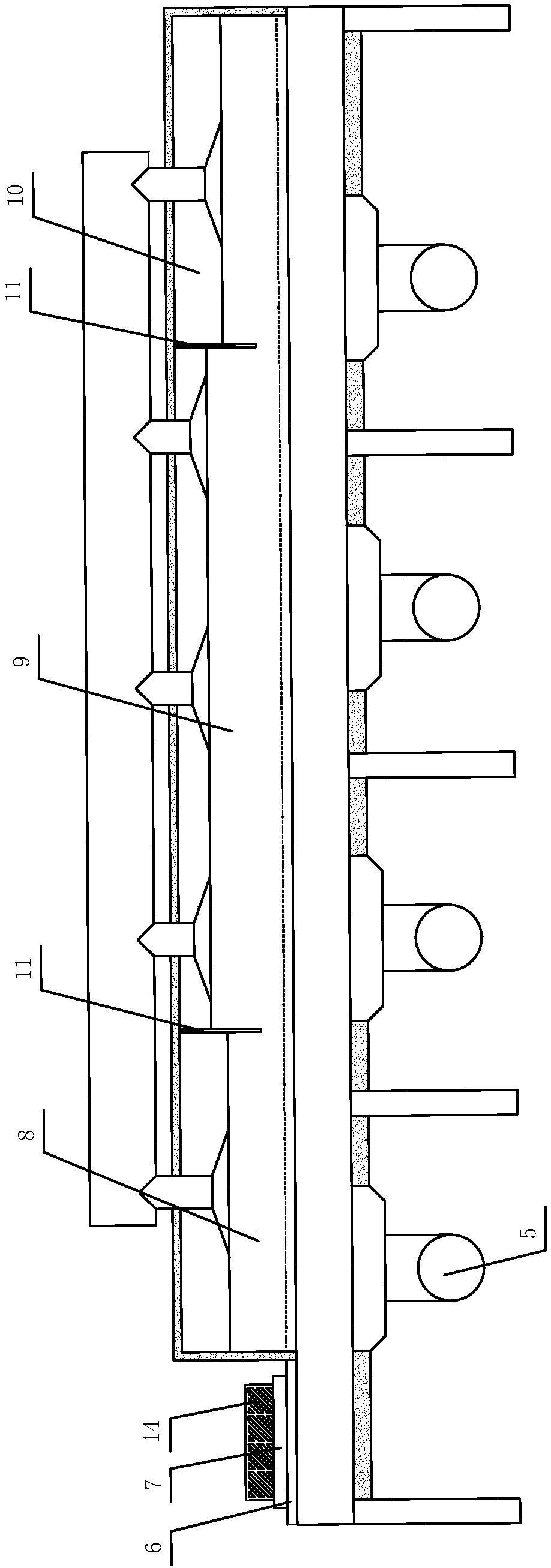

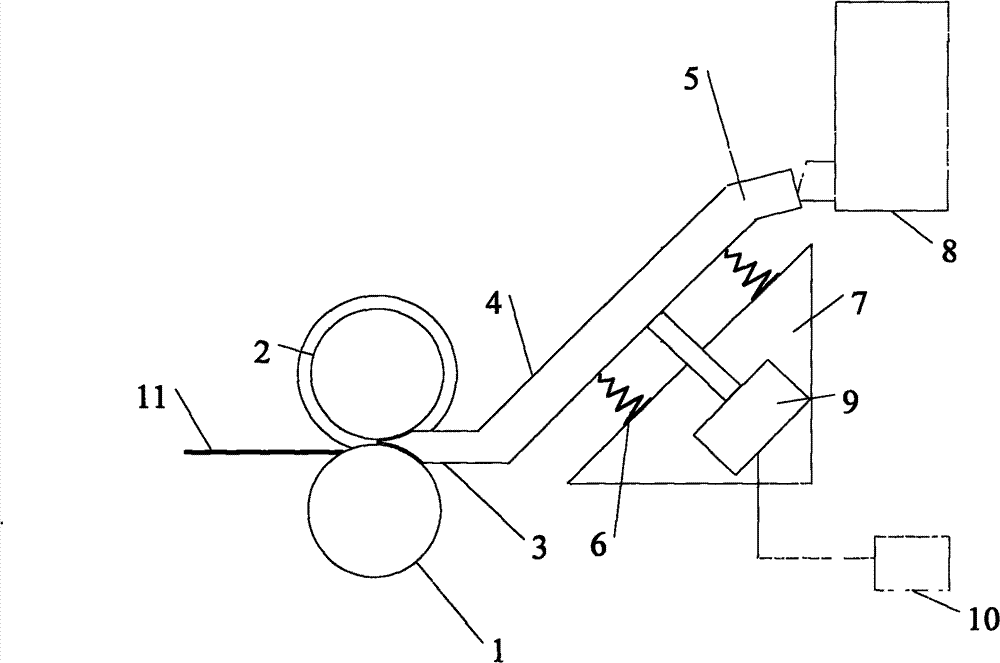

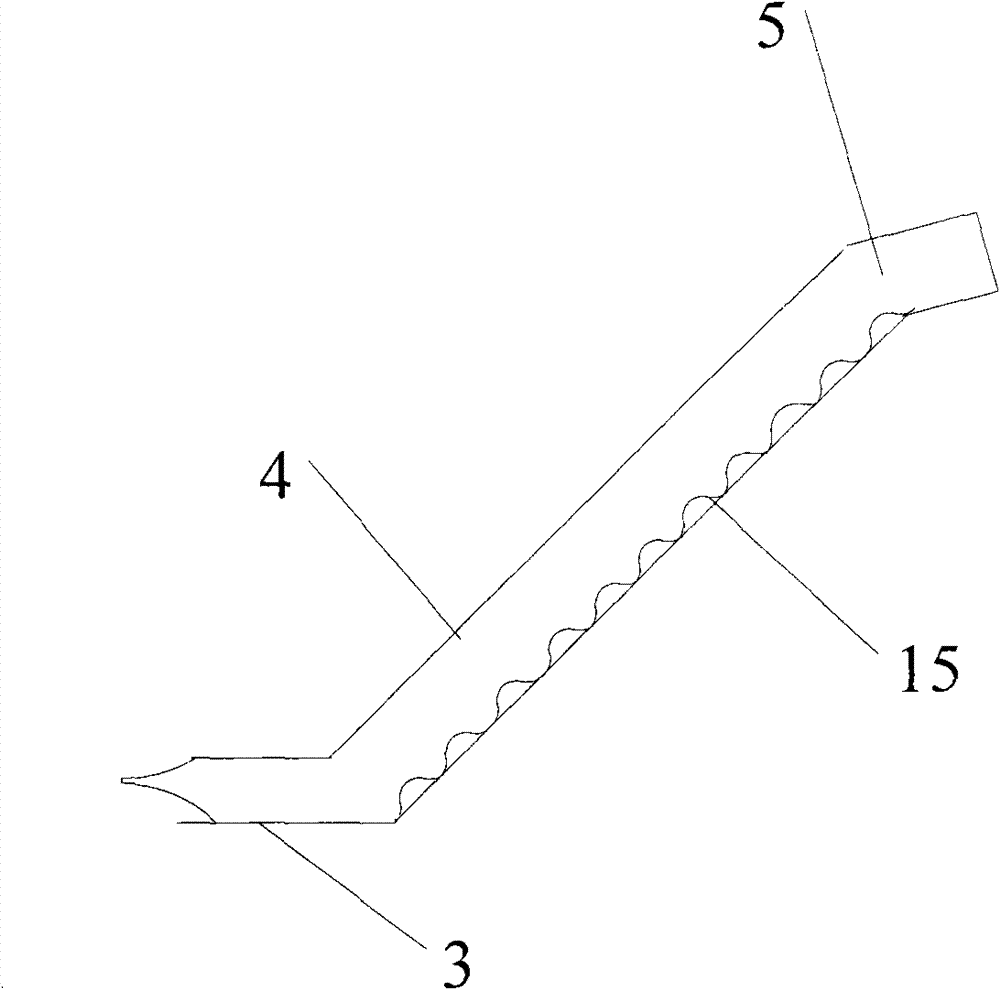

Continuous rheomolding device for manufacturing metal plate strips

InactiveCN101890431AIncreased speed of continuous rheological formingGood formabilityMetal rolling arrangementsEngineeringAlloy

The invention provides a continuous rheomolding device for manufacturing metal plate strips. The device comprises an inclined plate, a base, an electromagnetic vibration exciter and a double-roller rolling mill and is characterized by also comprising the double-roller rolling mill, wherein the inclined plate is formed by connecting a feeding section, a pulping section and a discharging section in turn; the lower side of a bottom plate of the pulping section is connected with the upper end of a spring; the lower end of the spring is fixed on the base; one end of the electromagnetic vibration exciter is fixed on the base, and the other end of the electromagnetic vibration exciter is connected with the lower side of the bottom plate of the pulping section; and gaps are formed between the bottom plate and two side plates of the discharging section and the roll surfaces of upper and lower rollers of the double-roller rolling mill. The range of vibration frequency which can be provided by the electromagnetic vibration exciter adopted by the device is expanded greatly and the vibration frequency is adjusted so that an alloy structure can be improved more effectively and molten metal is prevented from crusting on the surface of the inclined plate.

Owner:NORTHEASTERN UNIV

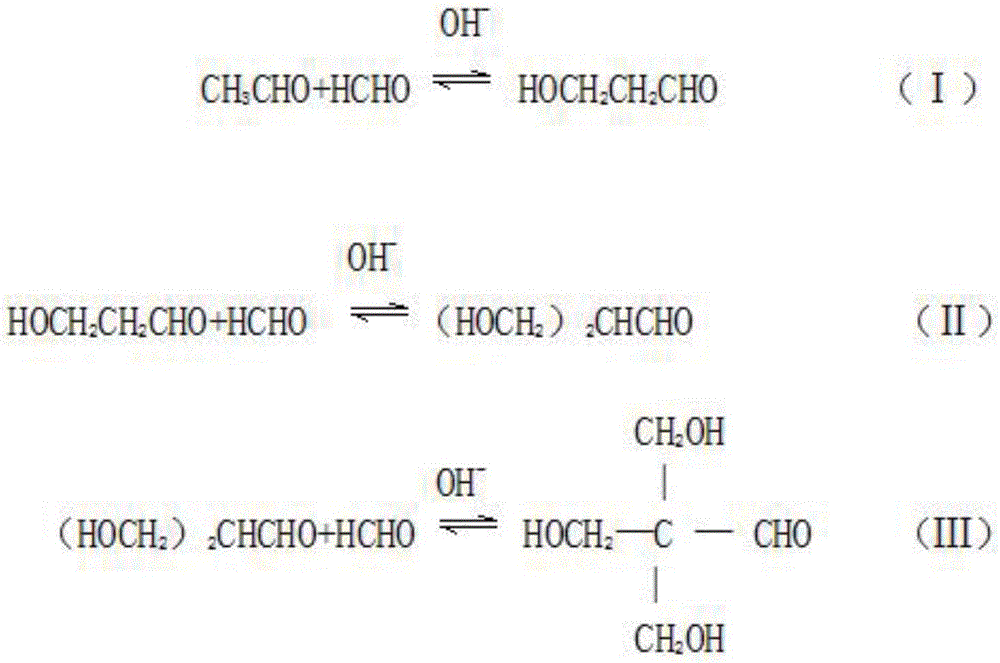

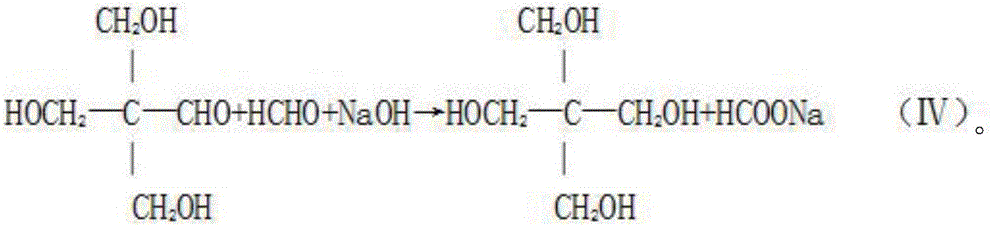

Energy-saving production method of pentaerythritol

ActiveCN105693467ASimple production processRealize energy-saving productionOrganic compound preparationChemical industryEnergy gradientPentaerythritol

The invention belongs to the technical field of production of pentaerythritol, and in particular discloses an energy-saving production method of pentaerythritol. The energy-saving production method of pentaerythritol comprises the following steps: obtaining secondary steam containing alcohol aldehyde and heat at tower top of a dealdehyding tower by using an energy gradient utilization concept, and carrying out gradient utilization of the secondary steam to a dealcoholization tower, an evaporator and a concentrated solution pre-dealdehyding tower to realize the aim of heating the dealcoholization tower, the evaporator, and the concentrated solution pre-dealdehyding tower by using the secondary steam at the tower roof of the dealdehyding tower, so that the energy source is comprehensively utilized; and recycling waste heat so as to heat the to-be-heated material, adding a dealcoholization tower gas phase heat exchanger, a dilute formaldehyde heat exchanger and an alcohol-containing dilute formaldehyde heat exchanger before entering the concentrated solution pre-dealdehyding tower, and increasing the feeding temperature of the concentrated solution pre-dealdehyding tower to 90 DEG C from 60 DEG C through the improvement. The energy-saving production method of pentaerythritol, provided by the invention, realizes one energy source with multiple purposes through series utilization according to the energy grade, the energy source is comprehensively utilized, and thus the energy-saving production of pentaerythritol is finally realized.

Owner:INNER MONGOLIA YIHUA CHEMICAL CO LTD

Method for producing sodium silicate by utilizing sodium sulfate

ActiveCN105460941AHigh purityShort processSulfur compoundsAlkali metal silicatesSodium silicateCarbon black

The invention belongs to the technical field of chemical production, and relates to a method for producing sodium silicate by utilizing sodium sulfate. The method can also be used for producing the sodium silicate or white carbon black. The method comprises the following steps of (1) raw material preparation: putting sodium sulfate, quartz sand and a reducing agent into a smelting reduction furnace according to a certain mass ratio; (2) reduction reaction: carrying out a heating reaction on the raw materials in the smelting reduction furnace and simultaneously stirring the raw materials; (3) product obtaining: carrying out water quenching on a sodium silicate melt body, which is generated after the reaction is completed, to make the sodium silicate melt body into a sodium silicate product, and collecting SO2 gas generated in the reaction to prepare concentrated sulfuric acid. The method disclosed by the invention is simple in technological process and low in energy consumption, the purity of the generated sodium silicate product is high, SO2 can be totally recycled, and the method has the characteristics of energy conservation, environment protection and the like.

