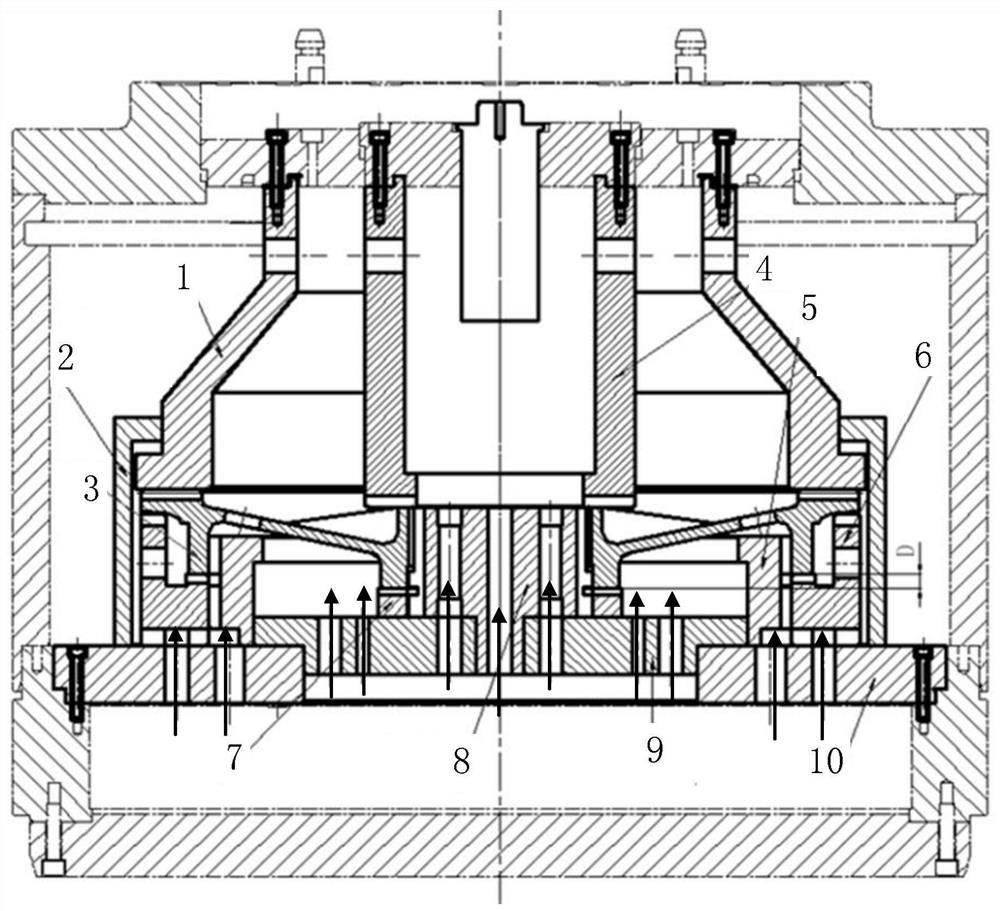

Combined quenching die for deformation control of long web large face gear and heat treatment method

A heat treatment method and deformation control technology, applied in heat treatment furnace, heat treatment equipment, heat treatment process control and other directions, can solve the problems of complex structure, scrapped parts, large deformation of parts, etc., and achieve the effect of reasonable process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

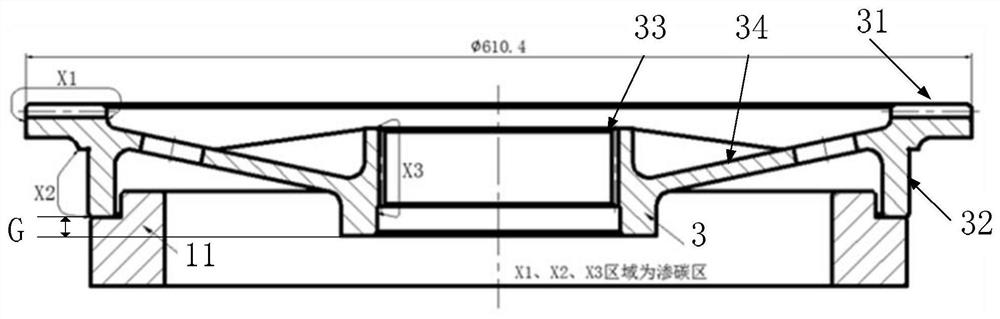

[0048] The part 3 of this embodiment requires the carburizing depth of the tooth portion 31, the spline 33 and the outer raceway to be 1.10-1.30mm, the hardness of the carburizing surface is 60-63HRC, and the deformation of the carburizing surface after carburizing and quenching is ≤0.2.

