Patents

Literature

42results about How to "Reasonable technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

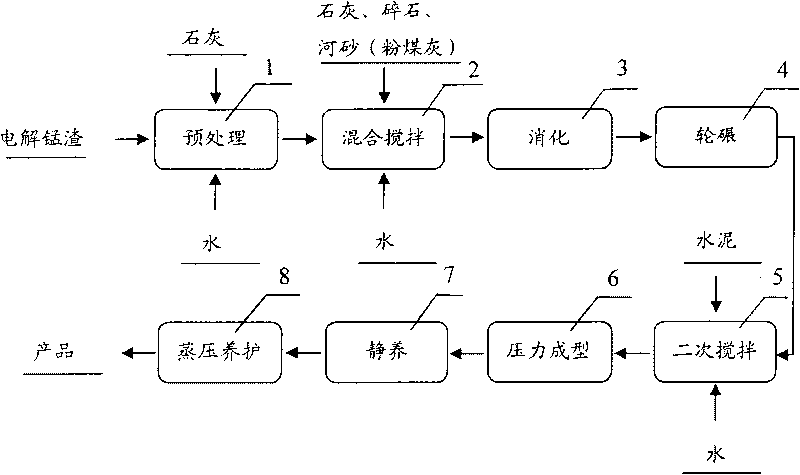

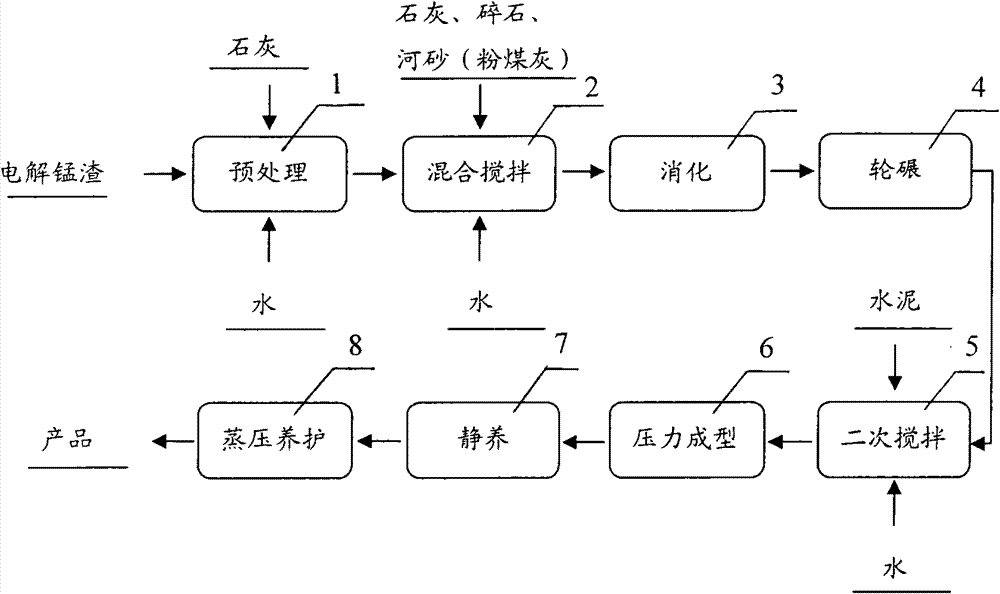

Preparation method of electrolytic manganese slag autoclaved brick

The invention provides a preparation method of an electrolytic manganese slag autoclaved brick. The method comprises the following steps: after preprocessing the electrolytic manganese slag, adding river sand (or fly ash), broken stone and lime in proportion; and stirring, assimilating, rolling, molding, standing, autoclaving and curing, and the like to obtain the electrolytic manganese slag autoclaved brick. The product meets the corresponding index requirements of Autoclaved Sand-lime Brick (GB11945-1999) or Fly Ash Brick (JC239-2001) for a first quality product with the strength level of more than 15MPa. The method has simple technology, high product quality, low production cost and good social, economic and environmental benefits.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Long shelf life fermented pickled vegetable and preparation method thereof

InactiveCN101518320AReasonable technologyThe process is simple and scientific and hygienicClimate change adaptationFruits/vegetable preservation using acidsSaline waterVegetable processing

The invention relates to long shelf life fermented pickled vegetable and a preparation method thereof, which belong to the technical field of picked fermented foods. The preparation method comprises the following steps: using tuber mustard as the raw material; slicing, picking, softening and then packaging the tuber mustard in a picked vegetable jar; filling ferment agent prepared by mixing 3-5 percent of Lact.Plantarum and Lact.Casei according to the proportion of 1:1 and salt water with 4-6 percent of salt content; fermenting for 48h under the temperature of 20-30 DEG C; ending the fermentation until the acidity of the fermented solution reaches 0.45-0.55 percent; dehydrating, seasoning and embrittlementing; packaging by using laminated film bags and sterilizing for 15min under the temperature of 70 DEG C. The preparation method basically keeps the fermented picked vegetable pure, tender and crisp, salubrious and tasty, the fermented picked vegetable has the basic characteristics of separating fat and stimulating the appetite, promoting the digestion, and the like, and can be kept for more than six months under the normal temperature. The invention can be popularized and applied to the vegetable processing industry.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES +1