Owner:钢研晟华科技股份有限公司

Steam-curing free coal ash brick and making method thereof

InactiveCN108059431AEfficient use ofRealize energy-saving productionSolid waste managementSocial benefitsPolymer science

The invention relates to a steam-curing free coal ash brick and a making method thereof. According to the steam-curing free coal ash brick and the making method thereof, coal ash, cement, gypsum, aggregate, an alkali mixing material, an excitant, a water retaining agent, a fiber and water are adopted as raw materials, and a coal ash brick which meets strength standard requirements is made throughpremixing, aging, cloth pressing and steam-curing free normal-temperature maintenance. By adopting the steam-curing free coal ash brick and the making method thereof, efficient utilization of coal ashis achieved, the mixing utilization rate is greater than 70%, reactions can be implemented at a normal temperature, steam-curing is avoided in a maintenance mode, energy-saving production is achieved, coal ash bricks which meet strength standard requirements can be made, and remarkable environment benefits, economic benefits and social benefits can be made.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

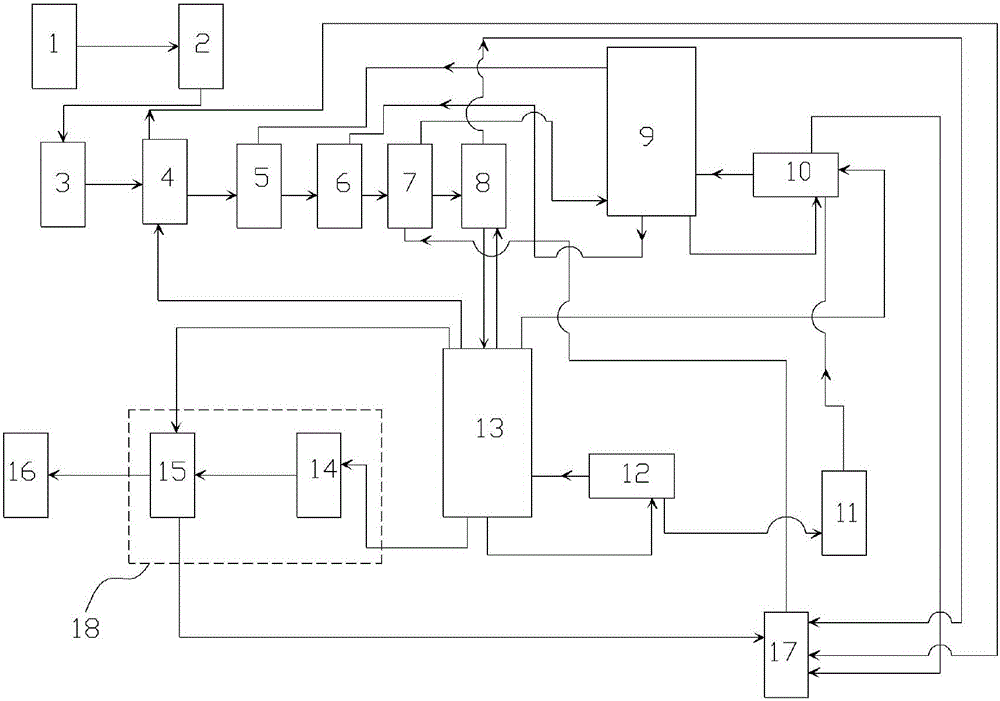

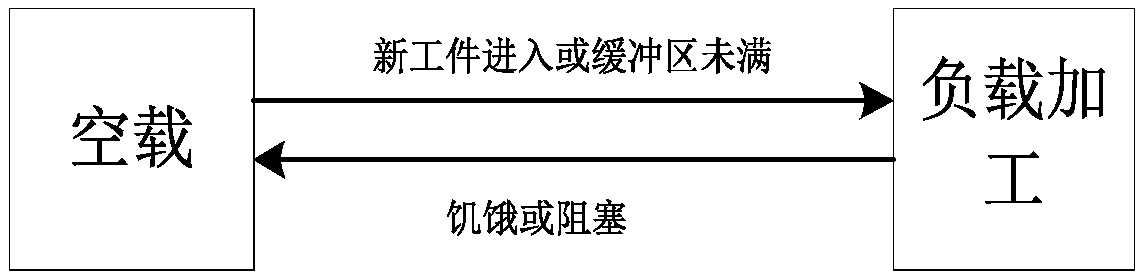

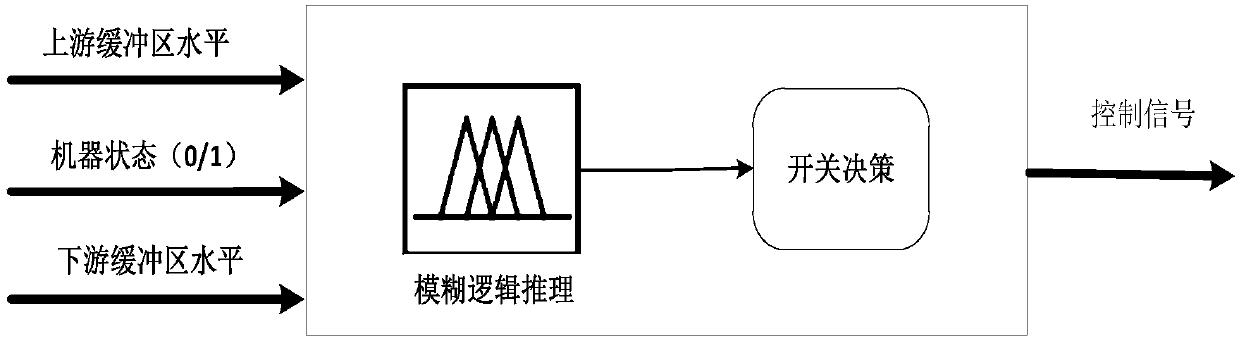

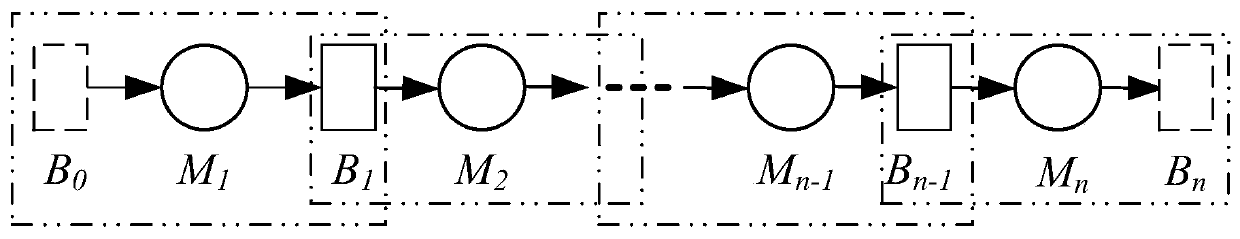

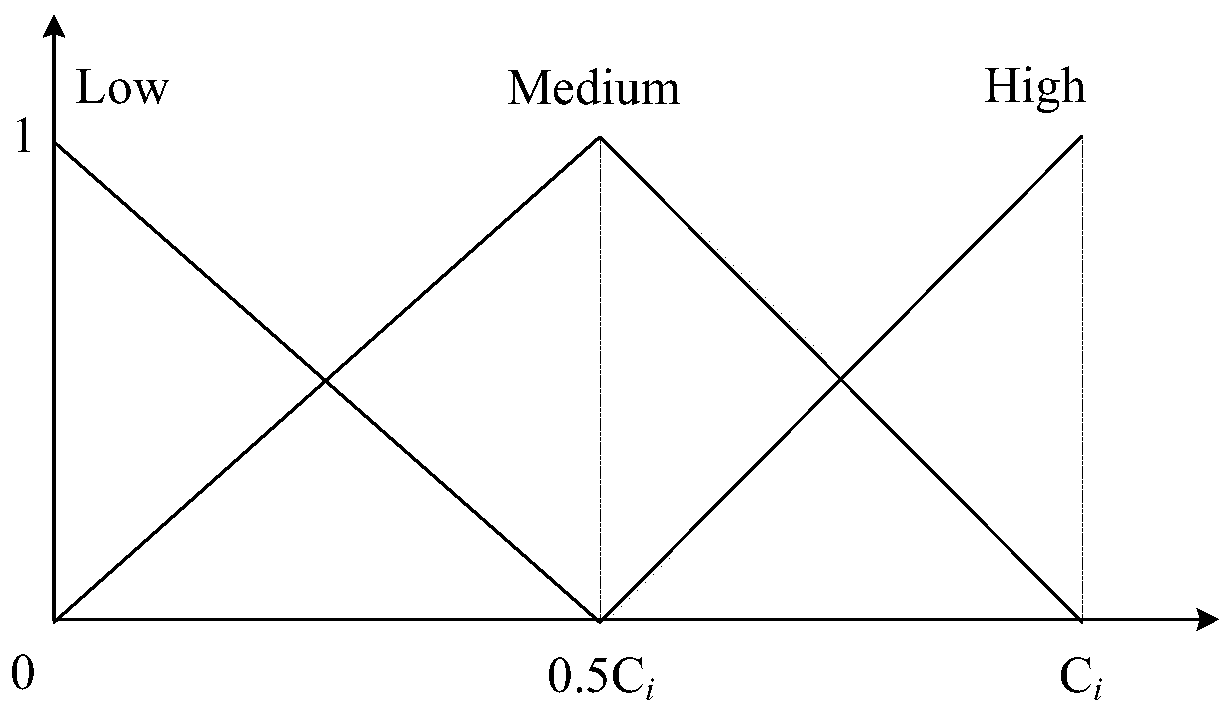

Manufacture system fuzzy control energy saving method based on real-time production data

InactiveCN107688294ARealize energy-saving productionEasy to controlDigital data processing detailsAdaptive controlFuzzy control systemEnergy consumption

The invention belongs to the field of production and manufacture system energy saving control, and specifically discloses a manufacture system fuzzy control energy saving method based on real-time production data. The manufacture system fuzzy control energy saving method comprises the following steps: (1) obtaining the amount of products in process in the upstream relief area and the amount of products in a downstream relief area in real time to serve as two input variables for fuzzy judgment; (2) on the basis of the amount of products in process in the upstream relief area and the amount of products in the downstream relief area, adopting a fuzzy judgment rule to carry out fuzzy judgment to obtain a fuzzy control output value; (3) comparing the fuzzy control output value with a preset threshold value, judging whether the fuzzy control output value is smaller than the preset threshold value or not, if the fuzzy control output value is smaller than the preset threshold value, halting amachine which runs at present, and otherwise, keeping the current state. By use of the manufacture system fuzzy control energy saving method based on the real-time production data, the effective control of the energy consumption of the production system can be realized, and the manufacture system fuzzy control energy saving method has the advantages of convenience in operation, high applicabilityand the like.

Owner:HUAZHONG UNIV OF SCI & TECH

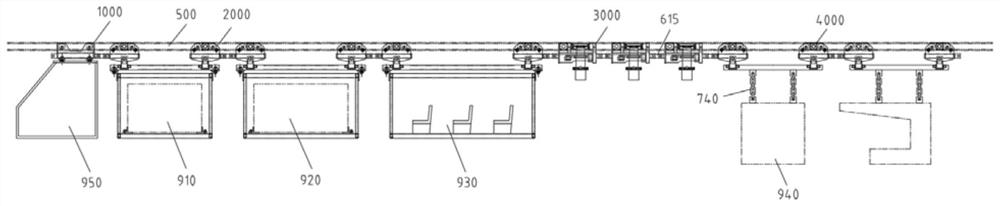

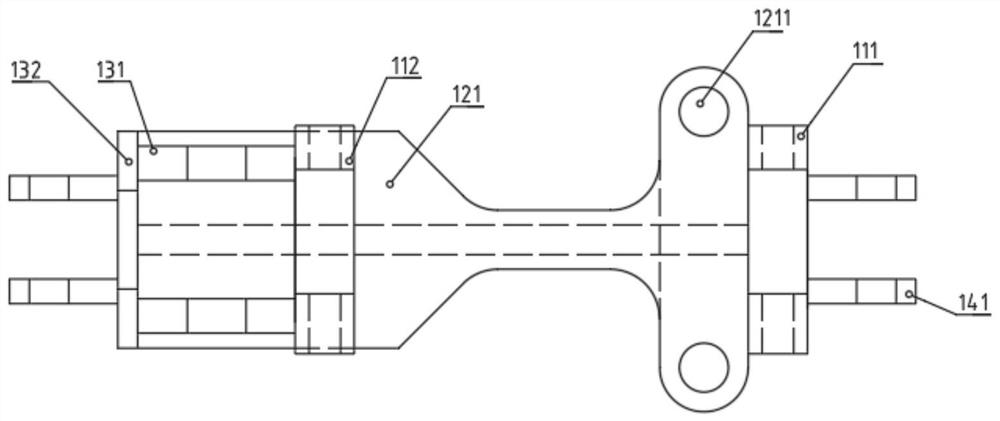

Electric monorail crane locomotive

PendingCN112208555ANo pollution in the processNo noiseRope railwaysTrack-braking member co-operationLow noiseElectrical battery

The invention discloses an electric monorail crane locomotive which comprises a battery cabinet used for installing a storage battery pack, a frequency conversion cabinet used for installing a motor frequency conversion control device, two cabinet body hanging devices hinged to each other and a plurality of driving devices hinged in sequence. Each cabinet body hanging device comprises a cabinet body hanging support used for hanging a cabinet body and a plurality of hanging mechanisms which are hung on an I-shaped rail of the monorail crane and can walk on the I-shaped rail, and the hanging mechanisms are connected to the cabinet body hanging support in a horizontal rotating mode. The battery cabinet and the frequency conversion cabinet are detachably hung on cabinet body hanging supports of the two cabinet body hanging devices respectively, the driving device is driven by a motor, and one hanging mechanism is hinged to the driving device adjacent to the hanging mechanism. The electricmonorail crane locomotive provided by the invention is powered by the storage battery to realize electric driving, the green operation of zero emission, no pollution, low noise and the like of the monorail crane locomotive are realized, and the underground working environment of a coal mine is improved.

