Lower electrode assembly for plasma processing equipment and plasma processing equipment

A technology for processing equipment and plasma, used in electrical components, circuits, discharge tubes, etc., to solve problems such as static charge accumulation, and reduce electrical damage or other risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] based on the following Figure 1 to Figure 6 , specifically explain the preferred embodiment of the present invention.

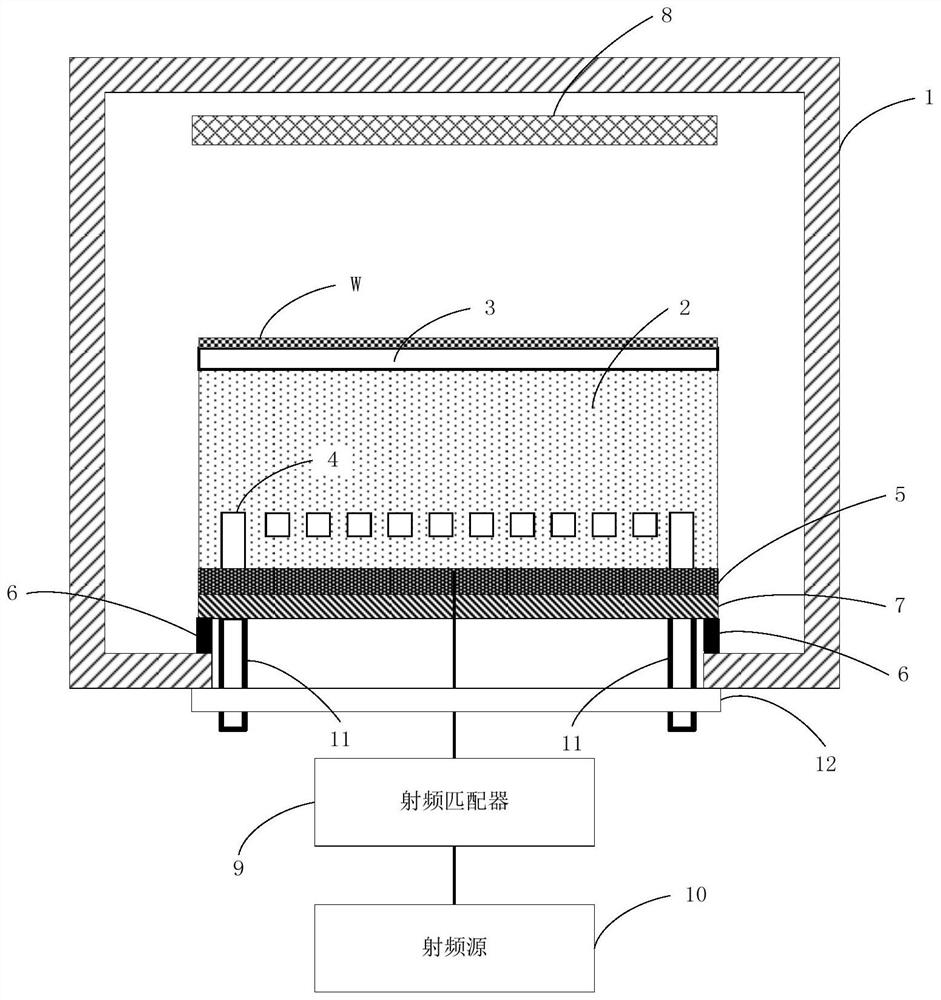

[0032] figure 1 It is a schematic structural diagram of a plasma processing device including a radio frequency electrode provided in an embodiment of the present invention.

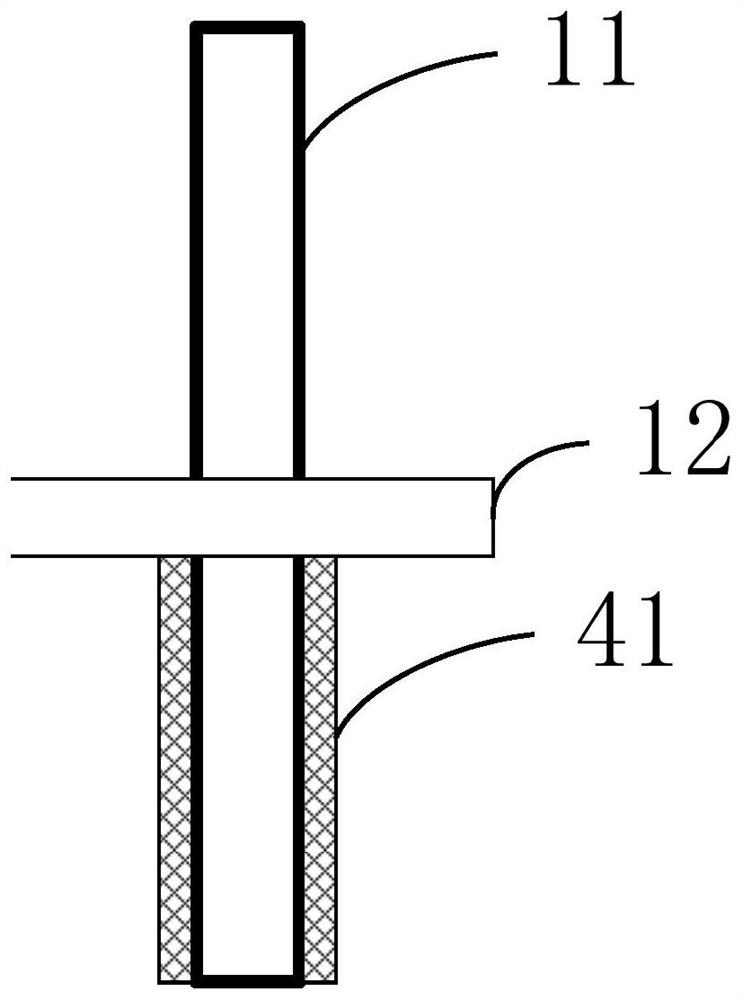

[0033] Such as figure 1 As shown, the plasma processing equipment includes a vacuum reaction chamber 1. A base 2 is arranged in the vacuum reaction chamber 1. An electrostatic chuck 3 is arranged on the base 2. The electrostatic chuck 3 is used to carry a substrate W to be processed. The base 2 is provided with a cooling passage 4, and the two ends of the cooling passage 4 are respectively connected with two cooling pipes 11, and the cooling pipe 11 leads out of the vacuum reaction chamber 1, and is connected with a cooling liquid storage device (not shown in the figure). 4 The insulating liquid circulates inside, and the heat on the base 2 and the electrostatic chuck 3 is tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com