Preparation method for composite magnetic adsorption material and method for removing heavy metal ions in waste water

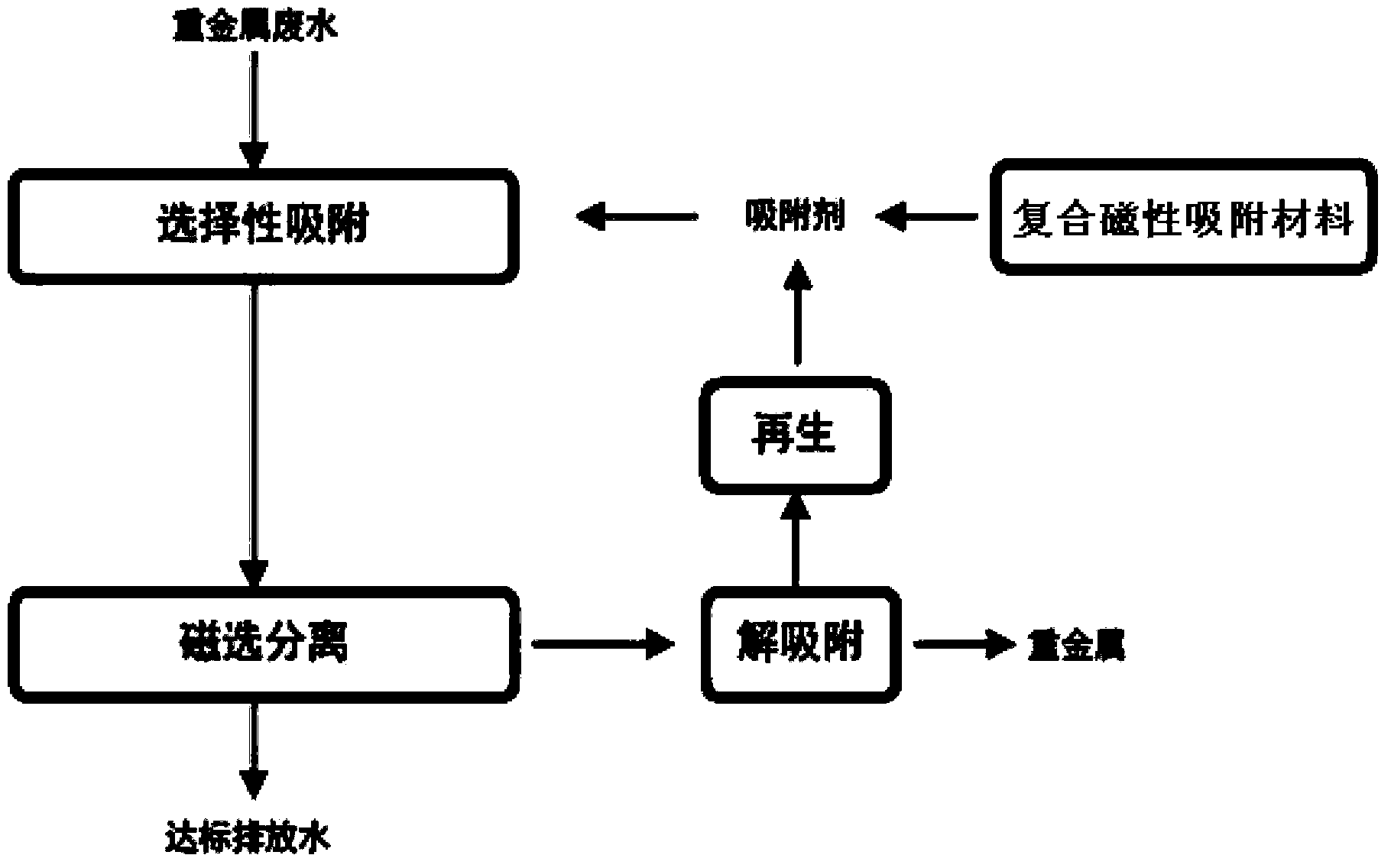

A heavy metal ion, composite magnetic technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sewage treatment and other directions, can solve the problems of cumbersome liquid-solid separation, application limitation, complexity, etc. Fast, cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The magnetite is finely ground in a pulverizer for a certain period of time to prepare a submicron magnetic particle powder with an average particle size of 0.8 μm. Put the above prepared magnetic particles into a three-necked flask, add chitosan, kerosene and water, magnetic particles: chitosan: kerosene: water (mass ratio) = 1:5:0.1:1000, keep the temperature at 70°C, stir React for 100 minutes. The magnetic substance is separated by magnetic separation, washed with deionized water for 3-5 times, and dried in vacuum to obtain a composite magnetic adsorption material.

Embodiment 2

[0033] The magnetite is finely ground in a pulverizer for a certain period of time to prepare a submicron magnetic particle powder with an average particle size of 0.8 μm. Put the prepared magnetic particles above into a three-necked flask, add chitosan, kerosene and water, magnetic particles: chitosan: kerosene: water (mass ratio) = 1:10:0.1:1000, keep the temperature at 70°C, stir React for 100 minutes. The magnetic substance is separated by magnetic separation, washed with deionized water for 3-5 times, and dried in vacuum to obtain a composite magnetic adsorption material.

Embodiment 3

[0035]The magnetite is finely ground in a pulverizer for a certain period of time to prepare a submicron magnetic particle powder with an average particle size of 0.8 μm. Put the above prepared magnetic particles into a three-necked flask, add chitosan, kerosene and water, magnetic particles: chitosan: kerosene: water (mass ratio) = 1:0.1:0.1:1000, keep the temperature at 90°C, stir React for 30 minutes. The magnetic substance is separated by magnetic separation, washed with deionized water for 3-5 times, and dried in vacuum to obtain a composite magnetic adsorption material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com