Pharmaceutical heat-preserving dispensing tank

A liquid dispensing tank and inner tank technology, which is applied in the field of pharmaceutical thermal insulation liquid dispensing tanks, can solve the problems of difficulty in ensuring the temperature uniformity of the internal medicinal liquid, affecting the quality of medicinal liquid preparation, and uneven internal temperature, so as to achieve rapid pharmaceutical production and reduce Quality, the effect of realizing energy-saving production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

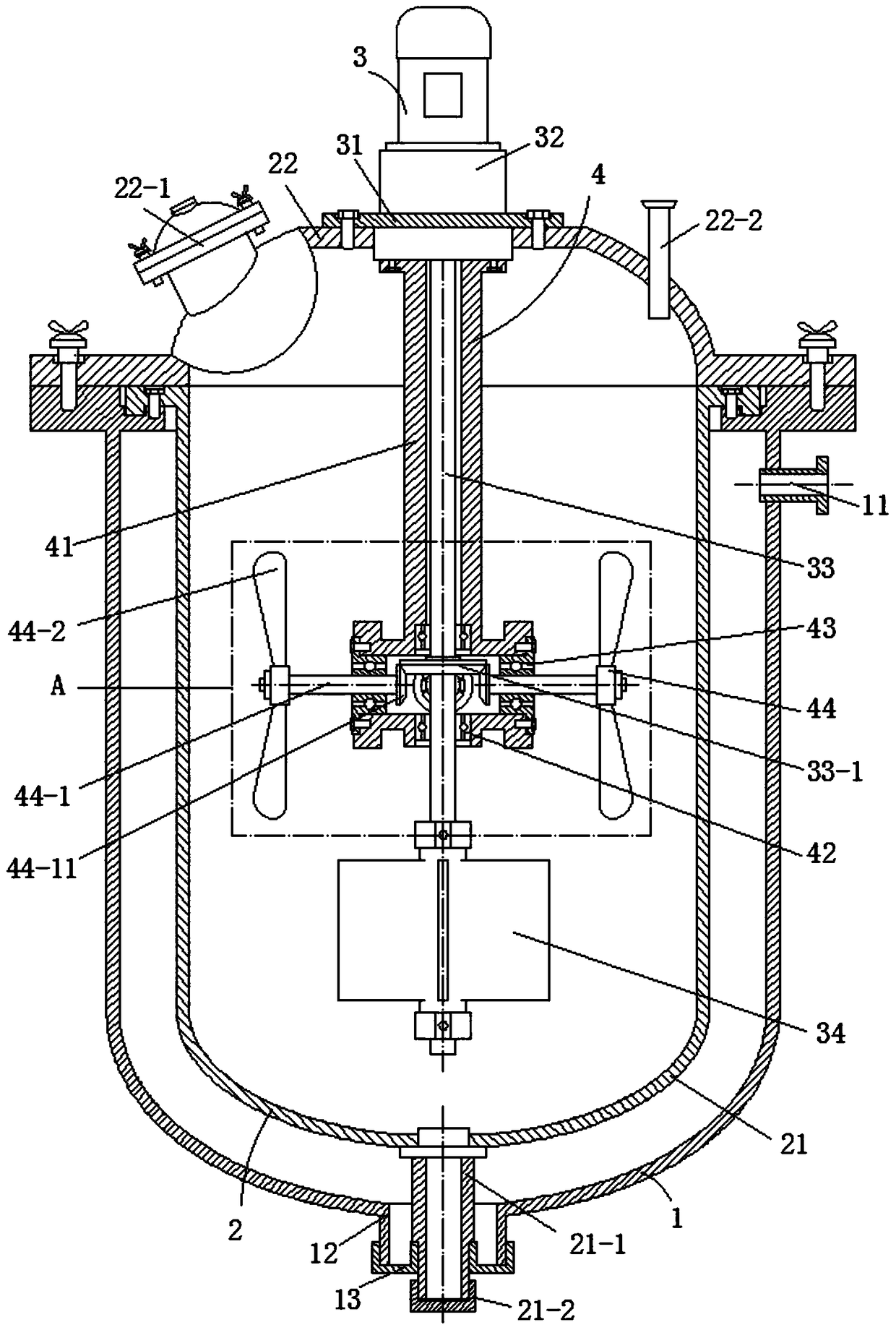

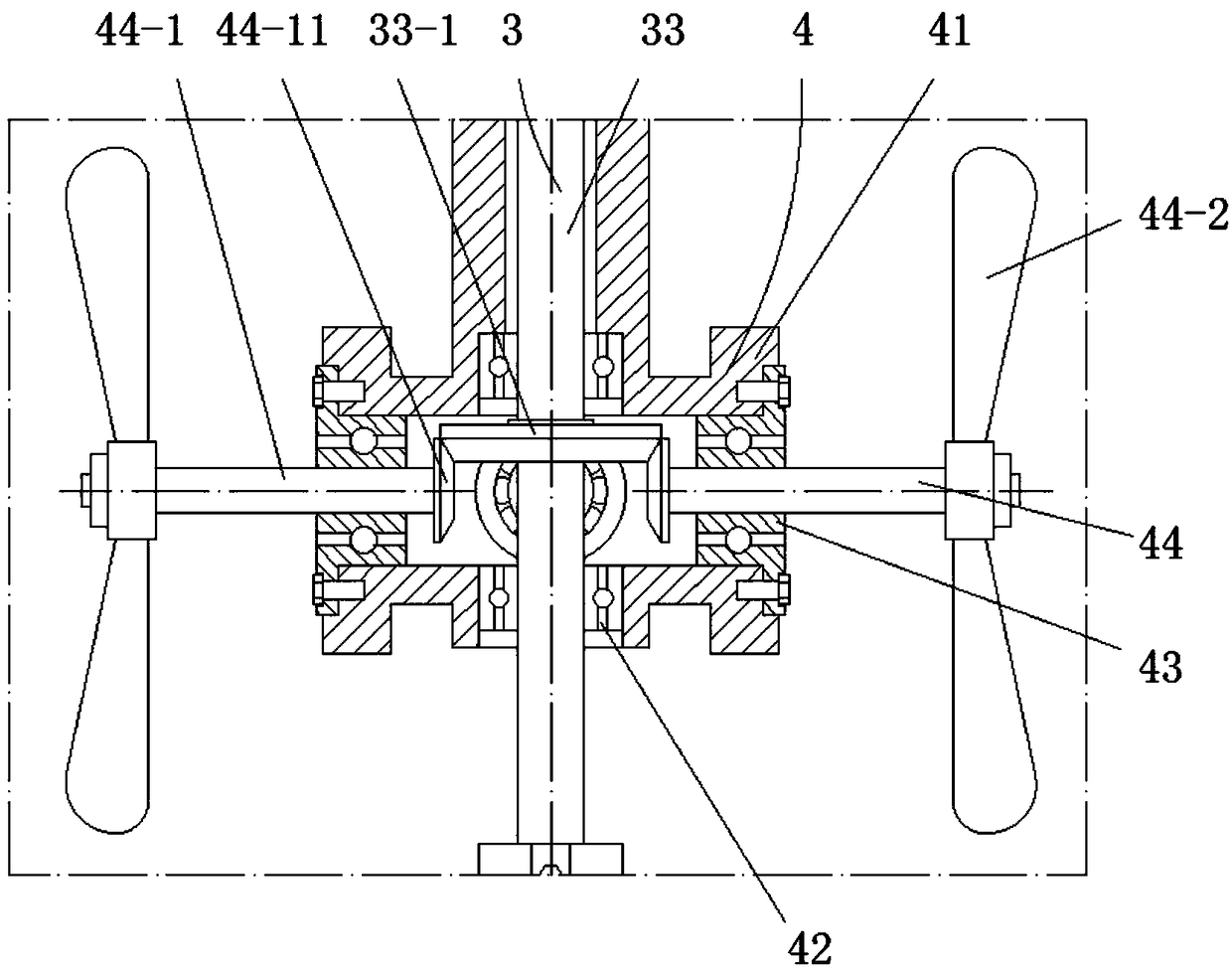

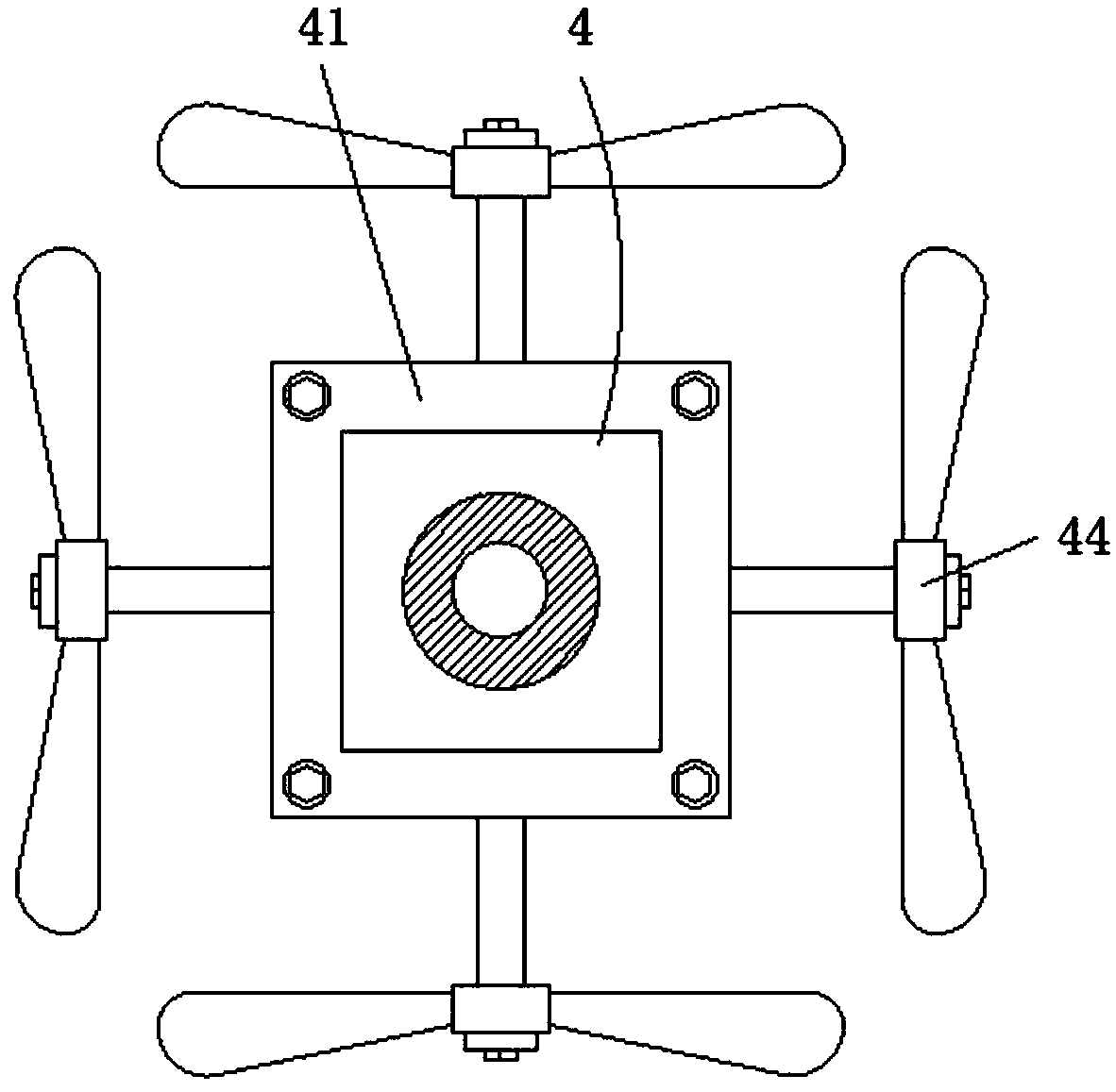

[0025] A heat-preserving liquid mixing tank for pharmaceuticals with a structure of the present invention has high liquid mixing and stirring efficiency. Specifically, the medicinal liquid to be mixed is poured from the manhole 