Device and method for laser shot blasting reinforcement of hard and brittle material

A technology of laser peening and hard and brittle materials, which is applied in the mechanical manufacturing and laser application fields of hard and brittle materials processing, to achieve the effect of suppressing microscopic cracks and impact lamination, avoiding the influence of material properties, and broadening the application field and application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

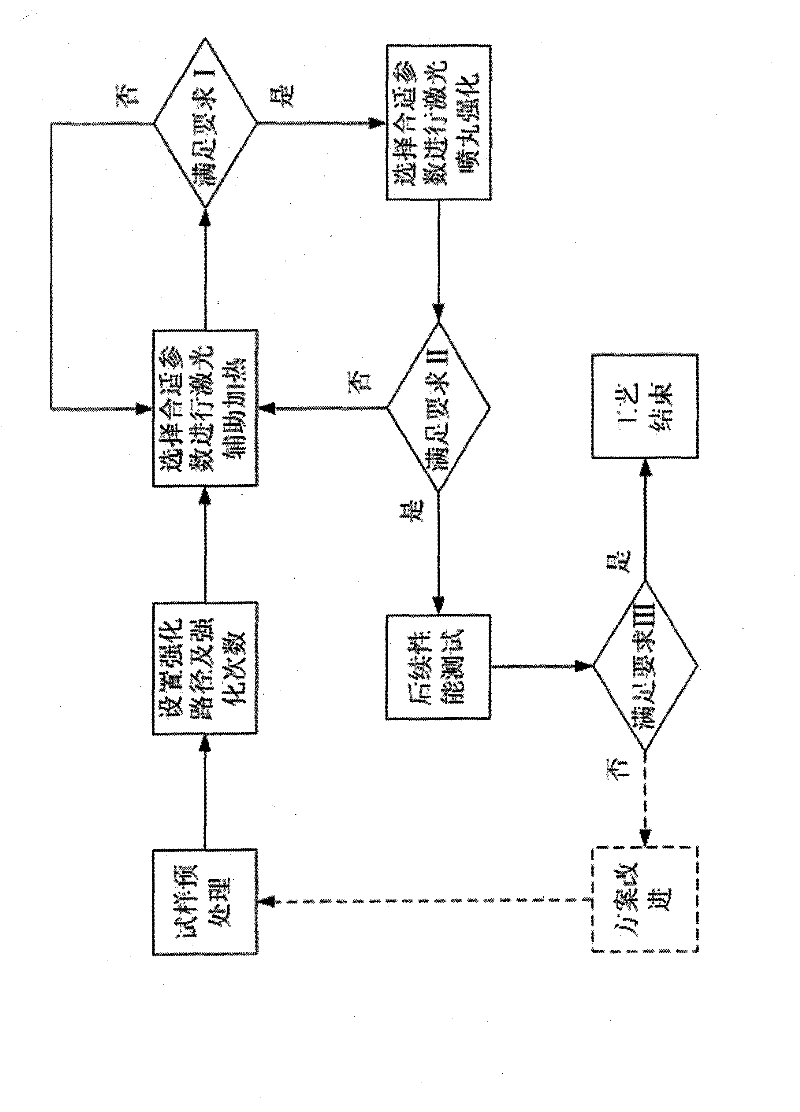

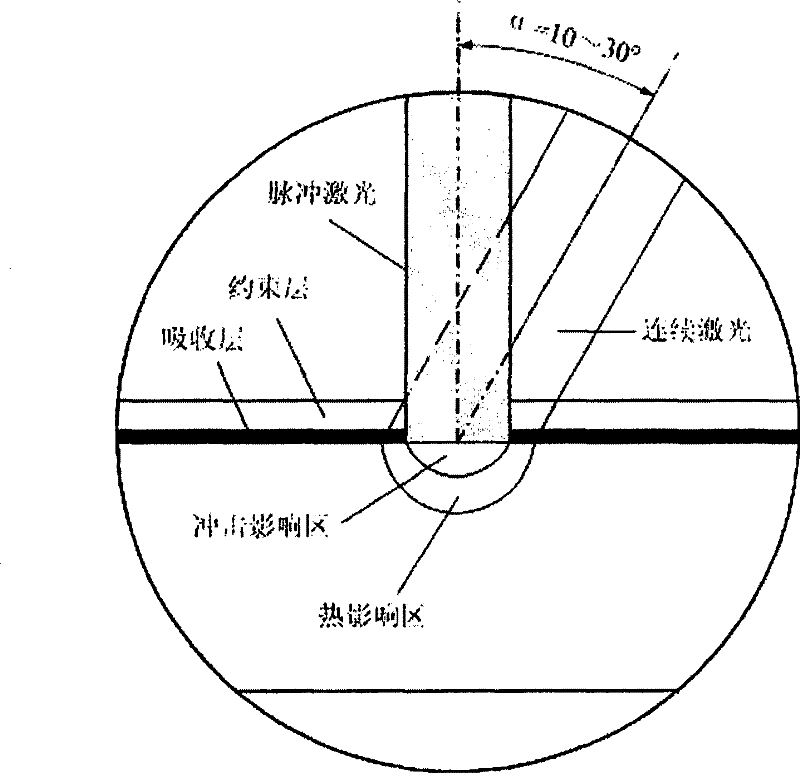

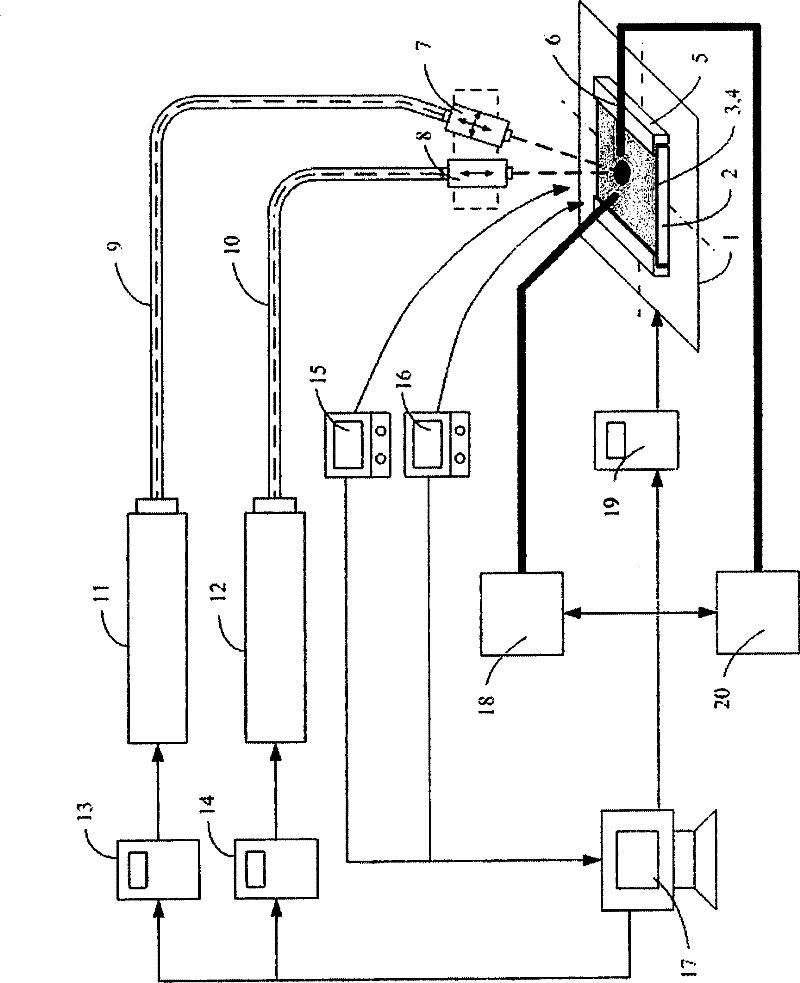

[0038] combine Figure 1 ~ Figure 2 To describe in detail the specific implementation process and process characteristics of the inventive method:

[0039] Step 1. Sample pretreatment. In order to prevent the impact of residual oil on the strengthening effect of the workpiece, the degreasing treatment is carried out by heating or cleaning. The heating method is to heat the sample to 300-450°C, and the cleaning method can use alkaline solution or 99.7% alcohol solution to clean the surface of the sample.

[0040] An energy absorbing layer (3) is coated on the area of the workpiece to be strengthened, and a transparent constraining layer (4) is fixed outside it. The energy absorbing layer (3) preferably chooses graphite coating, whose melting point is as high as 3850°C, and the absorption rate of graphite to laser light is as high as 77.3%. The confinement effect is 4 to 5 times that of ordinary glass.

[0041] Finally, clamp the processed sample on the workbench (1).

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com