Method for producing high-purity crystallized xylose by hydrolyzing corn skin

A corn husk, high-purity technology, applied in the preparation of sugar derivatives, chemical instruments and methods, monosaccharides, etc., can solve the problems of increasing the burden of three wastes treatment, affecting the quality of finished products, and low purity of xylose, and reducing production costs. and environmental pollution, conducive to popularization, and the effect of reasonable and feasible process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

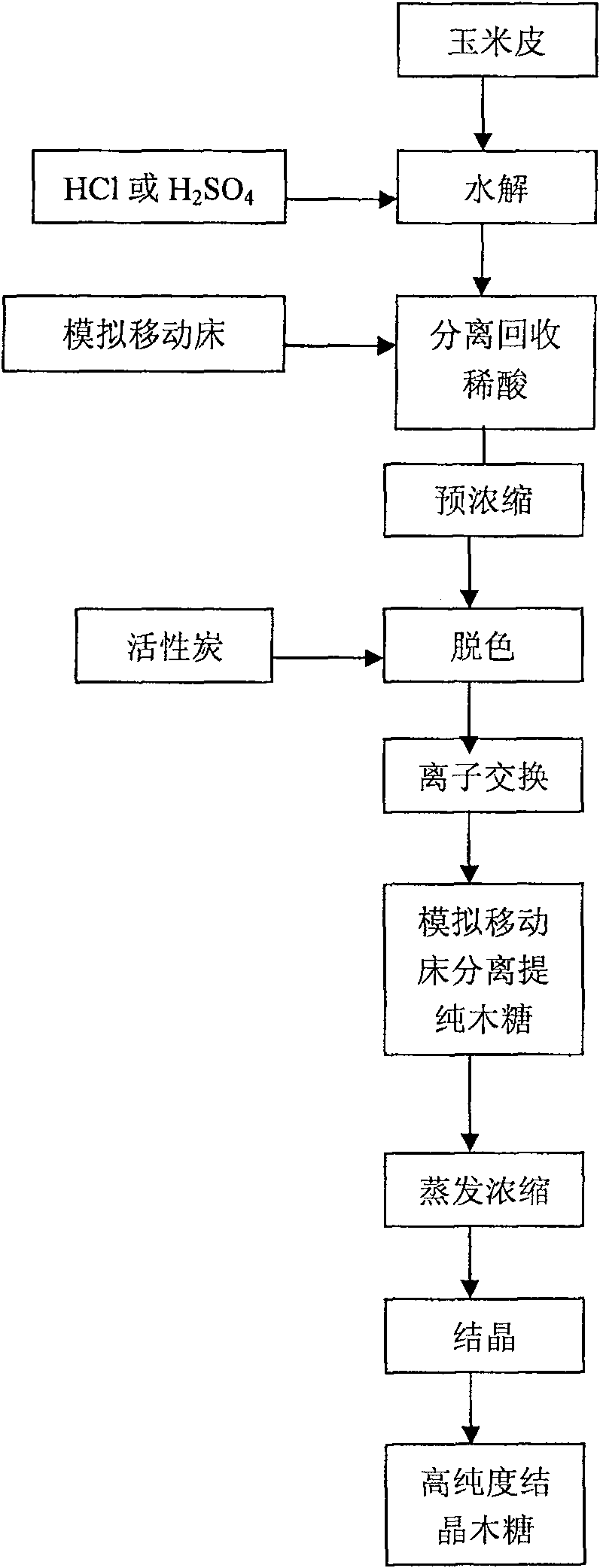

[0028] Embodiment 1: process flow chart as attached figure 1 shown.

[0029] The method for preparing high-purity crystalline xylose by hydrolyzing corn hulls, the steps are as follows:

[0030] (1) corn husk dry matter amount 2kg, obtain xylose hydrolyzate with 110 ℃ of boiling hydrolysis of 1.5% sulfuric acid 4.5 hours, this xylose hydrolyzate concentration is 7.6%, the hydrolysis of xylose hydrolyzate dissolves total reducing sugar 61%wt( Based on dry solid), the xylose purity is 64.5% (based on dry solid);

[0031] (2) Separating the sulfuric acid in the final hydrolyzate with a simulated moving bed, the separation yield is 91.4%, and the pH value of the sugar solution after separation is 4.6, and then pre-concentrated to a concentration of 25.3% with a three-effect falling film evaporator to obtain concentrated solution I, wood Sugar purity 66.5% (based on dry solids);

[0032] (3) The above-mentioned concentrated solution I was decolorized by adding 3.5% activated car...

Embodiment 2

[0036] Embodiment 2: process flow chart as attached figure 1 As shown, the specific steps are:

[0037] (1) 2 kg of dry matter of corn hulls was hydrolyzed with 2.0% hydrochloric acid at 120° C. for 5 hours to obtain a xylose hydrolyzate, the concentration of the hydrolyzate was 8.7%, 62.4% of the total reducing sugar was dissolved by hydrolysis, and the purity of xylose was 65.7%;

[0038] (2) Separating the hydrochloric acid in the final hydrolyzate with a simulated moving bed, the separation yield is 91.4%, the pH value of the sugar solution after separation is 6.1, and then pre-concentrated to a concentration of 26.7% with a three-effect evaporator to obtain concentrated solution I, xylose purity 68.3%;

[0039] (3) The above-mentioned concentrated solution I was decolorized by adding activated carbon with a mass of 4.0% xylose in the solution at a temperature of 78° C. for 45 minutes;

[0040] (4) Implement continuous ion exchange operation through cation and anion exch...

Embodiment 3

[0043] Embodiment 3: process flow chart as attached figure 1 As shown, the specific steps are:

[0044] (1) 2 kg of dry matter of corn husks was boiled and hydrolyzed with 2.0% sulfuric acid at 116°C for 3 hours to obtain a xylose solution. The concentration of the solution was 8.3%, 60.3% of total reducing sugars were dissolved by hydrolysis, and the purity of xylose was 65.4%;

[0045] (2) Separating the sulfuric acid in the final hydrolyzate with a simulated moving bed, the separation yield is 91.4%, the pH value of the sugar solution after separation is 4.9, and then pre-concentrated to a concentration of 26.1% with a three-effect evaporator to obtain concentrated solution I, xylose purity 68.7%;

[0046] (3) The above-mentioned concentrated solution I was decolorized by adding 5.0% activated carbon relative to the xylose mass in the solution at a temperature of 79° C. for 30 minutes;

[0047] (4) Implement continuous ion exchange operation through cation and anion excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com