Tooth-surface shot-blasting strengthening method for spiral bevel gear

A spiral bevel gear and shot peening technology, which is applied in the field of shot peening of the tooth surface of the spiral bevel gear, can solve the problems of increasing the surface roughness value and the inability to meet the roughness, so as to improve the surface integrity and improve the surface integrity. performance and fatigue properties, and the effect of improving surface integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

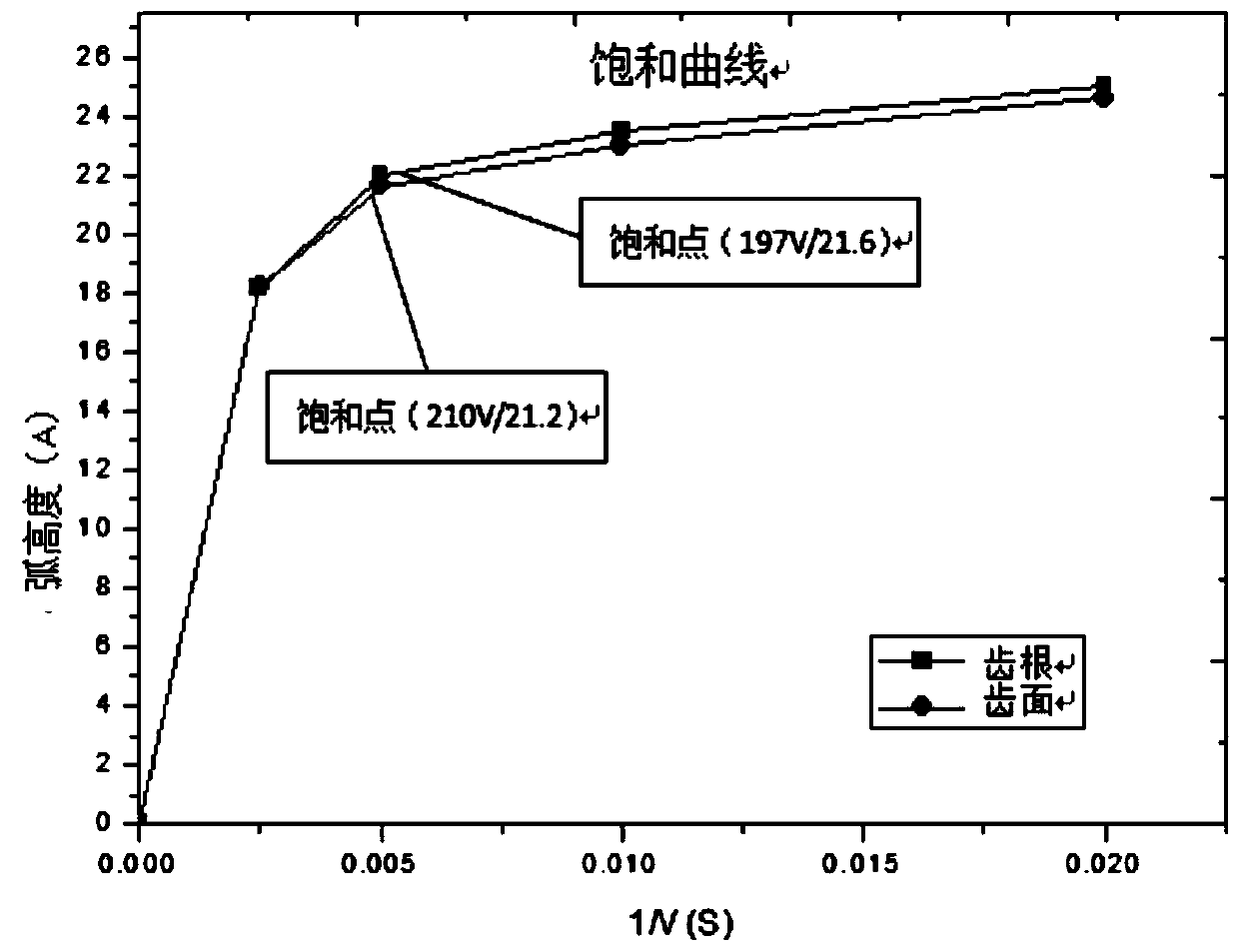

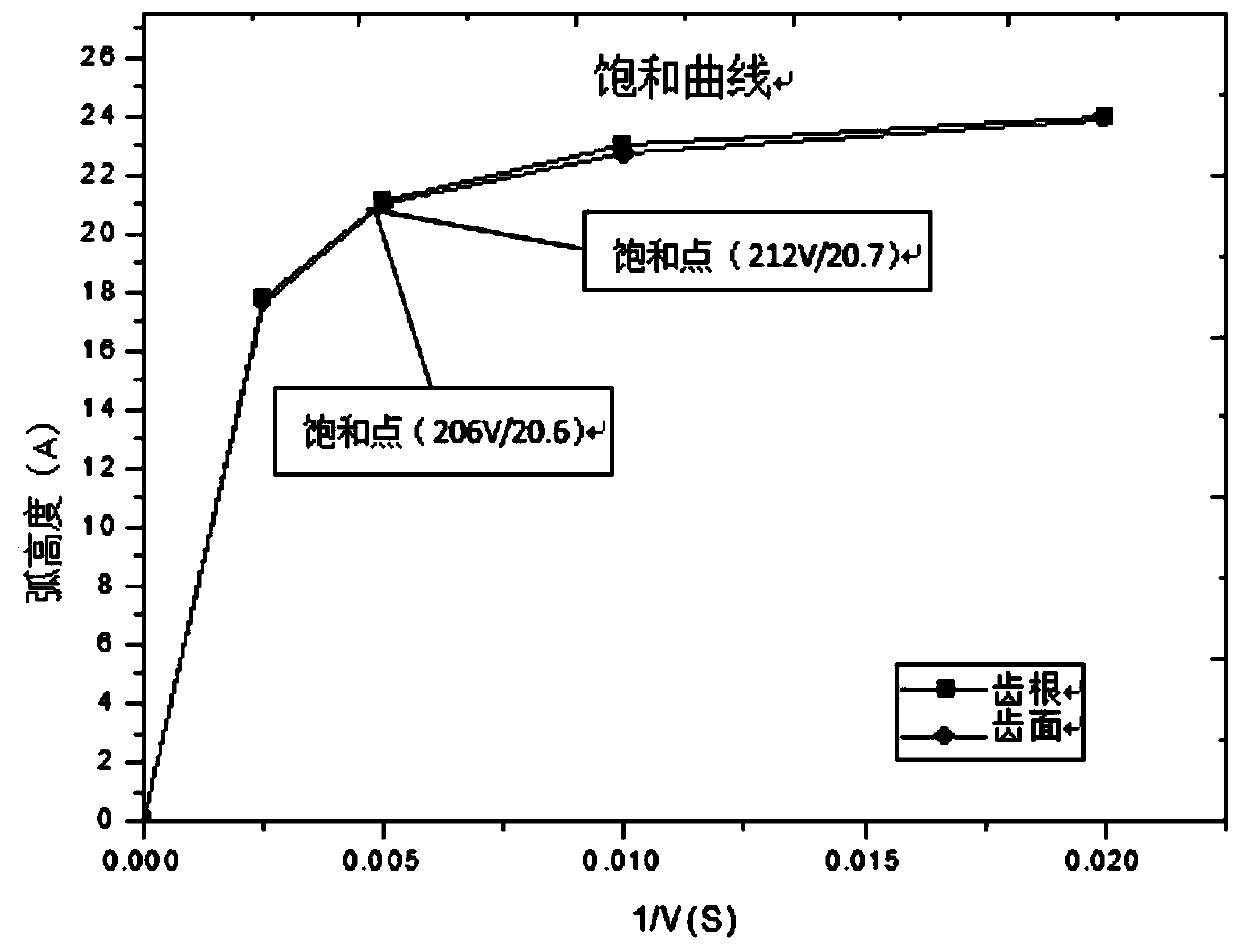

Embodiment 1

[0029] Such as Figure 5 As shown, a tooth surface shot peening method of a spiral bevel gear of the present embodiment comprises the following steps:

[0030] (1) Use the MP1000Ti pneumatic CNC shot blasting machine produced by the French Wheelabrator Group Co., Ltd., and select the projectile model SAE170 (projectile diameter 0.4mm, hardness HRC45~HRC52) cast steel shot to perform shot peening on the 18Cr2Ni4WA steel spiral bevel gear.

