Pretreatment process for industrial hazardous wastes with cement kiln

A hazardous waste and co-processing technology, applied in the field of industrial hazardous waste treatment, can solve the problems of high disposal cost, high disposal cost and small disposal scale, and achieve the effect of large disposal capacity, strong adaptability and good environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

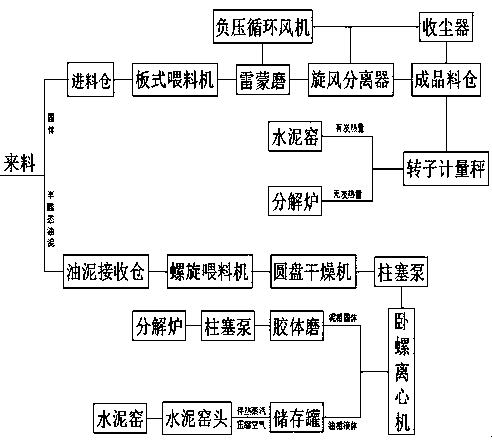

Method used

Image

Examples

Embodiment 1

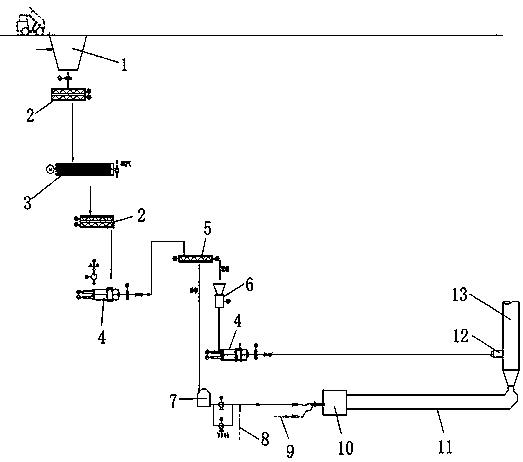

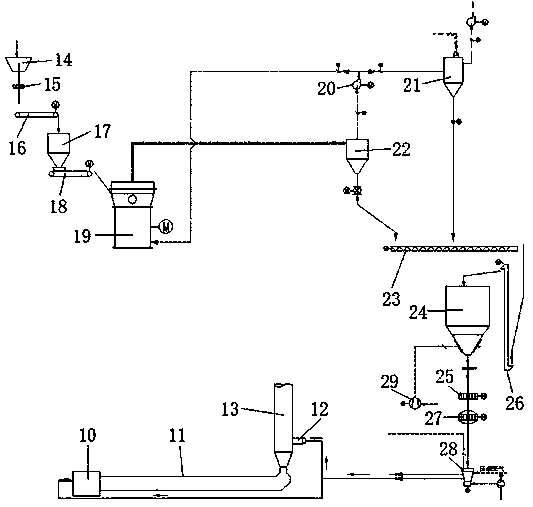

[0046] Embodiment 1: when this hazardous industrial waste is semi-solid oil sludge, it comprises the steps:

[0047] (1) Heating: The sludge is first transported to the sludge receiving bin 1 and electrically heated in the sludge receiving bin 1. An electric heating layer is installed on the outside of the sludge receiving bin 1, and the temperature of the inner cavity of the sludge receiving bin is maintained at 62°C. Then, The sludge in the sludge receiving bin 1 is transported to the disc dryer 3 through the screw feeder 2 and heated to 80°C to make the material flowable;

[0048] (2) Separation: The oil sludge heated by the disc dryer 3 is transported to the decanter centrifuge 5 by the plunger pump 4 to separate the mud phase solid and oil phase liquid;

[0049] (3) Grinding and entering the kiln:

[0050] The mud phase solids separated in step (2) are crushed in the colloid mill 6 to the raw meal fineness, specifically, when the mud phase solids are incombustible solids...

Embodiment 2

[0052] Embodiment 2: when this hazardous industrial waste is semi-solid oil sludge, it comprises the following steps:

[0053] (1) Heating: The oil sludge is first transported to the oil sludge receiving bin 1 and electrically heated in the oil sludge receiving bin 1. An electric heating layer is installed on the outside of the oil sludge receiving bin 1. The temperature of the inner cavity of the oil sludge receiving bin 1 is maintained at 65°C, and then , transport the sludge in the sludge receiving bin 1 to the disc dryer 3 through the screw feeder 2 and heat it to 95°C to make the material flowable;

[0054] (2) Separation: The oil sludge heated by the disc dryer 3 is transported to the decanter centrifuge 5 by the plunger pump 4 to separate the mud phase solid and oil phase liquid;

[0055] (3) Grinding and entering the kiln:

[0056] The mud phase solids separated in step (2) are crushed in the colloid mill 6 to the raw meal fineness, specifically, when the mud phase so...

Embodiment 3

[0058] Embodiment 3: when this hazardous industrial waste is semi-solid oil sludge, it comprises the following steps:

[0059] (1) Heating: The sludge is first transported to the sludge receiving bin 1 and electrically heated in the sludge receiving bin 1. There is an electric heating layer on the outside of the sludge receiving bin 1. The temperature of the inner cavity of the sludge receiving bin 1 is maintained at 68°C, and then , the sludge in the sludge receiving bin 1 is transported to the disc dryer 3 through the screw feeder 2 and heated to 100°C to make the material flowable;

[0060] (2) Separation: The oil sludge heated by the disc dryer 3 is transported to the decanter centrifuge 5 by the plunger pump 4 to separate the mud phase solid and oil phase liquid;

[0061] (3) Grinding and entering the kiln:

[0062] The mud phase solids separated in step (2) are crushed in the colloid mill 6 to the raw meal fineness, specifically, when the mud phase solids are incombusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com