Patents

Literature

69results about How to "Orderly feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

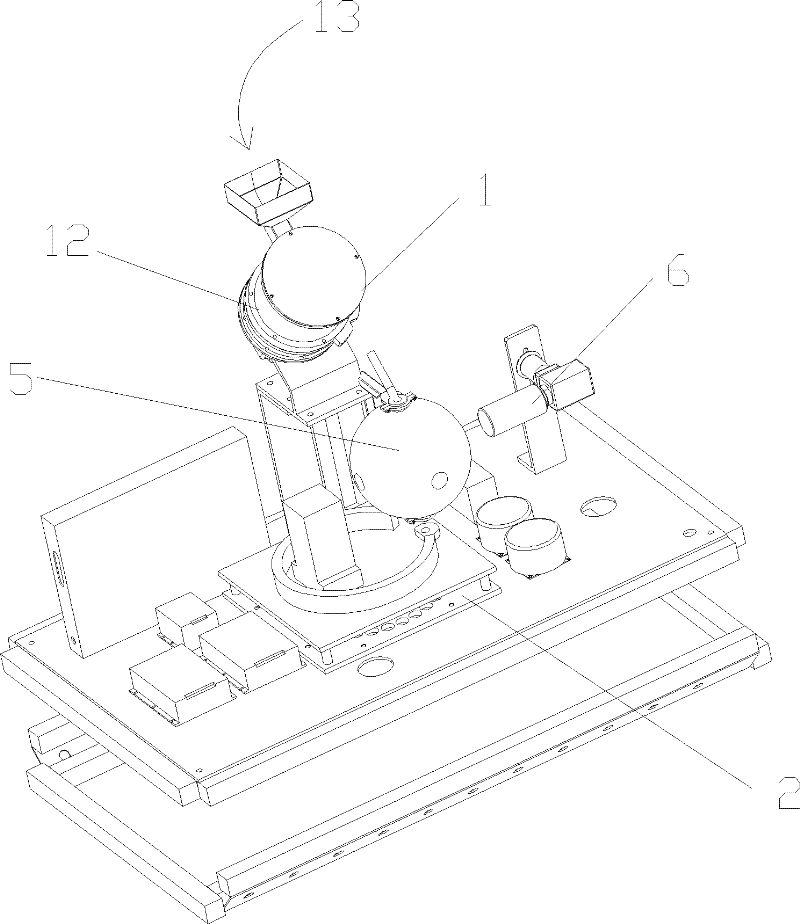

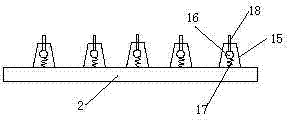

Automatic sorting equipment for pearls

InactiveCN102553841AReduce error rateNot easy to make mistakesSortingComputer engineeringLight source

The invention discloses automatic sorting equipment for pearls. According to the automatic sorting equipment, the technical problems of low efficiency and high labor cost by manual operation in the current sorting work of pearls are solved. The automatic sorting equipment comprises a one-by-one feeding device and a sorting device and is characterized in that the one-by-one feeding device comprises a feed opening and a discharge opening, wherein the lower part of the discharge opening is connected with a guiding element; a shooting area is arranged at the middle of the guiding element; a light source and a shooting device are arranged on two sides of the shooting area; the sorting device comprises a plurality of accommodation boxes and a plurality of falling holes; the lower end of the guiding element is matched with one falling hole of the sorting device; the shooting device is used for transmitting the obtained shooting signal to a controller; and the controller is used for analyzing the shooting signal and then transmitting the corresponding instruction to the sorting device. The automatic sorting equipment disclosed by the invention can be used for automatically sorting the pearls; compared with manual operation, the automatic sorting equipment has the advantages of low error rate, high efficiency and low cost; and in addition, the pearls are smoothly and orderly fed.

Owner:ZHEJIANG GRACE PEARL JEWELRY

Feed feeding device for livestock raising

InactiveCN107232078ADrinking water healthConvenient drinking waterAnimal watering devicesAnimal feeding devicesEngineeringFodder

The invention relates to a feeding device, in particular to a feed feeding device for animal husbandry. The technical problem to be solved by the present invention is to provide a feed feeding device for animal husbandry. In order to solve the above technical problems, the present invention provides such a feed feeding device for animal husbandry, which includes a bottom plate, a first bracket, a fixing block, a connecting rod, a first feed trough, a drinking water device, etc.; The first bracket, the lower right side of the first bracket on the left and the lower left side of the first bracket on the right are symmetrically provided with fixing blocks, a connecting rod is arranged between the fixing blocks on the left and right sides, and the first feed is arranged in the middle of the connecting rod Groove, the middle of the right side of the first bracket on the left is provided with a drinking device, and the drinking device is located directly above the first feed trough. The invention achieves the effect that the feeding is orderly, and the water and the feed can be eaten together. In order to prevent the feed from blocking the outlet of the feed box when the feed falls into the first feed tank, people can start the second electric push rod.