Owner:SHANDONG ENERGY HEAVY EQUIP MFG GRP TAIZHUANG ENG EQUIP MFG CO LTD

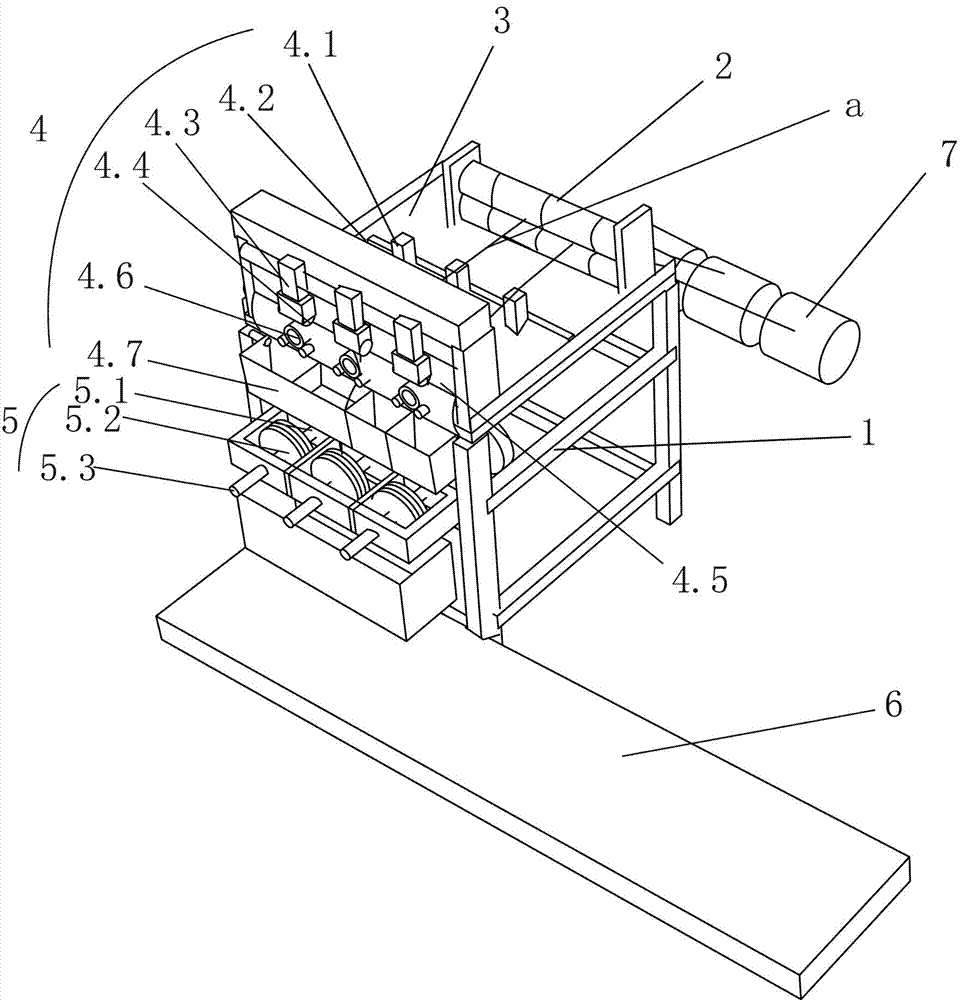

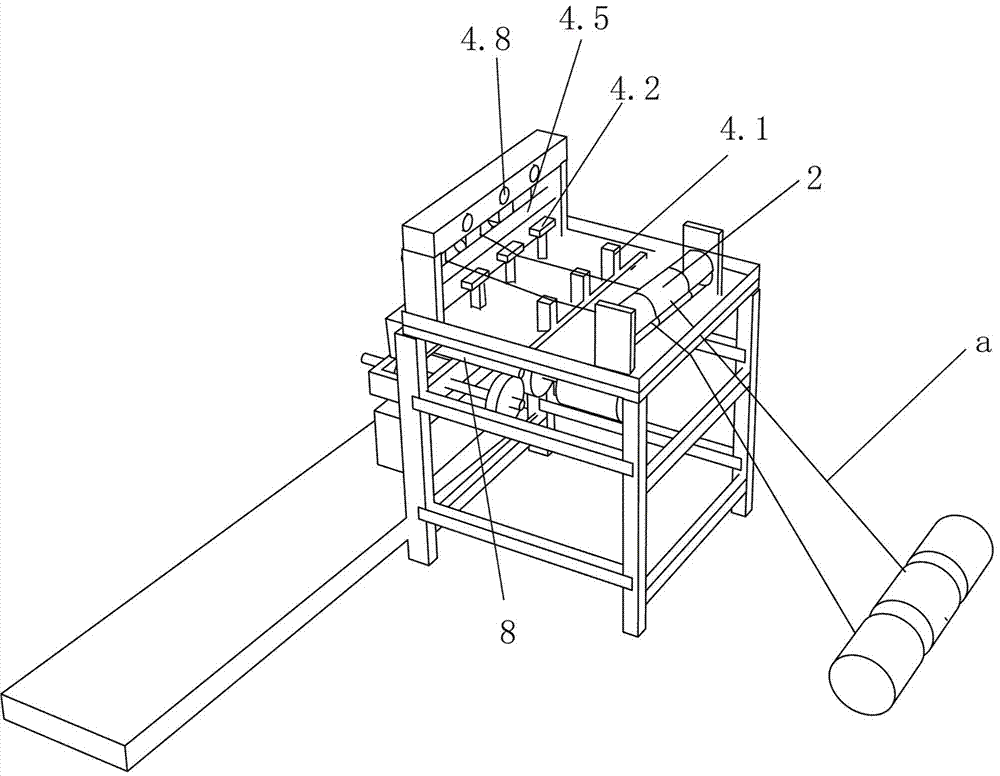

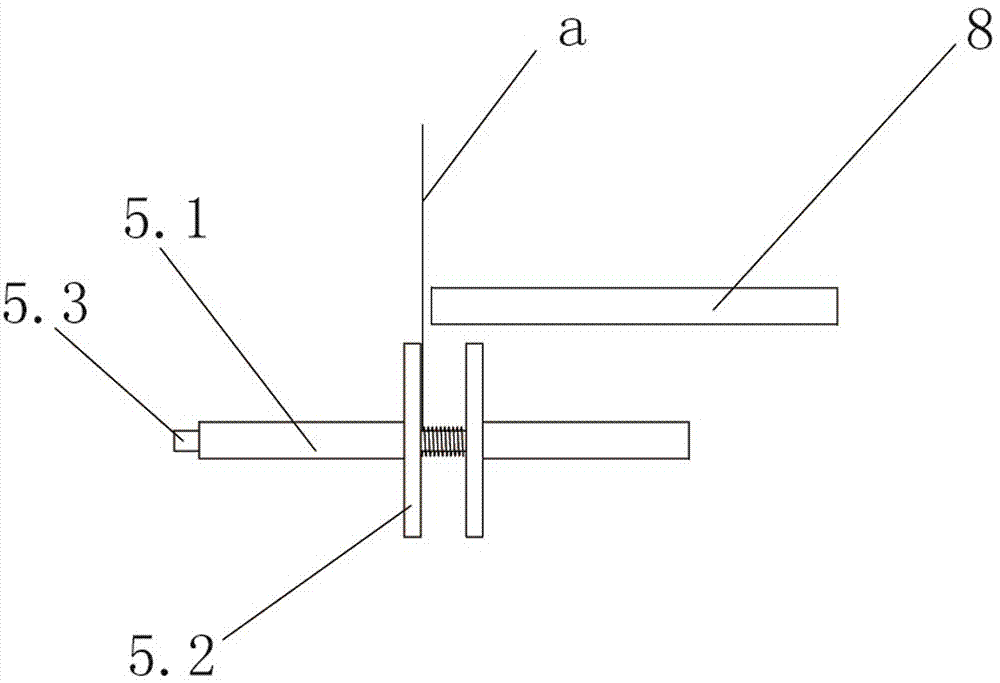

Multi-size steel wire ball production device

InactiveCN107253031ARealize automated productionRealize energy-saving productionEngineeringAutomation

The invention relates to a multi-size steel wire ball production device. The multi-size steel wire ball production device comprises a rack and a supporting platform on the top of the rack; a conveying belt is arranged on the front of the rack, and the device is characterized in that a wire grinding roller shaft is arranged on the upper portion of the supporting platform, a wire drawing unit is arranged on the end of the supporting platform, a wire stir fusing unit is arranged on the lower portion of the steel wire drawing unit, a steel wire is drawn through the wire grinding roller shaft and the wire drawing unit, and through rotation of the wire stir fusing unit, a spherical steel wire ball is formed. According to the multi-size steel wire ball production device, full-automation production can be achieved, multiple steel wire balls can be produced at one time, interruption is not needed in the production process, efficient production is achieved, energy-saving production is achieved, and the environment-friendly production is achieved.

Owner:柳州市淦兴金属制品有限公司

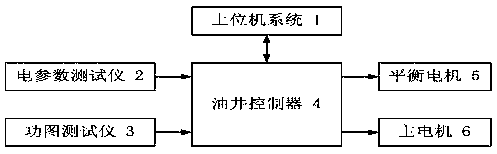

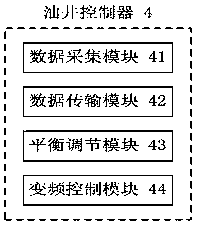

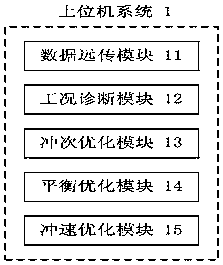

Oil well energy-saving production control system

InactiveCN109826615ARealize energy-saving productionTimely adjustment of production parametersSurveyElectric machineryOil well control

The invention provides an oil well energy-saving production control system which comprises a host computer system, an electrical parameter tester, an indicator diagram tester and an oil well controller. The electrical parameter tester is connected to the oil well controller and connected with a main motor to detect the voltage and current data of the main motor in running and transmit the voltageand current data to the oil well controller, the indicator diagram tester is connected to the oil well controller to detect the polished rod load and movement position of a pumping unit and transmit the polished rod load and the movement position to the oil well controller, the oil well controller transmits the received detection data to the host computer system, the host computer system analyzes,diagnoses and optimizes the oil well working condition according to the received detection data and transmits the optimization result to the oil well controller, and the oil well controller controlsthe work of the main motor and a balancing motor according to the optimization result. The oil well energy-saving production control system realizes oil well supply and discharge coordinated production, reduces the energy consumption of oil well production, realizes intelligent control over oil well production and improves the automation degree of oilfield production.

Owner:CHINA PETROLEUM & CHEM CORP +1

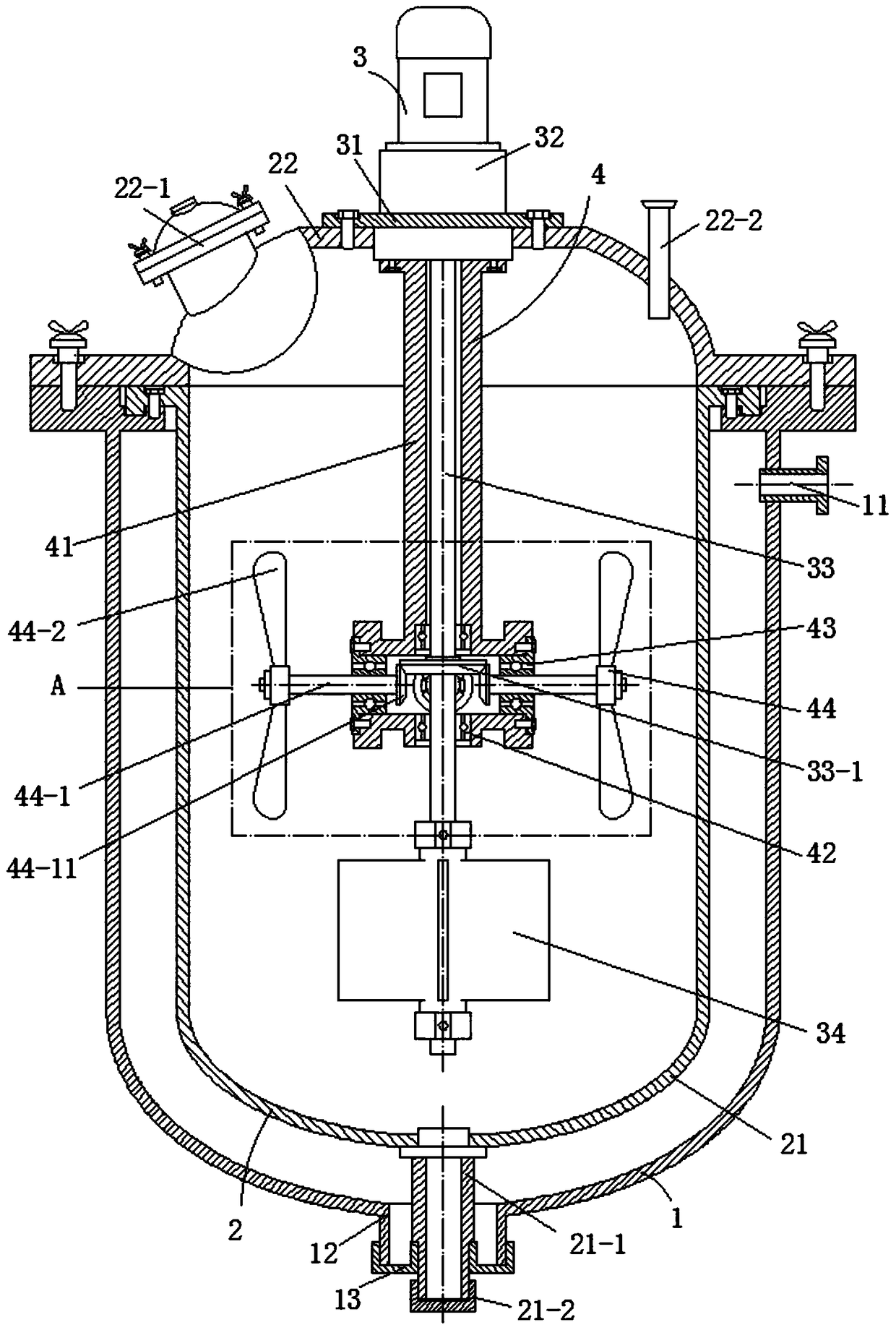

Pharmaceutical heat-preserving dispensing tank

InactiveCN108854748AGuaranteed formulation qualityImprove preparation efficiencyTransportation and packagingRotary stirring mixersDrugs solutionBiochemical engineering

The invention discloses a pharmaceutical heat-preserving dispensing tank, and relates to the technical field of pharmaceutical equipment. The pharmaceutical heat-preserving dispensing tank comprises an outer tank body, inner tank components, a driving stirring mechanism and a driven stirring mechanism, wherein the inner tank components comprise a inner tank body and a inner tank cover; the drivingstirring mechanism comprise a fixing plate, a gear motor, a rotating shaft and crossed agitation blades; the driven stirring mechanism comprise an hanger bearing frame, a vertical bearing, an lateralbearing and driven stirring components; the pharmaceutical heat-preserving dispensing tank adopts the stirring method of multi-directional stirring for higher stirring efficiency and providing an environment with more even and stable temperature during drug solution preparation.

Owner:WUHU KANGQI PHARMA

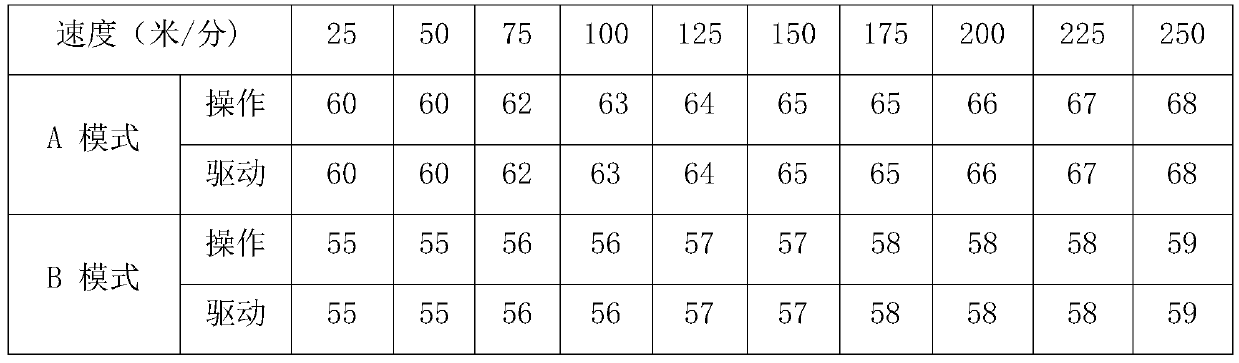

Low temperature production method for high speed corrugated board line, and steam system

PendingCN110281594ARealize energy-saving productionSave energyMechanical working/deformationPipeline systemsFiberEngineering

The invention discloses a low temperature production method for a high speed corrugated board line, and a steam system, and belongs to the field of corrugated board production. The low temperature production method mainly comprises the following steps that (1), making preparations; (2), setting base paper wrapping angles; (3), pressing a single-face corrugated board; (4), forming the single-face corrugated board; (5), regulating the clearance between a spreading roller and a scraping roller of a double-face machine and the clearance between contact rods; (6), setting the temperature of multiple preheaters; (7), regulating the spreading roller speed and spreading clearance of the double-face machine; (8), wrapping corners of a multilayered corrugated board; and (9), forming the multilayered corrugated board. According to the low temperature production method, the high speed production of the corrugated board line is achieved by adopting low temperature primary saturated steam, and meanwhile damage to base paper fibers is reduced; and the physical index of the corrugated board is ensured, and the warpage deformation of the produced corrugated board is avoided. The low temperature production method is mainly used for low temperature, low pressure and high speed production of the corrugated board.

Owner:LINYI XINGHUA PACKAGING

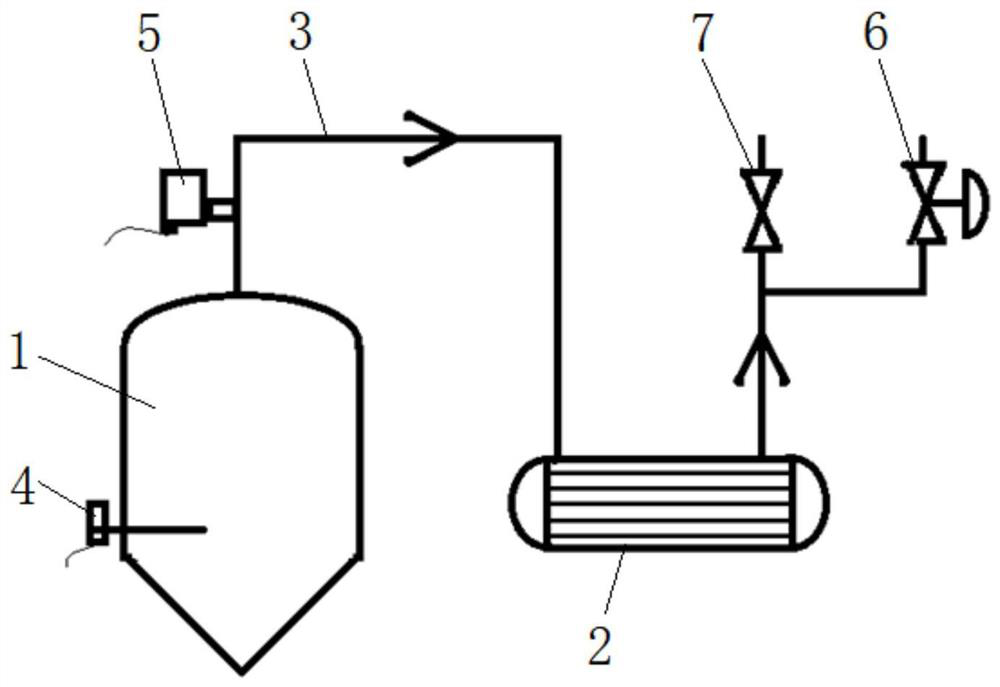

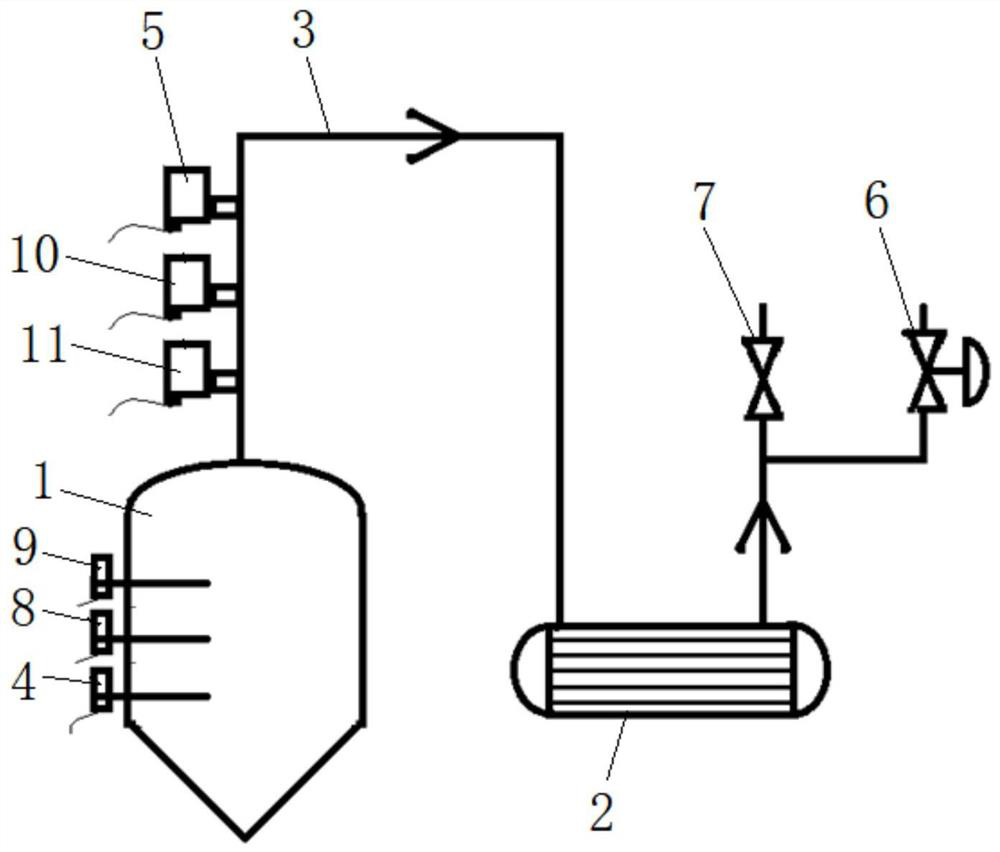

A pressure control system for a boiling pot

PendingCN113528258AMaintain colorGuaranteed tasteWort preparationSimultaneous control of multiple variablesThermodynamicsPressure stabilization

