Chicken manure fermentation organic fertilizer

A technology of organic fertilizer and chicken manure, applied in the direction of organic fertilizer, inorganic fertilizer, nitrogen fertilizer, etc., can solve the problems of not meeting the overall needs of nutrients, soil permeability, poor water absorption, insufficient trace element content, etc., to achieve good taste and juice. The effect of rich and high effective viable count

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

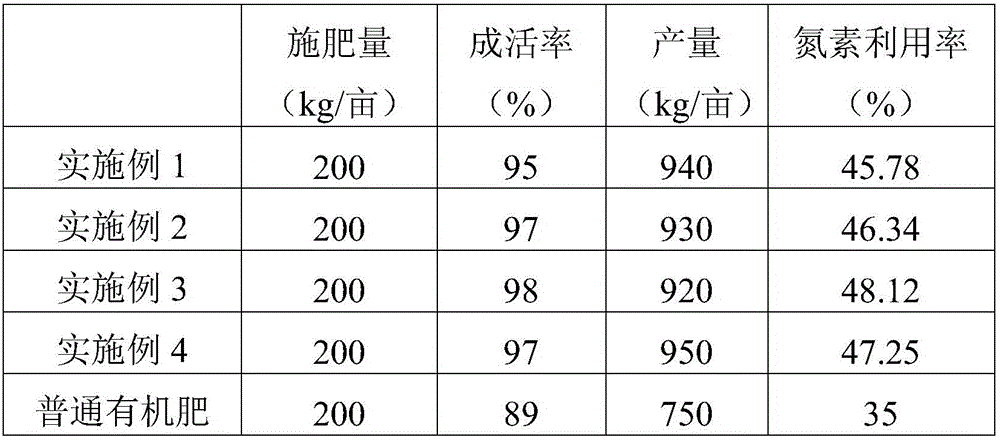

Examples

Embodiment 1

[0043] A chicken manure fermented organic fertilizer is composed of the following raw materials:

[0044] Chicken manure 200kg, straw powder 50kg, konjac flour 15kg, corn flour 10kg, cellulase 0.03kg, zeolite 3kg, humic acid 10kg, potassium dihydrogen phosphate 12kg, urea 10kg, peat soil 10kg, starter 10kg, soil conditioner 12kg , coating agent 5kg, potassium sulfate 5kg, borax 5kg, superphosphate 5kg;

[0045] The starter is prepared from the following raw materials in weight percentage: 30% of lactic acid bacteria, 10% of phosphobacteria, 10% of potassium solubilizers, 10% of streptococcus faecalis, 15% of aspergillus niger, 15% of bacillus subtilis, actinomycetes 10%;

[0046] The soil conditioner is made from raw materials:

[0047] Chitosan powder 50kg, tapioca starch 20kg, fly ash 5kg, medical stone powder 8kg, ascorbic acid 2kg, ferrous sulfate 1kg, sodium alginate 5kg, egg shell 10kg, ammonium sulfate 5kg, acrylamide 2kg, sodium acrylate 2kg; The preparation method ...

Embodiment 2

[0056] A chicken manure fermented organic fertilizer is composed of the following raw materials:

[0057] Chicken manure 400kg, straw powder 80kg, konjac flour 30kg, corn flour 15kg, cellulase 0.05kg, zeolite 8kg, humic acid 15kg, potassium dihydrogen phosphate 18kg, urea 10kg, peat soil 20kg, starter 15kg, soil conditioner 18kg , Coating agent 10kg, potassium sulfate 8kg, borax 8kg, superphosphate 10kg;

[0058] The starter is prepared from the following raw materials in percentage by weight: 20% of lactic acid bacteria, 10% of phosphate solubilizing bacteria, 10% of potassium solubilizing bacteria, 18% of faecal streptococcus, 20% of aspergillus niger, 12% of bacillus subtilis, actinomycetes 10%;

[0059] The soil conditioner is made from raw materials:

[0060] Chitosan powder 80kg, tapioca starch 30kg, fly ash 10kg, medical stone powder 15kg, ascorbic acid 5kg, ferrous sulfate 5kg, sodium alginate 15kg, egg shell 15kg, ammonium sulfate 8kg, acrylamide 5kg, sodium acrylat...

Embodiment 3

[0069] A chicken manure fermented organic fertilizer is composed of the following raw materials:

[0070] Chicken manure 300kg, straw powder 70kg, konjac flour 20kg, corn flour 12kg, cellulase 0.05kg, zeolite 5kg, humic acid 15kg, potassium dihydrogen phosphate 15kg, urea 12kg, peat soil 18kg, starter 13kg, soil conditioner 16kg , coating agent 8kg, potassium sulfate 8kg, borax 7kg, superphosphate 8kg;

[0071] Described leavening agent is the leavening agent prepared in embodiment 2;

[0072] The soil conditioner is made from raw materials:

[0073] Chitosan powder 70kg, tapioca starch 25kg, fly ash 8kg, medical stone powder 10kg, ascorbic acid 3kg, ferrous sulfate 3kg, sodium alginate 12kg, egg shell 12kg, ammonium sulfate 7kg, acrylamide 4kg, sodium acrylate 4kg; The preparation method is to mix and grind egg shells and fly ash into 300-400-mesh powder, then add other ingredients and continue grinding to obtain 300-400-mesh powder, and fully stir and mix the obtained powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com