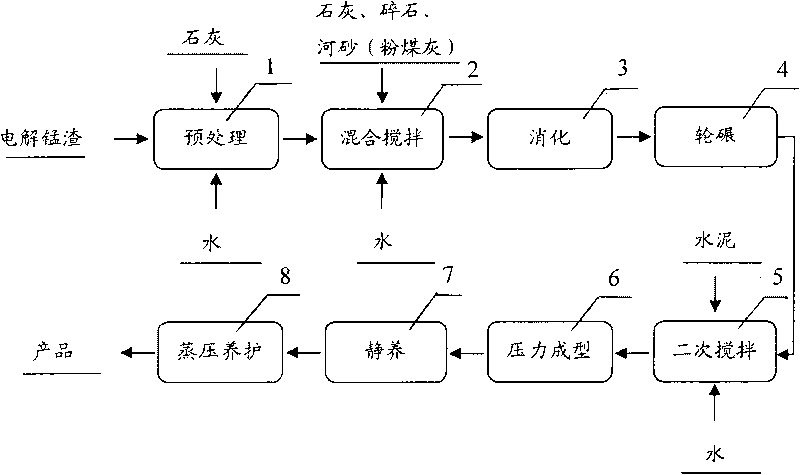

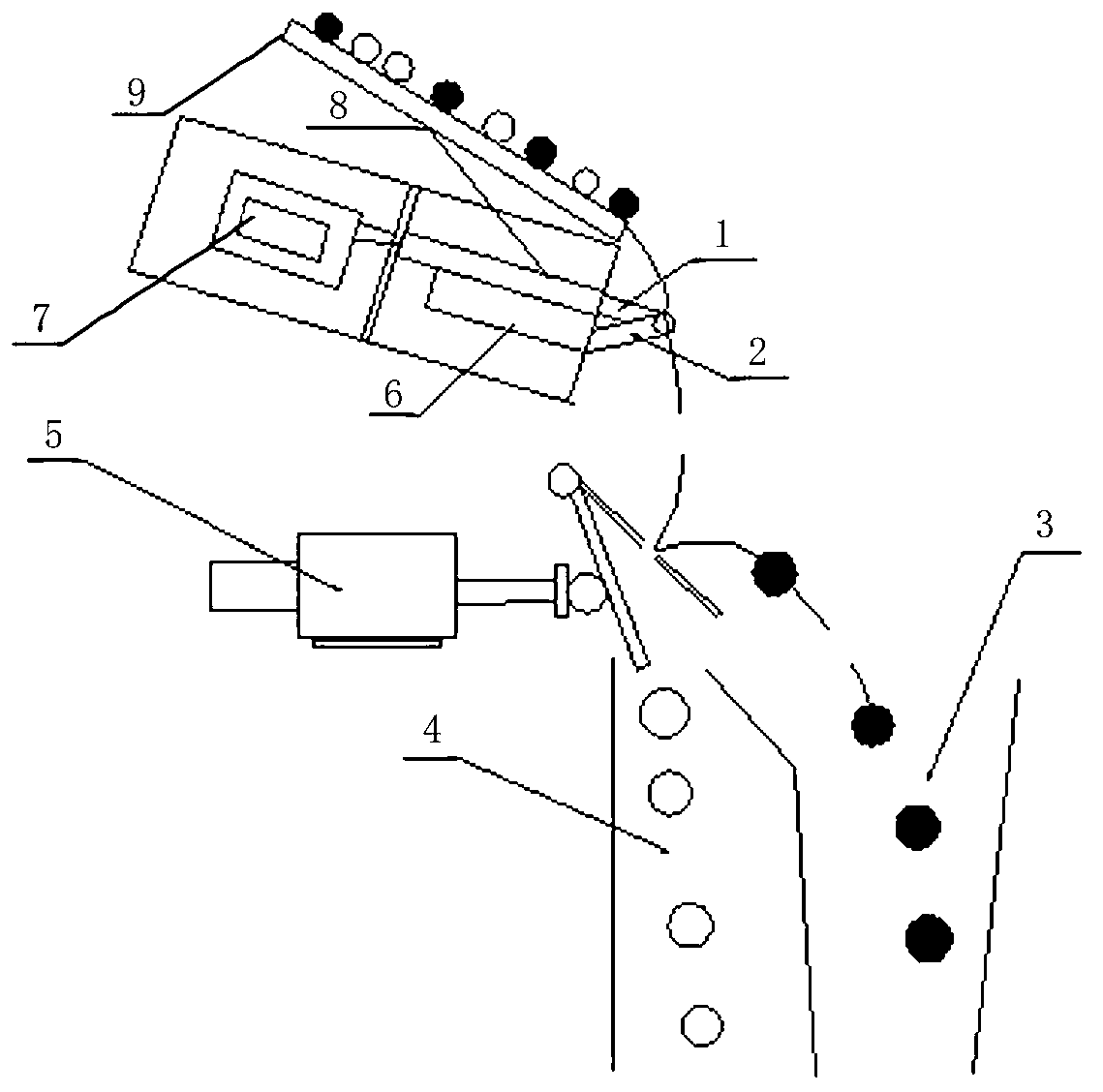

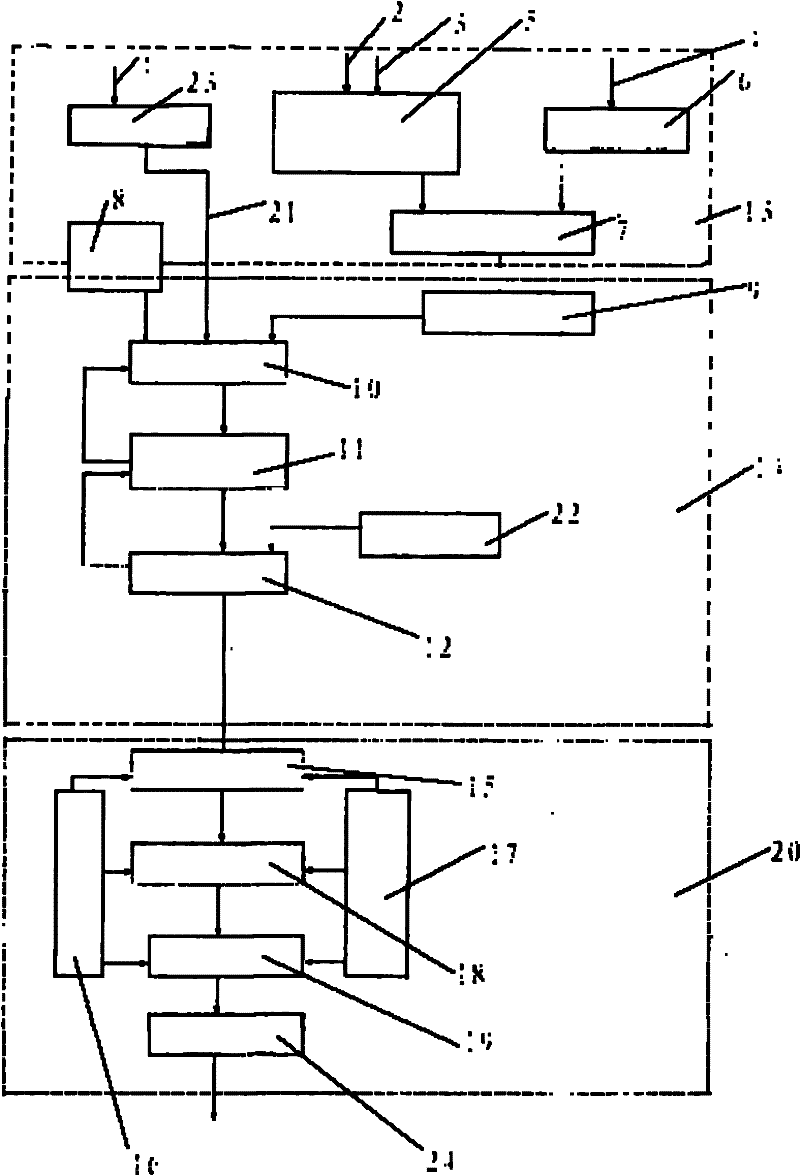

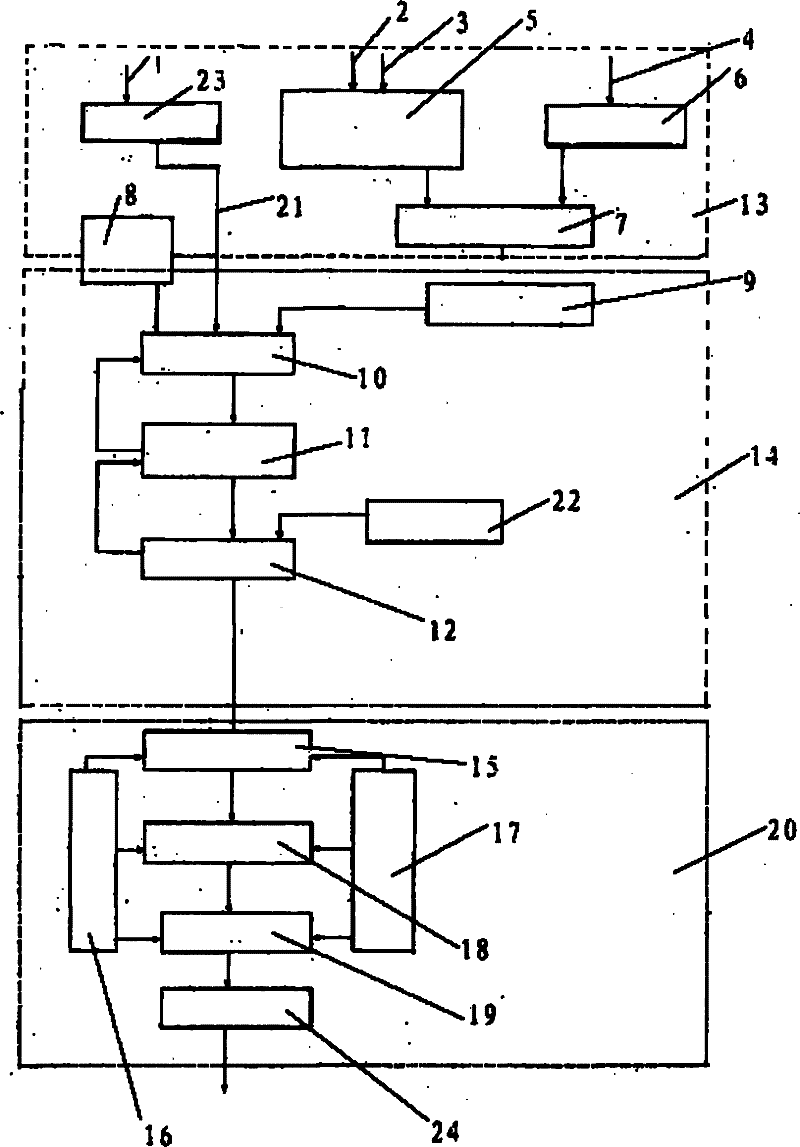

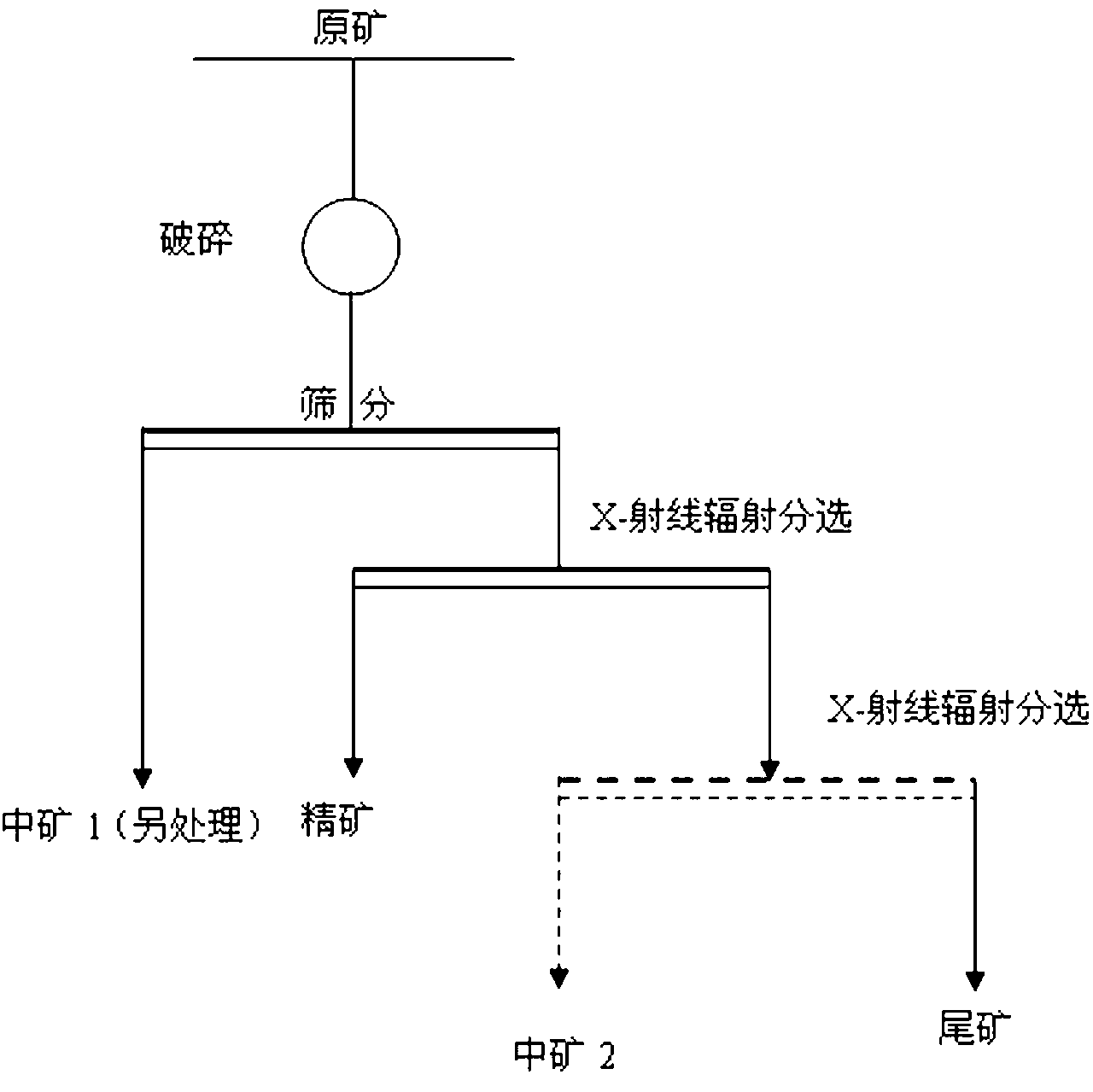

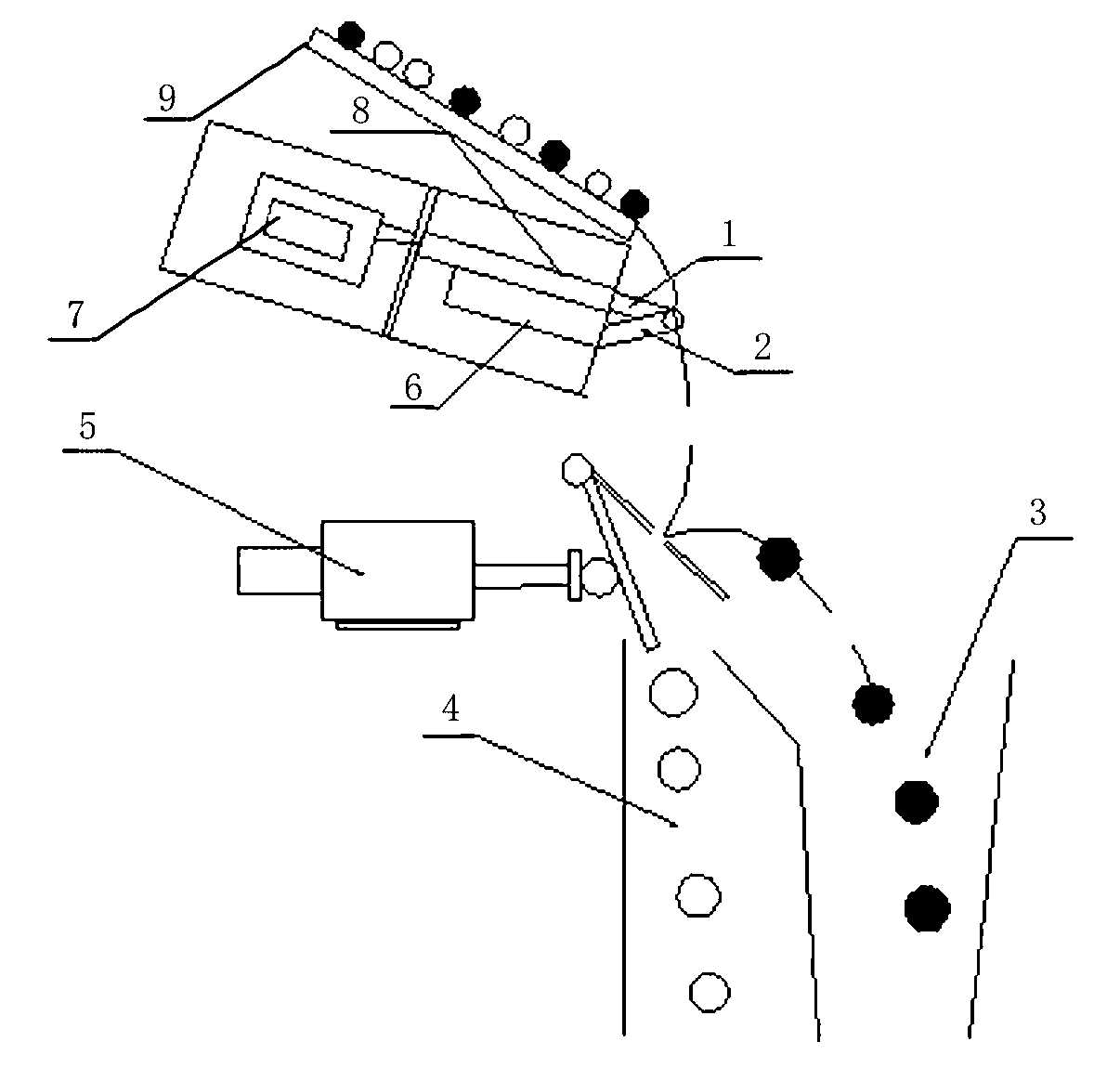

Method for sorting and pre-enriching lean hematite by using X-ray radiation

The invention relates to a method for sorting and pre-enriching lean hematite by using X-ray radiation. The invention belongs to the technical field of mineral processing. The method comprises the steps that: copper-containing ores are crushed to a size below 150mm by using a crusher; the crushed material is sieved by using a sieving machine with a mesh size greater than or equal to 20mm; on-sieve material is delivered to an X-ray radiation sorting machine through a feeder; a sorting threshold is set in the control system of the X-ray radiation sorting machine according to the iron content in crude ore; and after the sorting of the X-ray radiation sorting machine, concentrate and tailings are obtained. The method provided by the invention is domestically initiative. Target component grade of processed ore is low, mechanical and automation degrees are high, ore-sorting cost is saved, the grade of selected material iron of a concentrator is greatly improved, and equipment utilization rate is substantially improved. Also, the process provided by the invention has the advantages of reasonable technology and stable running. With the method, industrialization of lean hematite pre-sorting can be easily realized, and concentrator economic and technical indicators and comprehensive benefits can be greatly improved.

Owner:NORTHEASTERN UNIV

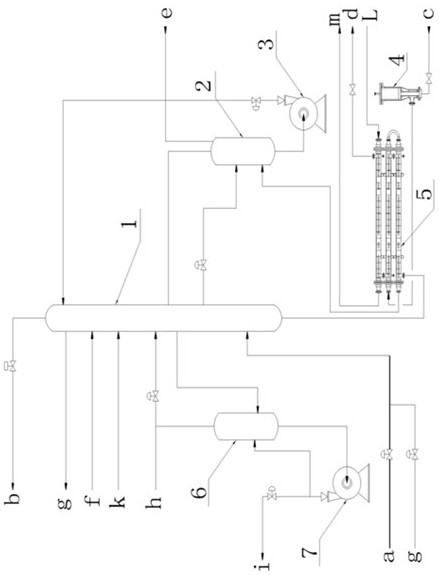

Process technology of method for preparing silane by using magnesium silicide

InactiveCN102205968AIdeal production technologyReasonable methodSilicon hydridesMolecular sieveSilanes

The invention discloses a process technology of a method for preparing silane by using magnesium silicide. In the method process for preparing the silane, a raw material preparation system, a silane gas preparation system and a molecular sieve adsorption purification silane liquefaction and vaporization system are mainly provided. The technology has a reasonable process, makes manufacture simple and is an ideal technology for silane preparation.

Owner:TIANJIN TAIHENG GASES

Method for separating pre-concentrated copper gold by adopting X-ray radiation

The invention belongs to the technical field of mineral processing and particularly relates to a method for separating pre-concentrated copper gold by adopting X-ray radiation. The method comprises the steps as follows: crushing the copper gold to be less than 150 mm through a crushing machine; sieving the crushed material by a sieving machine with the mesh size of not less than 20 mm; feeding the sieved material onto an X-ray radiation separating machine through a feeding machine; setting a separating threshold value according to the content of copper in original mineral in a control system of the X-ray radiation separating machine; separating by the X-ray radiation separating machine; and separating out gold mineral concomitant with copper mineral to obtain gold concentrate and tailings. The method is domestically initiated, the target component of the treated mineral is low in quality, the mechanical and automatic level is high, the mineral separation cost is saved, the quality of the separated gold is greatly improved, and the utilization rate of equipment is remarkably increased; and meanwhile, the process technology is reasonable, the operation is stable, the copper gold pre-selection industrialization is facilitated, and the economic technical index and the comprehensive benefit of dressing plants are greatly increased.