Owner:谢陈钗

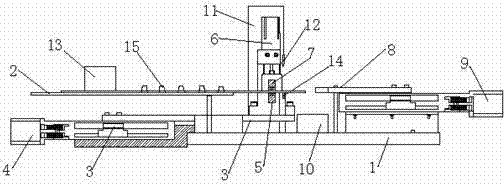

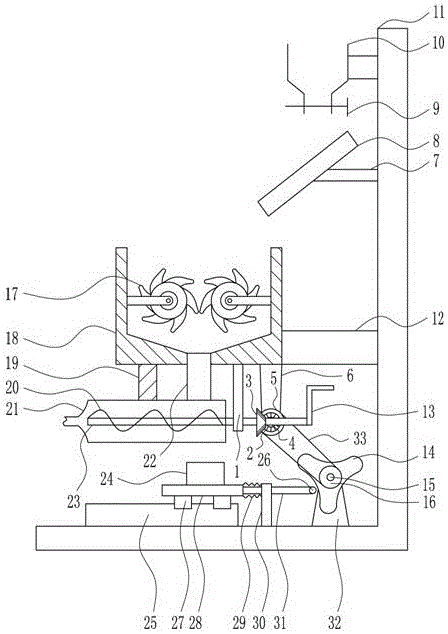

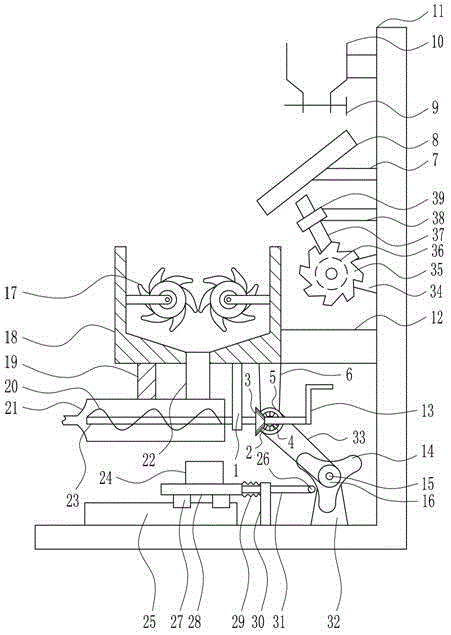

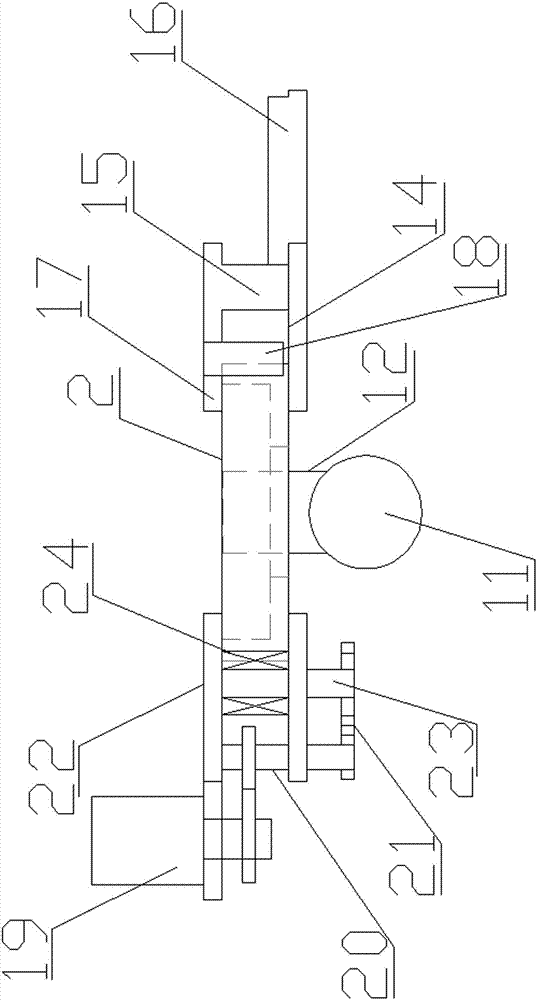

Automatic stock cutter for nibs

InactiveCN103112048AImprove material cutting efficiencyEasy to useMetal working apparatusEngineeringSlide plate

