Process technology of method for preparing silane by using magnesium silicide

A process technology, the technology of magnesium silicide, applied in the field of silicon chemical products, can solve problems such as pollution, and achieve the effect of reasonable process technology and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

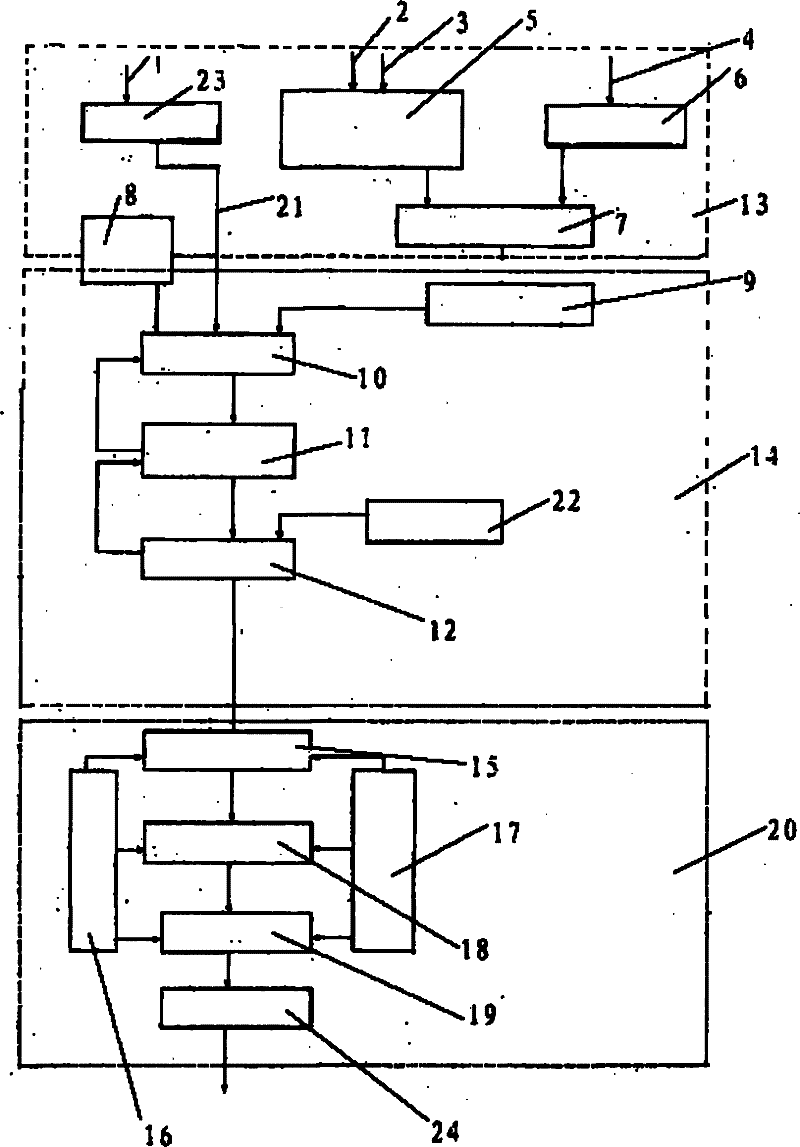

[0025] refer to figure 1 The method for preparing silane is → raw material preparation system (13) → silane gas preparation system (14), → molecular sieve adsorption purification silane liquefaction and vaporization system (20). In this method, magnesium silicide and ammonium chloride are reacted in liquid ammonia at about -20°C to obtain silane.

[0026]

[0027] Preparation of silane method equipment consists of liquid ammonia feed port (1), silicon powder feed port (2), magnesium powder feed port (3), ammonium chloride feed port (4), magnesium silicide synthesis furnace (5), pulverizing and drying equipment ( 6), magnesium silicide and ammonium chloride mixing device (7), vacuum equipment (8), liquid ammonia storage tank (23) is assembled into raw material preparation system (13) by connecting pipeline (21); continuous feeding device (9) , reaction kettle (10), liquid ammonium reflux column (11), ammonia condenser (12), refrigeration equipment (22) is assembled into sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com