Owner:NORTHEASTERN UNIV

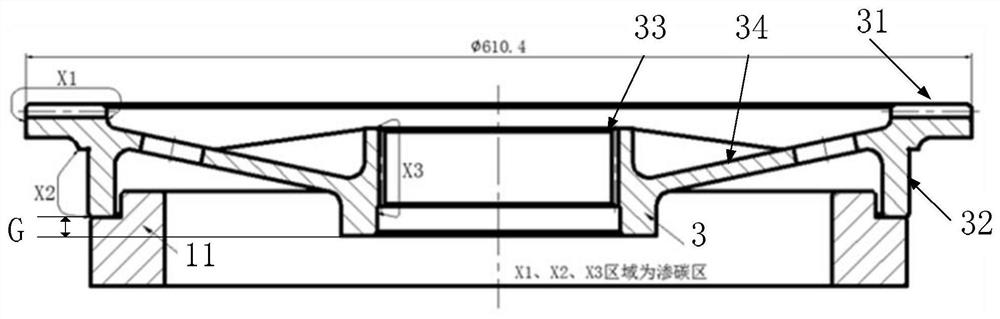

Method for preventing excessive seepage of 16Cr3NiWMoVNbE material narrow-tooth-shaped component tooth crest

ActiveCN105386043ANo over seepageEasy to useSolid state diffusion coatingSuperimposed coating processCopper platingThermal treatment

The invention relates to a method for preventing excessive seepage of a 16Cr3NiWMoVNbE material narrow-tooth-shaped component tooth crest. The traditional thermal treatment technology is changed, primary carburization is changed into secondary carburization, and after the primary carburization is ended, only a tooth crest copper plating layer area is reserved, and secondary carburization is carried out. By means of the technology, a carburization layer of the tooth crest of a component in the thermal treatment process is finally qualified, and the phenomenon of excessive seepage of the tooth crest cannot happen. The technology is reasonable, when the high and medium part of component teeth can meet the design requirement, the thickness of the carburization layer of the tooth crest can also meet the requirement, and normal usage of the component is guaranteed.

Owner:HARBIN DONGAN ENGINE GRP

Compound complexing calcium preparation for treating and nourishing bones for middle and old aged people and preparation method thereof

ActiveCN103656626AResolve the dual systemAchieve calcium absorptionOrganic active ingredientsPeptide/protein ingredientsBiotechnologyVitamin K2

The invention discloses a compound complexing calcium preparation for treating and nourishing bones for middle and old aged people and a preparation method thereof. The preparation is scientifically processed by a formula comprising deep sea fish bones, deep sea cuttle bones, biological calcium carbonate, tigris artifactus powder, collagen powder, vitamin K2, vitamin D, glucosamine, eucommia ulmoides, cordyceps sinensis, bovine coloctrum, magnesium, alpha-linolenic acid, xylitol and magnesium stearate. The formula of the invention is scientific in compatibility and reasonable in match of nutritional elements, and integrates the health-care effects of calcium supplement for bone-formation, calcium supplement for treating bones, calcium supplement for nourishing bones, calcium supplement for reinforcing bones, calcium supplement for improving the immunity and calcium supplement for enhancing the self-healing and rehabilitating capacity of the body. The preparation is remarkable in effect, high in clinical cure rate and excellent in contrast result with other calcium products clinically. The preparation is reasonable and feasible in process technology and is convenient to take by prilling and coating. The advanced, scientific and unique structure of the product is an advantage of the preparation.

Owner:王爱景 +1

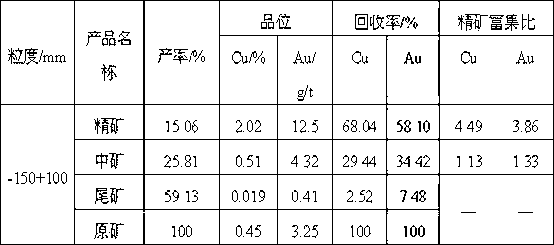

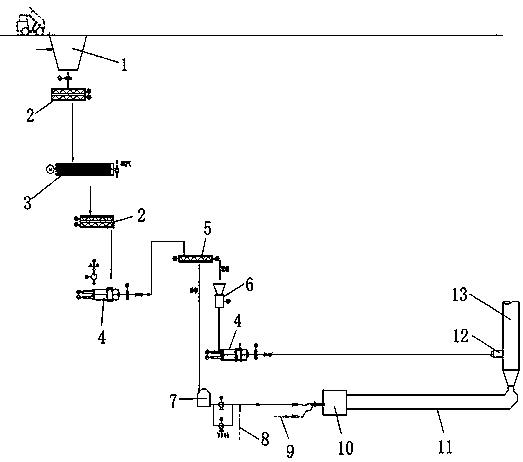

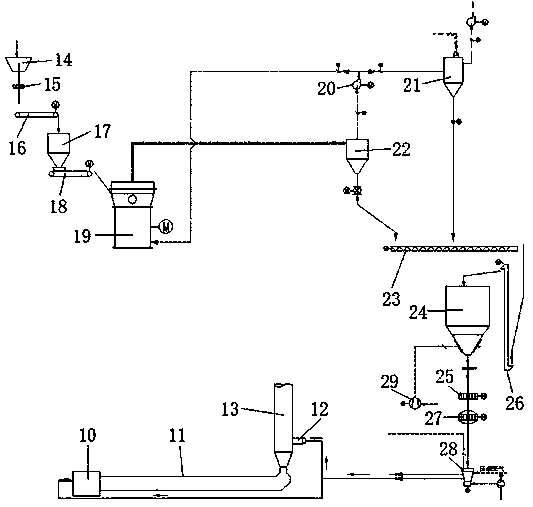

Pretreatment process for industrial hazardous wastes with cement kiln

ActiveCN109248900AGood environmental benefitsAdaptableSolid waste disposalDecompositionPre treatment

The invention provides a pretreatment process for industrial hazardous wastes with a cement kiln. The process comprises the following steps: (A) when the industrial hazardous waste is semi-solid sludge, (1) heating: the sludge enters a disc drying machine and is heated until the material can flow; (2) separation: a mud phase solid and an oil phase liquid are separated by a centrifuge; and (3) grinding into the kiln: the mud phase solid is broken to the raw material fineness and transported to a decomposition furnace; and the oil phase liquid is used as an alternative fuel and then transportedto the cement kiln for calcining cement; and (B) when the industrial hazardous waste is solid: (1) Raymond mill classified grinding: a Raymond mill is used for respectively grinding solid waste with heat value and the solid waste without the heat value; (2) metering; and (3) kiln feeding: the solid waste with the heat value is used as the alternative fuel and transported to the cement kiln for calcining cement; and the solid waste without the heat value is sent to the decomposition furnace as a raw material for cement. The process can save energy and reduce emission, and reduce energy waste.

Owner:自贡金龙水泥有限公司

Method for solving problem of excessive seepage of 18CrNi4A material narrow-tooth-shaped component tooth crest

ActiveCN105386044AReasonable technologyGuaranteed normal use requirementsSolid state diffusion coatingSuperimposed coating processCopper platingHeat treated

The invention relates to a method for solving the problem of excessive seepage of an 18CrNi4A material narrow-tooth-shaped component tooth crest. The traditional thermal treatment technology is changed, primary carburization is changed into secondary carburization, the measure that before primary carburization, a copper plating protection area extends to the two side tooth face parts connected with the tooth crest from the tooth rest is taken, finally, a carburization layer of the tooth crest of the component in the thermal treatment process is qualified, and the phenomenon of excessive seepage of the tooth crest cannot happen. The technology is reasonable, an ideal effect is achieved, and the normal usage requirement for the component is guaranteed.

Owner:HARBIN DONGAN ENGINE GRP

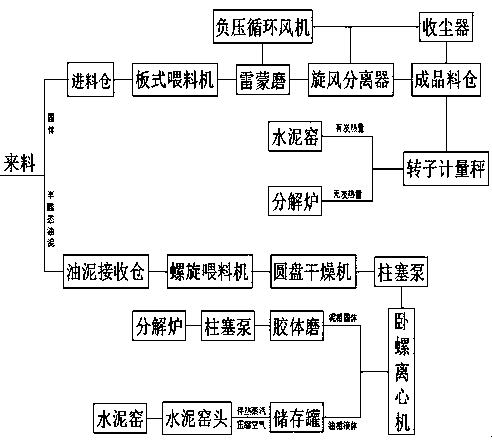

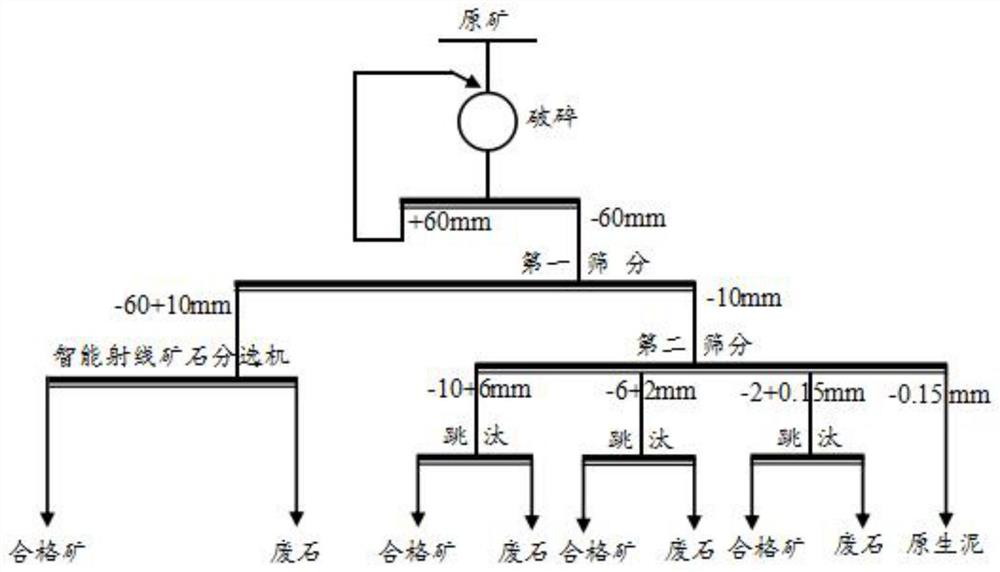

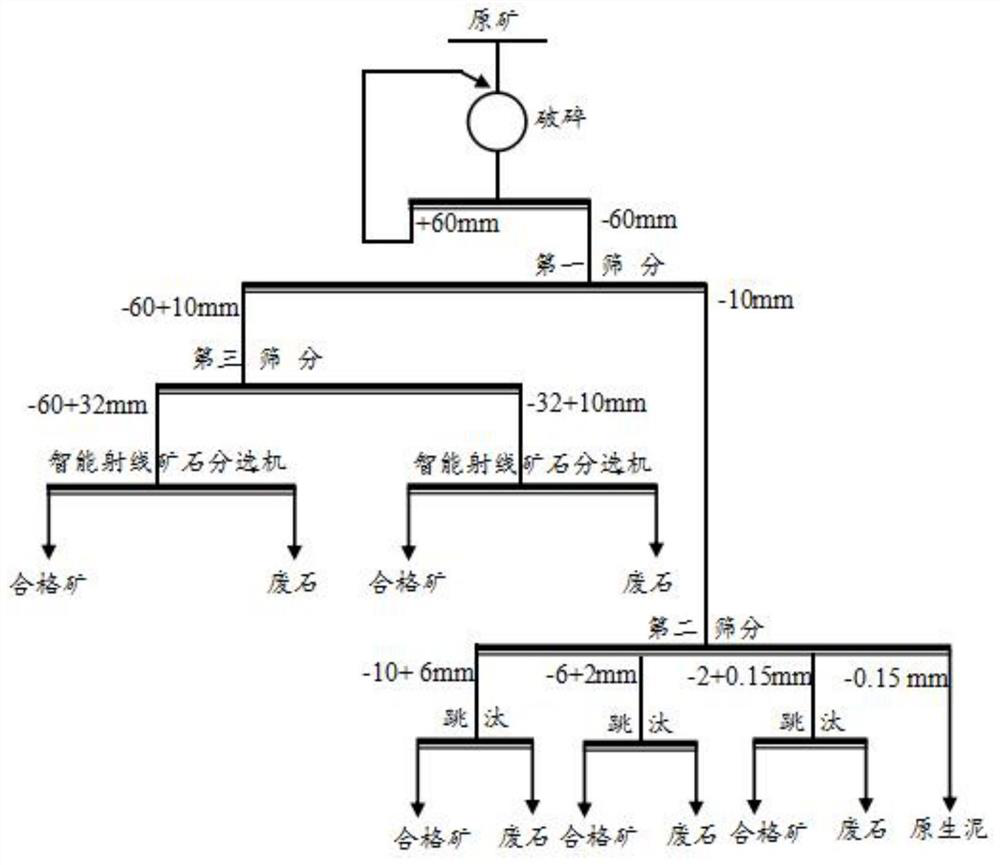

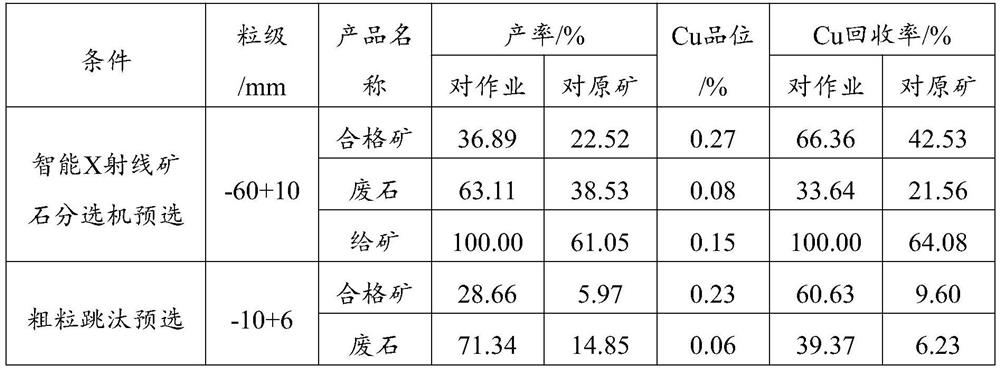

Pre-separation and waste-discarding beneficiation method for low-grade copper sulphide ores

