Low temperature production method for high speed corrugated board line, and steam system

A corrugated cardboard and production method technology, applied in piping systems, mechanical processing/deformation, mechanical equipment, etc., can solve the problems of inability to produce high-speed, weaken the protective performance of corrugated cardboard, and waste heat energy, etc., and improve the qualified rate of product quality. , Improve the protection effect of packaging and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

[0034] The low-temperature production method of the high-speed corrugated cardboard line includes the following steps:

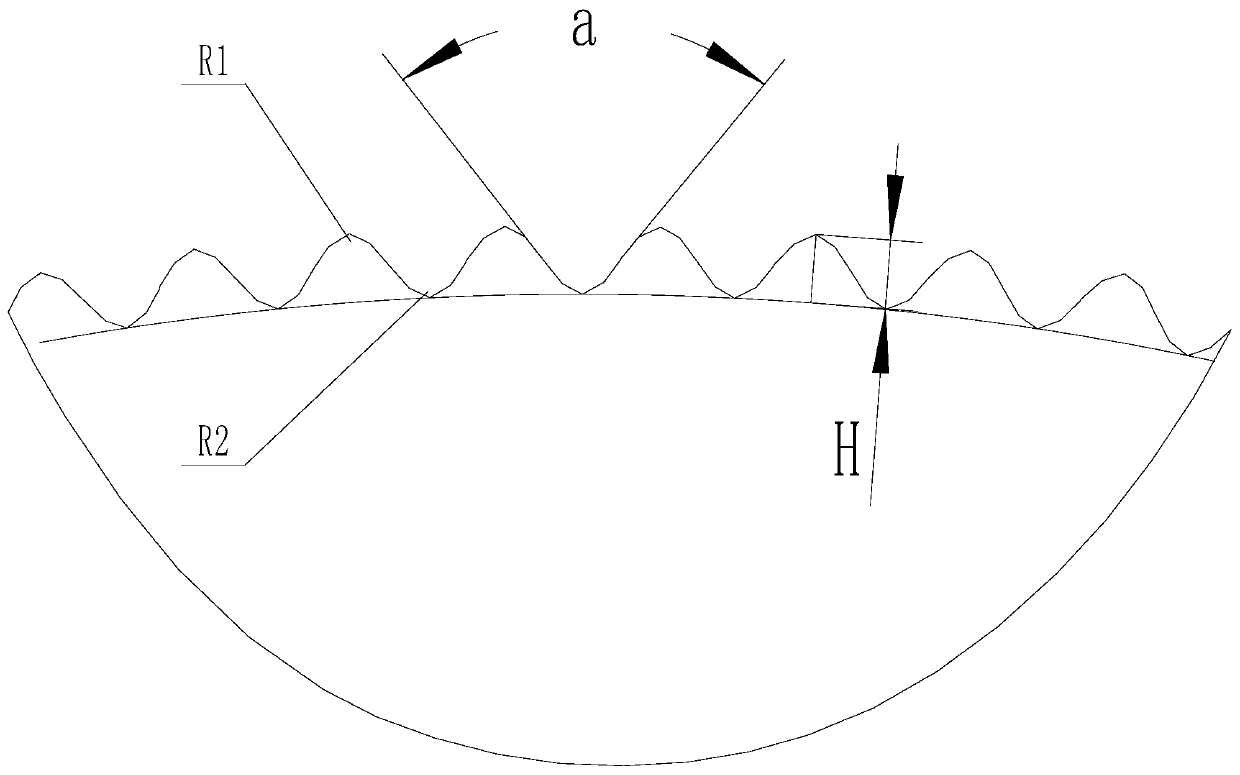

[0035] 1) Preparation process: adjust the parallelism of the corrugating roller, the gap between the corrugating roller and the glue roller, the gap is 0.1-0.15mm; every day before starting up or changing the corrugating roller during the production process, it is necessary to check the parallelism of the corrugating roller The adjustment method is as follows: first separate the gluing system of the single-sided machine from the main machine of the single-sided machine, then start the main machine of the single-sided machine, and preheat the temperature of the corrugating roller to above 120°C. The best preheating temperature is 140°C. Both ends of the roller are pressurized to 40-50kgf / cm 2 , the optimal pressure is 40kgf / cm 2 , one person will slowly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com