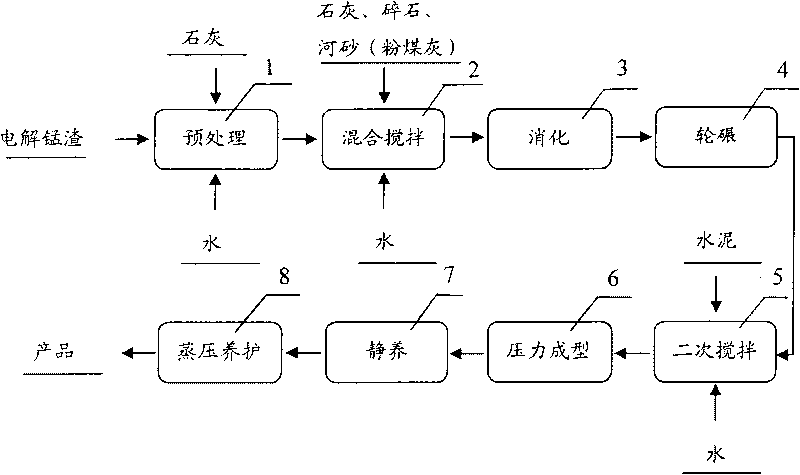

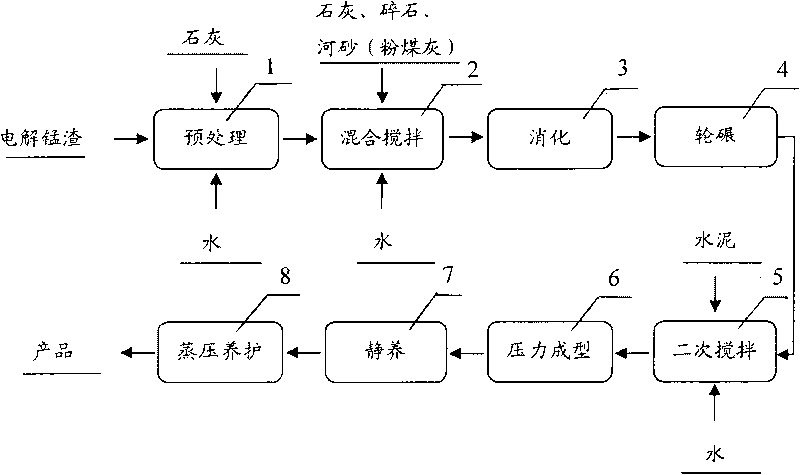

Preparation method of electrolytic manganese slag autoclaved brick

A technology for electrolytic manganese slag and autoclaved bricks, which is applied in the fields of resource recycling and recycling and building materials, can solve the problems of less practical application of enterprises and society, large consumption of electrolytic manganese slag, and large product market capacity, and achieves good social and economic benefits. , the effect of promoting employment and strong market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) In the electrolytic manganese slag, based on 36% (weight) of electrolytic manganese slag, 4% lime is blended, and water at a temperature of 45°C is added at the same time, stirred in a forced mixer for 40 minutes, and then stacked in the open air 5 days;

[0030] (2) Add 26% river sand, 20% gravel, and 12% lime to the pretreated electrolytic manganese slag, add water and stir to mix evenly;

[0031] (3) Transport the mixture to the DHL1600 wheel mill for grinding for 1 minute, and then transport the wheel-milled mixture to the digestion bin for digestion for 6 hours.

[0032] (4). Add 2% cement to the digested mixture, then add water and stir thoroughly, and control the moisture content of the mixture at 16%.

[0033] (5). Transport the stirred mixture to the DY850 pressure forming machine. The mixture is pressed into bricks with a molding pressure of 18 MPa. After the bricks are stacked, they are rested for 6 hours in the resting room.

[0034] (6). Transfer the ...

Embodiment 2

[0037](1) In the electrolytic manganese slag, based on 45% (weight) electrolytic manganese slag, mix 6% lime, add water at a temperature of 60°C at the same time, stir in a forced mixer for 40 minutes, and then stack in the open air 5 days;

[0038] (2) In the pretreated electrolytic manganese slag, add 20% river sand, 19.5% gravel, 9% lime, add water and stir to mix evenly;

[0039] (3) Transport the mixture to the DHL1600 wheel mill for grinding for 1 minute, and then transport the wheel-milled mixture to the digestion bin for digestion for 6 hours.

[0040] (4). Add 0.5% cement to the digested mixture, then add water and stir evenly, and control the moisture content of the mixture at 14%.

[0041] (5). Transport the agitated mixture to the DY850 pressure forming machine. The mixture is pressed into bricks with a molding pressure of 20 MPa. After the bricks are stacked, they are rested in the resting room for 6 hours.

[0042] (6). Transfer the static-cured adobe to an aut...

Embodiment 3

[0045] (1) In the electrolytic manganese slag, based on 25% (weight) of electrolytic manganese slag, 5% lime is mixed, and water at a temperature of 40°C is added at the same time, stirred in a forced mixer for 45 minutes, and then stacked in the open air 3 days;

[0046] (2) Add 40% river sand, 18% gravel, and 11% lime to the pretreated electrolytic manganese slag, add water and stir to mix evenly;

[0047] (3) Transport the mixture to the DHL1600 wheel mill for grinding for 1 minute, and then transport the wheel-milled mixture to the digestion bin for digestion for 6 hours.

[0048] (4). Add 1% cement to the digested mixed material, then add water and stir evenly, and control the moisture content of the mixed material at 15%.

[0049] (5). Transport the stirred mixture to the DY850 pressure molding machine. The mixture is pressed into bricks with a molding pressure of 16.0 MPa. After the bricks are stacked, they are rested for 4 hours in the resting room.

[0050] (6). Tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com