InactiveCN112264181AAchieve pre-separationSave capacityWet separationCopper sulfideMaterials science

The invention relates to the technical field of beneficiation, and provides a pre-separation and waste-discarding beneficiation method for low-grade copper sulphide ores. According to the method, low-grade copper sulfide ores are screened into -60+10 mm, -10+6 mm, -6+2 mm, -2+0.15 mm and -0.15 mm ores through crushing and repeated screening, the -0.15 mm ores are regarded as primary slime and aredirectly used as qualified ores, the -2+0.15 mm, -6+2 mm and -10+6 mm ores are subjected to pre-separation and waste discarding through jigging, and the -60+10 mm ores are subjected to pre-separationand waste discarding through intelligent ray ore separation, and the copper grade of the finally obtained qualified ores is 0.27% or above. According to the provided method, pre-separation of the copper sulphide ore and a large amount of barren rock is realized, the copper grade of the selected ores is improved, the amount of ores entering a concentrating mill for grinding and separation is reduced, operation is stable, the cost is low and industrial production is realized easy.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

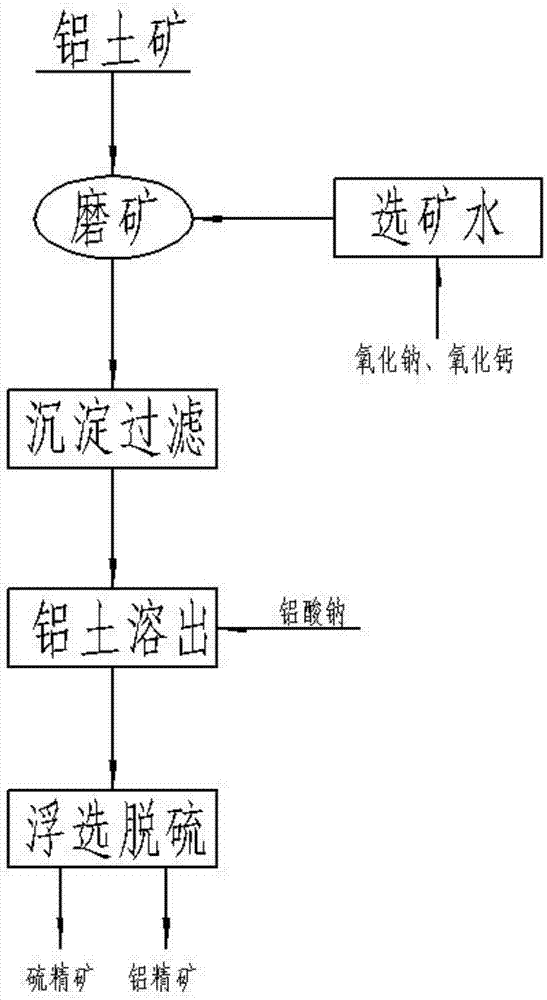

Method for ore dressing of bauxite

InactiveCN103691551ASolve cumulative problemsEnsure safetyWet separationSulfate radicalsMining engineering

The invention relates to an ore dressing method, in particular to a method for ore dressing of bauxite. The method for ore dressing of bauxite comprises the steps of ore grinding and flotation desulfurization. The method is characterized in that the treatment process comprises ore grinding, sediment filtering, bauxite dissolving out and flotation desulfurization; and ore is subject to grinding and synchronously subject to washing. The method guarantees safety of an industrial production flotation desulfurization device and can also effectively solve the problem of accumulation of sulfate radical in a system, good flotation desulfurization process technical indexes can be achieved, the method is suitable for any high-sulfur bauxite and particularly suitable for acidifying the high-sulfur bauxite, the environmental influence of the process is small, and the application prospect is optimistic.

Owner:GUANGXI KESHENGDA MACHINERY MFG

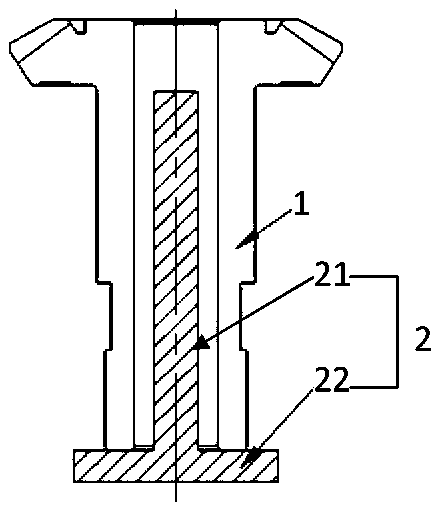

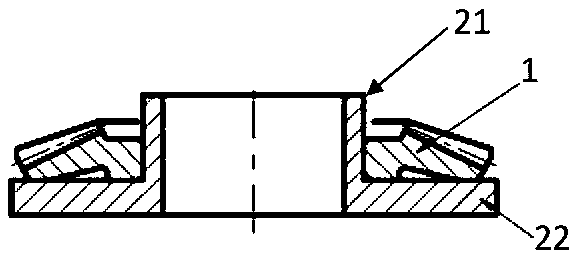

Heat treatment deformation control method of spiral bevel gear

ActiveCN111057832AReasonable technologyRealization of quenching deformation controlFurnace typesHeat treatment furnacesDeformation controlBevel gear

The invention discloses a heat treatment deformation control method of a spiral bevel gear. A quenching die is designed to reasonably distribute a cooling oil path, an expansion ring die is located above a central hole of a rod part and applies pressure to the top of the central hole of the rod part, and quenching deformation control of the outer circle of the rod part and a tooth part is realized.

Owner:ZHONGNAN TRANSMISSION MACHINERY FACTORY CHANGSHAAVIATION IND

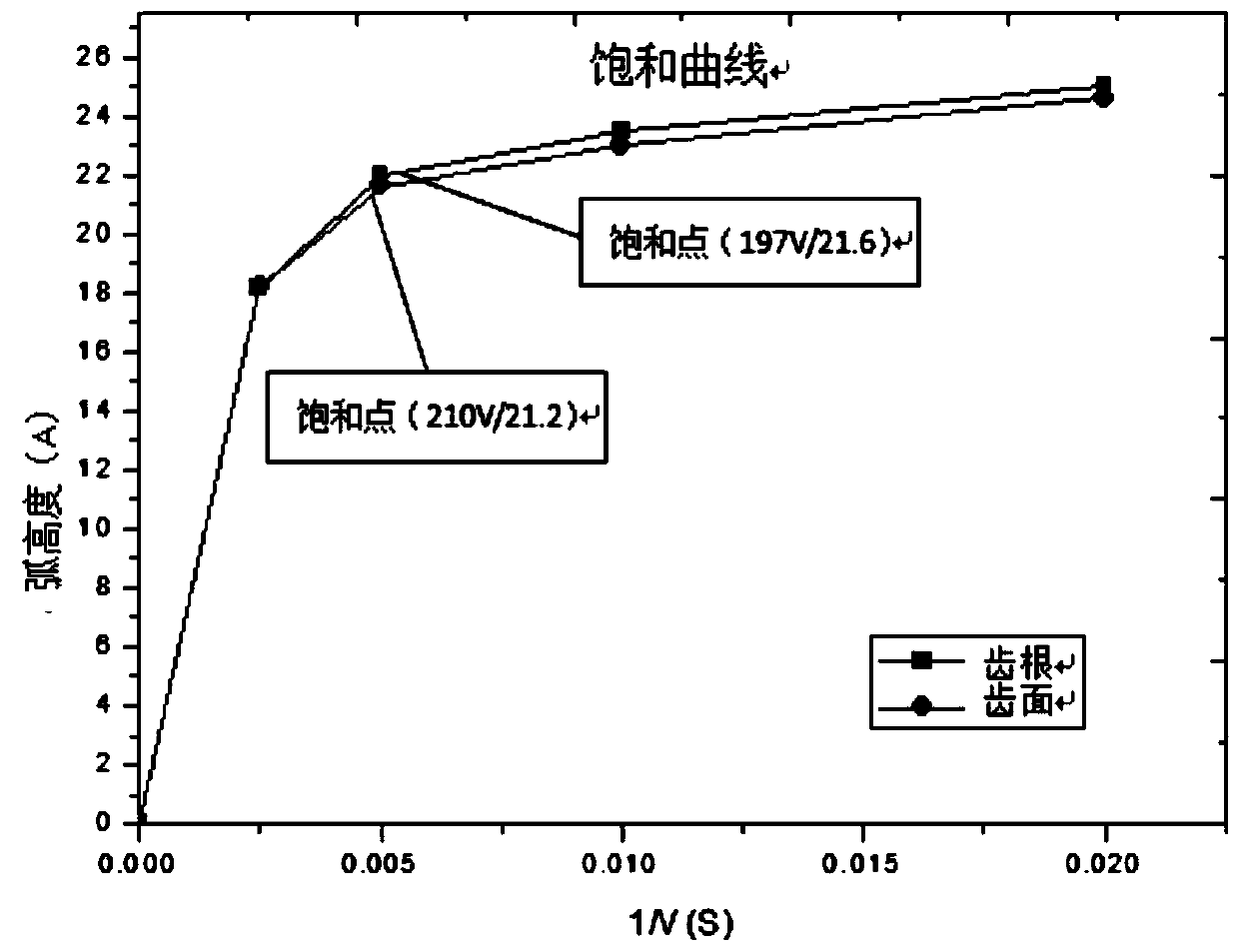

Tooth-surface shot-blasting strengthening method for spiral bevel gear

The invention discloses a tooth-surface shot-blasting strengthening method for a spiral bevel gear. The tooth-surface shot-blasting strengthening method for the spiral bevel gear comprises the following steps that the spiral bevel gear is pre-treated to remove surface impurities; a test piece is used for simulating a shot-blasting test, so that the camber height value of the test piece is obtainedto determine a shot-blasting strength value; a non-shot-blasted area of the spiral bevel gear is protected through a protection device; primary shot-blasting is conducted on the tooth surface of thespiral bevel gear, wherein during primary shot-blasting, the air pressure is 2.5+ / -0.25Bar; secondary shot-blasting is conducted on the tooth surface of the spiral bevel gear, wherein during secondaryshot-blasting, the air pressure is 1.3+ / -0.25Bar; and the protection device is removed, and the spiral bevel gear is cleaned. According to the tooth-surface shot-blasting strengthening method for thespiral bevel gear, after two times of shot-blasting, the roughness of the tooth surface meets requirements.

Owner:ZHONGNAN TRANSMISSION MACHINERY FACTORY CHANGSHAAVIATION IND

Method of recycling low-concentration nitric acid solution in calcium carbide furnace tail gas to ethylene glycol process

ActiveCN109456197ASolve recycling difficultiesReduce contentChemical industryNitrous acid preparation ester preparationDimethyl oxalateEthylene glycol

The invention relates to a method of recycling low-concentration nitric acid solution in calcium carbide furnace tail gas to ethylene glycol process. NO in cyclic gas a from an outlet of a cycle compressor of a DMO (dimethyl oxalate) synthesis system reacts with methanol and nitric acid in low-concentration nitric acid solution c from an MN (methyl nitrite) regeneration unit under the action of methanol steam tracing through a low-concentration nitric acid waste liquid recycling system so as to generate methyl nitrite and water. The problem is solved that dilute nitric acid from side reactionin methyl nitrite regeneration is difficult to recycle; the content of nitric acid in methyl nitrite is effectively reduced. The method has the advantages of high recycle rate of nitric acid, good economy and reasonableness, good technical feasibility and the like.

Owner:XINJIANG TIANZHI CHENYE CHEM +1

Heat treatment method for controlling hardness and deformation of low-carbon alloy steel gear

InactiveCN110846472AReasonable technologySolve the problem of machine plus difficultySolid state diffusion coatingFurnace typesCarbon alloyCarburizing

The invention discloses a heat treatment method for controlling hardness and deformation of a low-carbon alloy steel gear. The heat treatment method comprises the following steps that a low-carbon alloy steel gear part is pretreated; the pretreated low-carbon alloy steel gear part is subjected to carburizing treatment; the carburized low-carbon alloy steel gear part is firstly placed at the temperature of 650 + / -10 DEG C for first tempering treatment and then placed at the temperature of 630 + / -10 DEG C for second tempering treatment; a carburized layer of the tempered low-carbon alloy steel gear part is removed according to preset requirements, and the tempered low-carbon alloy steel gear part is placed at the temperature of 810 + / -10 DEG C for quenching treatment; and the quenched low-carbon alloy steel gear part is sequentially subjected to cold treatment, tempering treatment and post-treatment. The heat treatment method has the advantages that the hardness of the part after carburizing and before quenching is low, and the thermal deformation of the part after quenching is small.