The invention belongs to the technical field of nib manufacturing tools and particularly relates to an automatic stock cutter for nibs. The automatic stock cutter for nibs comprises a machine frame. A stock-placing plate is disposed on the machine frame. A sliding plate is disposed, below the stock-placing plate, on the machine frame, one end of the sliding plate is connected with an electric cylinder, and the other end of the sliding plate is fixed with a lower square tube. Cylinders are disposed on the sliding plate and located at both sides of the lower square tube. The cylinder are connected with an upper square tube, and under the action of the cylinders, the upper square tube can be clamped tight with the lower square tube for feeding. A sliding limit plate is disposed on the machine frame and is connected with a fixed-length motor. A blanking groove is disposed on the machine frame and located between the sliding limit plate and the lower square tube. A stamping device is arranged on the machine frame and is connected with a cutter which is located above the portion between the sliding limit plate and the lower square tube. The electric cylinder, the stamping device, the cylinder and the fixed-length motor are connected with a controller. The automatic stock cutter for nibs achieves automatic and mechanical operation of stock cutting, greatly improves efficiency of stock cutting, and is safer in use.

Owner:吴鸣寰

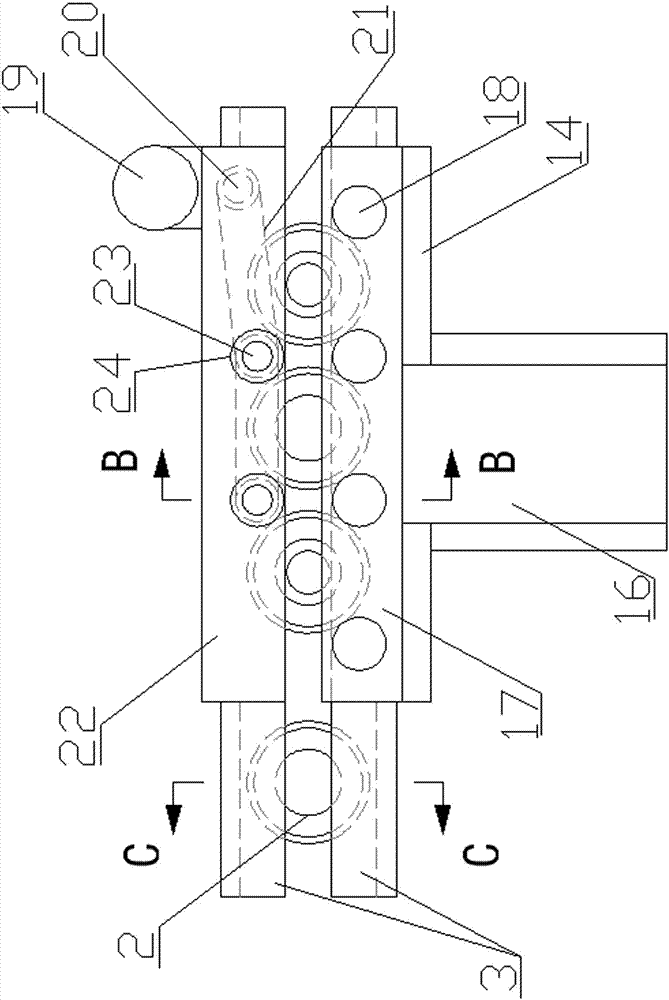