The invention discloses a pressure control system for a boiling pot, relates to the technical field of beer production, and solves the technical problem that the pressure of the boiling pot is inconvenient to control. The system comprises a boiling pot body, a controller and a secondary steam heater, wherein a pressure discharge port of the boiling pot is connected with an input port of the secondary steam heater through a secondary steam pipe, and the boiling pot is provided with a first temperature sensor; a first pressure transmitter is arranged at a pressure discharge port of the boiling pot, a regulating valve and a pressure discharge valve which are connected in parallel are arranged at an output port of the secondary steam heater, and the controller is electrically connected with the first temperature sensor, the first pressure transmitter, the regulating valve and the pressure discharge valve. The controller is used for adjusting the opening degree of the adjusting valve and the pressure discharging valve in real time, so that the pressure in the boiling pot is stabilized at the first set value, the boiling temperature in the boiling pot is always at the optimal boiling temperature, the beer quality can be guaranteed, the recovery rate of secondary steam can be increased, and energy-saving production is achieved.

Owner:YANJING BEER YULIN

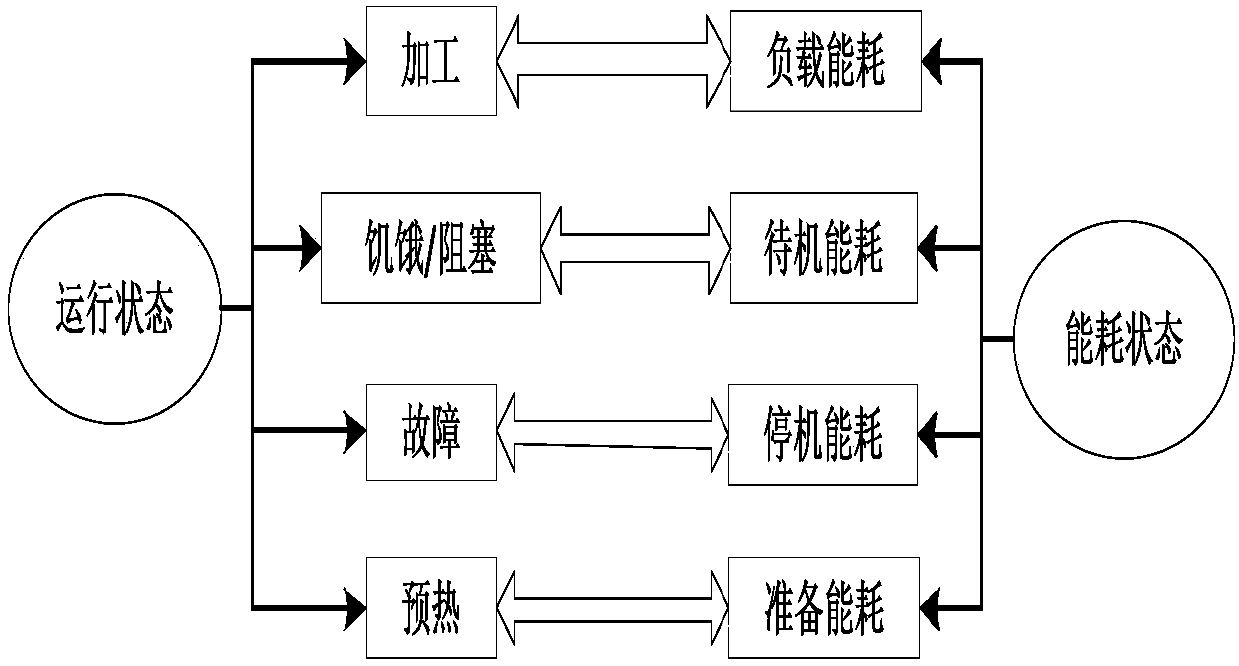

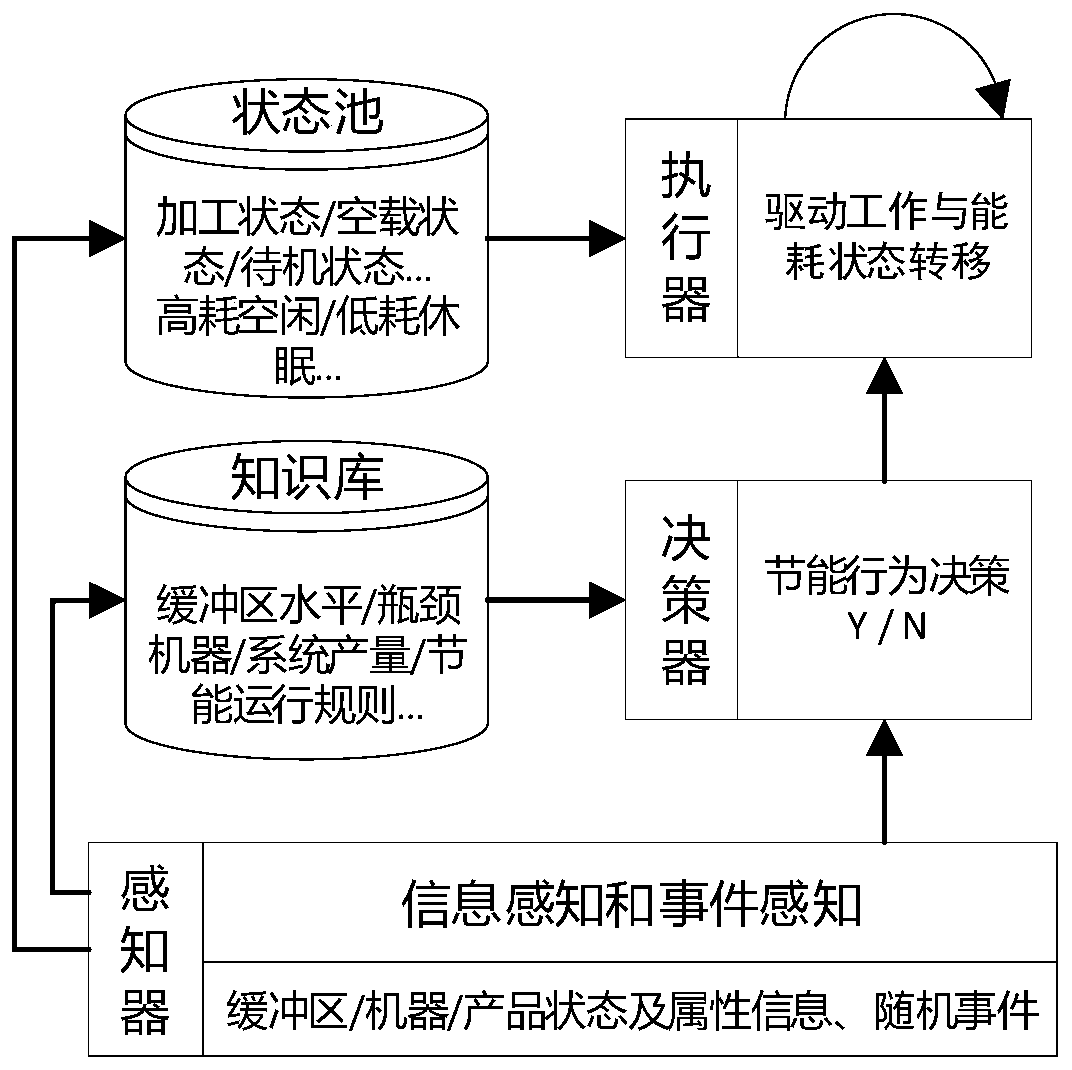

Manufacturing system energy-saving operation decision-making method and device based on fuzzy Petri net

InactiveCN110750920ARealize energy-saving productionQuick responseData processing applicationsDesign optimisation/simulationFuzzy inferenceFuzzy inference rules

The invention belongs to the field of energy-saving optimization of the production and manufacturing industry, and discloses a manufacturing system energy-saving operation decision-making method and device based on a fuzzy Petri net. The method comprises the following steps: (1) acquiring real-time state information of a machine and real-time in-process product levels of upstream and downstream buffer areas of the machine as input variables of an energy-saving decision; (2) taking the decision state of the machine as an output variable, establishing a fuzzy reasoning rule base of an energy-saving operation decision, and determining influence weights of an input variable and the output variable; (3) establishing a fuzzy Petri net model of an energy-saving operation decision according to theinput and output variables, the influence weight and a fuzzy reasoning rule base; (4) obtaining the credibility of a conclusion proposition through fuzzy Petri network reasoning calculation; and (5)the decision corresponding to the conclusion proposition with the maximum credibility being the machine decision state at the current moment. While the yield of the production system is effectively maintained, remarkable energy consumption saving can be achieved, the execution process is simple, and the application range is wide.

Owner:HUAZHONG UNIV OF SCI & TECH

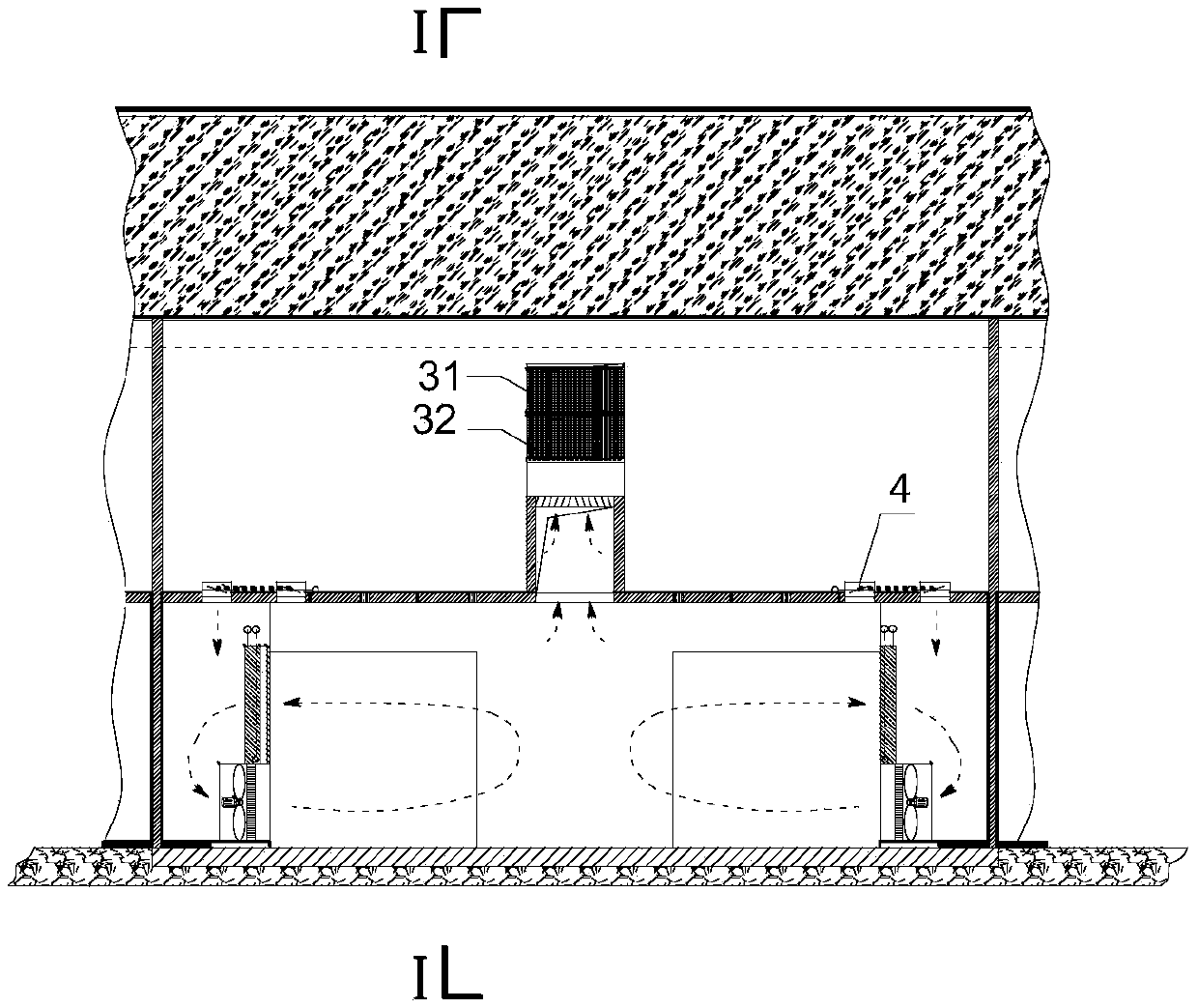

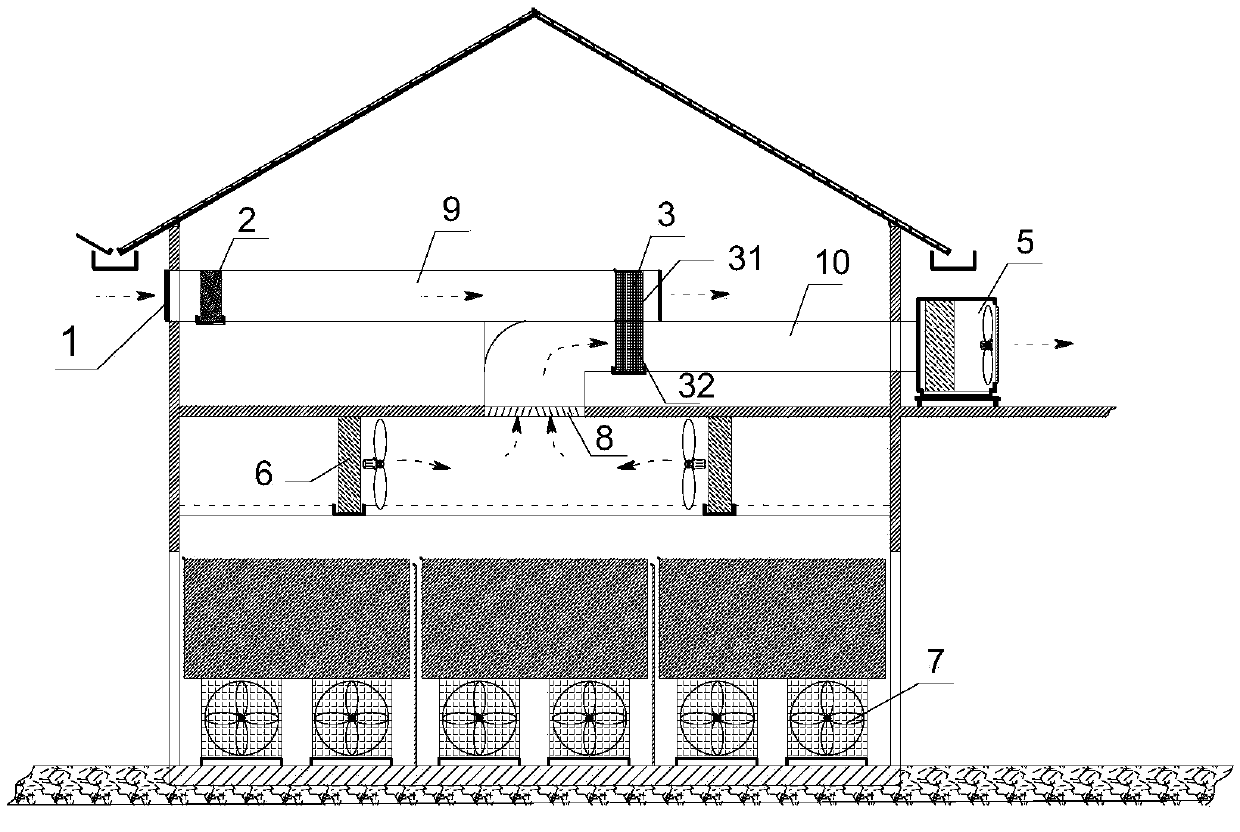

Setting device and method for drying honeycombed ceramic by waste heat air

InactiveCN108253766ARealize energy-saving productionLow costDrying gas arrangementsDrying machines with progressive movementsProduction lineWater vapor

