Method of recycling low-concentration nitric acid solution in calcium carbide furnace tail gas to ethylene glycol process

A technology of calcium carbide furnace tail gas and nitric acid solution, applied in the chemical industry, can solve the problems of a large number of catalysts, achieve high recycling rate, reduce steam consumption, and reduce alkali consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

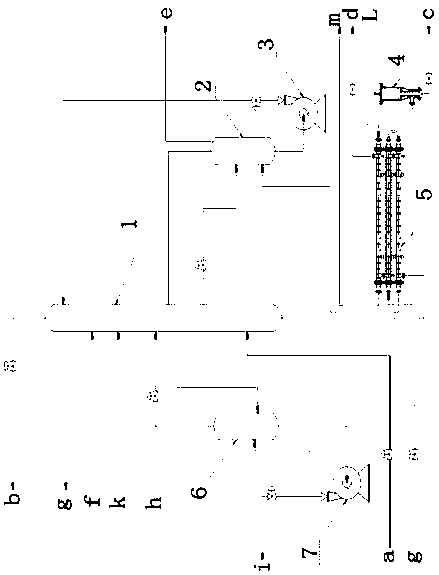

[0031] Refer to attached figure 1 , a method for recovery and utilization of low-concentration nitric acid solution in the production of ethylene glycol from calcium carbide furnace tail gas, from NO in the recycle gas a at the outlet of the recycle compressor in the DMO synthesis system and methanol and in the low-concentration nitric acid solution c from the MN regeneration unit Nitric acid, under the action of methanol vapor heat tracing, passes through the recovery and utilization system of low-concentration nitric acid waste liquid, and reacts to generate methyl nitrite and water.

[0032]Another implementation example is different in that the recycling system of low-concentration nitric acid waste liquid includes a nitric acid purification liquid fine filter (4), a nitric acid purification inlet and outlet heat exchanger (5), and a nitric acid purification tower feed tank (2) , nitric acid purification tower liquid circulation pump (3), nitric acid purification tower (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com