A pressure control system for a boiling pot

A boiling pot and pressure technology, applied in control/regulation systems, non-electric variable control, and simultaneous control of multiple variables, etc., can solve problems such as economic waste, inaccurate pressure control, and reduced bitterness, and achieve energy-saving production, improve The effect of recovery rate and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

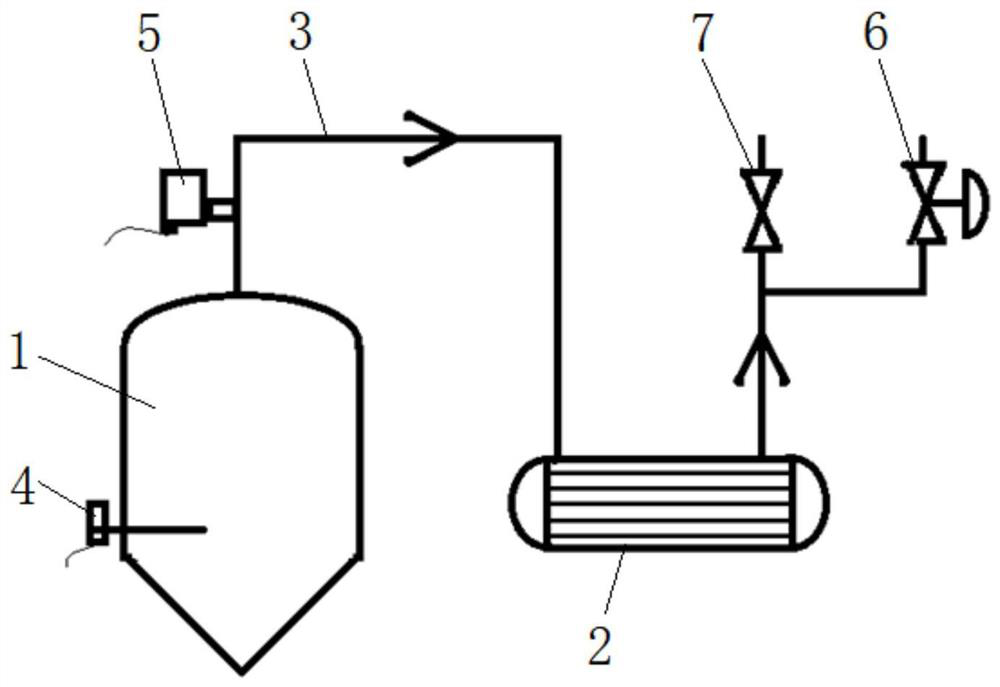

[0022] refer to figure 1 , a boiling pot pressure control system, including a boiling pot 1, also includes a controller, a secondary steam heater 2, the pressure discharge port of the boiling pot 1 is connected to the input port of the secondary steam heater 2 through a secondary steam pipe 3, The boiling pot 1 is provided with a first temperature sensor 4, the pressure discharge port of the boiling pot 1 is provided with a first pressure transmitter 5, and the output port of the secondary steam heater 2 is provided with a regulating valve 6 and a pressure relief valve 7 connected in parallel , the controller is electrically connected to the first temperature sensor 4, the first pressure transmitter 5, the regulating valve 6, and the pressure relief valve 7;

[0023] The controller adjusts the opening of the regulating valve 6 in real time, so that the pressure in the boiling pot 1 is stabilized at the first set value;

[0024] When the regulating valve 6 is fully opened (tha...

Embodiment 2

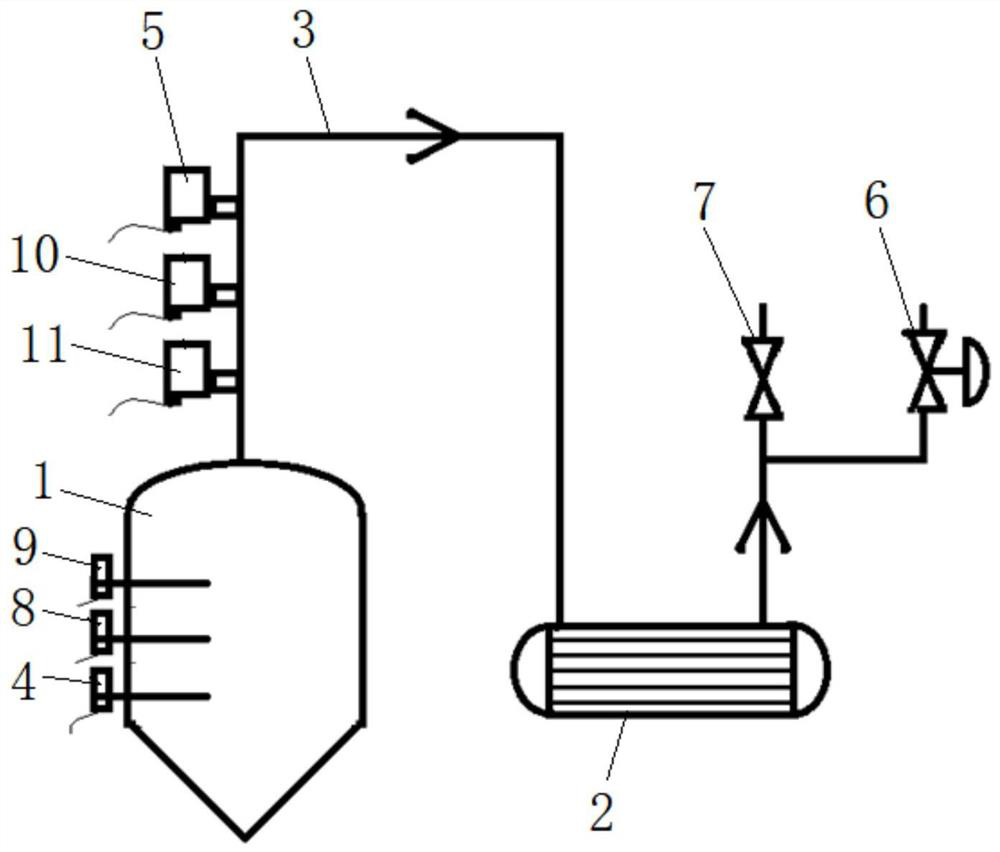

[0028] refer to figure 2 , on the basis of Embodiment 1, the boiling pot 1 is also provided with a second temperature sensor 8 and a third temperature sensor 9, and the pressure outlet of the boiling pot 1 is also provided with a second pressure transmitter 10 and a third pressure transmitter. The controller 11 is electrically connected to the second temperature sensor 8 , the third temperature sensor 9 , the second pressure transmitter 10 and the third pressure transmitter 11 . Read the temperature that the first temperature sensor 4, the second temperature sensor 8, the 3rd temperature sensor 9 detect simultaneously and compare, can know whether any one of the temperature sensors makes a mistake, prevents a single temperature sensor from making a mistake and causes boiling in the boiling pot 1 The temperature is not at the optimum boiling temperature. At the same time, read the pressure detected by the first pressure transmitter 5, the second pressure transmitter 10, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com