Owner:ZHONGNAN TRANSMISSION MACHINERY FACTORY CHANGSHAAVIATION IND

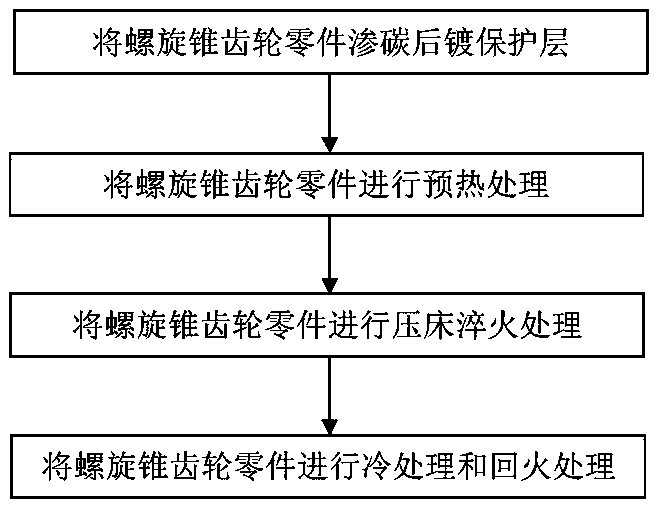

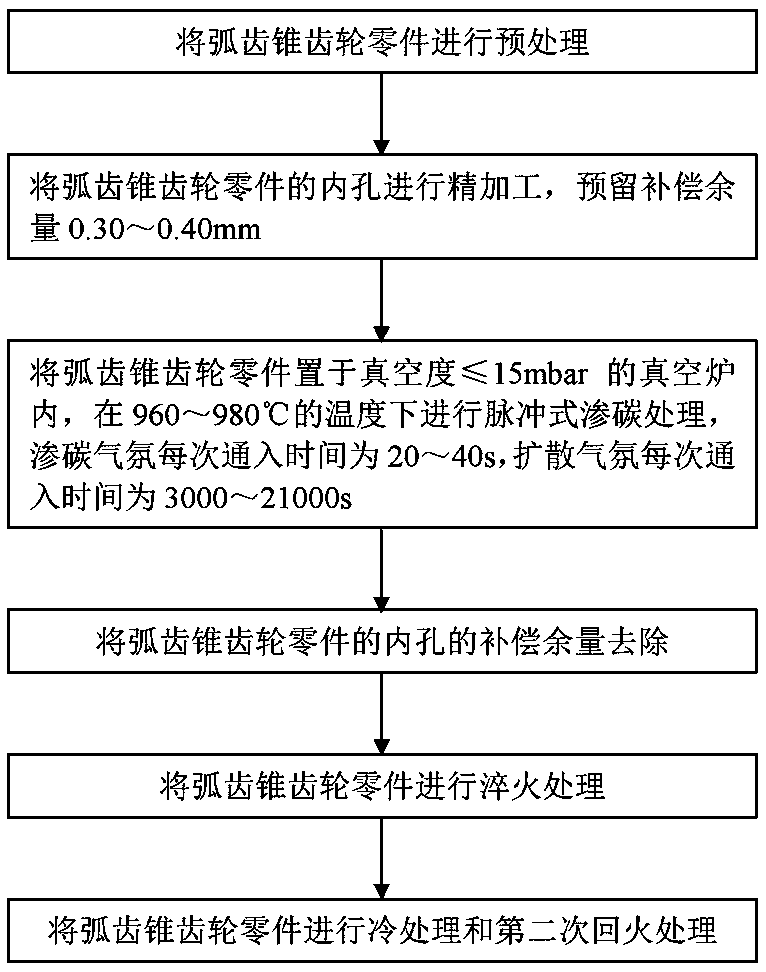

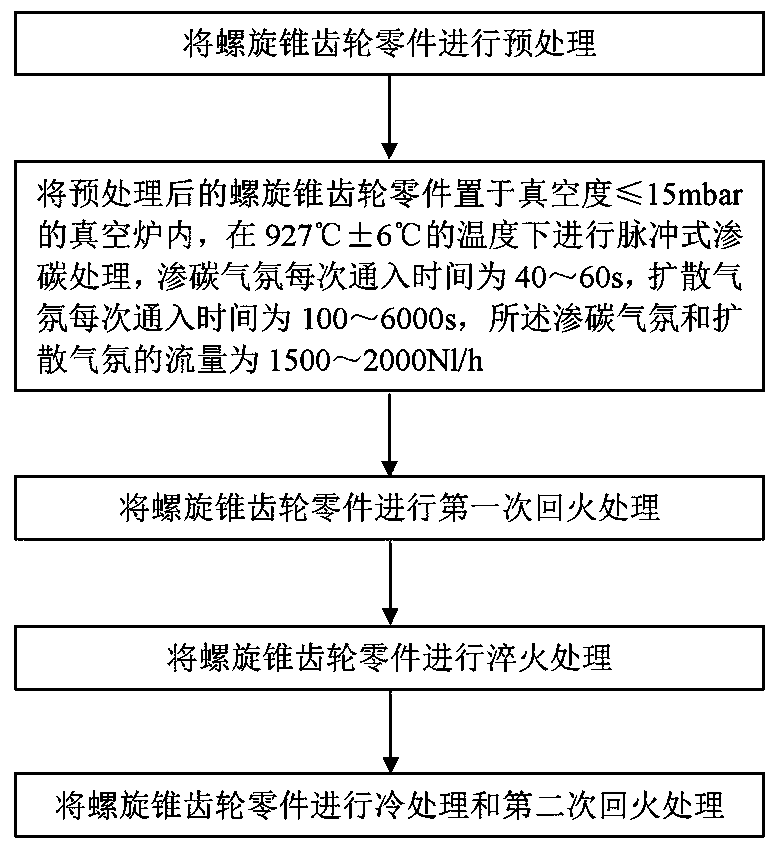

Carburization heat treatment control method for Spiral bevel gear

ActiveCN111020457AControl depthControl quenching deformationSolid state diffusion coatingFurnace typesTemperingCarburizing

The invention discloses a carburization heat treatment control method for a spiral bevel gear. The carburization heat treatment control method includes the following steps that pretreatment is conducted on the spiral bevel gear part; finish machining is conducted on an inner hole of the spiral bevel gear part, and the compensation allowance of 0.30 mm-0.40 mm is reserved; the spiral bevel gear isput into a vacuum furnace with the vacuum degree being smaller than or equal to 15 mbar, impulse type carburization treatment is conducted under the temperature of 960 DEG C to 980 DEG C, the chargingtime of the carburization atmosphere of each time is 20 s to 40 s, and the charging time of the diffusion atmosphere of each time is 3000 s to 21000 s; first-time tempering treatment is conducted onthe spiral bevel gear part; the compensation allowance of the inner hole of the spiral bevel gear part is removed; and quenching treatment, cold treatment and second-time tempering treatment are conducted on the spiral bevel gear part. By means of the carburization heat treatment control method for the spiral bevel gear, different carburization layer depth requirements and deformation requirementsexist for different parts of the spiral bevel gear.

Owner:ZHONGNAN TRANSMISSION MACHINERY FACTORY CHANGSHAAVIATION IND

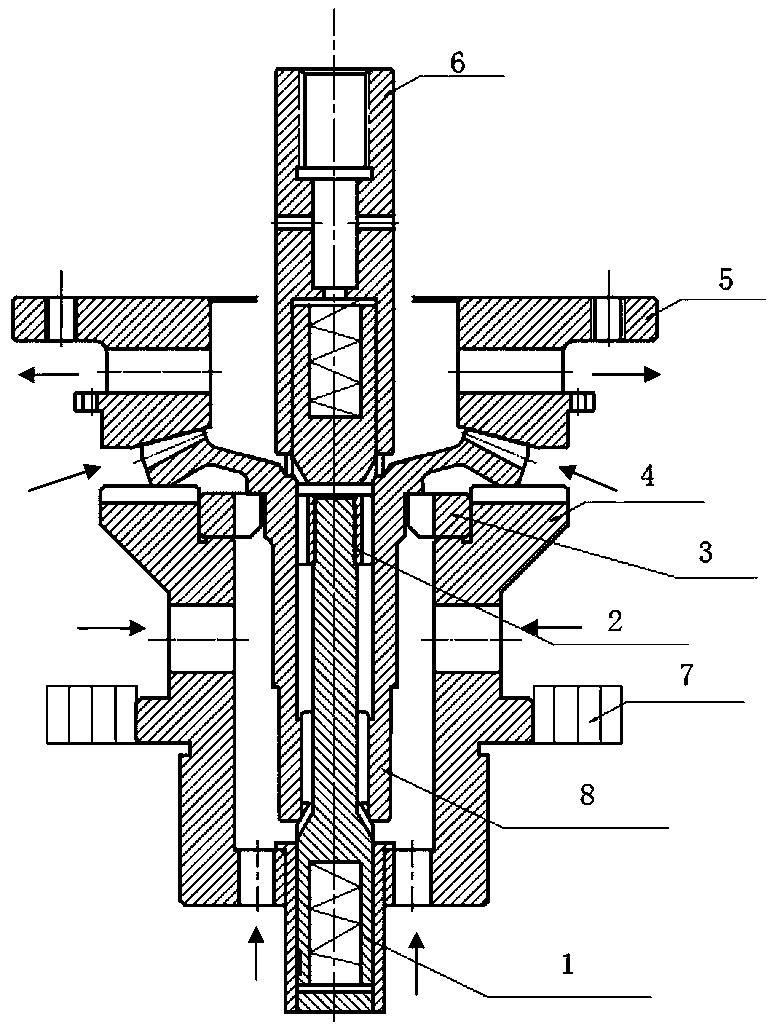

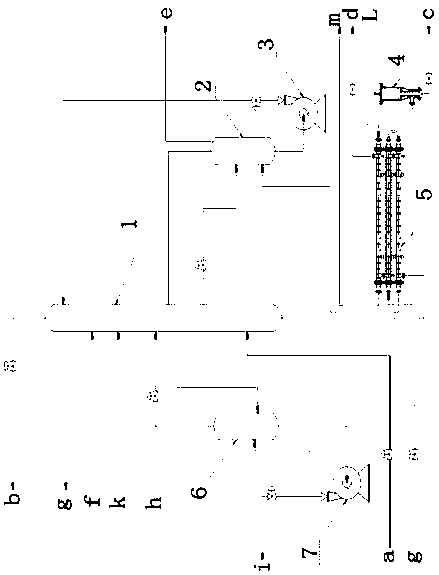

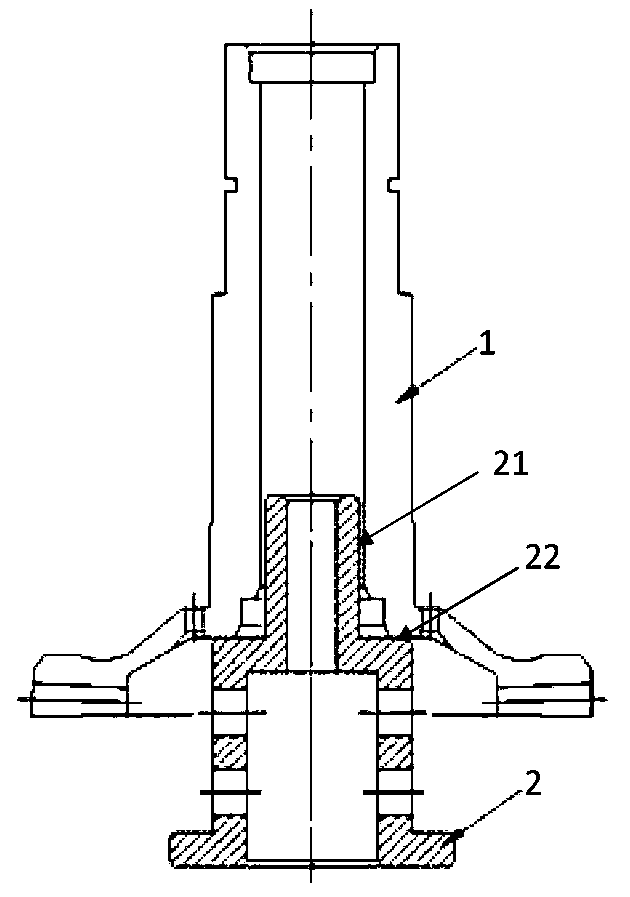

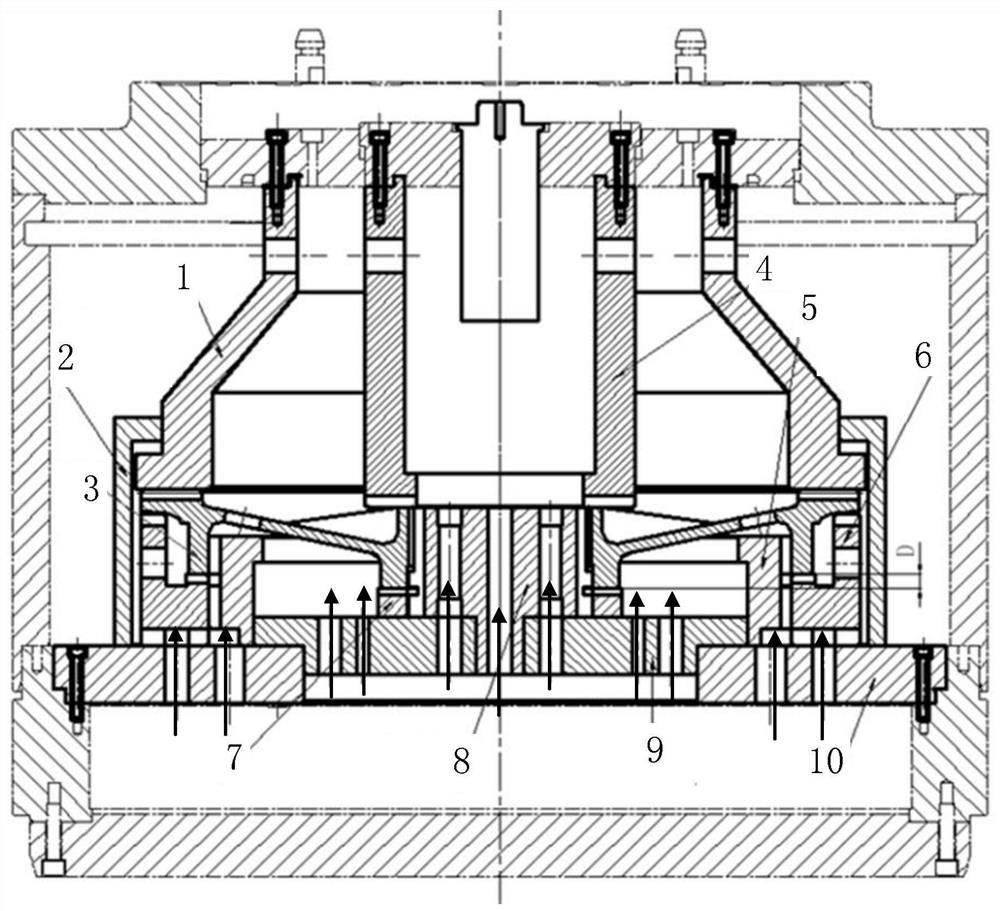

Combined quenching die for deformation control of long web large face gear and heat treatment method