The invention discloses a setting device and method for drying a honeycomb ceramic by waste heat air. The setting device and method are mainly used for heating, drying and forming of the honeycombed ceramic, the setting device comprises a main body and a continuous production line, and a waste heat air storage box and a waste heat air supply pipe are arranged under the production line; and a sliding rail is arranged on the upper part of the waste heat air storage box, and a plurality of heat dissipating micro holes are formed in the upper top surface of the waste heat air storage box. The waste heat air heats the honeycombed ceramic through the heat dissipating micro holes, and the discharged water vapor is uniformly discharged through moisture exhausting holes above the continuous production line; the honeycomb ceramic is loaded in a product box, and the product box is continuously propelled by a hydraulic top machine and sequentially enters a preheating section, a high temperature section and a cooling section; and after drying, the water content is about 3-5%, and blank cutting can be carried out during firing.

Owner:醴陵友立特种陶瓷有限公司

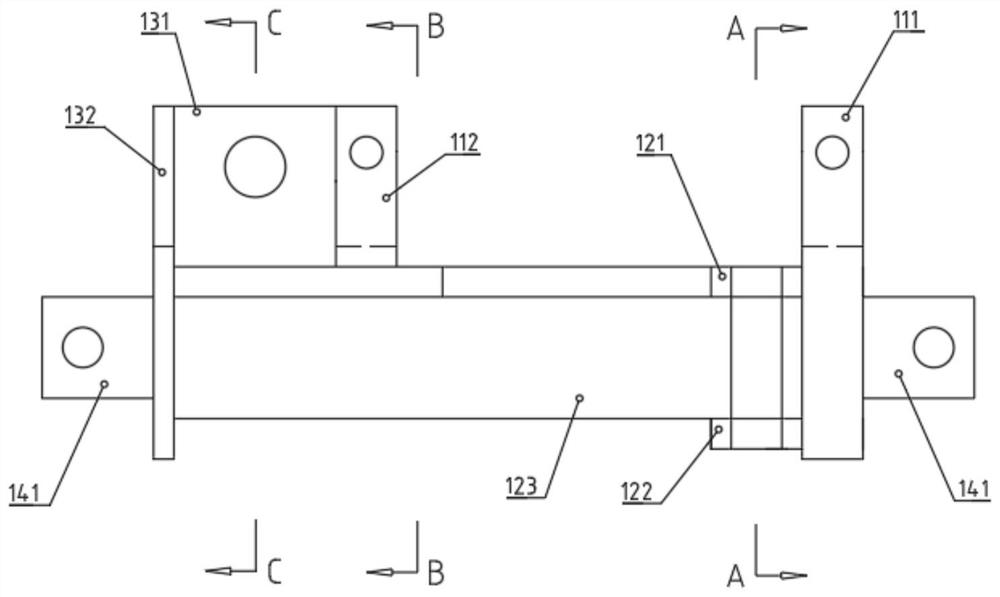

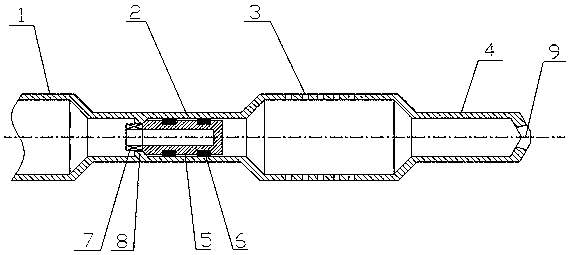

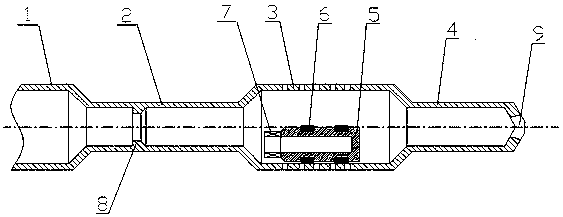

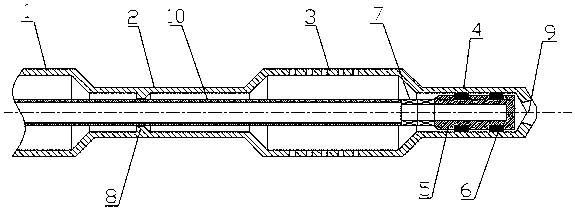

Underground blockage device of casing pressure balanced working method

InactiveCN105952410ARealize the blocked stateReasonable structureSealing/packingEngineeringPressure balance

The invention discloses an underground blockage device of a casing pressure balanced working method. The lower end of an upper-stage casing is connected with a blockage casing through a transition conical face. The diameter of the blocking casing is smaller than that of the upper-stage casing. A limiting device is arranged on the inner wall of the blocking casing. The lower end of the blocking casing is connected with a through hole sieve tube. The through hole sieve tube is connected with a correcting tube through a transition conical face. The diameter of the correcting tube is equal to that of the blocking casing. A blocking opening of the lower end of the correcting tube is provided with a vent hole. A blocking blind tube or a blocking device with a closed lower opening is installed in the blocking casing in a matched mode. A disengagement device is arranged on an upper tube opening of the blocking blind tube or the blocking device. A seal ring is installed on the outer wall of the blocking blind tube through a seal ring groove. The blocking blind tube is matched with the blocking casing or the correcting tube through the seal ring, or underground blocking is achieved through the blocking device. The underground blockage device is reasonable in structure and reliable in performance, a pipeline can be blocked underground, pressure inside the casing and pressure outside the casing are separated, and the well repairing work of detaching a sucker rod, an oil tube or a casing under pressure can be achieved.

Owner:KARAMAY SHENGLI PLATEAU MACHINERY CO LTD

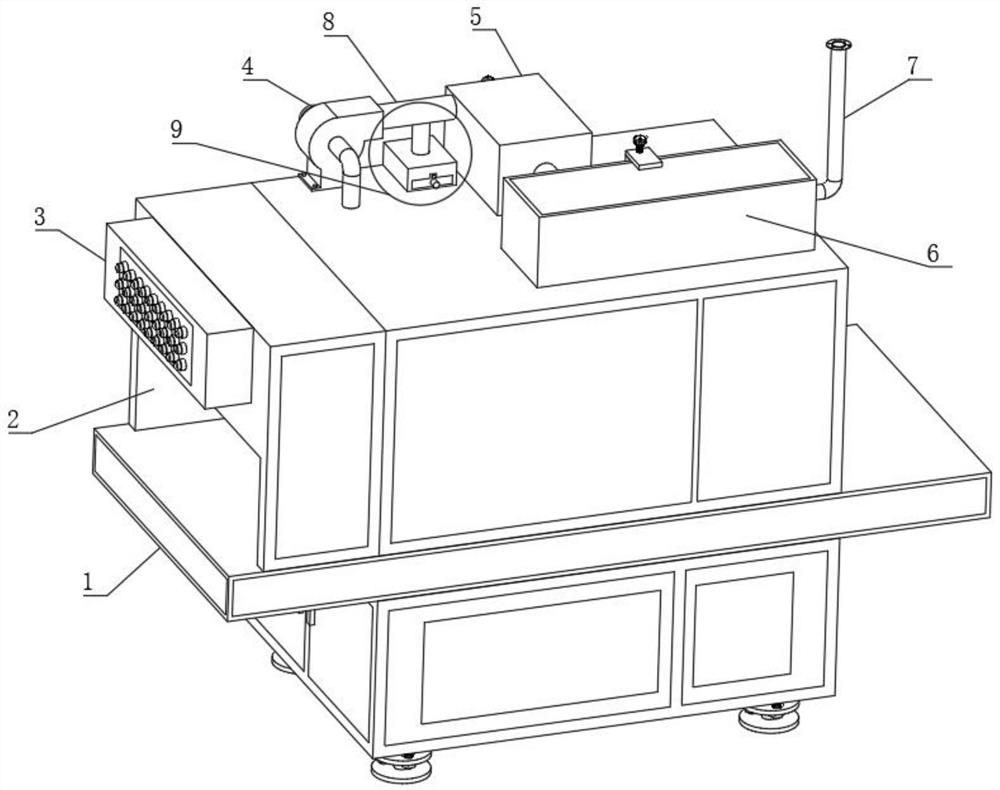

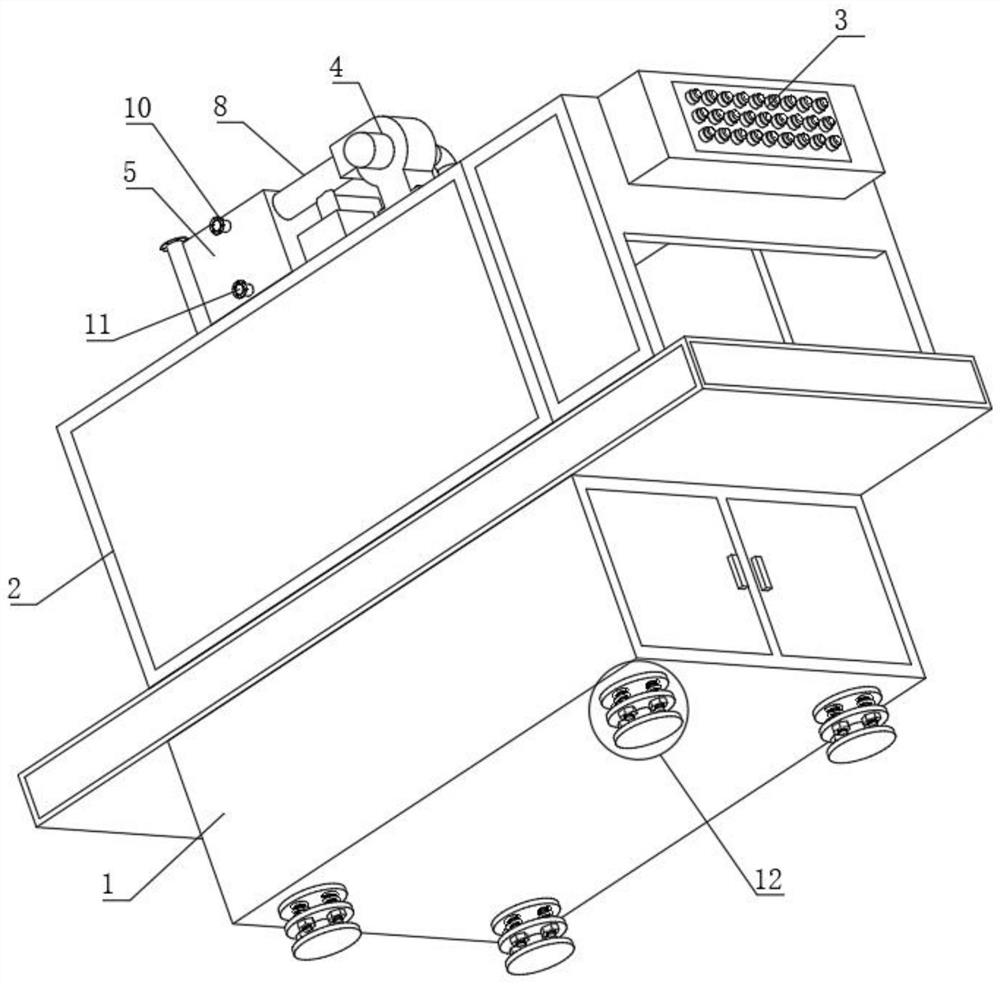

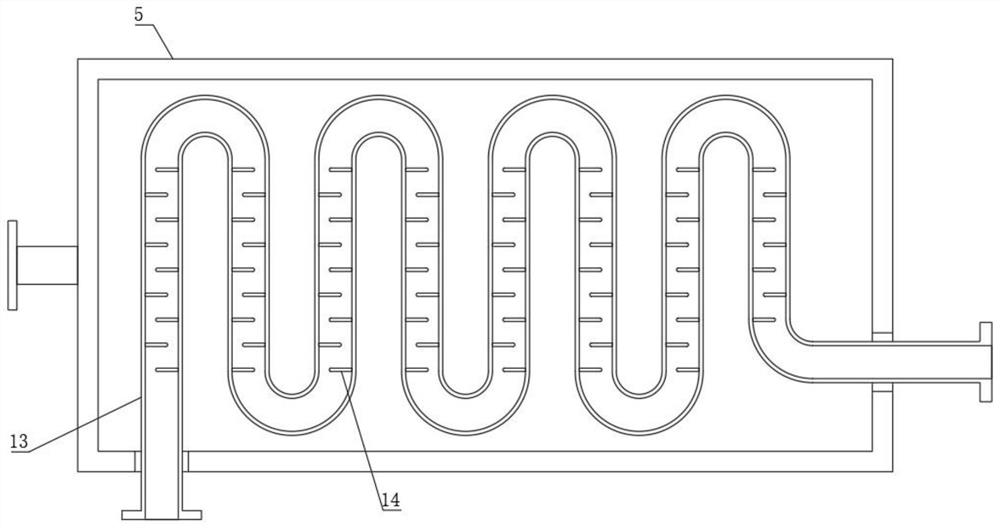

Industrial internet-based energy-saving heat treatment textile setting machine

PendingCN113089236AHarmful to healthEasy maintenanceCombination devicesGas treatmentNumerical controlTextile technology

The invention belongs to the technical field of textile, and particularly relates to an industrial internet-based energy-saving heat treatment textile setting machine. The machine comprises a machine body; a setting bin is fixed on the top surface of the machine body; a numerical control box is mounted on the setting bin; the machine further comprises an exhaust fan, a heat exchange water tank, a tail gas treatment box and a gas outlet pipe; a metal heat exchange pipe is mounted in the heat exchange water tank; and a solvent tank is fixed in the tail gas treatment box, and an activated carbon filter screen is arranged in the tail gas treatment box. A pretreatment assembly aims to eliminate dust and other large-particle solid impurities mixed in waste gas, so that the overhaul and maintenance of components and parts of the machine are facilitated; the tail gas waste heat recovery function is achieved through the arranged heat exchange water tank, a metal heat exchange pipe is combined with a spoiler, the relatively high heat exchange efficiency is achieved, and heat in tail gas is fully absorbed; and the solvent tank and the activated carbon filter screen are arranged to remove harmful substances in the tail gas, so that energy-saving production and environment-friendly production are realized, and the harmful gas is prevented from damaging the body health of processing personnel.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