[0031] (2) Parts are cleaned and degreased before shot peening to remove dirt and oil stains on the surface of the parts. The cleaning liquid is selected from organic solvents (hydrocarbon cleaning agent is used in this embodiment, aviation gasoline can be used in other embodiments), and the treatment temperature is normal temperature. , The degreasing time is 5min~10min (the degreasing time of this embodiment is 8min).

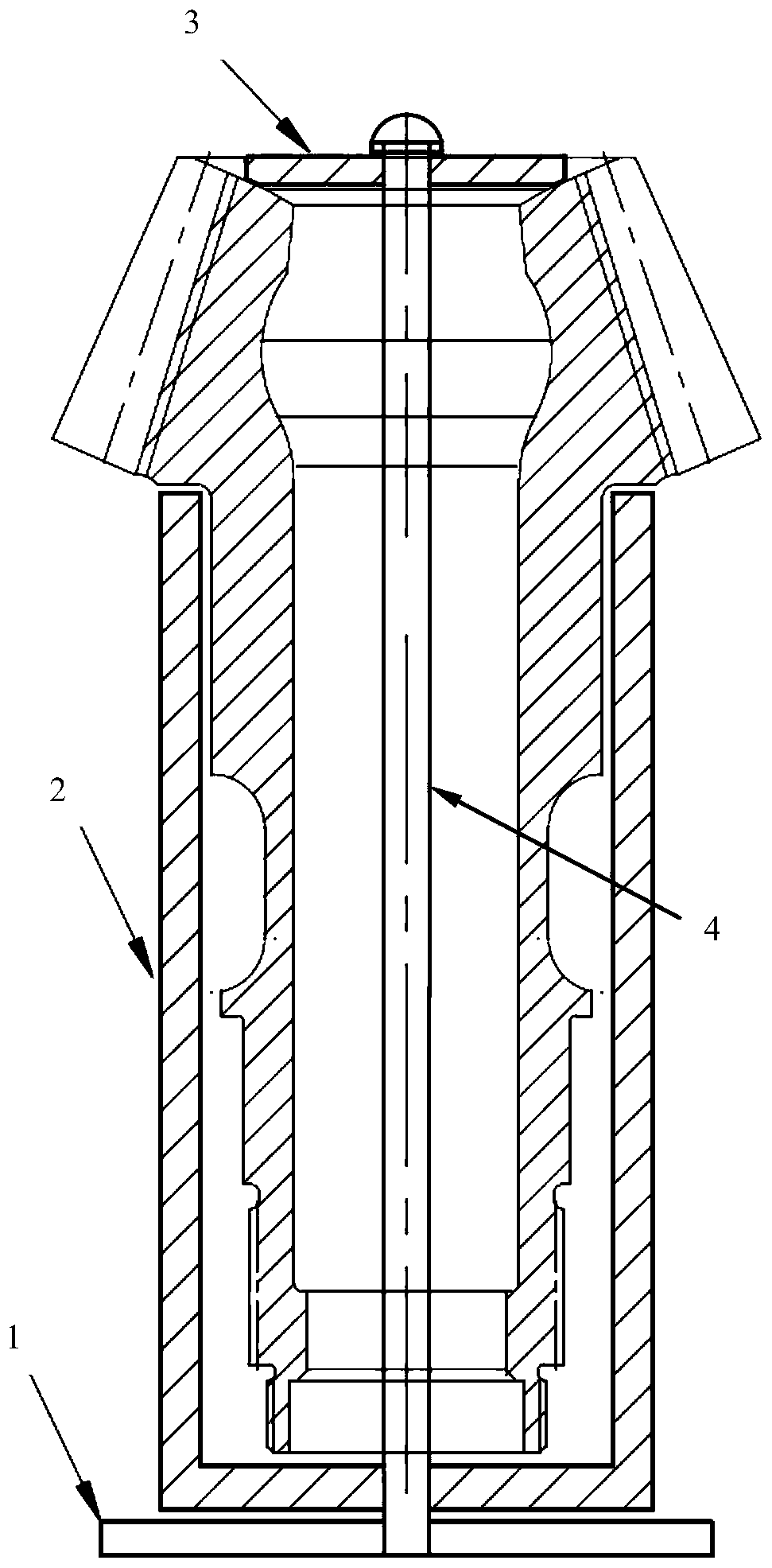

[0032] (3) The non-shot blasting area of the part is protected, and the combined protection device is used to protect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com