Underground blockage device of casing pressure balanced working method

A plugging device and casing technology are applied to the downhole plugging device, the matching device of the casing workover operation method, the sucker rod can be pulled up and down under pressure, and the tubing field can solve the problems of high cost, long operation period, and limitation. downhole pressure and other problems, to achieve the effects of energy-saving production, reliable performance and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

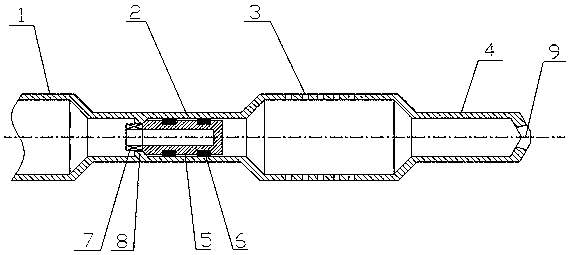

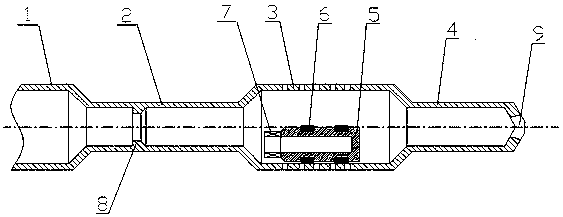

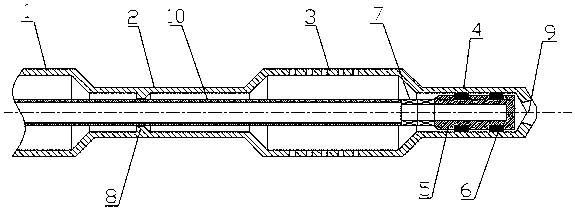

[0019] A downhole plugging device for a casing snubbing operation method, such as figure 1 , figure 2 , image 3 In the shown embodiment 1, the lower end of the superior casing 1 is connected to the plugging casing 2 through a transitional conical surface. The diameter of the blocking casing 2 is smaller than that of the upper casing 1. On the inner wall of the blocking casing 2 A limiting platform 8 is provided, and the lower end of the plugging sleeve 2 is connected to the through-hole screen 3 with evenly distributed through-holes on the pipe wall through the transitional conical surface, and the through-hole screen 3 is connected to the centralizing pipe 4 through the transitional conical surface. The diameter of the pipe 4 is equal to the diameter of the plugging sleeve 2, and a ventilation hole 9 is arranged on the sealing of the lower end of the centralizing pipe 4, and a plugging blind pipe 5 with a closed lower mouth is installed in the plugging sleeve 2, and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com