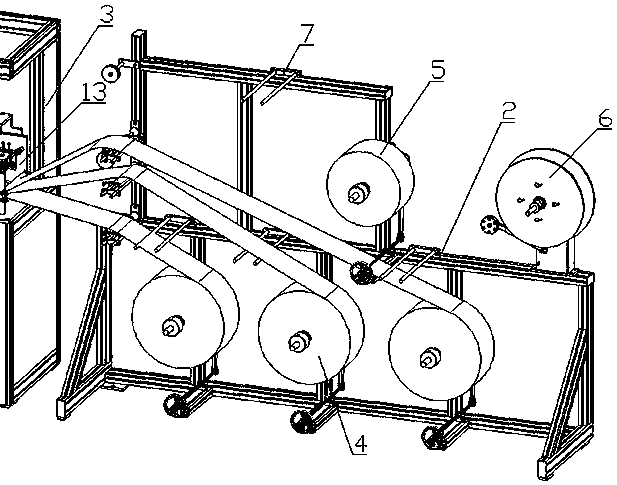

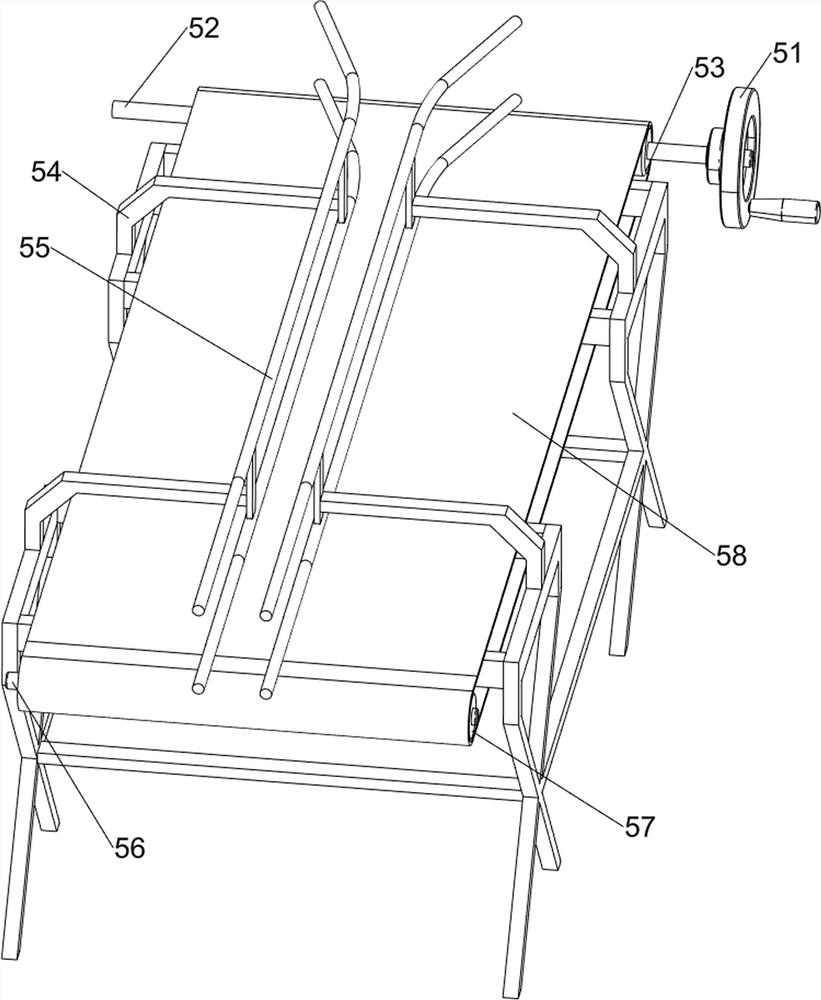

Full-automatic winding machine

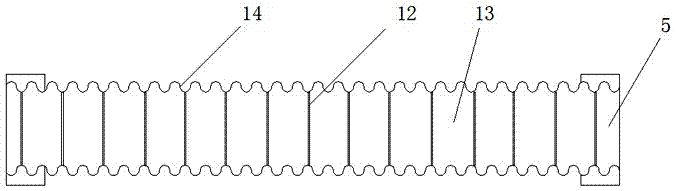

ActiveCN105775225AAchieve shrinkageReduce or expand the distancePackagingWinding machineConductor Coil

The invention discloses a full-automatic winding machine. The full-automatic winding machine comprises a rack structure, a feeding device, a winding mechanism and a material pushing device; the feeding device is arranged at the outer side of the front end of the rack structure; the winding mechanism is arranged at the front end in the rack structure; and the material pushing device is arranged at the rear end of the winding mechanism. The rack structure in the full-automatic winding machine can make parts in the machine being fixed or move at relative positions; the feeding device is fixedly connected with the rack structure and used for orderly feeding to-be-packaged wound products; the winding mechanism is used for winding the products conveyed by a conveying belt and making the products meet the packaging requirement; and the material pushing device is used for pushing the products which are wound and meet the packaging requirement into a packaging container. An automatic manner is adopted for the four parts of the full-automatic winding machine to perform the whole winding process, the four parts coordinate with one another, each part completes one regulated operation, and the neat and orderly winding procedure is achieved.

