Proportioning apparatus for flavorings

A technology for seasoning and seasoning bottle, applied in application, food preparation, food science and other directions, can solve the problems of air dust pollution, strong randomness of errors, and difficult to correct, and achieve the effect of high batching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

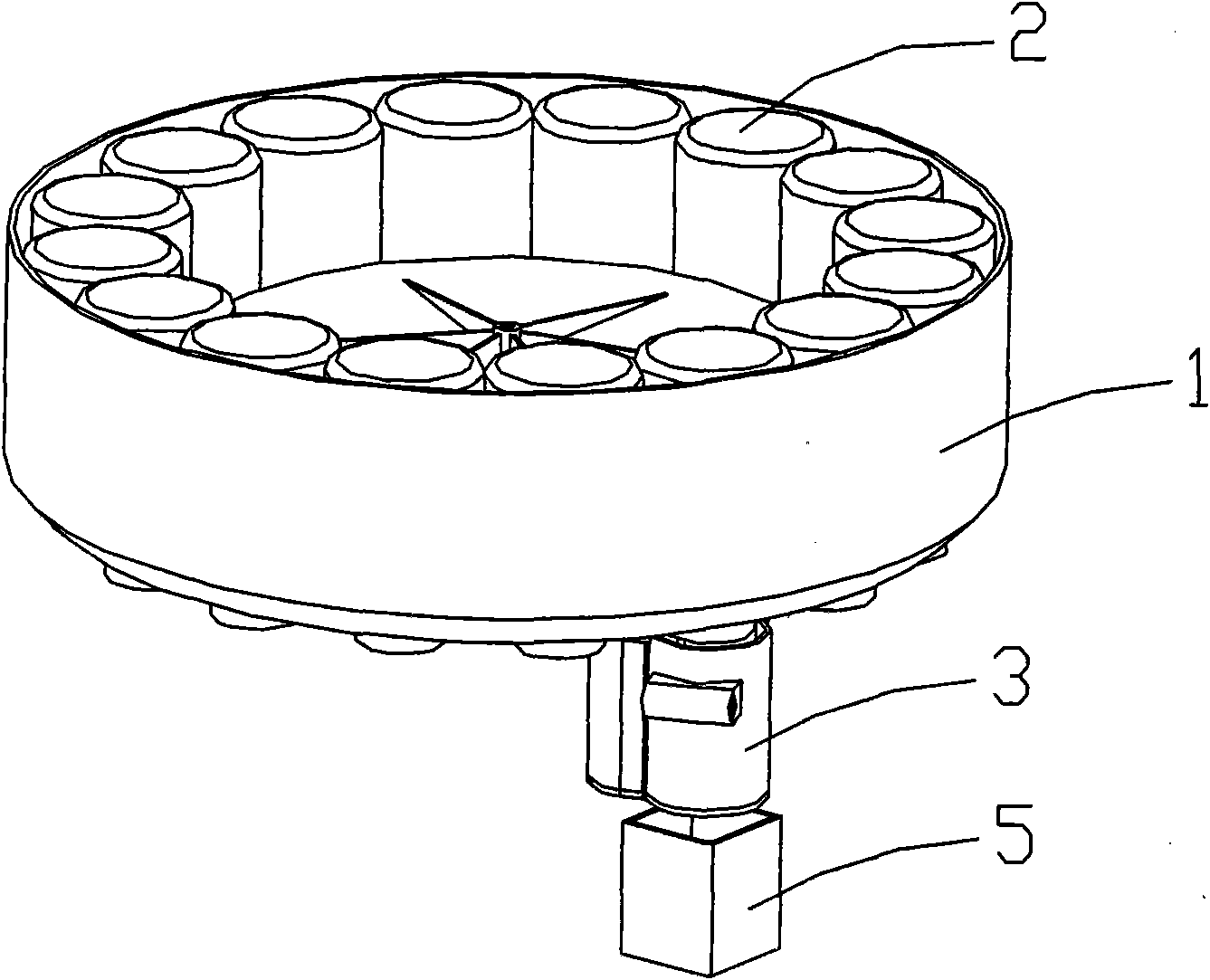

[0026] like figure 1 As shown, it is a schematic structural view of the first embodiment of the seasoning batching device of the present invention. The seasoning batching device is electrically connected to a control system (not shown), and includes: a feed bin 1, a plurality of seasoning bottles 2, a grinding mechanism 3. The driving device (not shown) and the material forming cup 5. The control system is an intelligent control system with a microcomputer as the core. Of course, the control system can also adopt a conventional electrical control system.

[0027] The silo 1 is a circular trough, the bottom of which is provided with a plurality of intermittently distributed outlets (not shown), and the outlets are integrated into a ring at the bottom edge of the silo.