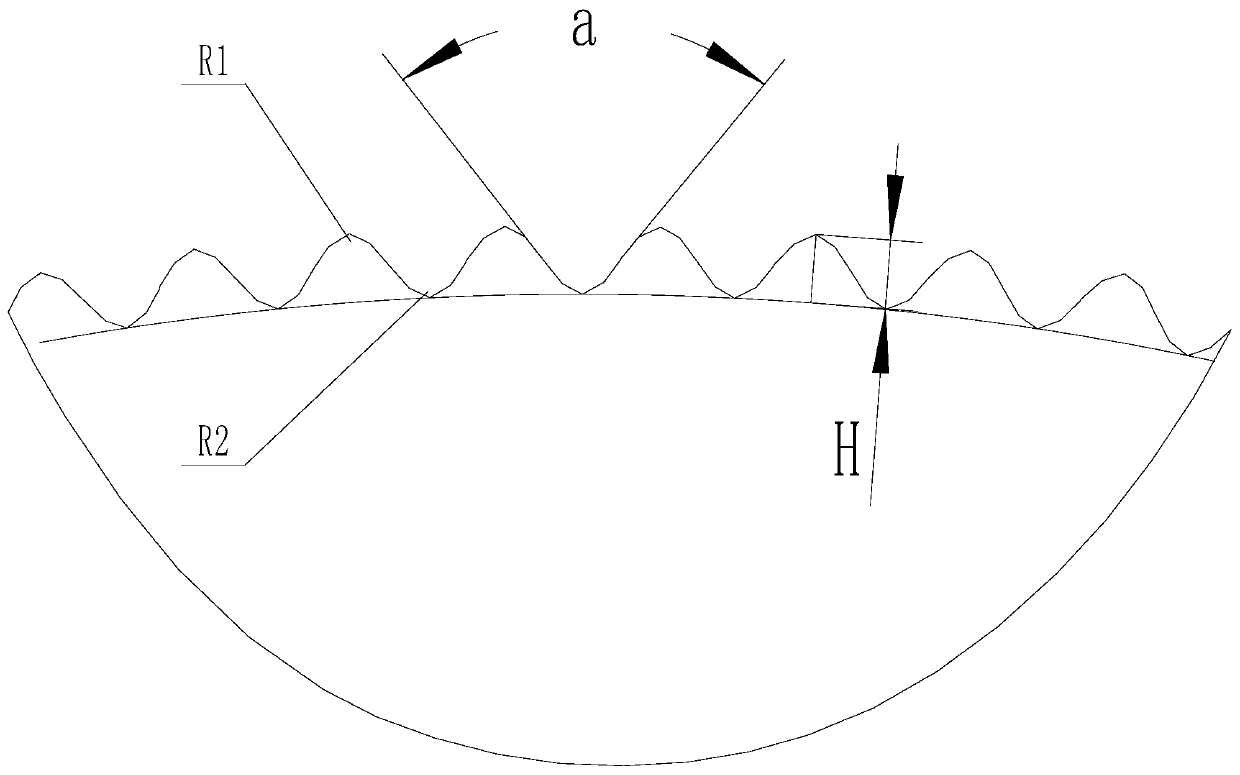

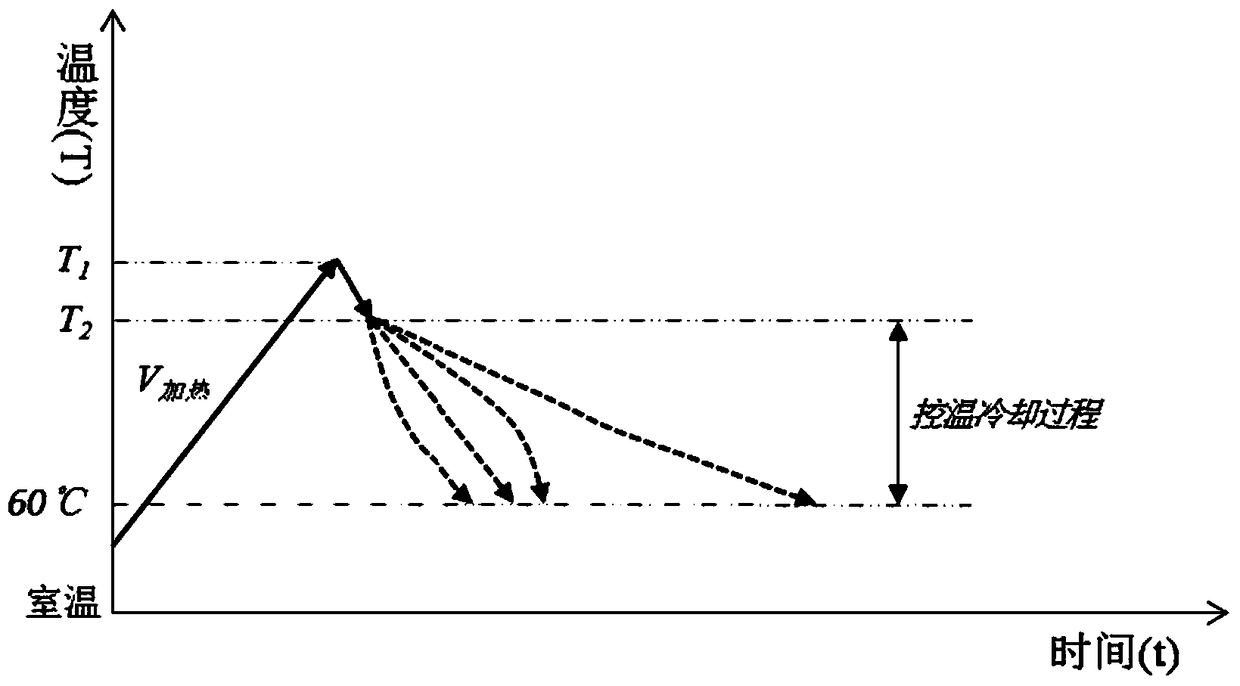

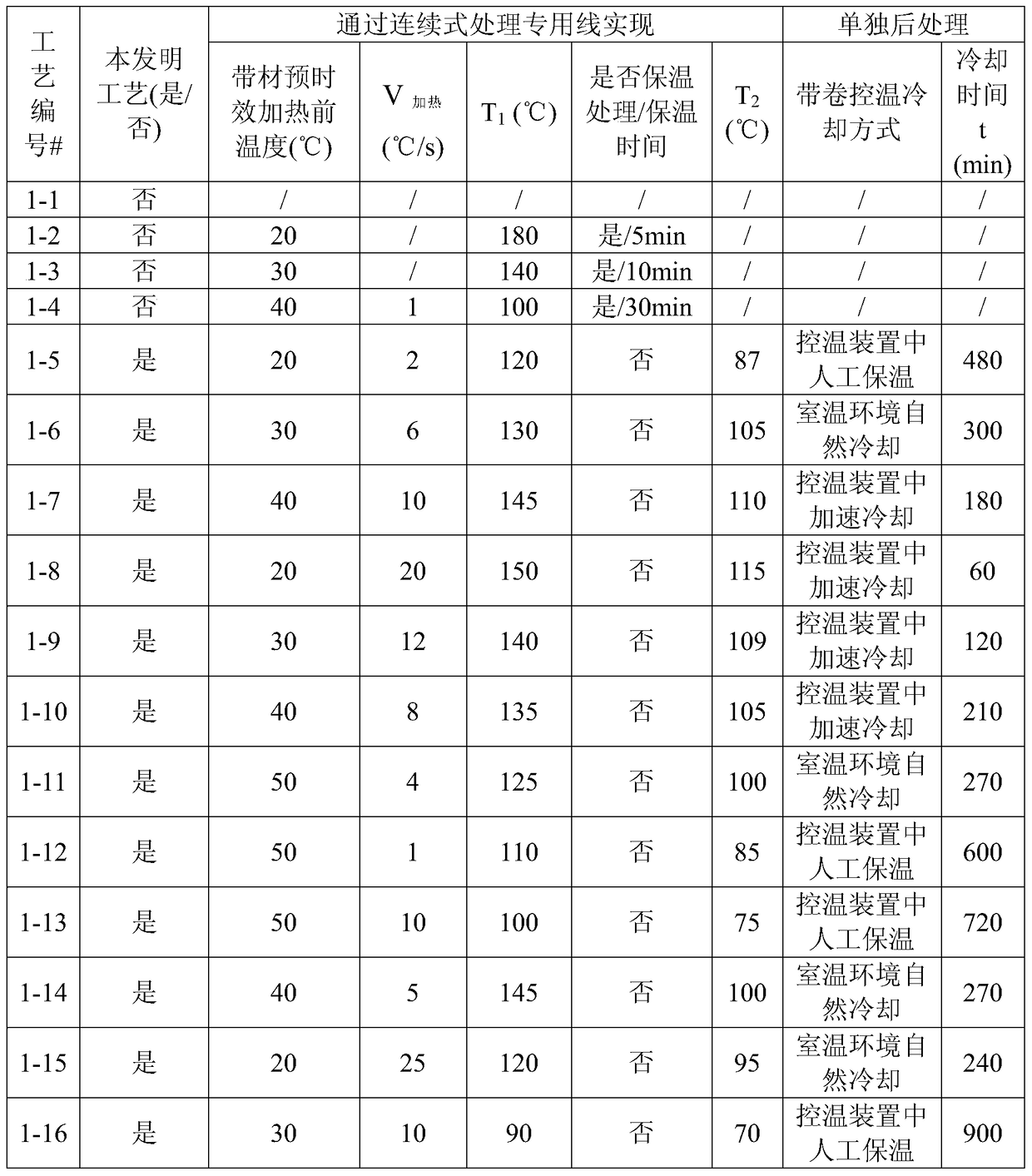

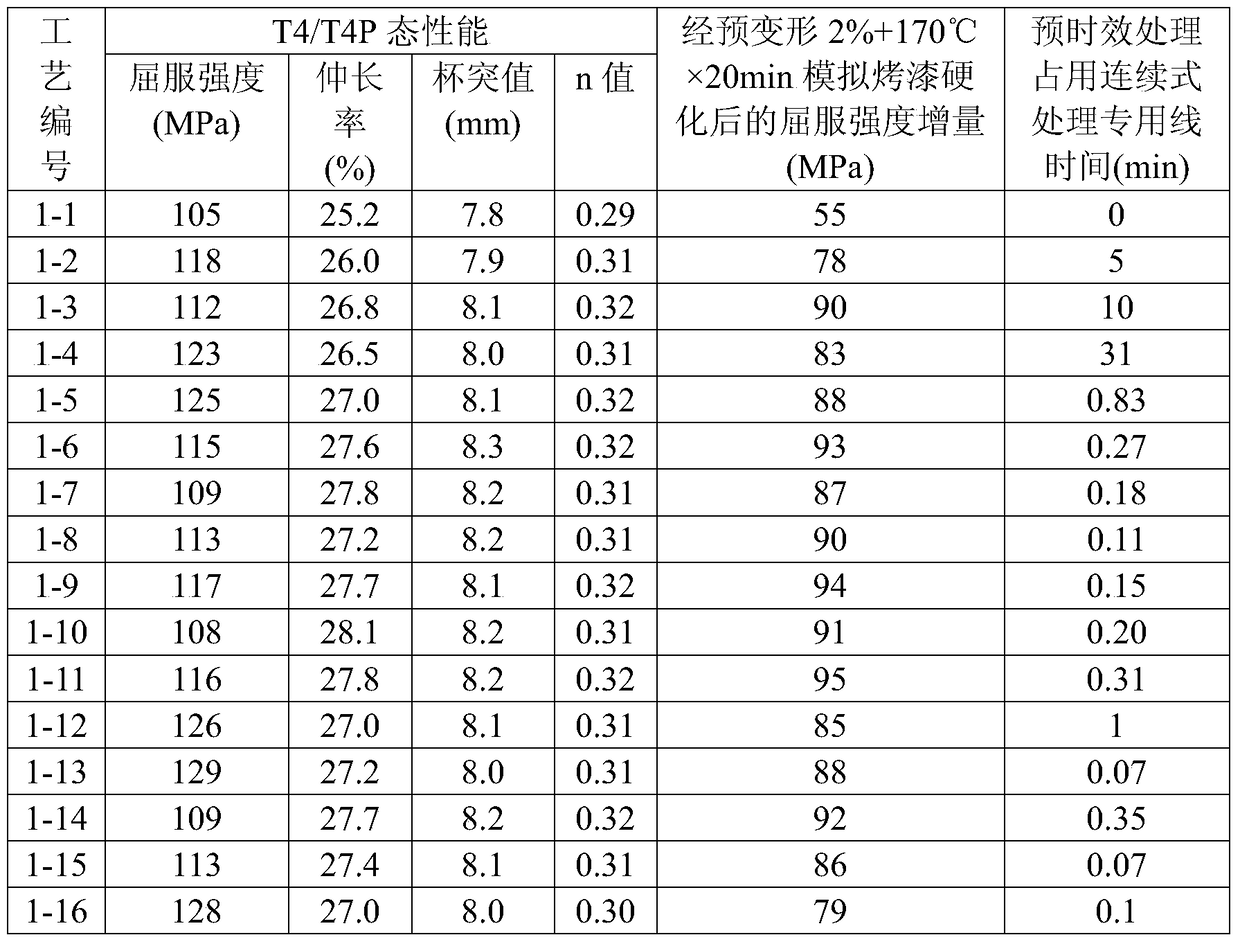

A high-efficiency preparation process of aluminum alloy sheet for automobile body

The invention discloses an efficient preparation process of an aluminum alloy plate for an automobile body. The efficient preparation process comprises the following steps that (1) aluminum alloy casting is conducted; (2) homogenization heat treatment is conducted; (3) a blank is subjected to hot rolling and / or cold rolling to obtain a plate strip coiled material; and (4) the plate strip coiled material is subjected to continuous on-line treatment comprising working procedures such as pre-aging heating, oil smearing, coiling and temperature control cooling treatment. The strip material is heated with the heating rate V and subjected to continuous temperature rising to the temperature T1 in a pre-aging heating device, then the strip material is subjected to the working procedures of continuous oil smearing and coiling, after coiling, the temperature of the coiled material is T2, finally the coil material is subjected to temperature control cooling for the time t and cooled to 60 DEG C or below, and the treatment is finished. V heating is larger than or equal to 1 DEG C / s and smaller than or equal to 30 DEG C / s; T1 is larger than or equal to 90 DEG C and smaller than or equal to 150 DEG C; T2 is larger than or equal to 70 DEG C and smaller than or equal to 120 DEG C; T1 is larger than or equal to T2+15 DEG C; and T is larger than or equal to 60 min and smaller than or equal to 900 min. The prominent problem that the traditional pre-aging technology occupies long time for a continuous production line, and the production efficiency is low is better solved, and efficient and energy-saving production of the plate is realized.

Owner:GRIMAT ENG INST CO LTD

Continuous rheomolding device for manufacturing metal plate strips

InactiveCN101890431BIncreased speed of continuous rheological formingGood formabilityMetal rolling arrangementsAlloyMolten metal

The invention provides a continuous rheomolding device for manufacturing metal plate strips. The device comprises an inclined plate, a base, an electromagnetic vibration exciter and a double-roller rolling mill and is characterized by also comprising the double-roller rolling mill, wherein the inclined plate is formed by connecting a feeding section, a pulping section and a discharging section inturn; the lower side of a bottom plate of the pulping section is connected with the upper end of a spring; the lower end of the spring is fixed on the base; one end of the electromagnetic vibration exciter is fixed on the base, and the other end of the electromagnetic vibration exciter is connected with the lower side of the bottom plate of the pulping section; and gaps are formed between the bottom plate and two side plates of the discharging section and the roll surfaces of upper and lower rollers of the double-roller rolling mill. The range of vibration frequency which can be provided by the electromagnetic vibration exciter adopted by the device is expanded greatly and the vibration frequency is adjusted so that an alloy structure can be improved more effectively and molten metal is prevented from crusting on the surface of the inclined plate.

