Preparation method for anti-mud-type polycarboxylic-acid water-reducing agent and application thereof

A technology of polycarboxylic acid and water-reducing agent, which is applied in the field of preparation of clay-resistant polycarboxylate water-reducing agent, can solve the problem of side chain entering into clay frame structure, poor clay resistance, poor plasticity retention over time, and mixing of water-reducing agent with water-reducing agent. To solve the problems of large amount, etc., to achieve the effect of shortening the synthesis time, high water reduction rate, and weakening the interspersed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

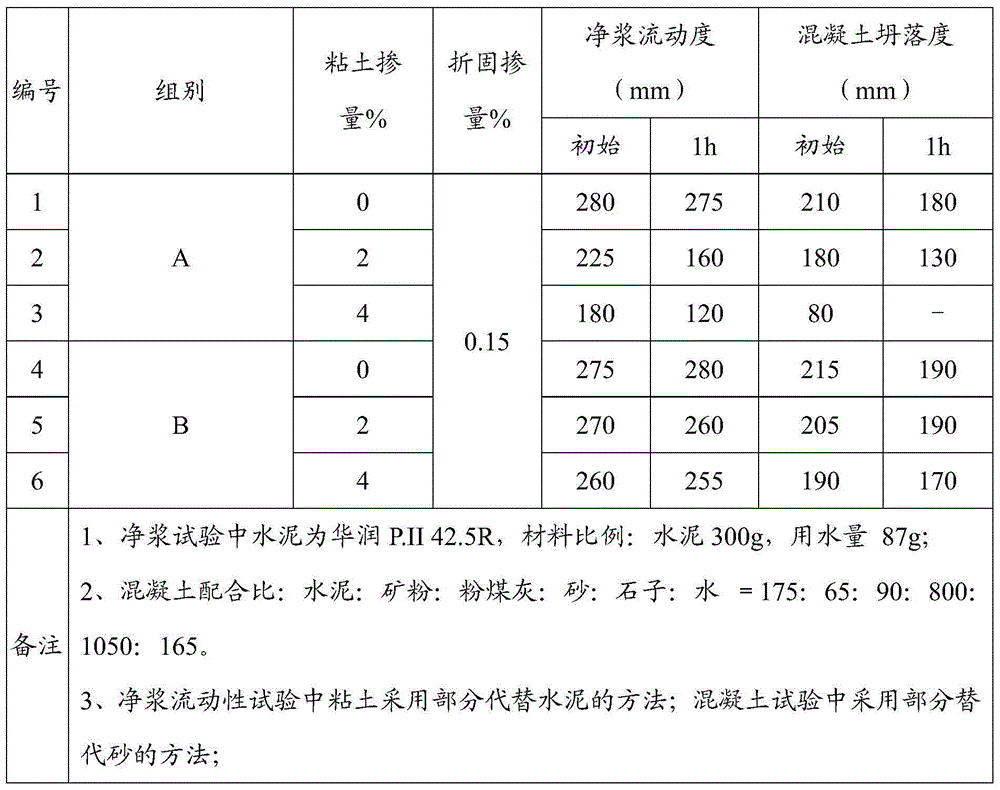

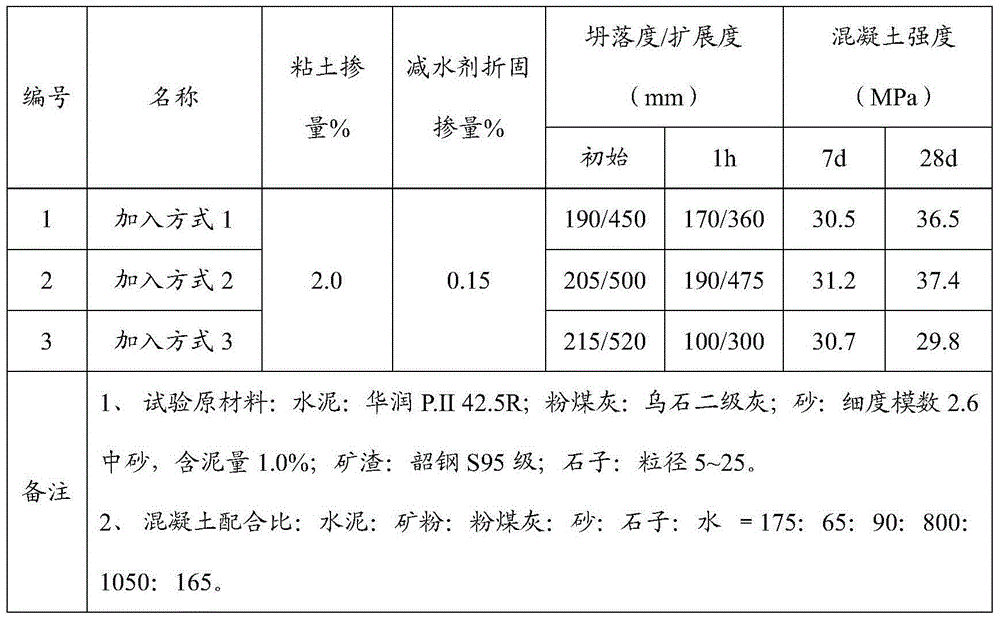

Examples

preparation example Construction

[0029] The invention provides a preparation method of mud-resistant polycarboxylate superplasticizer, comprising:

[0030] Material preparation, butenol polyoxyethylene ether, acrylic acid, p-styrene formate, maleic anhydride-β-cyclodextrin, mercaptopropionic acid, ascorbic acid, sodium dithionite, and hydrogen peroxide in a mass ratio of 100- 130: 15-25: 1-5: 5-15: 0.1-10.0: 0.3-1.2: 0.1-1.0: 0.5-5.0;

[0031] Under normal temperature conditions of 5-35°C, mix and dissolve isobutylene alcohol polyoxyethylene ether and maleic anhydride-β-cyclodextrin in water to obtain an aqueous monomer solution with a mass concentration of (50-70)%;

[0032] Mixing acrylic acid and p-styrene methacrylate to form an aqueous solution with a mass concentration of (80-95)% to obtain a mixed solution of acrylic acid and p-styrene methacrylate;

[0033] Adding (5-15)% of the mixed solution of acrylic acid and p-styrene formate to the aqueous monomer solution;

[0034] Add (27-50)% hydrogen perox...

Embodiment 1

[0043]Mix 18.0 g of acrylic acid with 4.0 g of p-styrene methacrylate, and add deionized water to prepare solution A with a concentration of 80%.