22-1, and then the reduction motor 32 is started, and the reduction motor 32 will Drive the rotating shaft 33 to rotate. On the one hand, the cross stirring blade 34 fixedly installed on the rotating shaft 33 will rotate with the rotation of the rotating shaft 33, so that the cross stirring blade 34 will stir the medicinal liquid in the horizontal direction. On the other hand, the driving The bevel gear 33-1 will drive the driven bevel gear 44-11 meshed with it, thereby driving the driven bevel gear 44-11 to rotate, that is, driving the driven shaft 44-1 to rotate along the horizontal bearing 43, and then the paddle 44 -2 With the rotation of the driven shaft 44-1, the paddles 44-2 of the four driven stirring components 44 will stir the liquid medicine i...

Embodiment 2

[0027]A thermal insulation liquid mixing tank for pharmaceuticals with the structure of the present invention has a good thermal insulation effect. Specifically, an effective thermal insulation material layer is sprayed on the inner layer of the outer tank body 1, which reduces the temperature transfer between the outer tank body 1 and the surrounding environment In addition, the inner tank body 21 is clipped and fixedly installed on the upper end of the outer tank body 1, forming a gap layer between the inner tank body 21 and the outer tank body 1, avoiding direct contact between the inner tank body 21 and the surrounding environment. Contact, that is, to avoid direct temperature exchange, at the same time, the water at the temperature required for dispensing can be introduced through the water inlet flange pipe 11 on the outer tank body 1, and the gap between the outer tank body 1 and the inner tank body 21 can be filled. The gap forms an effective water insulation layer. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com