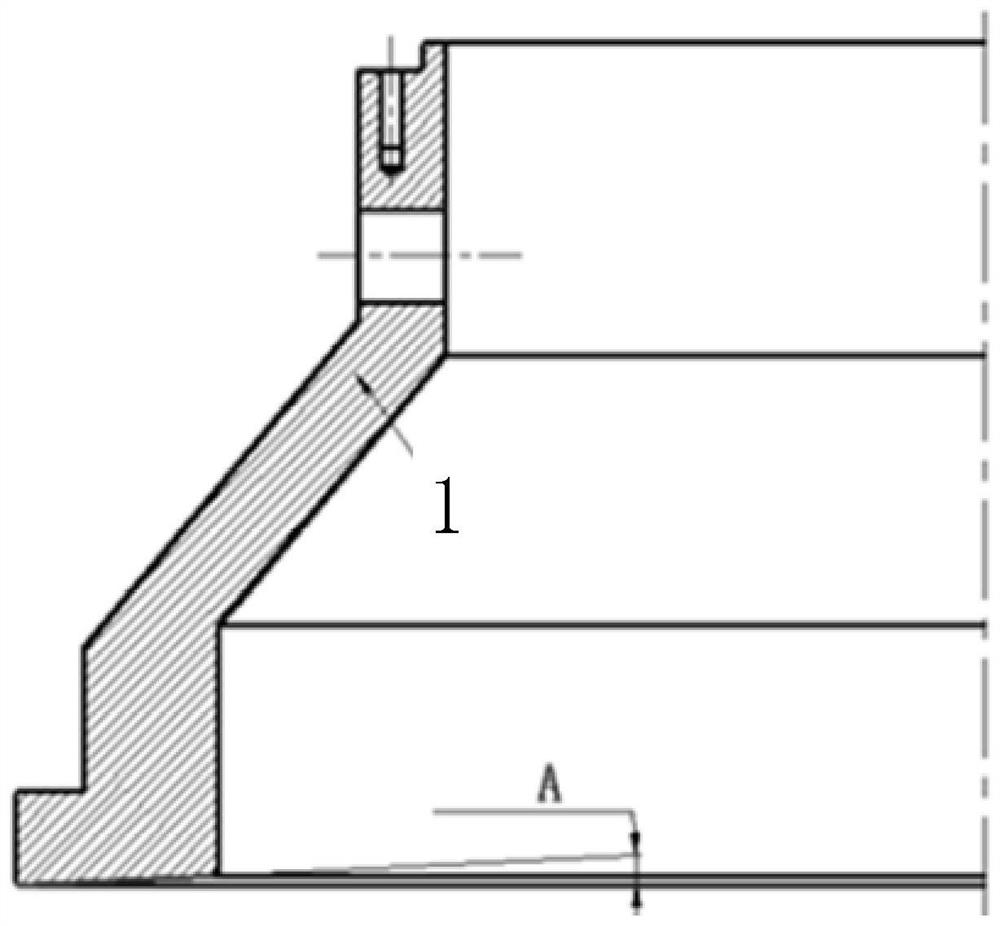

[0049] (1) The carburized surface of part 3 has been completed before carburizing ( figure 2 In X1, X2, X3), the rest of the surface is copper-plated to protect the structure of the part 3 before carburizing.

[0050] (2) Part 3 is placed in the sand blower to clean the carburized surface ( figure 2 Middle X1, X2, X3), corundum sand grain size is 100 mesh, wind pressure ≤ 0.10Mpa (0.1MPa in this embodiment), ensure that the carburized surface is gray after sand blowing.

[0051](3) Part 3 is placed in a controlled-atmosphere carburizing furnace for controlled-atmosphere carburizing: Part 3 adopts carburizing furnace loading tooling 11 for stable furnace loading; the distance between parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com