[0028] The seasoning bottle 2 is placed upside down in the feed bin 1, the neck of the seasoning bottle is stuck in the discharge port of the feed bin 1, the head of the seasoning bottle passes through the disch...

Embodiment 2

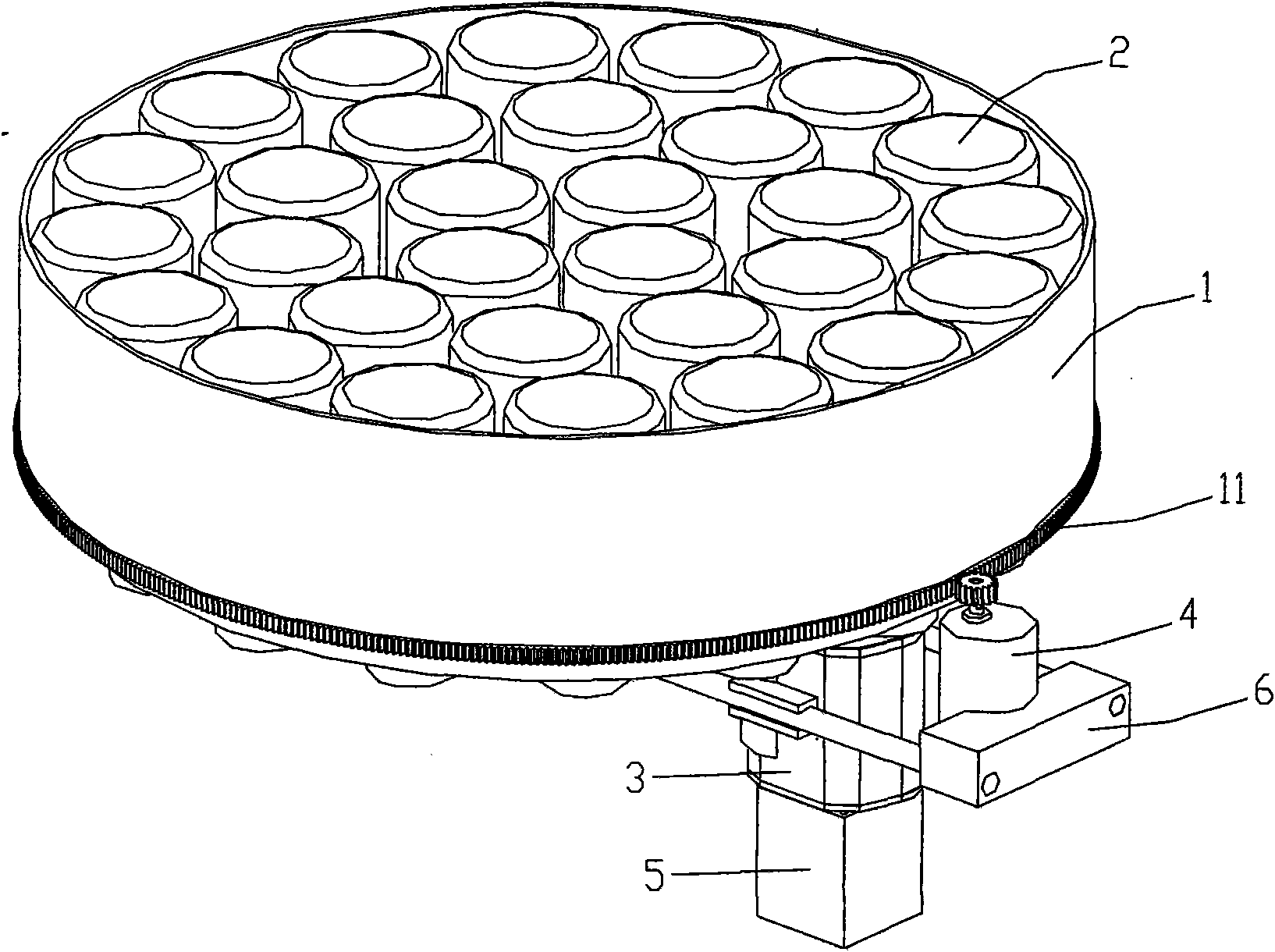

[0034] like figure 2 As shown, it is a schematic structural diagram of the second embodiment of the seasoning batching device of the present invention. The seasoning batching device of this embodiment is electrically connected to a control system (not shown), including: a silo 1, a plurality of seasoning bottles 2, a grinding Mechanism 3, driving device, material cup 5 and support 6. The control system is an intelligent control system with a microcomputer as the core. Of course, the control system can also use a conventional electrical control system.

[0035] The silo 1 is a circular trough, and its bottom is provided with a plurality of outlets (not shown). The outlets are radially distributed at the bottom of the silo with the center of the bottom as the center. V-shaped teeth 11 are provided on the outer edge of the outer edge.

