Treatment process for preparing new material by utilizing recycled renewable energy

A treatment process and renewable energy technology, applied in the direction of energy input, fibrous filler, silicon dioxide, etc., can solve environmental pollution, smog endangering human health and other problems, achieve reduction of environmental pollutant emissions, environmentally friendly green technology, Reduce the effect of environmental pollution and smog on human health and survival

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

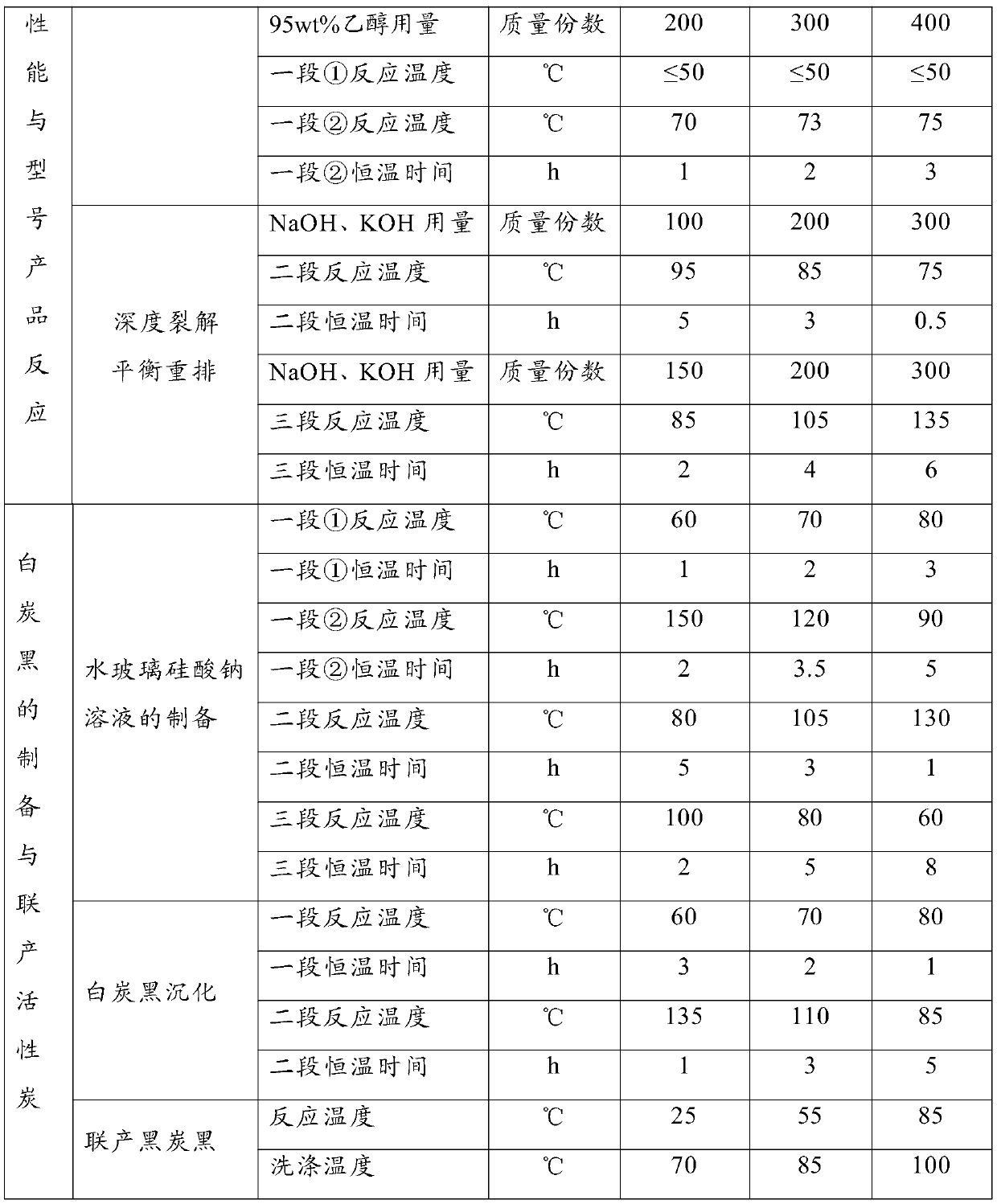

[0059] (1) Preparation of water glass sodium silicate solution: add plant ashes into a four-necked reaction flask, and the reaction can be carried out in one stage or in stages.

[0060] One-step reaction: It is necessary to add a sufficient amount of catalyst Na to the four-necked reaction flask at a uniform speed at one time 2 CO 3 , NaOH, KOH solution or the light yellow or brownish red clear liquid obtained in step 2, the electric stirring speed is 516-850r / min, and the temperature is 30-135°C for 5-16h;

[0061] Reaction in stages: first add part of the catalyst at a uniform speed, and keep it at 60-80°C for 1-3 hours; then raise the temperature to 90-150°C and keep it for 2-5 hours; continue to add catalyst to the four-necked reaction flask, and keep it at 80-130°C for 1 hour ~5h; then add the catalyst and keep at 60-100°C for 2-8h; stop the reaction, cool down and filter to obtain light yellow or brown-red filtrate and black filter residue for later use.

[0062] (2) ...

Embodiment

[0067] (1) First, take a certain amount of a certain amount of straw or plant residues and burn them in a specific incinerator to obtain 500 parts (mass parts, the same below) of ash. The combustion heat is applied to various reactions for heating, and 100 parts are taken Gray spare.

[0068] (2) Esterify 500 parts of organosilicon monomer with methanol and ethanol, then indirect hydrolyze or directly hydrolyze with 2000-2500 parts of water at 0-50°C to obtain light yellow or colorless transparent acidic liquid and The white acid gel or gray-brown acid gel is ready for use; the gas generated during the process is absorbed by the absorption tower.

[0069] (3) In step (2), the white acid gel or gray-brown acid gel is washed with water, neutralized with lye or solid alkali until it is neutral, weakly acidic or weakly alkaline, and then put into the reaction with condensing reflux at one time In the reactor, start electric stirring and use different catalysts to react in three s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com