Owner:NORTHEASTERN UNIV LIAONING

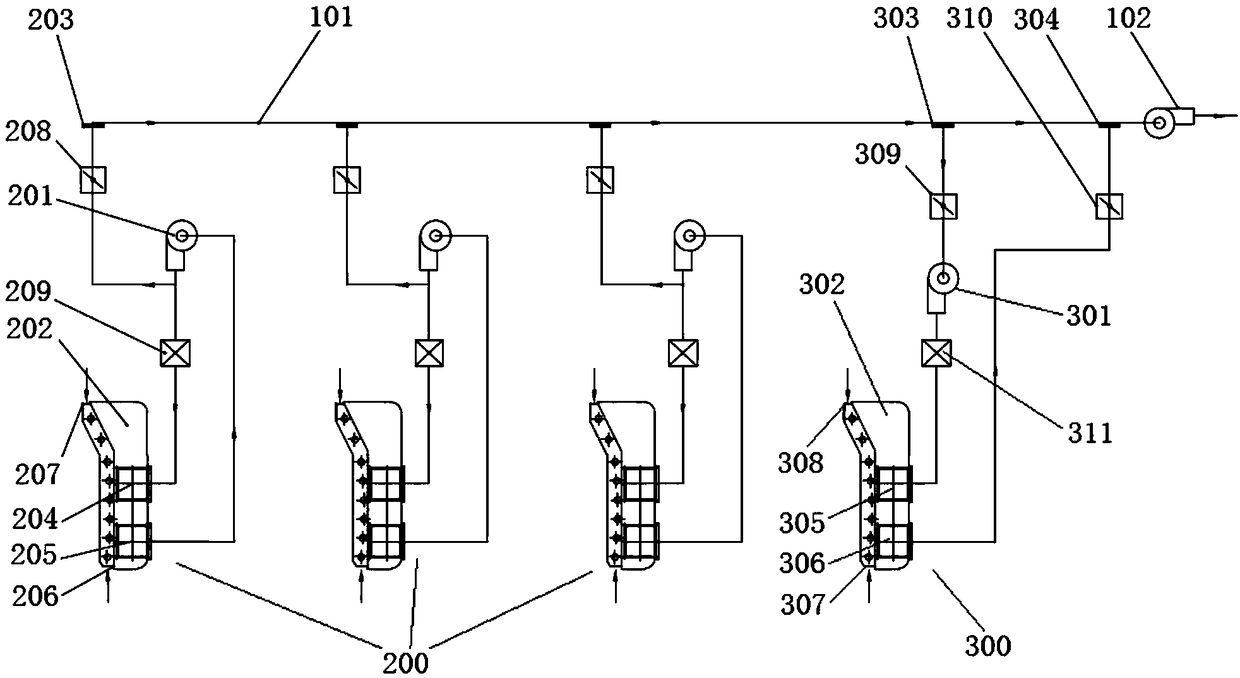

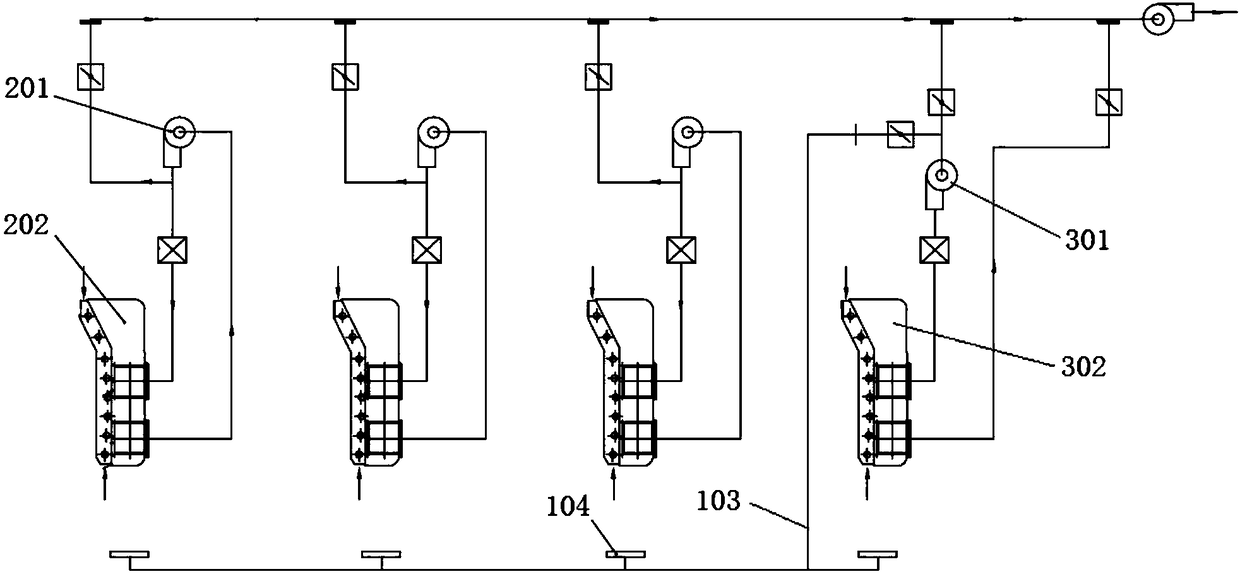

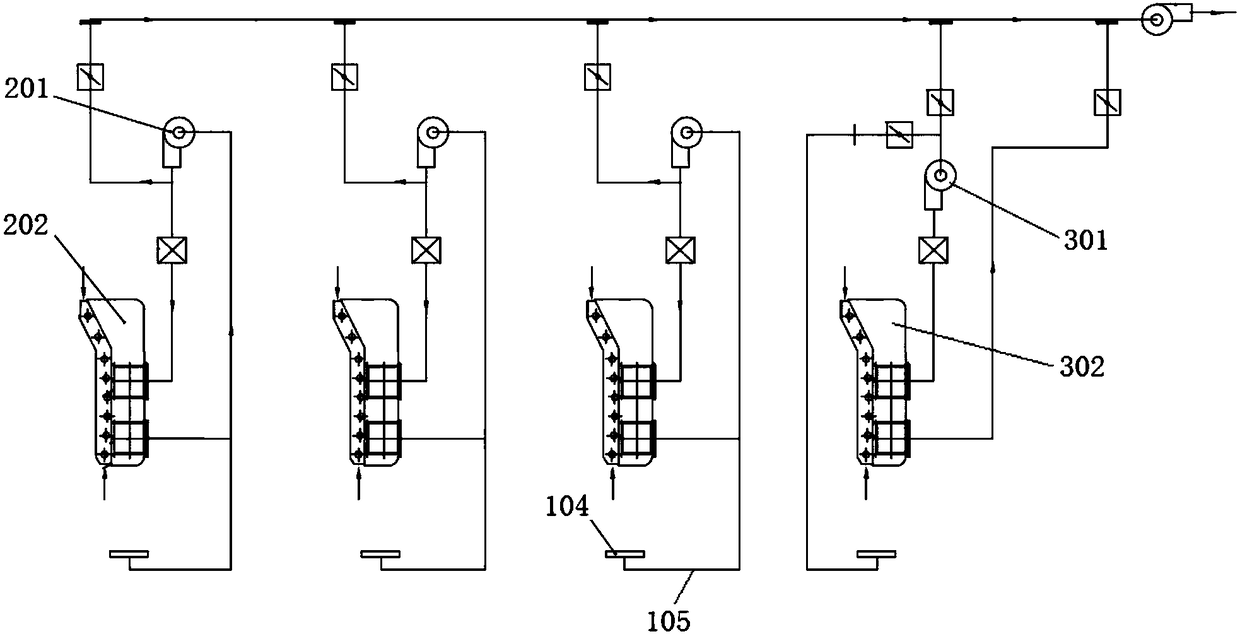

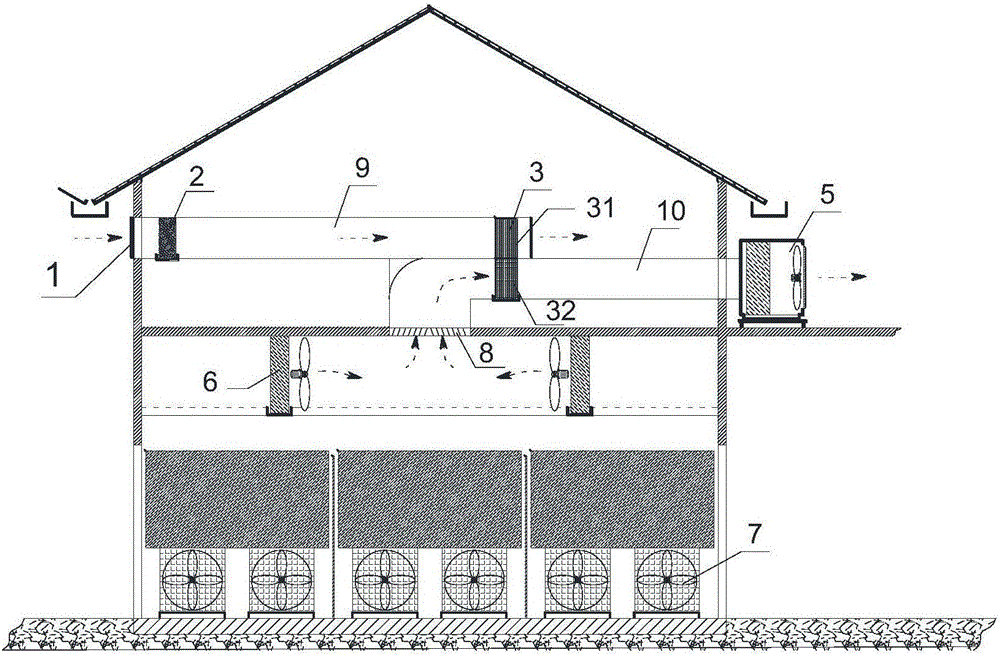

An exhaust hot air drying system

ActiveCN105972979BSimple structureImprove cleanlinessDrying gas arrangementsAir volumeEnergy consumption

The invention provides an exhaust hot air drying system. The exhaust hot air drying system comprises an exhaust manifold, an exhaust fan and at least two first drying units, wherein the exhaust fan is arranged at the tail end of the exhaust manifold; the first drying units comprise first unit air supply fans and first drying boxes, and are provided with first unit exhaust holes; the first drying boxes are provided with first drying box air inlets, first drying box air outlets, first drying box feed inlets and first drying box discharge holes; the first drying units are sequentially connected on the exhaust manifold through the first unit exhaust holes; air outlets of the first unit air supply fans are connected with the first drying box air inlets; the air outlets of the first unit air supply fans are connected with the first unit exhaust holes; and the first drying box air outlets are connected with air inlets of the first unit air supply fans. The exhaust hot air drying system can radically achieve the purpose of energy conservation and emission reduction, and has the advantages that the system is concise and stable, the adjustment is simple, the exhaust volume is small, the energy consumption is low, the potential safety hazard is avoided, the environmental protection treatment cost is low, and the like.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

Solar fruit and vegetable hot air vacuum combined drying equipment and drying method

ActiveCN102487993BTake advantage ofSave conventional energyFood processingFruits/vegetable preservation by dehydrationAir preheaterAutomatic control

The invention discloses solar fruit and vegetable hot air vacuum combined drying equipment and a drying method. The solar fruit and vegetable hot air vacuum combined drying equipment mainly comprises an air pre-heater, an intelligent controller, a solar water heater, a vacuum pump, a water catcher, a drying box, a hot air auxiliary heater, a draught fan and the like. A 'hot air-vacuum' combined drying technology is adopted, not only can the advantages of high drying efficiency and good economy of 'hot air' be displayed, but also the advantages of dryness, sanitation, sterilization, freshness preservation, low temperature, high efficiency and the like 'vacuum' can be utilized, so that not only can the final product which is dried maintain the original color, flavor, taste and appearance, but also various physical activity nutrients in fruit and vegetables can be best preserved; solar energy serves as a main drying heat source, so that solar radiant energy can be fully utilized, a lot of conventional energy can be saved, energy is saved, environment is protected and economic benefits are significant; and an automatic control technology is adopted, so that the automation degree of the equipment is high, and the operation is simple and convenient.

Owner:临沂市高新汽车租赁服务有限公司

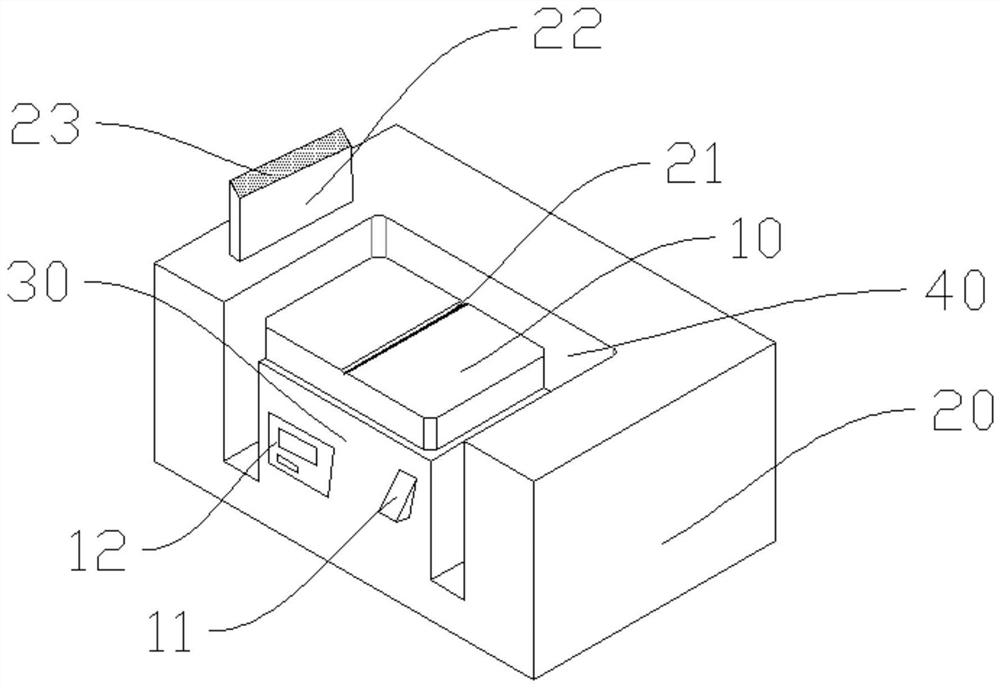

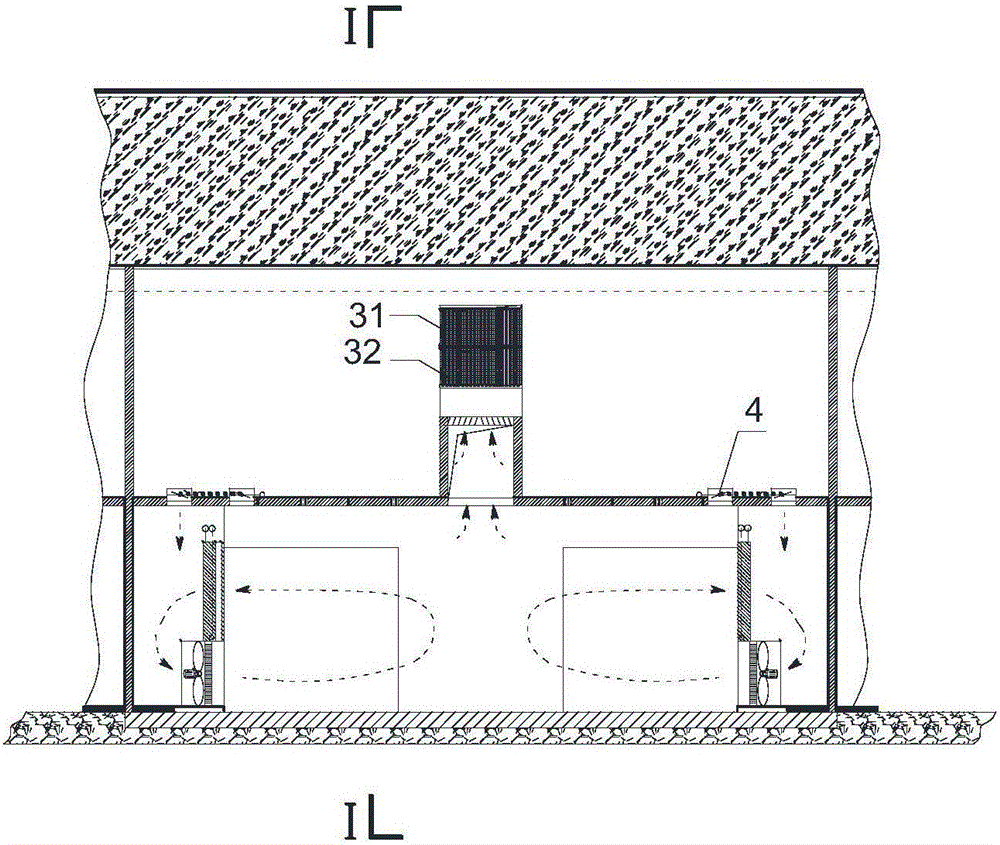

A drying room and a dehydration method using the drying room

ActiveCN106225432BAchieve coolingAchieve dehydrationDrying gas arrangementsDrying machines with local agitationFresh airPulp and paper industry

The invention discloses a drying room and a method for dehydration through the drying room. The drying room comprises an air freshening machine dew point cooler, an oscillating heat pipe, a duplex electric air valve, an exhaust air waste heat recovery wind cabinet, surface air coolers and fans; and an air inlet is formed in an entrance of the drying room, and an air exhaust port is formed in the drying room. The invention further provides the method for dehydration through the drying room. After entering the drying room, fresh air carries out heat exchange with the air freshening machine dew point cooler and then carries out heat exchange with the oscillating heat pipe, air on the top of the drying room carries out heat exchange with the surface air coolers and then carries out heat exchange with the oscillating heat pipe, and therefore the air can be cooled; and heat of cold water is absorbed after the cold water passes through the air freshening machine dew point cooler, the surface air coolers and the oscillating heat pipe, and therefore energy-saving production of air dehydrating and drying can be realized.

