A high-efficiency preparation process of aluminum alloy sheet for automobile body

A technology for aluminum alloy sheets and automobile bodies, which is applied in the field of preparation and processing of aluminum alloy materials, can solve the problems of low production efficiency and long occupation time of continuous production lines, and achieve energy-saving production and solve the effects of long occupation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

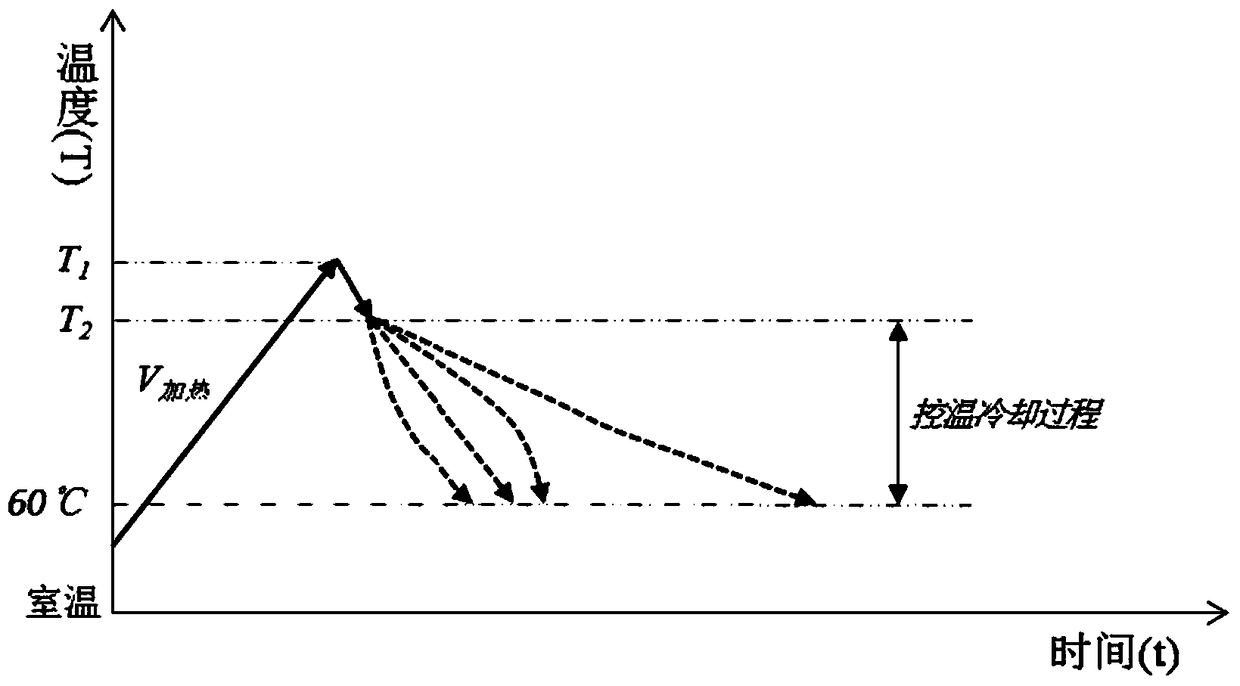

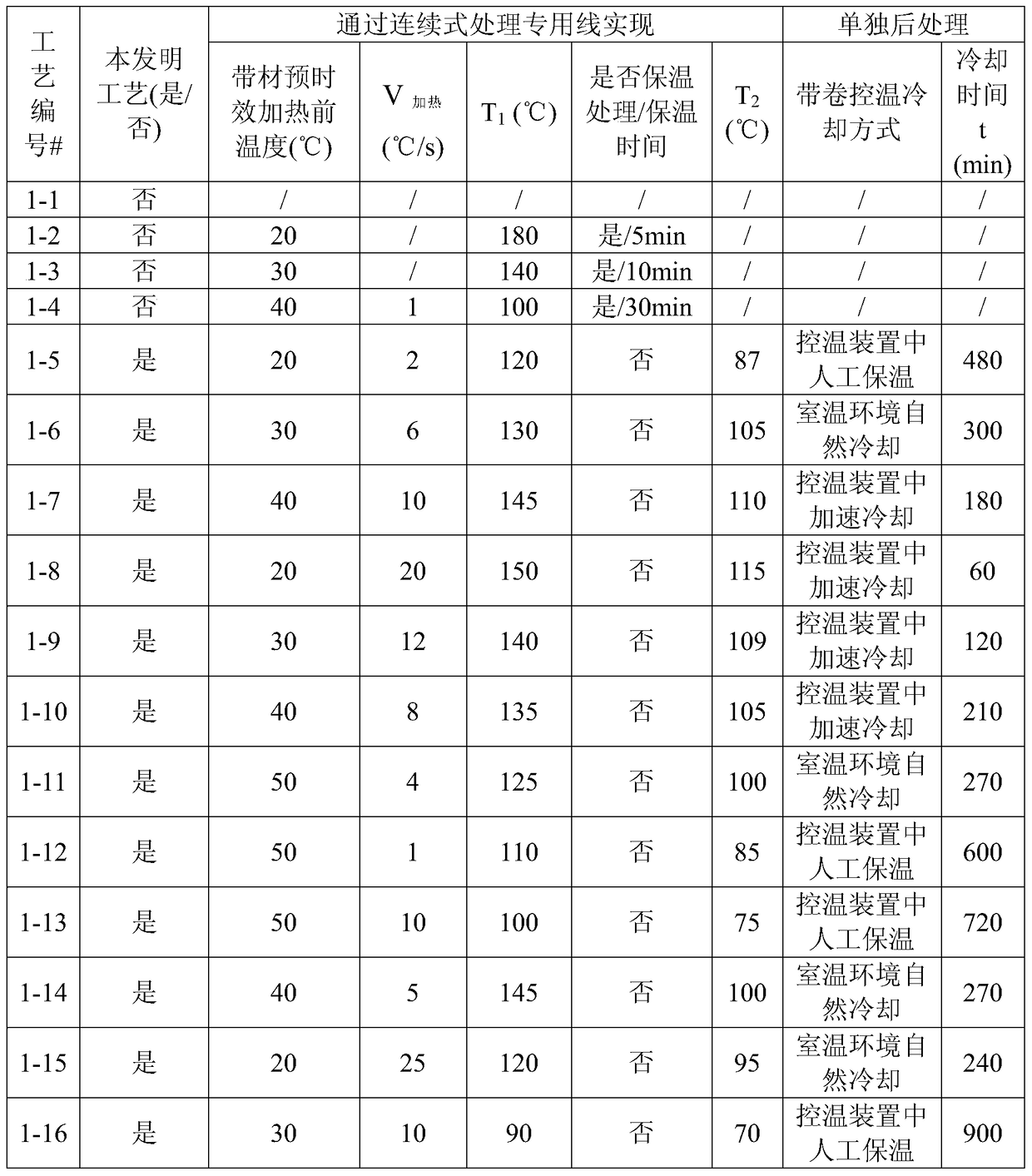

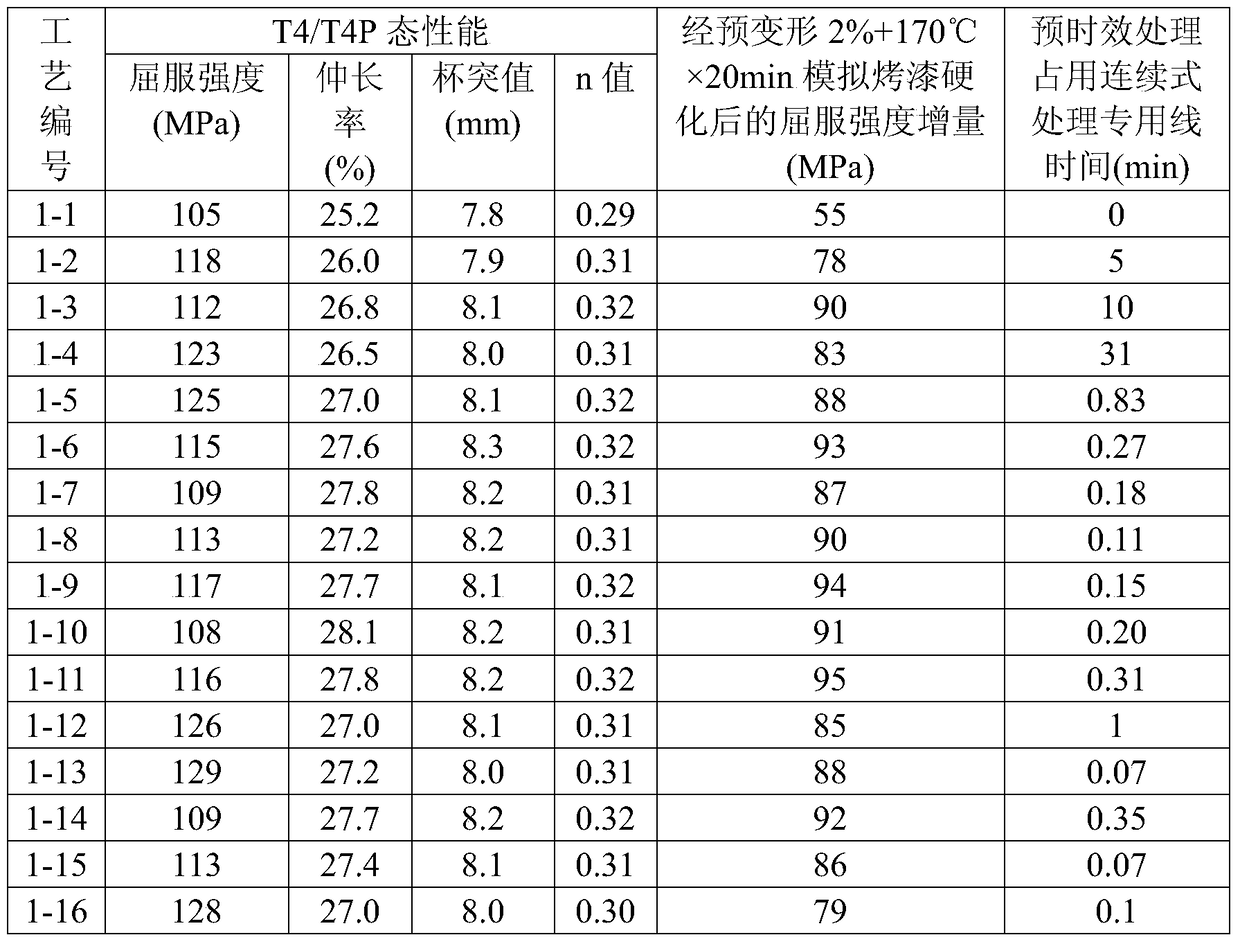

[0024] Apply the present invention to commercialized AA6016 aluminum alloy, its nominal composition range (mass fraction, %): Si 1.0-1.5, Fe not higher than 0.5, Cu not higher than 0.2, Mn not higher than 0.2, Mg 0.25-0.6, Cr is not higher than 0.1, Zn is not higher than 0.2, Ti is