A device for preparing nano-zinc oxide by non-equilibrium oxidation of metal zinc

A nano-zinc oxide and metal zinc technology, applied in the direction of carbon monoxide, zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems of increasing the production cost of indirect zinc oxide, difficulty in meeting nano-level requirements, and coarse particle size of zinc oxide , to achieve high energy utilization efficiency, excellent performance, and small product particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

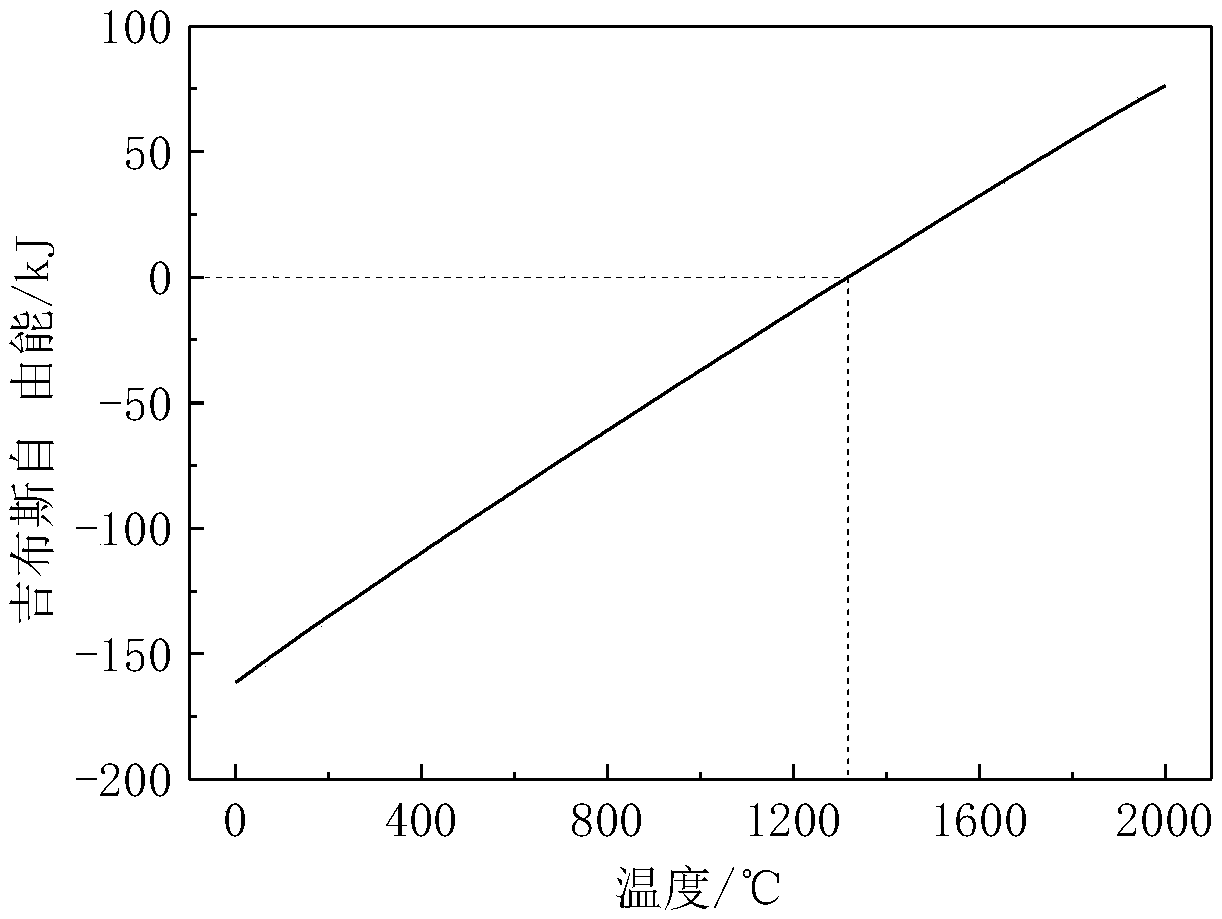

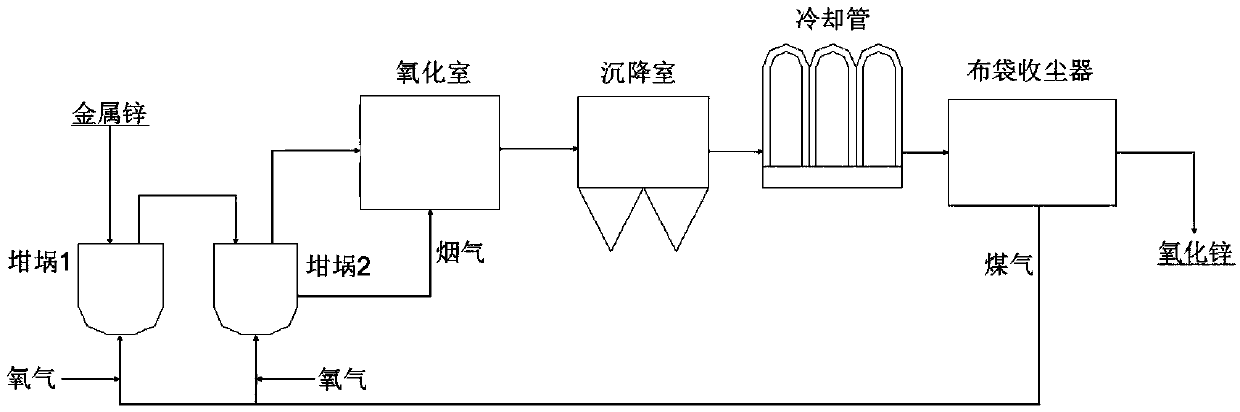

Embodiment 1

[0042] The process steps are as follows: put 100kg of zinc ingot into the first graphite crucible for external heating and melting; the melted metal zinc liquid flows into the second graphite crucible for external heating and evaporation, and the evaporated zinc vapor enters the oxidation chamber for oxidation, oxidation The gas is CO produced by external heating 2 Smoke, the volume of smoke is 100m 3 , the oxidation temperature is around 1300°C. The zinc oxide dust obtained by oxidation passes through the gravity settling chamber, the cooling pipe, and then through the bag dust collection to obtain the zinc oxide product with the gas. The particle size of the zinc oxide product is 100-800nm, and the gas after the bag dust collection is returned to be used for external heating and melting of metal zinc And the evaporation process, the combustion air used is oxygen with an oxygen content of 90%.

Embodiment 2

