Heat treatment deformation control method of spiral bevel gear

A spiral bevel gear, heat treatment deformation technology, applied in the field of heat treatment, can solve problems such as uneven deformation, affect product quality, affect product size structure, etc., and achieve reasonable results in process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

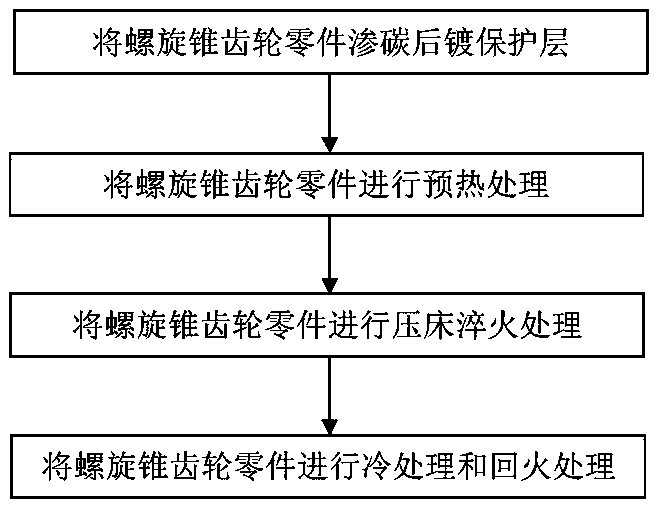

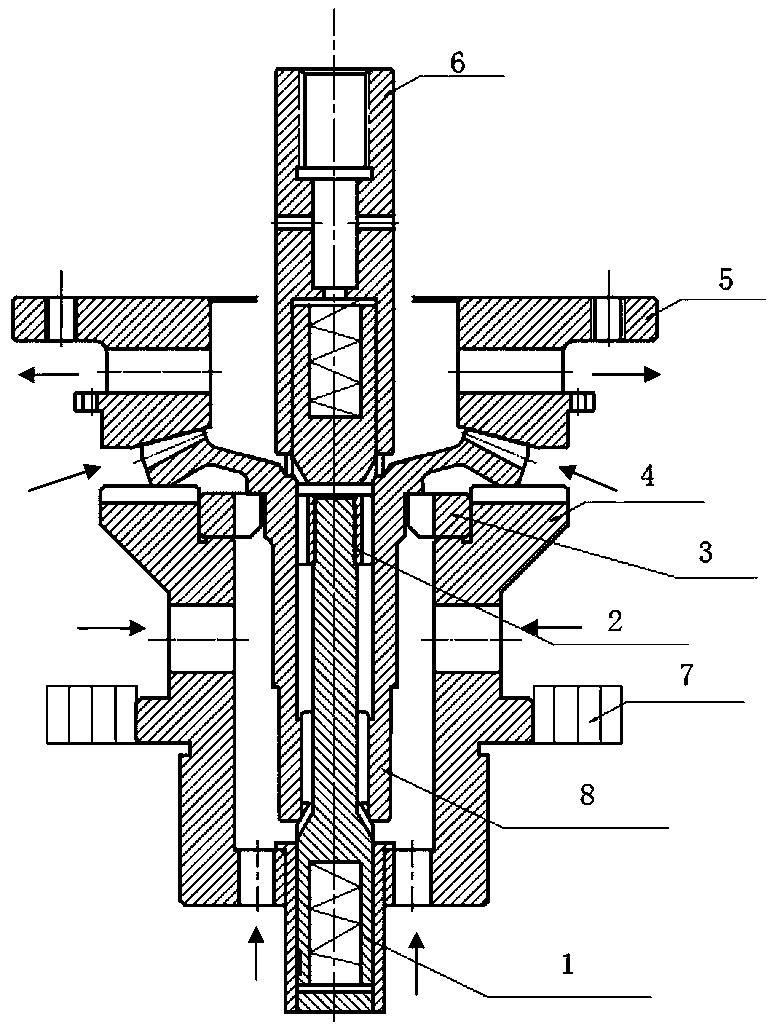

[0028] Such as figure 1 As shown, a heat treatment deformation control method of a spiral bevel gear in this embodiment specifically includes the following steps:

[0029] (1) After carburizing the outer circle of the rod part and the tooth part of the spiral bevel gear part 8, the overall copper plating is carried out, and the thickness of the copper layer is 0.04mm;

[0030] (2) Preheating the spiral bevel gear part 8: Pack the spiral bevel gear part 8 together with a small amount of carburizing agent, place the box in a box furnace and heat it to 815°C for 130 minutes.

[0031] In this embodiment, the function of the carburizing agent is to prevent oxidative decarburization of the parts when they are heated. The carburizing agent can be spread on the bottom of the box in a flat layer with a thickness of about 10mm. The box is generally made of stainless steel, and the size can be designed according to the situation, without special requirements.

[0032] (3) Put the spira...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com