Drying room and method for dehydration through drying room

A drying room, cold water technology, applied in drying, dryer, dryer for static materials, etc., can solve the problems of energy consumption, environmental damage, low efficiency, etc., and achieve the effect of low energy consumption and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

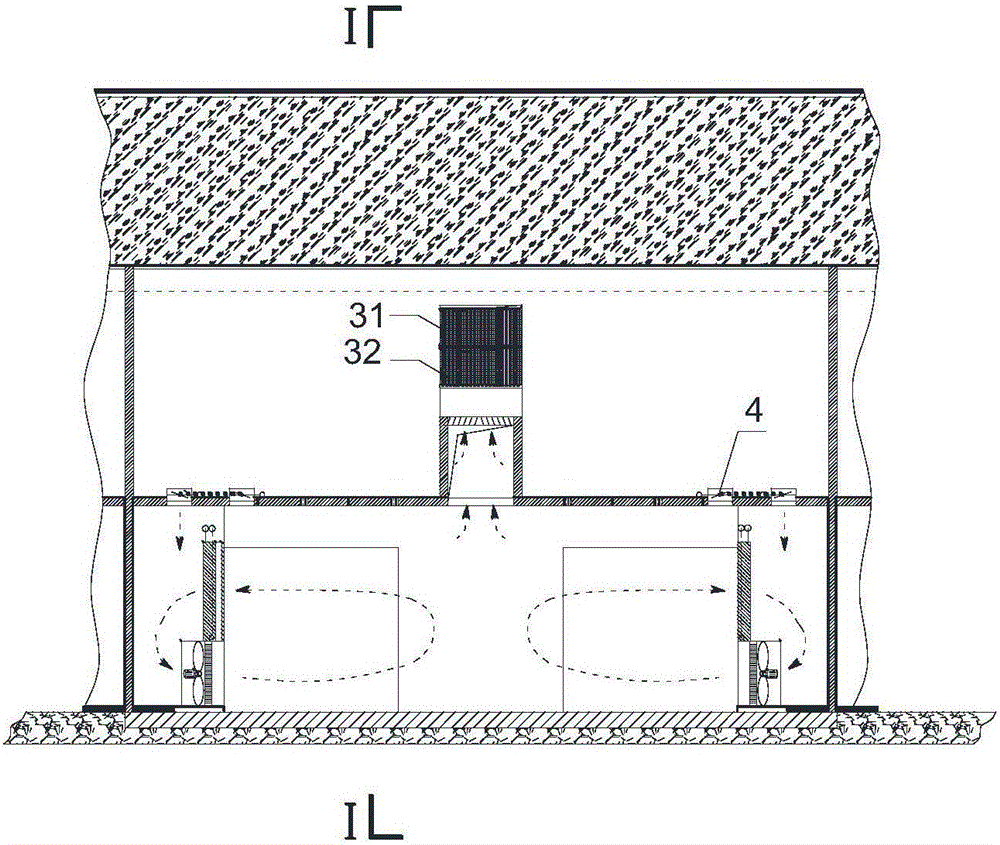

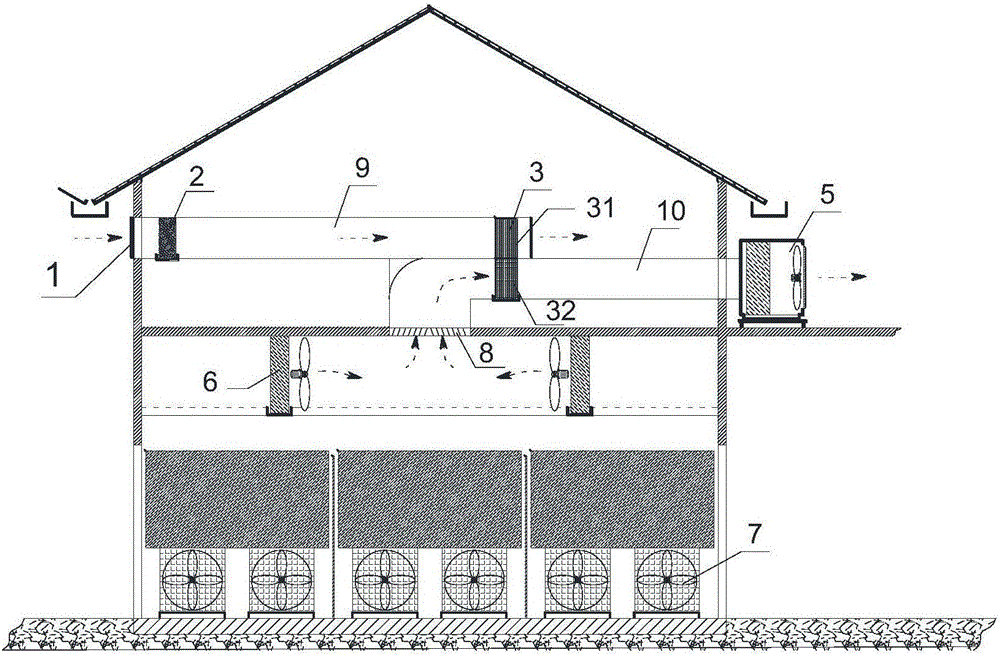

[0028] refer to Figure 1-2 , a drying room, including fresh fan 7 dew point cooler 2, oscillating heat pipe, double electric air valve 4, exhaust and waste heat recovery wind cabinet 5, surface cooler 6 and fan 7.

[0029] The inlet of the drying room is provided with an air inlet 1, and the drying room is provided with an air outlet 8; the inlet air is connected to the air inlet end of the dew point cooler 2 of the fresh fan 7, and the air outlet end of the dew point cooler 2 of the fresh fan 7 is connected There is a first air duct 9, the other end of the first air duct 9 is connected to the exothermic end of the oscillating heat pipe,

[0030] The heat absorbing end 32 of the oscillating heat pipe is connected to the double electric air valve 4, the air outlet 8 is connected to the heat absorbing end 32 of the oscillating heat pipe, and the heat absorbing end 32 of the oscillating heat pipe is connected with the second air pipe 10, The other end of 10 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com