Method for sorting and pre-enriching lean hematite by using X-ray radiation

A pre-concentration and ray technology, applied in the field of mineral processing, can solve the problem of not many treatment methods, achieve the effect of reasonable process technology, improve economic and technical indicators and comprehensive benefits, and improve equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

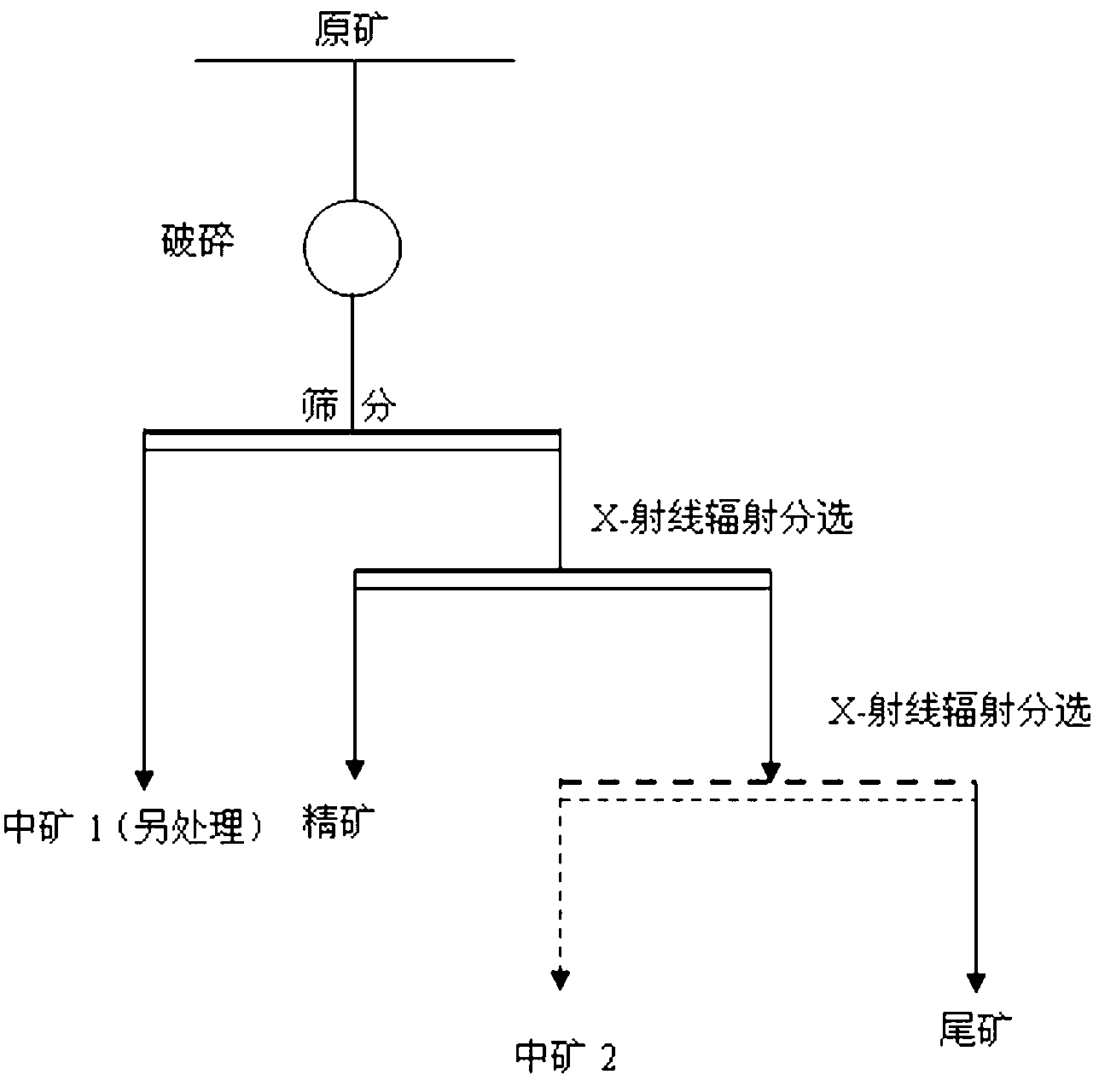

[0026] (1) Crushing: Crushing the lean hematite ore to less than 150mm through a crusher;

[0027] (2) Screening: Use a screening machine with a sieve size of 90mm to sieve the crushed material, and the material on the sieve (+90mm) will be treated separately, and the material under the sieve will be screened with a sieving machine with a sieve size of 60mm The material (-60mm) will be processed separately, and the material on the screen (-90mm +60mm) will be transported to the pre-selection operation ore bin of the X-ray radiation sorter through the belt conveyor. The iron content of the material on the screen is 17.42%, and the rest are gangue minerals ;