PendingCN112779393AReasonable technologySolve the problem of large heat treatment deformationSolid state diffusion coatingFurnace typesPhysicsHeat treating

The invention discloses a combined quenching die for deformation control of a long web large face gear. The combined quenching die comprises an upper die and a lower die, wherein the upper die comprises an outer pressure ring and an inner pressure ring, the outer pressure ring is used for applying pressure to a tooth part of a face gear part, the inner pressure ring is used for applying pressure to a spline end face of the part, the lower die comprises a base, and a lower supporting ring, a large supporting pad, a small supporting pad and a positioning mandrel, wherein the lower supporting ring, a large supporting pad, a small supporting pad and a positioning mandrel are positioned on the base, the lower supporting ring is located between the base and a web of the part and used for supporting the web, the large supporting pad comprises an inner supporting platform and an outer supporting platform, the outer supporting platform is used for supporting the tooth part of the part, the inner supporting platform is used for supporting a supporting part of the part, and the small supporting pad is located between the part lower end journal part and the base and used for supporting the part lower end journal part. According to the combined quenching die for the deformation control of the long web large face gear and the heat treatment method, the quenching deformation can be effectively controlled.

Owner:ZHONGNAN TRANSMISSION MACHINERY FACTORY CHANGSHAAVIATION IND

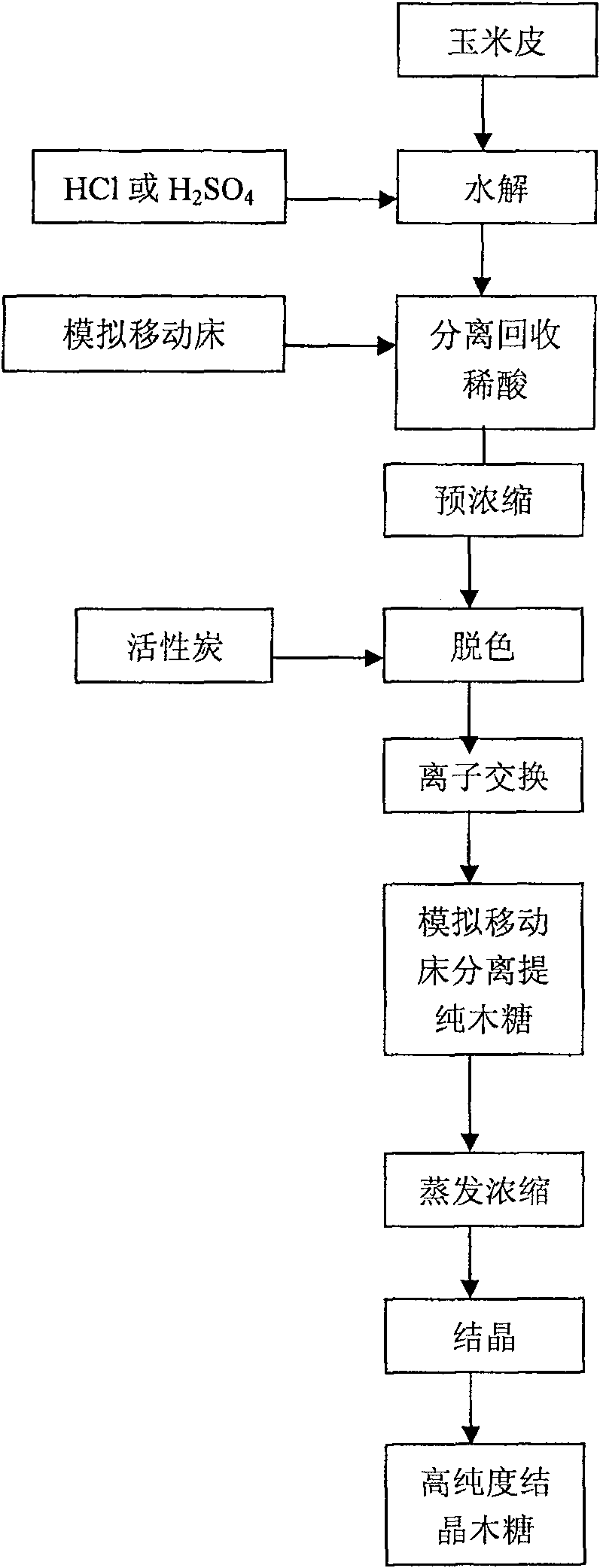

Method for producing high-purity crystallized xylose by hydrolyzing corn skin

InactiveCN100577674CReasonable technologyAvoid it happening againSugar derivativesSugar derivatives preparationIon exchangeSimulated moving bed

A process for preparing high-purity xylose crystal by hydrolyzing corn peel includes such steps as boiling hydrolyzing with sulfuric acid or hydrochloric acid at 105-125 deg.C, separating and recovering the sulfuric acid or hydrochloric acid from the hydrolyte by analog moving-bed, decoloring, refining by ion exchange, purifying by analog moving-bed, and crystallizing in thee-effect evaporator.

Owner:SHANDONG LUZHOU FOOD GROUP

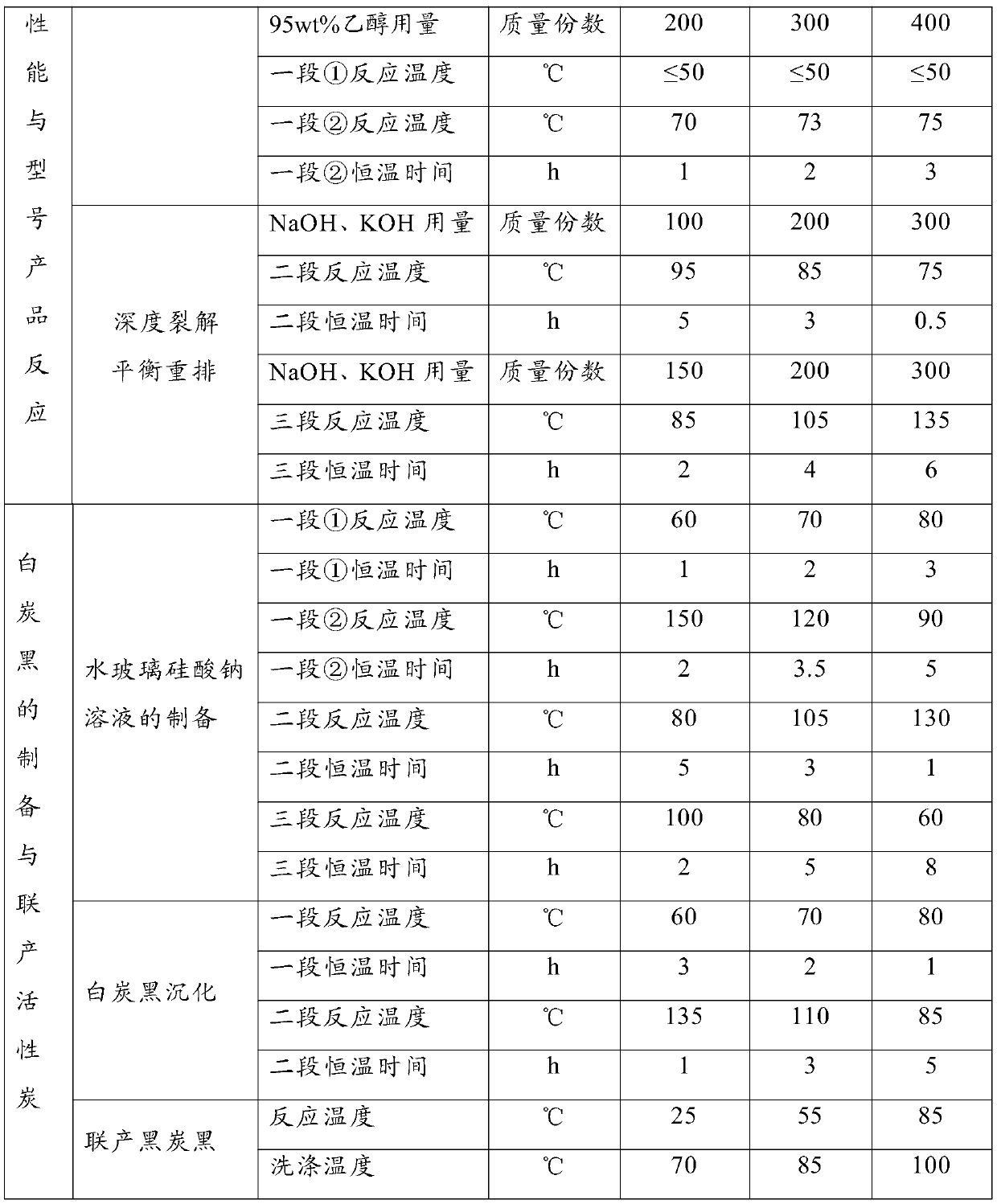

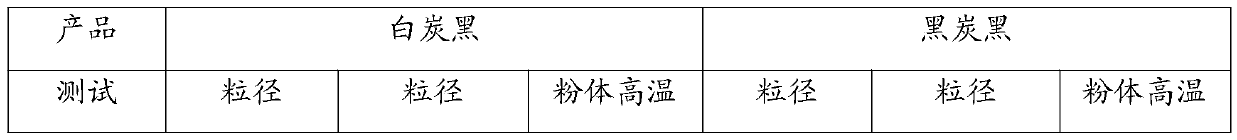

Treatment process for preparing new material by utilizing recycled renewable energy

ActiveCN109911904AAchieve recyclingRealize rational treatment and disposalPigmenting treatmentSilicaHaze pollutionCalcination

The invention discloses a treatment process for preparing a new material by utilizing recycled renewable energy. The treatment process comprises the following steps: taking various plant wastes as rawmaterials to obtain ash through incineration and calcination; hydrolyzing organic silicon monomers as a raw material to obtain an acidic liquid and an acidic colloid, wherein the liquid is used for washing and neutralizing gas, solid colloid blocks or colloid generated in an absorption process, and then a light yellow liquid is obtained by catalysis, cracking and rearrangement; carrying out catalysis on the ash, and then carrying out procedures such as filtering, acid precipitation, water washing, drying and grinding to obtain a product white carbon black; performing procedures such as acid neutralization, water washing, drying and grinding on filter residues to obtain black carbon black; and recycling a neutralized liquid through procedures of crystallization, recrystallization and the like to obtain various salts. According to the treatment process, the purposes of reasonable recycling of waste resources and multi-treatment of three wastes are achieved, a novel high-molecular material with high added value and excellent performance is produced, useful substances are co-produced, haze pollution can be effectively relieved, and an environment-friendly green process standard is achieved.

Owner:高 铭鸿

Heat treatment method for 18CrNi4A steel spiral bevel gear

PendingCN113430484ACarburizing Depth ControlGuaranteed Performance RequirementsSolid state diffusion coatingFurnace typesTemperingCopper plating

The invention discloses a heat treatment method for an 18CrNi4A steel spiral bevel gear. The heat treatment method comprises the following steps that (1) copper plating protection is carried out on parts, except a tooth part, of a workpiece; (2) first carburizing treatment is carried out on the workpiece; (3) copper is removed from the whole workpiece, and then copper plating protection is carried out on other parts of the workpiece except the tooth part and the outer circle; (4) the workpiece is subjected to second carburizing treatment; and (5) quenching is carried out on the workpiece, then subzero treatment is carried out on the workpiece, and then tempering treatment is carried out. According to the method, the process control problem of different carburizing depths of different parts in the prior art is solved, the problem of low precision of two-time carburizing depth control is solved, a two-time carburizing superposition technology is adopted, and quenching-subzero treatment-tempering treatment is performed after carburizing, so that different requirements of different parts of the workpiece on the carburizing depths can be met, the carburizing depth of each part can be accurately controlled, and the performance requirement of the carburized workpiece can be ensured.

