Method for ore dressing of bauxite

A bauxite and ore technology, used in chemical instruments and methods, wet separation, solid separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

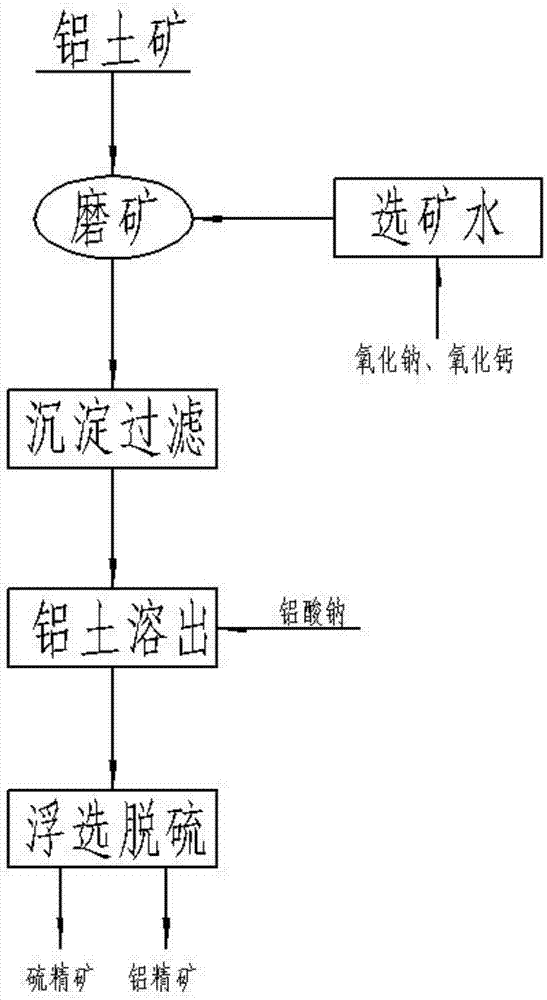

Image

Examples

Embodiment 1

[0018] The method for beneficiation of bauxite, including ore grinding, flotation desulfurization process, is characterized in that: the processing process is ore grinding, conventional sedimentation filtration, bauxite dissolution and flotation desulfurization; The ore is ground and washed simultaneously.

[0019] The ore is ground to 0.082mm, accounting for 85%.

[0020] The ore mill equipment is provided with a washing nozzle, which is connected to a washing tank, and a washing liquid is housed in the washing tank; calcium oxide and aluminum oxide are added to the washing liquid, and the amount of addition is 5 liters of calcium oxide per liter of the washing liquid. gram and alumina 1 gram.

[0021] Described bauxite stripping adopts the sodium aluminate solution stripping bauxite that contains caustic soda; The stripping temperature in the process is 50 ℃; The stripping time is 1d; The concentration of sodium is always greater than 21% throughout the dissolution process...

Embodiment 2

[0024] The method for beneficiation of bauxite, including ore grinding, flotation desulfurization process, is characterized in that: the processing process is ore grinding, conventional sedimentation filtration, bauxite dissolution and flotation desulfurization; The ore is ground and washed simultaneously.

[0025] The ore is ground to 0.082mm, accounting for 87%.

[0026] The ore mill equipment is provided with a washing nozzle, which is connected to a washing pool, and a washing liquid is housed in the washing pool; calcium oxide and aluminum oxide are added to the washing liquid, and the addition amount is 15% calcium oxide per liter of the washing liquid. grams and alumina 1.5 grams.

[0027] Described bauxite stripping adopts the sodium aluminate solution stripping bauxite that contains caustic soda; The stripping temperature in the process is 70 DEG C; The stripping time is 1.5d; The addition of calcium oxide is 9% of bauxite weight, The concentration of sodium oxide i...

Embodiment 3

[0030] The method for beneficiation of bauxite, including ore grinding, flotation desulfurization process, is characterized in that: the processing process is ore grinding, conventional sedimentation filtration, bauxite dissolution and flotation desulfurization; The ore is ground and washed simultaneously.

[0031] The ore is ground to 0.082mm, accounting for 90%.

[0032] The ore mill equipment is provided with a washing nozzle, which is connected to a washing tank, and a washing liquid is housed in the washing tank; calcium oxide and aluminum oxide are added to the washing liquid, and the addition amount is 20% calcium oxide per liter of the washing liquid. grams and 2 grams of alumina.

[0033] Described bauxite stripping adopts the sodium aluminate solution stripping bauxite that contains caustic soda; The stripping temperature in the process is 100 DEG C; The stripping time is 2d; The addition of calcium oxide is 15% of the bauxite weight, The concentration of sodium is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com