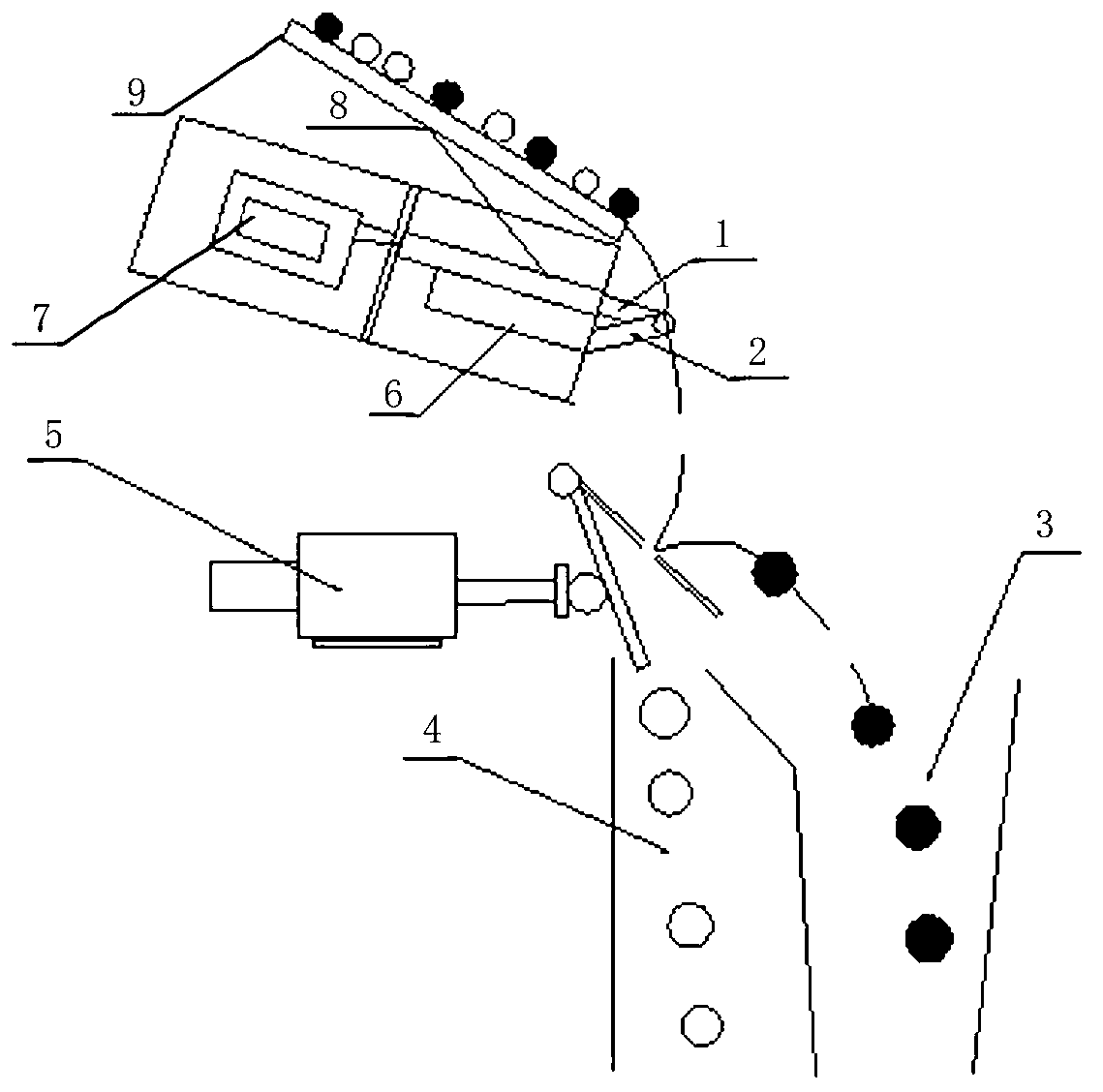

[0028] (3) X-ray radiation sorting machine pre-selection: the material on the screen obtained in step (2) is fed to the X-ray radiation sorting machine through the feeder, and in the control system of the X-ray radiation sorting machine according to the original ore The Fe content in the Fe content sets the threshold for ...

Embodiment 2

[0035] (1) Sieving: Screen the under-sieve material (-60mm) obtained in step (2) of Example 1 with a sieving machine with a sieve size of 30mm, and the under-sieve material (-30mm) will be treated separately, and the sieve The material is transported to the ore bin of the X-ray radiation sorter through the conveyor belt. The grade of iron in the lean hematite ore on the screen is 19.48%, and the rest are gangue minerals;

[0036] (2) X-ray radiation sorting machine pre-selection: feed the sieved material obtained in step (1) to the X-ray radiation sorting machine through the feeder, and in the control system of the X-ray radiation sorting machine according to the original ore The iron content in the iron content sets the threshold for the separation of concentrate and tailings to be 0.12. After being sorted by the X-ray radiation sorter, the ore with the threshold greater than 0.12 will be considered as concentrate and enter the concentrate receiving tank, while the threshold i...

Embodiment 3

[0042] (1) Crushing: Crushing the lean hematite ore to less than 150mm through a crusher;

[0043] (2) Screening: Use a screening machine with a screen hole size of 90mm to screen the crushed material, and the material under the screen (-90mm) will be processed separately, and the material on the screen will be transported to the X-ray radiation sorter for pre-selection by the belt conveyor In the ore bin, the grade of iron in the hematite ore on the sieve is 17.66%, and the rest are gangue minerals;

[0044] (3) X-ray radiation sorting machine pre-selection: the material on the screen obtained in step (2) is fed to the X-ray radiation sorting machine through the feeder, and in the control system of the X-ray radiation sorting machine according to the original ore The iron content in the iron content sets the threshold for the separation of concentrate and tailings to be 0.18. After being sorted by the X-ray radiation sorter, the ore with the threshold greater than 0.18 will be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com