Owner:ZHONGNAN TRANSMISSION MACHINERY FACTORY CHANGSHAAVIATION IND

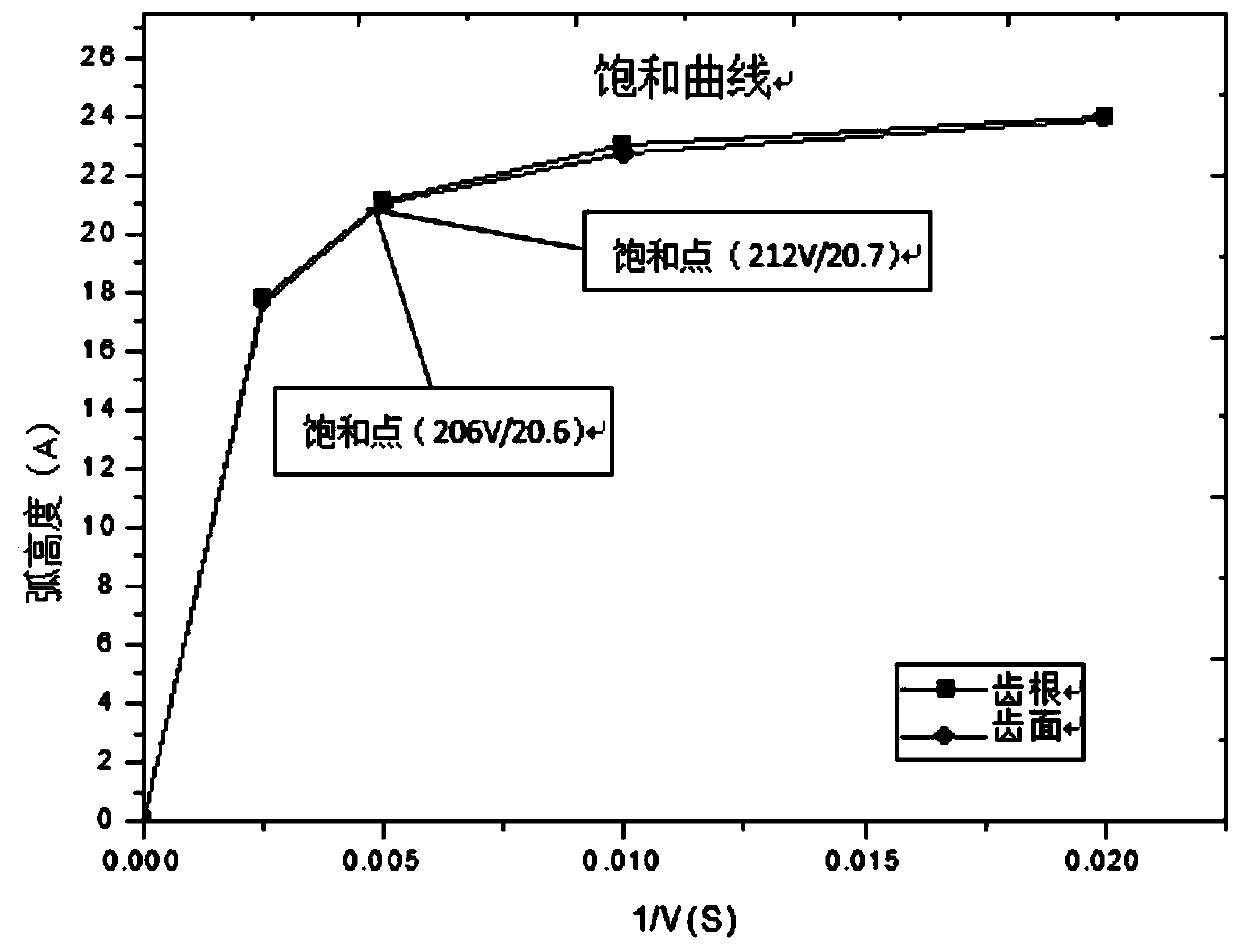

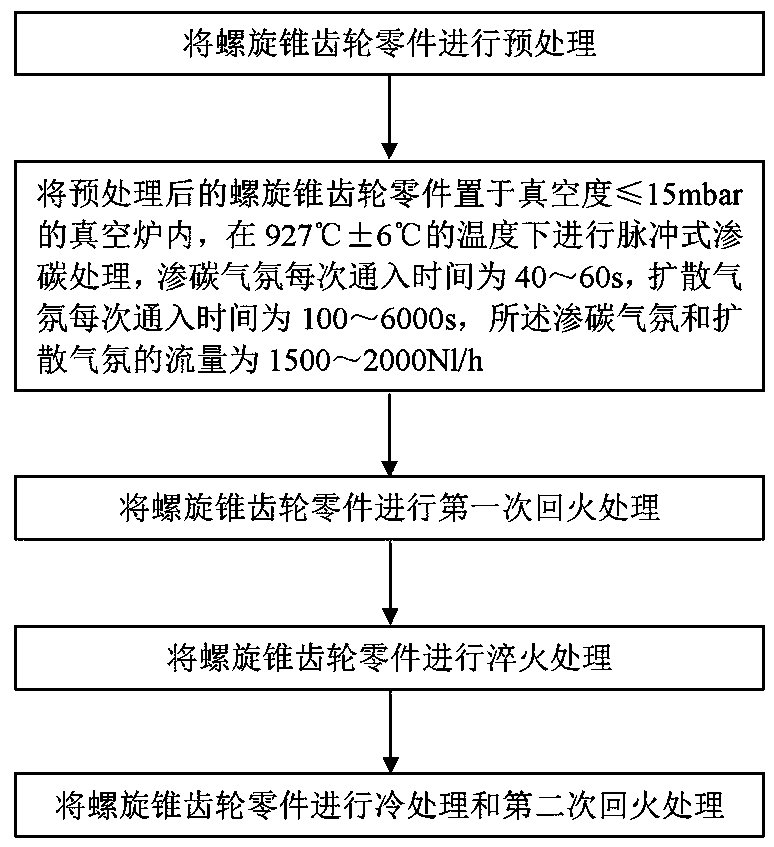

Carburizing method of 9310 steel spiral bevel gear

ActiveCN110699632AReasonable technologyCarburizing Depth ControlSolid state diffusion coatingFurnace typesCold treatmentTempering

The invention discloses a carburizing method of a 9310 steel spiral bevel gear. The method includes the following steps of performing pretreatment on a spiral bevel gear part; putting the spiral bevelgear part in a vacuum furnace with the vacuum degree smaller than or equal to 15 mbar for pulse type carburizing treatment at the temperature of 927 DEG C, wherein the time of each time of introducing of the carburizing atmosphere is 40-60 seconds, the time of each time of introducing of the diffusing atmosphere is 100-6000 seconds, and the flow of the carburizing atmosphere and the diffusing atmosphere is 1500-2000 Nl / h; performing primary tempering treatment on the spiral bevel gear part; performing quenching treatment on the spiral bevel gear part; and performing cold treatment and secondary tempering treatment on the spiral bevel gear part. The carburizing depth can be precisely controlled.

Owner:ZHONGNAN TRANSMISSION MACHINERY FACTORY CHANGSHAAVIATION IND

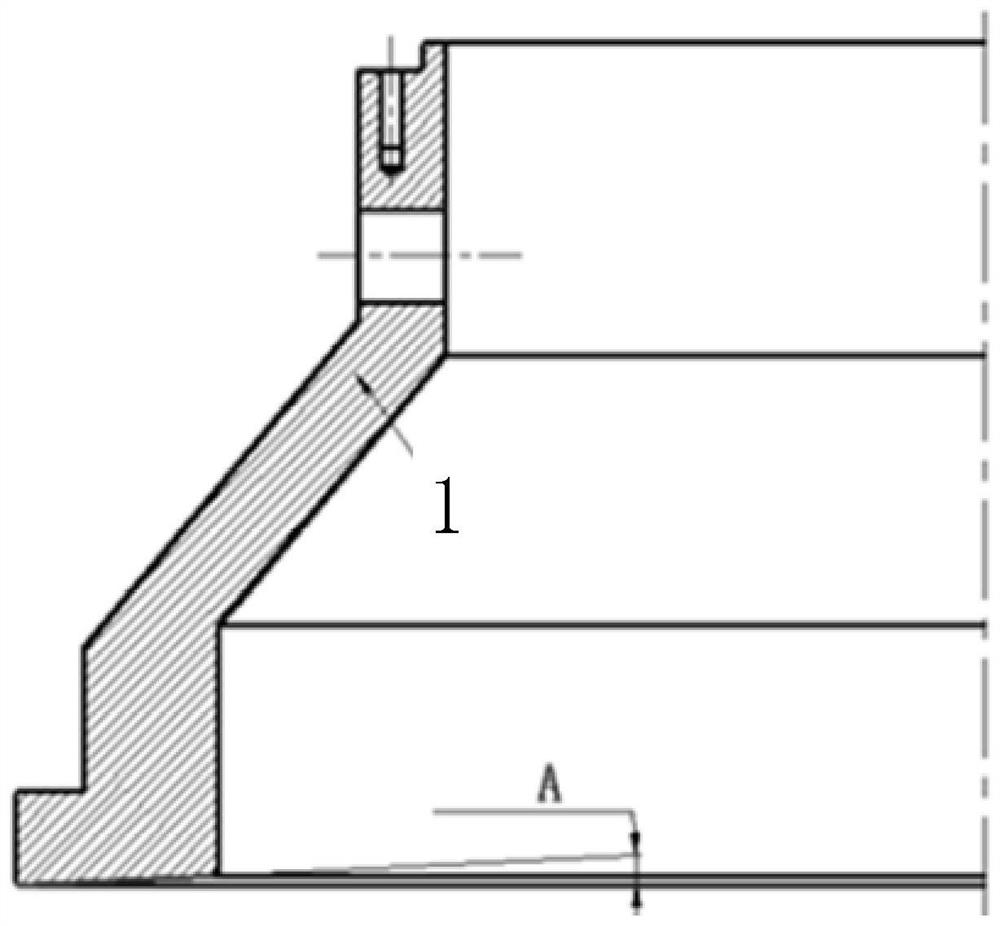

Heat Treatment Deformation Control Method for Duplex Spiral Bevel Gears

ActiveCN104372157BSolve problems with different depthsReasonable technologyFurnace typesHeat treatment furnacesDeformation controlThermal treatment

The invention relates to a thermal treatment deformation control method for a duplicate spiral bevel gear. By carburizing on a component for twice, a problem that carburizing layers of different parts of the component are different in depth is solved, and the conventional quenching mode is changed; allowance is reserved during machining, and the machining allowance is changed into deformation compensation dosage under the action of quenching pressure of a mould on the top of the bevel gear, so that the carburizing layer precision of the duplicate spiral bevel gear is controlled within 0.1mm, and the + / -10' error control on taper angle at two sides is realized. The thermal treatment deformation control method disclosed by the invention is reasonable in process technology, remarkable in deformation control effect, and capable of providing a novel thought for deformation control of similar products.

Owner:HARBIN DONGAN ENGINE GRP

A method for recycling low-concentration nitric acid solution in the production of ethylene glycol from calcium carbide furnace tail gas

ActiveCN109456197BSolve recycling difficultiesReduce contentChemical industryNitrous acid preparation ester preparationSide reactionGlycol synthesis

The invention relates to a method for recycling low-concentration nitric acid solution in the production of ethylene glycol from calcium carbide furnace tail gas. Methanol and nitric acid, under the action of methanol vapor heat tracing, pass through the recovery and utilization system of low-concentration nitric acid waste liquid, and react to form methyl nitrite and water. The invention solves the problem of difficult recovery of dilute nitric acid produced by side reactions in the regeneration of methyl nitrite, and effectively reduces the content of nitric acid in the regeneration of methyl nitrite. It has the advantages of high recovery and utilization rate of nitric acid, reasonable economy, feasible process technology and the like.

Owner:XINJIANG TIANZHI CHENYE CHEM +1

Aronia melanocarpa fruit wine and brewing method thereof

InactiveCN113061507AReasonable technologyLess loss of beneficial substancesAlcoholic beverage preparationFruit juiceBiotechnology

The invention discloses aronia melanocarpa fruit wine and a brewing method thereof. The brewing method comprises the following steps: cleaning aronia melanocarpa fruits, removing stems, crushing, and extracting fruit juice into an extraction fermentation tank; inoculating the fruit juice into mature sorbus pohuashanensis saccharomycetes, performing fermentation propagation, and after the temperature rises to 23 DEG C, putting the fruit juice into a 600L liter box to be in full contact with oxygen; after temperature control, conducting fermentation, after fermentation of the remaining sugar is finished, adding potassium metabisulfite and sulfur dioxide, adjusting the concentration to 30 mg / L, and when the temperature of wine liquid is reduced to 8-10 DEG C, pouring the wine liquid into a storage tank to be stored and aged; carrying out aging at the temperature of 5-10 DEG C, and supplementing wine in time when the wine liquid in the storage tank drops in winter; in the middle ten days of March of the next year, adjusting sulfur dioxide to be 25 mg / L, carrying out sampling for a fining test, the dosage of selected edible gelatin is 160-220 g per time, adding pure water into sol, then using warm water with the temperature of 55 DEG C for dissolving the sol, adding the sol slowly into raw wine in a circulating liter box, starting a circulating pump, pumping the raw wine into a storage tank, keeping the storage tank full and storing it statically for 21 days, adopting a plate and frame filter for clarification plate filtration, so that the sorbus raw wine is brewed.