[0044] 0.7 g of ascorbic acid was mixed with 1.0 g of mercaptopropionic acid, and deionized water was added to prepare solution B with a concentration of 5%.

[0045] Mix 3.0 g of sodium dithionite with 7.0 g of deionized water to prepare solution C with a concentration of 30%.

[0046] At room temperature of 20°C, 120.0g of isobutenol polyoxyethylene ether with a molecular weight of 2400 and 7.0g of maleic anhydride-β-cyclodextrin were added to the reactor, and then 98.0g of deionized water was added to prepare a monomer mass concentration of 56% macromonomer solution, then add 3.0g solution A, after stirring evenly, add 3.0g 27.5% hydrogen peroxide solution. After the above mixture was stirred for 10 minutes, solution B, the remaining solution A and solution C were added dropwise under nitrogen protection, and the addition was c...

Embodiment 2

[0048] 21.0 g of acrylic acid was mixed with 2.5 g of p-styrene methacrylate, and deionized water was added to prepare solution A with a concentration of 85%.

[0049] Mix 0.5 g of ascorbic acid and 0.5 g of mercaptopropionic acid, and add deionized water to prepare solution B with a concentration of 2.5%.

[0050] Mix 1.5 g of sodium dithionite with deionized water to prepare solution C with a concentration of 35%.

[0051] At room temperature at 5°C, add 130.0 g of isobutenol polyoxyethylene ether with a molecular weight of 2400 and 5.5 g of maleic anhydride-β-cyclodextrin into the reactor, and then add 60.0 g of deionized water to prepare a monomer mass concentration of 69% macromonomer solution, then add 2.0g solution A, after stirring evenly, add 1.5g 27.5% hydrogen peroxide solution. After the above mixture was stirred for 10 minutes, solution B, the remaining solution A and solution C were added dropwise under nitrogen protection, and the addition was controlled within...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com