[0036]The seasoning bottle 2 is placed upside down in the feed bin 1, the neck of the seasoning bottle is stuck in the discharge port of the fe...

Embodiment 3

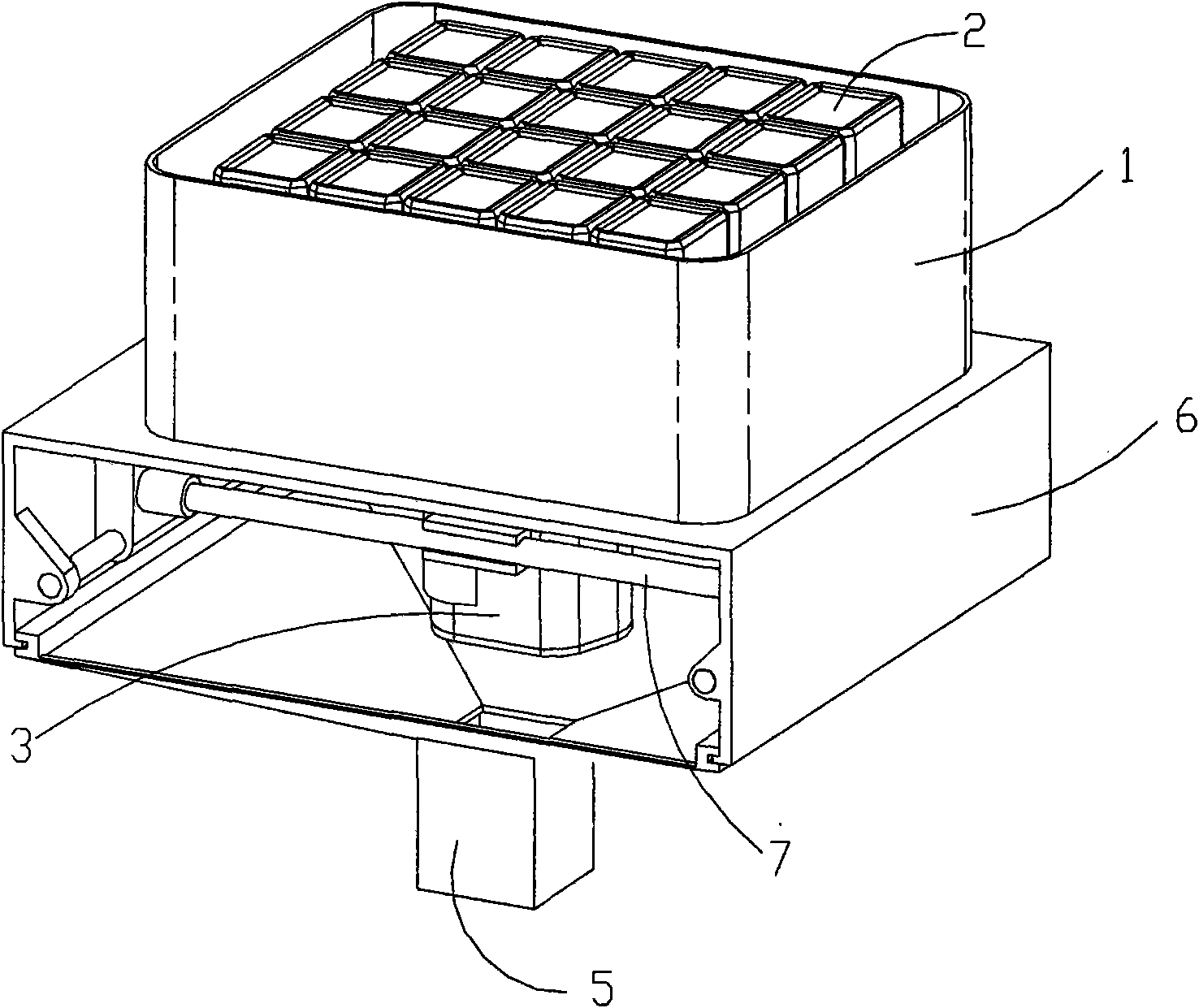

[0042] Such as Figure 3a As shown, it is a schematic structural diagram of the third embodiment of the seasoning batching device of the present invention. The seasoning batching device is electrically connected to a control system (not shown), and includes: a feed bin 1, a plurality of seasoning bottles 2, and a grinding mechanism 3 , drive unit (not shown), material cup 5 and mobile frame body 7, described control system is the intelligent control system with microcomputer as the core, certainly this control system can also adopt conventional electric control system.

[0043] The silo 1 is a square trough with a plurality of outlets (not shown) arranged at the bottom of the silo in a rectangular shape with multiple rows and columns.

[0044] The seasoning bottle 2 is placed upside down in the feed bin 1, the neck of the seasoning bottle is stuck in the discharge port of the feed bin 1, the head of the seasoning bottle passes through the discharge port and is exposed to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com