Owner:张亚祥

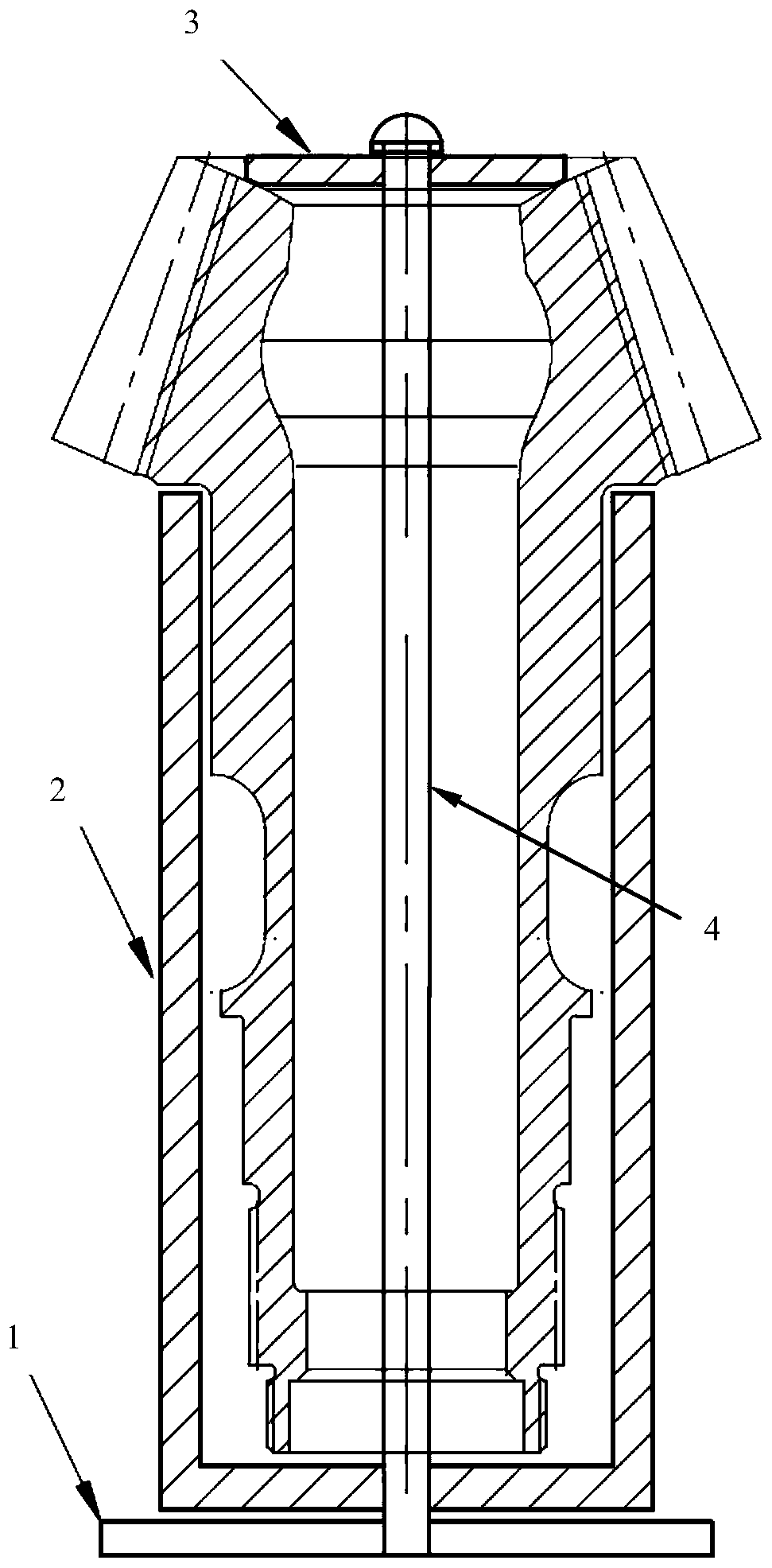

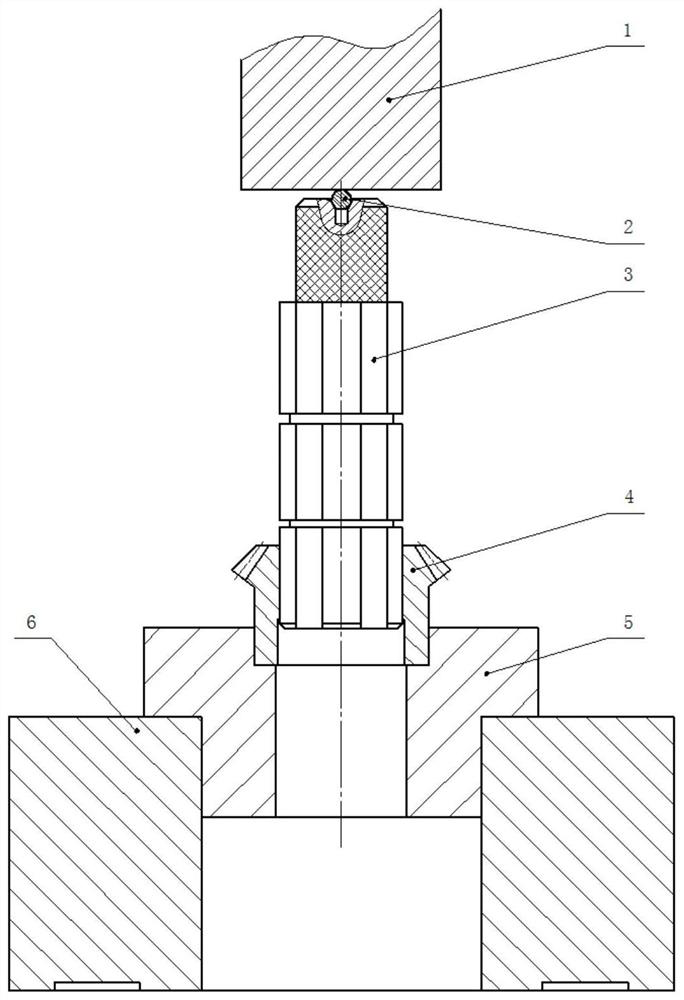

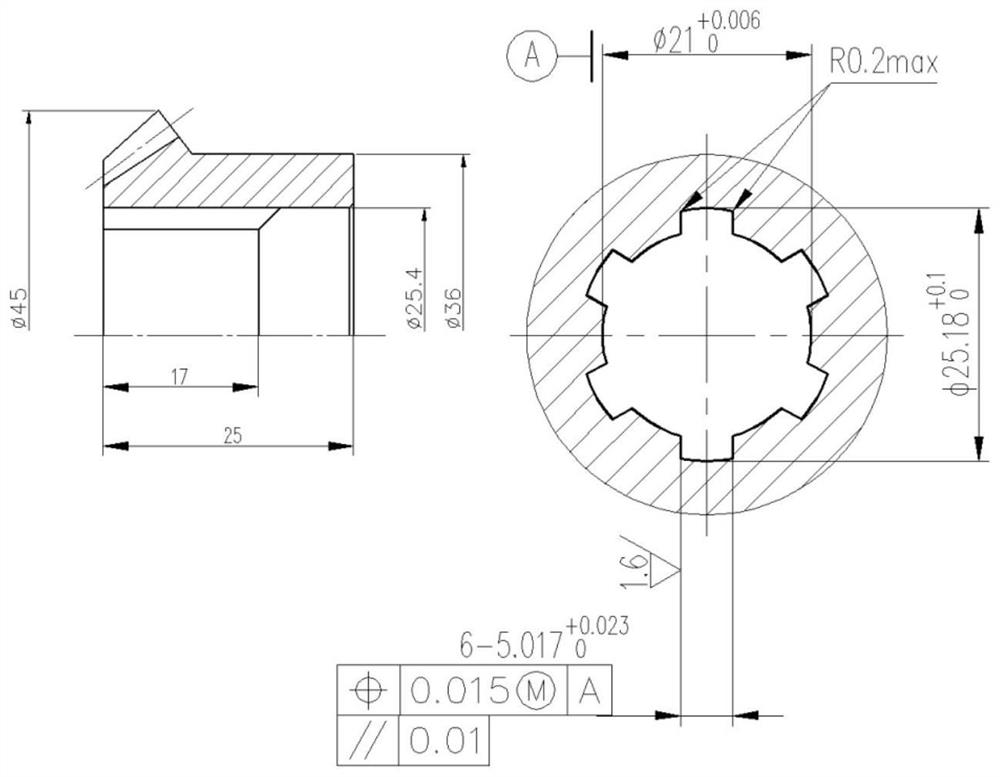

Device and method for machining rectangular splines in hard tooth surfaces

The invention discloses a device for processing rectangular splines in a hard tooth surface. The device is an adaptive centering device. The self-adaptive centering grinding device includes a grinding head, an adaptive steel ball, a grinding Rod, bushing and base, the bushing is installed and fixed in the inner hole of the base, the parts are placed in the positioning hole in the bushing, the top end of the grinding rod is provided with a center hole, and the self-adaptive steel ball is placed in the center hole of the grinding rod for grinding The rod matches the inner rectangular spline of the part, and the grinding head presses on the adaptive steel ball to push the grinding rod down to grind the inner rectangular spline of the part. The invention can ensure the dimensional accuracy, parallelism and positional degree of the inner rectangular spline.

Owner:ZHONGNAN TRANSMISSION MACHINERY FACTORY CHANGSHAAVIATION IND

Preparation method of electrolytic manganese slag autoclaved brick

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Method for preparing fluorine by electrolyzing potassium fluoride-hydrogen fluoride

InactiveCN103898547AIncrease productivityReasonable workmanshipElectrolysis componentsPotassium fluorideSpiral line

The invention discloses a method for preparing fluorine by electrolyzing potassium fluoride-hydrogen fluoride. The method is achieved at the temperature of 80-110 DEG C, wherein the wall of an electrolytic cell is taken as a cathode; an anode is prepared from a thick nickel wire spiral line; KF.2HF and anhydrous HF are added to the electrolytic cell, and then an electrolytic cell copper plate is covered; the material inside the cell is heated to 70 DEG C; the material is heated from the upper part of a drum when being heated by a light flame; the temperature is measured by a thermometer inside a copper thermometer sleeve; a lid on the drum is covered when the material inside the electrolytic cell becomes liquid due to easy-to-melt KF.3HF; the temperature ascends to 90 DEG C; then electrolysis is carried out; the voltage is 10V; and the current intensity is 4-6A. The method is reasonable in process, and simple to fabricate, and is the simplest and optimal method for preparing fluorine.

Owner:TIANJIN TAIHENG GASES

Pills capable of warming kidney, strengthening yang, consolidating constitutions and strengthening vitality, and preparation method of pills capable of warming kidney, strengthening yang, consolidating constitutions and strengthening vitality

InactiveCN111150781AReasonable formulaTargetedHeavy metal active ingredientsNervous disorderSexual functioningMedicinal herbs

The invention discloses pills capable of warming kidney, strengthening yang, consolidating constitutions and strengthening vitality, and a preparation method of the pills capable of warming kidney, strengthening yang, consolidating constitutions and strengthening vitality, and belongs to the technical field of composite traditional Chinese medicines. The pills capable of warming kidney, strengthening yang, consolidating constitutions and strengthening vitality are mainly used for treating symptoms of impotence and premature ejaculation of men, cold wombs of women, low sexual functions, male infertility, female sterility and the like. The pills capable of warming kidney, strengthening yang, consolidating constitutions and strengthening vitality are mainly characterized by comprising 1-9 parts of cynomorium songaricum, 1-8 parts of actinolite, 1-9 parts of epimedium, 1-10 parts of herba cistanches, 1-10 parts of common cnidium fruits, 1-8 parts of acorus tatarinowii, 1-6 parts of radix polygalae, 1-7 parts of fructus schisandrae chinensis, 1-8 parts of semen cuscutae, 1-8 parts of cortex eucommiae and 1-8 parts of stalactite. The pills are prepared through the steps of performing ultrafine pulverization treatment on the above medicinal materials, uniformly mixing the medicinal materials after the ultrafine pulverization treatment with honey, and performing baking.

Owner:CHONGQING MEDICAL & PHARMA COLLEGE

A Method to Solve Tooth Top Overseepage of 18crni4a Material Narrow Tooth Shaped Parts

ActiveCN105386044BNo over seepageMeet the use requirementsSolid state diffusion coatingSuperimposed coating processCopper platingDentistry

The invention relates to a method for solving the problem of excessive seepage of an 18CrNi4A material narrow-tooth-shaped component tooth crest. The traditional thermal treatment technology is changed, primary carburization is changed into secondary carburization, the measure that before primary carburization, a copper plating protection area extends to the two side tooth face parts connected with the tooth crest from the tooth rest is taken, finally, a carburization layer of the tooth crest of the component in the thermal treatment process is qualified, and the phenomenon of excessive seepage of the tooth crest cannot happen. The technology is reasonable, an ideal effect is achieved, and the normal usage requirement for the component is guaranteed.

Owner:HARBIN DONGAN ENGINE GRP

A method for preventing excessive seepage of tooth tops of narrow toothed parts made of 16cr3niwmovnbe material

ActiveCN105386043BNo over seepageEasy to useSolid state diffusion coatingSuperimposed coating processCopper platingThermal treatment

The invention relates to a method for preventing excessive seepage of a 16Cr3NiWMoVNbE material narrow-tooth-shaped component tooth crest. The traditional thermal treatment technology is changed, primary carburization is changed into secondary carburization, and after the primary carburization is ended, only a tooth crest copper plating layer area is reserved, and secondary carburization is carried out. By means of the technology, a carburization layer of the tooth crest of a component in the thermal treatment process is finally qualified, and the phenomenon of excessive seepage of the tooth crest cannot happen. The technology is reasonable, when the high and medium part of component teeth can meet the design requirement, the thickness of the carburization layer of the tooth crest can also meet the requirement, and normal usage of the component is guaranteed.

Owner:HARBIN DONGAN ENGINE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com