Carburizing method of 9310 steel spiral bevel gear

A spiral bevel gear and carburizing technology, applied in the field of heat treatment of low-carbon high-alloy steel, can solve the problems of difficult to achieve precise control of carburized layer depth, large fluctuations in carburized layer depth, etc., to achieve control of carburized layer depth and quenching deformation , Reasonable effect of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] For a spiral bevel gear part of an aviation product, the carburizing depth of the tooth is required to be 1.25~1.5mm (measured to HV513), the hardness of the carburizing surface of the tooth is 81~83HRA, and the depth of the tooth surface HRC60 is ≥0.56mm.

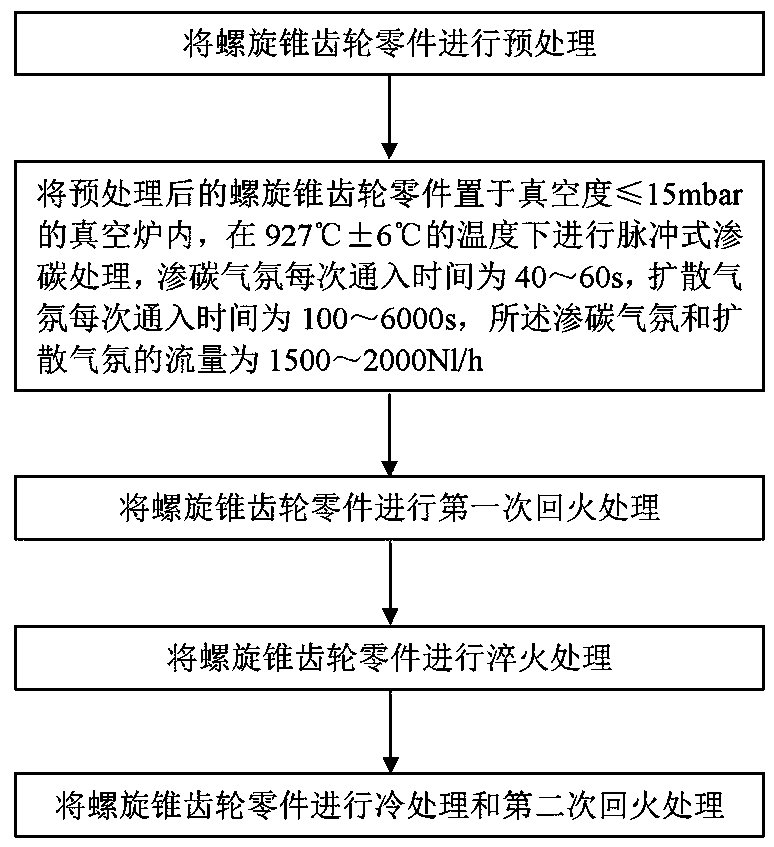

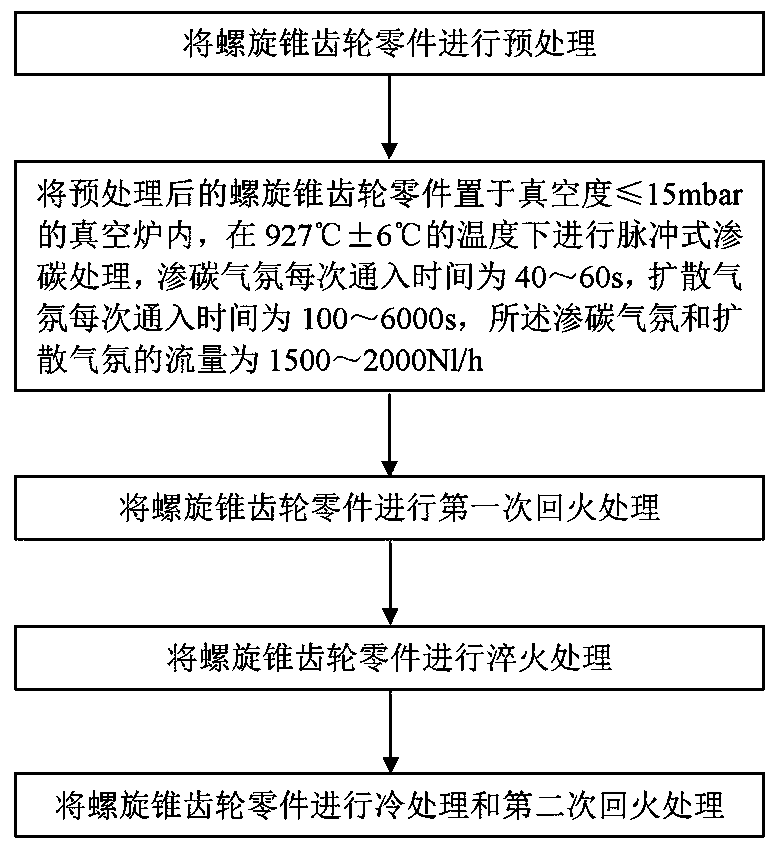

[0028] Such as figure 1 As shown, the carburizing method of a kind of 9310 steel spiral bevel gear of the present embodiment specifically comprises the following steps:

[0029] (1) The surface of the spiral bevel gear parts is protected by copper plating except for the teeth, and the thickness of the copper layer is 0.03-0.05mm (0.035mm in this embodiment).

[0030] (2) The spiral bevel gear parts are placed in the sand blowing machine to clean the carburized surface of the teeth. The corundum sand grain size is (60-100) mesh, and the wind pressure is ≤0.15MPa to ensure that the sand blowing surface is gray after sand blowing.

[0031] (3) The spiral bevel gear parts are placed in the vacuum carburizing furnace, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com