not higher than 0.15, the balance of Al and other inevitable impurities; choose a typical alloy composition: 1.04% Si, 0.44% Mg, 0.1% Cu, 0.08 %Mn, 0.05% Zn, 0.02% Cr, balance Al and unavoidable other impurities. Alloy coils with a thickness of 0.95mm are obtained through melting and casting, homogenization treatment, hot rolling, intermediate annealing and cold rolling, and uncoiling, cleaning, solution quenching, tension straightening, alkali cleaning, Pickling, conversion treatment, pre-aging heating, oiling, coiling and other processes, followed by temperature-controlled cooling of the coil, the technical scheme of pre-aging heating and temperature-controlled cooling is shown in Table 1, and the...

Embodiment 2

[0031] Applying the present invention to a novel 6000 series aluminum alloy, its nominal composition range (mass fraction, %): Si0.6-1.2, Cu 0.01-0.2, Mn 0.01-0.25, Mg 0.7-1.3, Zr 0.01-0.20, Zn 0.25-0.82, Fe not higher than 0.4, the balance of Al and other unavoidable impurities; among them, select a typical alloy composition: 0.9% Si, 0.95% Mg, 0.16% Cu, 0.10% Mn, 0.5% Zn, 0.11 %Zr, balance Al and unavoidable other impurities. Alloy coils with a thickness of 0.95mm are obtained through melting and casting, homogenization treatment, hot rolling, intermediate annealing and cold rolling, and uncoiling, cleaning, solution quenching, tension straightening, alkali cleaning, Pickling, conversion treatment, pre-aging heating, oiling, coiling and other processes, followed by temperature-controlled cooling of the coil, the technical scheme of pre-aging heating and temperature-controlled cooling is shown in Table 3, and the T4P state sample was obtained. Finally, the T4P state samples ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com