Owner:GUANGZHOU HUANGSHANGHUANG GRP

A kind of method utilizing sodium sulfate to produce sodium silicate

ActiveCN105460941BRealize energy-saving productionHigh puritySulfur compoundsAlkali metal silicatesProduct gasSodium silicate

Owner:钢研晟华科技股份有限公司

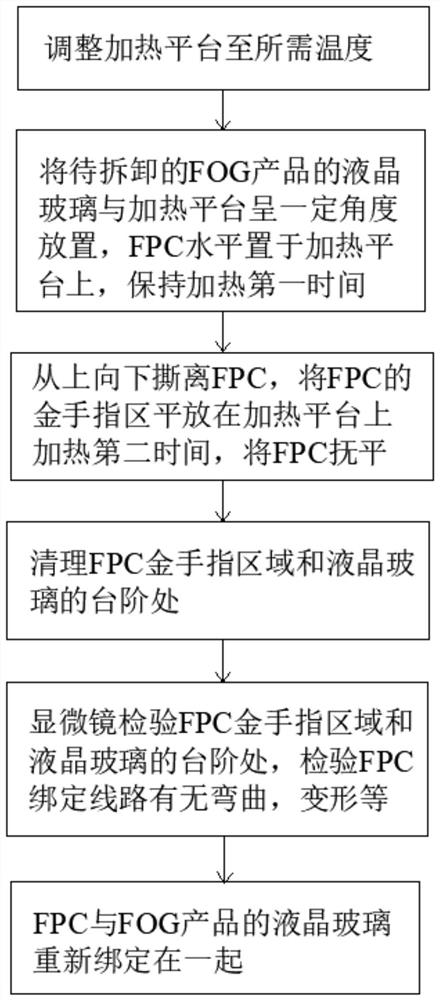

FPC reworking jig and FPC reworking method

The invention discloses an FPC reworking jig and an FPC reworking method. The FPC reworking jig comprises a main frame, a heating control circuit, a heating platform and a supporting part, wherein a mounting table is formed on the main frame; the heating platform is arranged on the mounting table; the heating control circuit is arranged in the mounting table; the heating control circuit is electrically connected with the heating platform; the supporting part is arranged at one side of the main frame; the working temperature of the heating platform is 100 to 200 DEG C; a positioning part is arranged on the heating platform; the positioning part is matched with the supporting part, so that a to-be-disassembled FOG product is placed on the heating platform; and liquid crystal glass of the FOGproduct and the heating platform form an angle of 30-120 degrees. Thus, the liquid crystal panel and the FPC after the FOG defective product is disassembled are reworked and reutilized, the success rate is high, the waste of raw materials is greatly reduced, and green and environment-friendly energy-saving production is realized.

Owner:SHENZHEN TXD TECH CO LTD

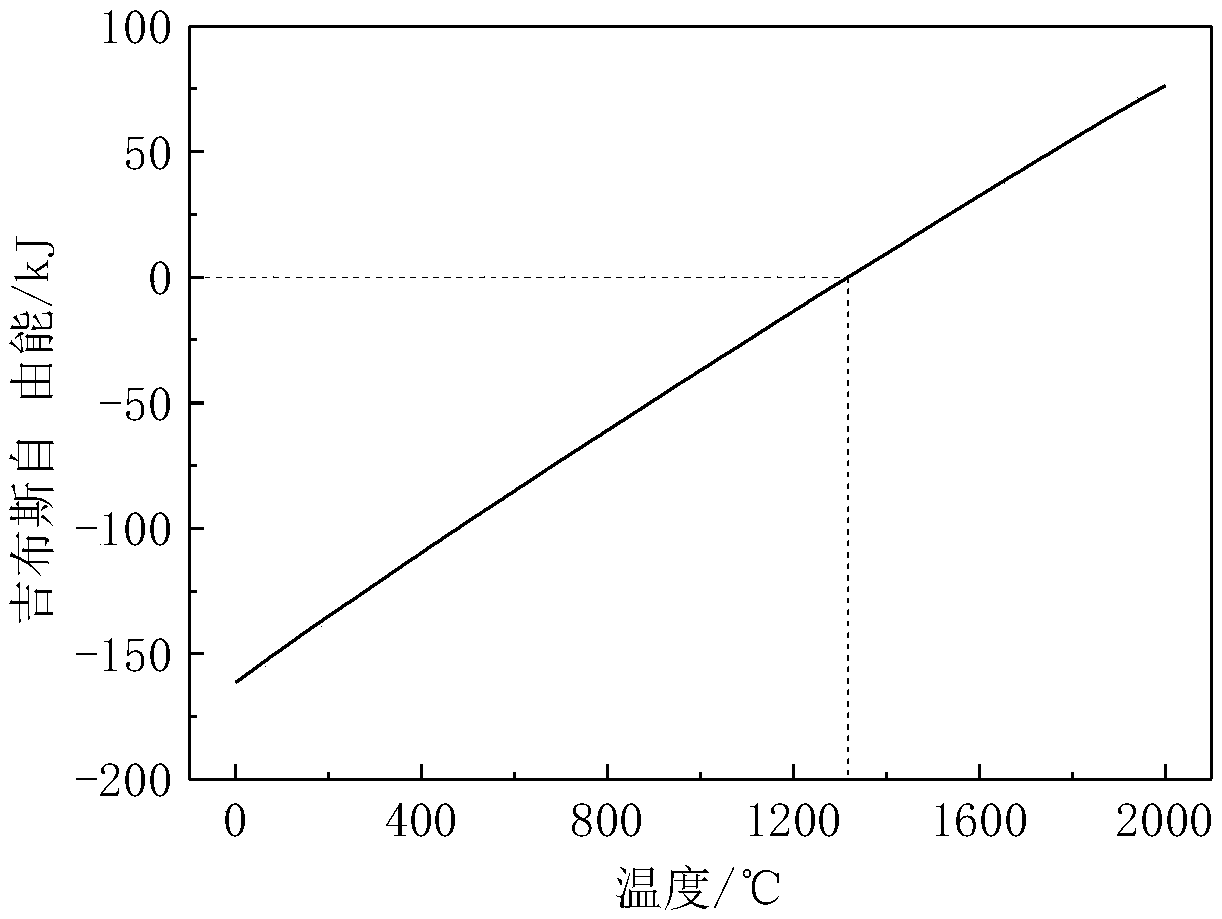

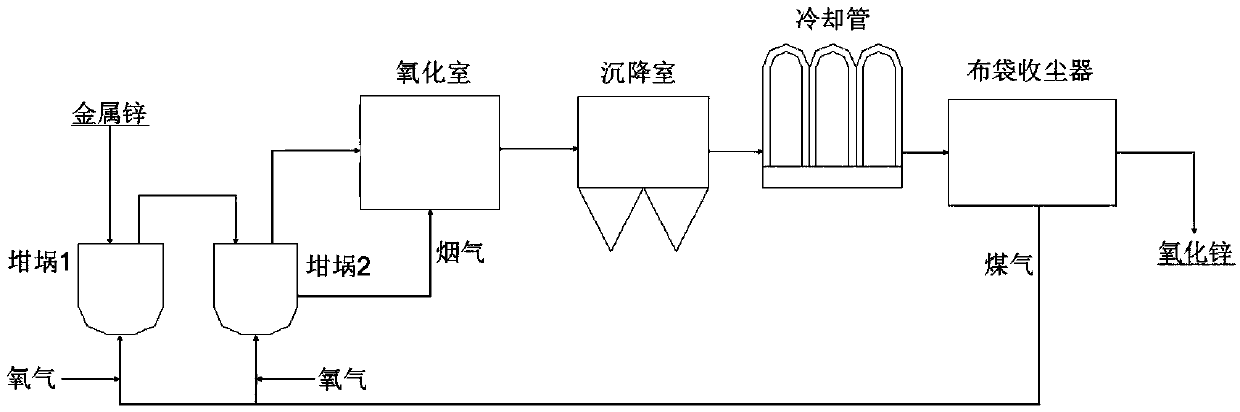

A device for preparing nano-zinc oxide by non-equilibrium oxidation of metal zinc

ActiveCN107720805BSmall particle sizeImprove performanceMaterial nanotechnologyZinc oxides/hydroxidesHigh energyEvaporation

The invention discloses a method for preparing nano-zinc oxide by a metal zinc non-equlibrium oxidation method. The method comprises the following steps: using carbon dioxide as an oxidizing agent foroxidizing metal zinc vapor, and synthesizing the zinc oxide, wherein while the metal zinc is fused and evaporated, the carbon dioxide is provided by smoke generated by burning a fuel; and providing the fuel for the fusion and the evaporation of the metal zinc by a coal gas generated in the oxidation process. In the reaction process of the method, other energy sources are not consumed. The methodhas the characteristics of high energy utilization efficiency, good product quality and low production cost. In the production process, an external heat source does not need to be consumed, so the economic benefit is better. A zinc oxide product obtained by the CO2 zinc oxide vapor has the characteristics of small particle size, good property and extensive use.

Owner:钢研晟华科技股份有限公司

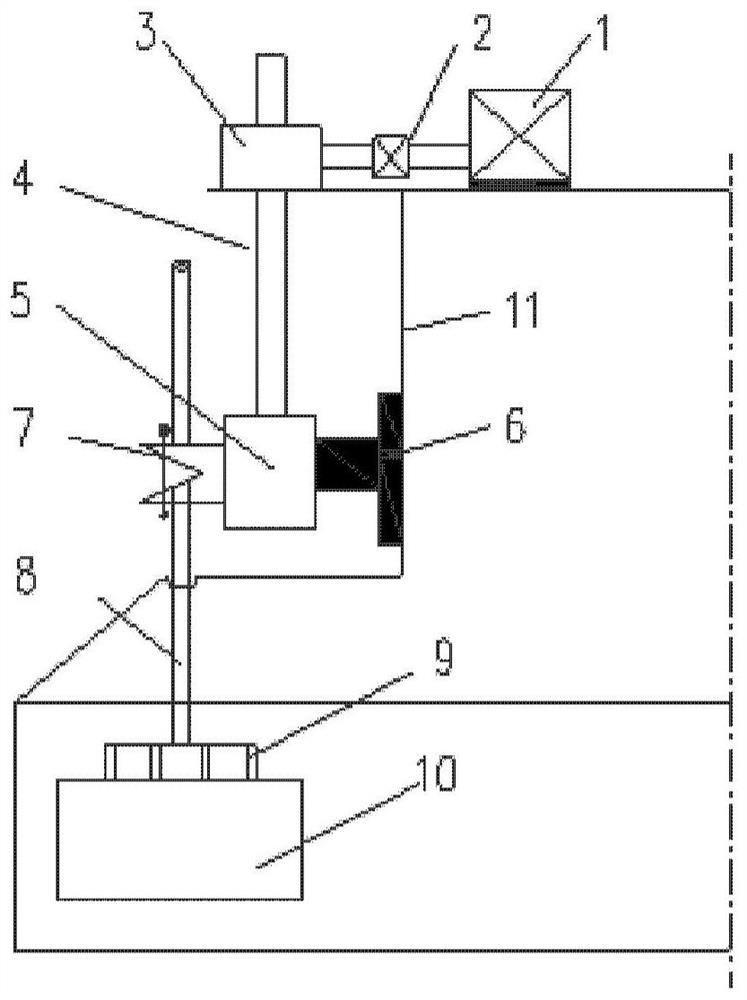

An anode lifting device and aluminum electrolytic cell equipment

The present invention provides an anode lifting device used in aluminum electrolytic cell equipment including a cathode and a plurality of anodes, characterized in that the anode lifting device includes a transmission assembly and a drive assembly, wherein: the drive assembly and the transmission The components are connected, and the driving component drives one of the multiple anodes to move up and down through the transmission component, so that the anode is close to or far away from the cathode when the aluminum electrolytic cell is in an energized state. In this application, by setting the anode lifting device corresponding to each anode, the adjustment of the position of each anode can be realized when the electrolytic cell is powered on, so that the distance between each anode and the cathode can be adjusted more finely, and the aluminum liquid can be weakened. The fluctuation at the bottom of the tank reduces the pole distance, improves the current efficiency, and realizes energy saving in the production process.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

A kind of steel slag aluminothermic reduction method for producing ferroalloy and refining slag

ActiveCN106676223BAchieve recyclingImprove resource utilization efficiencyRecycling and recovery technologiesProcess efficiency improvementMetallic aluminumResource recovery

The invention discloses a method for producing an iron alloy and refining slag through steel slag aluminothermic reduction. Liquid state steel slag and metallic aluminum are contained into a first reactor according to a certain mass ratio to be stirred to obtain phosphorus containing pig iron, the remaining liquid state steel slag and metallic aluminum obtained after reacting are contained into a second reactor according to a certain mass ratio to be stirred to obtain silicomanganese, and molten slag obtained after reacting in the second step serves as the steel-making refining slag. The obtained phosphorus containing pig iron and silicomanganese can be used for producing special steel, and the refining slag can be used for producing clean steel. The method has the beneficial effects that aluminum simple substance is led into the steel slag, the problems that the steel slag resource recovery rate is low, and the added value of products is low are solved, and meanwhile, efficient utilization of liquid state steel slag sensible heat and comprehensive recycling of iron, phosphorus, manganese, silicon and molten slag in the steel slag are achieved.

Owner:临沂市钢铁产业协同创新中心 +1

A method for producing nickel-containing molten iron by smelting reduction of liquid nickel slag

ActiveCN104120209BRealize comprehensive utilizationRealize energy-saving productionProcess efficiency improvementSteelmakingLiquid state

The invention provides a method for producing nickel-containing molten iron by smelting and reducing liquid-state nickel slag. The method comprises the following steps: feeding liquid-state nickel slag and a reducing agent into a smelting and reducing furnace according to a predetermined mass ratio; enabling the liquid-state nickel slag and the reducing agent to react in the smelting and reducing furnace, and stirring at the same time; and generating nickel-containing molten iron and smelting slag after the reaction is ended, wherein the nickel-containing molten iron is at the lower layer of the smelting and reducing furnace, and the smelting slag is at the upper layer of the nickel-containing molten iron. The nickel-containing molten iron can be directly used for steelmaking, and the obtained smelting slag can be used for producing building materials. The method for producing the nickel-containing molten iron by smelting and reducing liquid-state nickel slag, which is provided by the invention can realize energy-saving production, comprehensive utilization of resources and good economic benefits.

Owner:CENT IRON & STEEL RES INST +1

Drying room and method for dehydration through drying room

ActiveCN106225432AImprove efficiencyLow energy consumptionDrying gas arrangementsDrying machines with local agitationChillerDew point

The invention discloses a drying room and a method for dehydration through the drying room. The drying room comprises an air freshening machine dew point cooler, an oscillating heat pipe, a duplex electric air valve, an exhaust air waste heat recovery wind cabinet, surface air coolers and fans; and an air inlet is formed in an entrance of the drying room, and an air exhaust port is formed in the drying room. The invention further provides the method for dehydration through the drying room. After entering the drying room, fresh air carries out heat exchange with the air freshening machine dew point cooler and then carries out heat exchange with the oscillating heat pipe, air on the top of the drying room carries out heat exchange with the surface air coolers and then carries out heat exchange with the oscillating heat pipe, and therefore the air can be cooled; and heat of cold water is absorbed after the cold water passes through the air freshening machine dew point cooler, the surface air coolers and the oscillating heat pipe, and therefore energy-saving production of air dehydrating and drying can be realized.

Owner:GUANGZHOU HUANGSHANGHUANG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com