Owner:LANGXI ZHENHAI MACHINERY

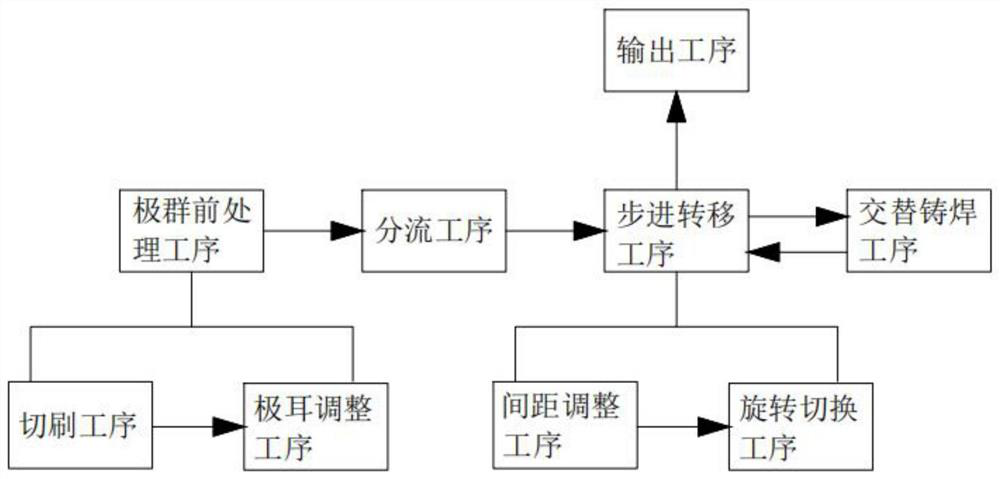

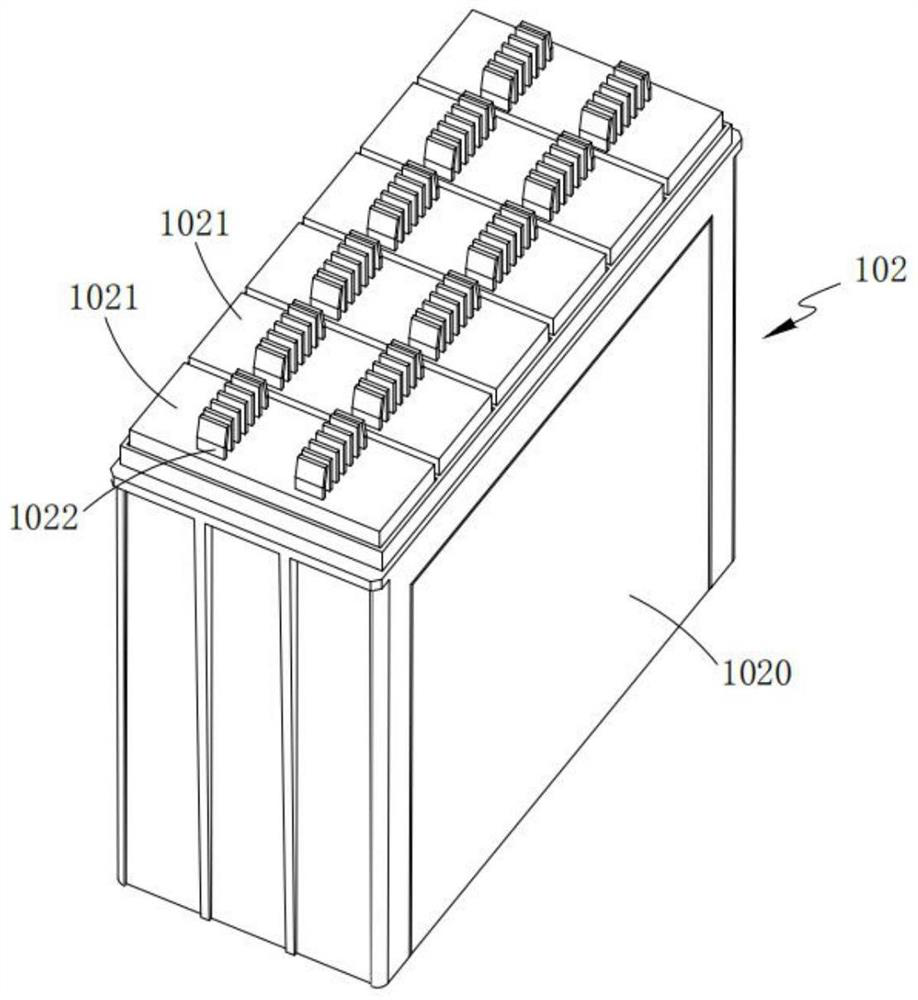

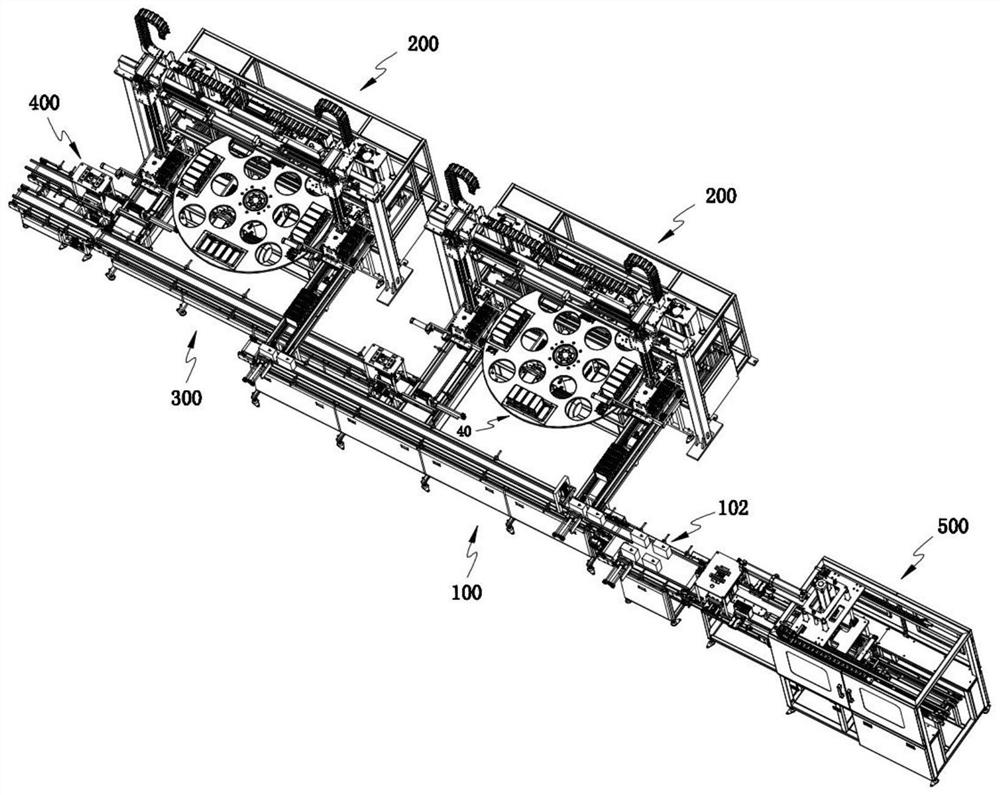

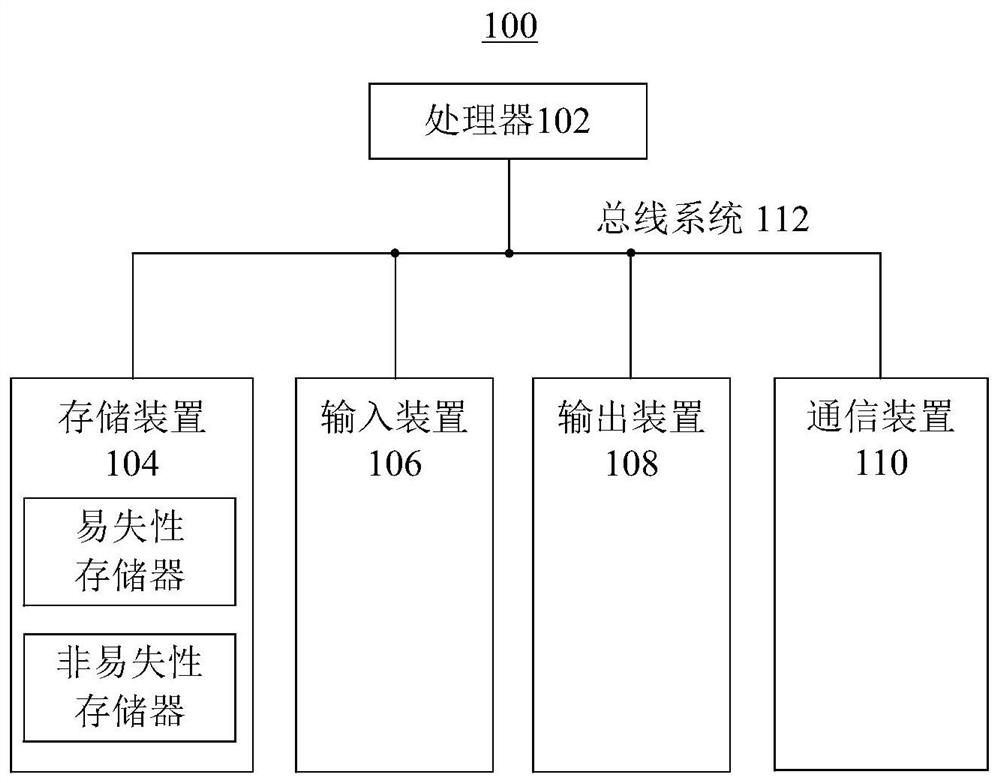

Efficient lead-acid storage battery cast-welding production process

ActiveCN112756588ARealize flow operationShorten production timeCasting plantsFinal product manufactureEngineeringProcess engineering

The invention relates to the technical field of storage battery production equipment, in particular to an efficient lead-acid storage battery cast-welding production process which is characterized by comprising the following steps: S1, a shunting procedure: a storage battery is automatically conveyed forwards by a feeding conveying system, and a plurality of cast-welding production systems are arranged on the side of the feeding conveying system; and S2, a cast-welding alternating procedure: each cast-welding production system comprises a cast-welding mechanism, a plurality of sets of lead dipping mechanisms and cast-welding molds which are arranged in one-to-one correspondence with the lead dipping mechanisms and can be conveyed and transferred between the cast-welding mechanism and the corresponding lead dipping mechanisms, the cast-welding mechanisms bear storage battery packs conveyed by a shunting mechanism in a shunting mode, the cast-welding molds obtain molten lead liquid from the lead dipping mechanisms to the cast-welding mechanisms to be subjected to cast-welding work with the storage battery packs, and the multiple cast-welding molds alternately change the cast-welding mechanisms to convey the lead liquid needed by cast-welding. Cast-welding flow production of the storage battery is achieved, the cast-welding molds are matched to alternately conduct cast-welding on the cast-welding mechanisms, and the production time is shortened.