[0044] The process steps are as follows: put 100kg of zinc slag into the first silicon carbide crucible for external heating and melting; the melted metal zinc liquid flows into the second silicon carbide crucible for external heating and evaporation, and the evaporated zinc vapor enters the oxidation chamber for oxidation , the oxidizing gas is CO produced by external heating 2 Smoke, the volume of smoke is 150m 3 , the oxidation temperature is around 1150°C. The zinc oxide dust obtained by oxidation passes through the gravity settling chamber, the cooling pipe, and then through the bag dust collection to obtain the zinc oxide product with the gas. The particle size of the zinc oxide product is 50-500nm. The gas after the bag dust collection is returned to be used for external heating and melting of metal zinc And evaporation process, the used combustion air is oxygen with an oxygen content of 95%.

Embodiment 3

[0046] The process steps are as follows: put 100kg of zinc slag into the first graphite crucible for external heating and melting; the melted metal zinc liquid flows into the second graphite crucible for external heating and evaporation, and the evaporated zinc vapor enters the oxidation chamber for oxidation, oxidation The gas is CO produced by external heating 2 Smoke, the volume of smoke is 200m 3 , the oxidation temperature is around 950°C. The zinc oxide dust obtained by oxidation passes through the gravity settling chamber, the cooling pipe, and then through the bag dust collection to obtain the zinc oxide product with the gas. The particle size of the zinc oxide product is 50-500nm. The gas after the bag dust collection is returned to be used for external heating and melting of metal zinc And the evaporation process, the combustion air used is oxygen with an oxygen content of 100%.

[0047] The present invention also provides a kind of device that is used for preparin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com