Owner:长兴金润科技有限公司

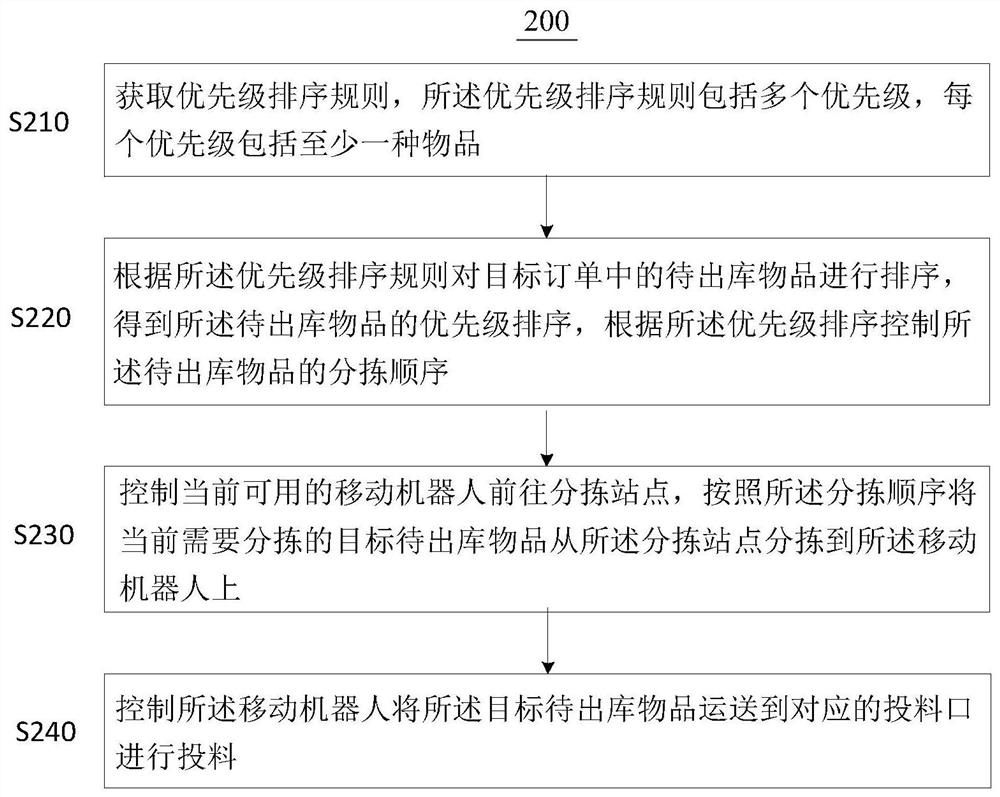

Sorting method, electronic equipment and sorting system

A sorting method, electronic equipment and a sorting system, the method comprising: acquiring a priority ranking rule, the priority ranking rule comprising a plurality of priorities, each priority comprising at least one article; sorting to-be-delivered articles in a target order according to the priority sorting rule to obtain a priority sequence of the to-be-delivered articles, and controlling a sorting sequence of the to-be-delivered articles according to the priority sequence; controlling a currently available mobile robot to go to a sorting station, and sorting the target to-be-delivered objects which need to be sorted currently to the mobile robot from the sorting station according to the sorting sequence; and controlling the mobile robot to convey the target to-be-delivered article to a corresponding feeding port for feeding. According to the sorting method, electronic equipment and sorting system, the to-be-delivered articles can be fed in order according to the preset priority ranking rule.

Owner:MEGVII BEIJINGTECH CO LTD

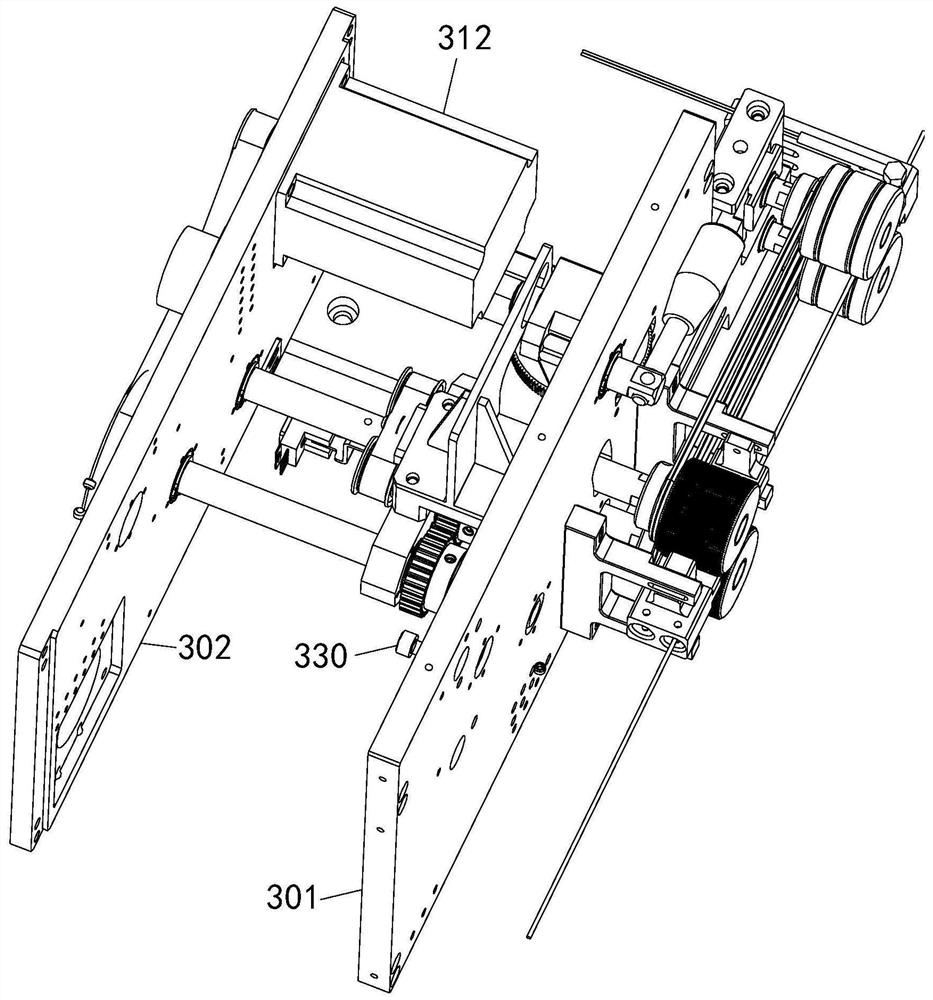

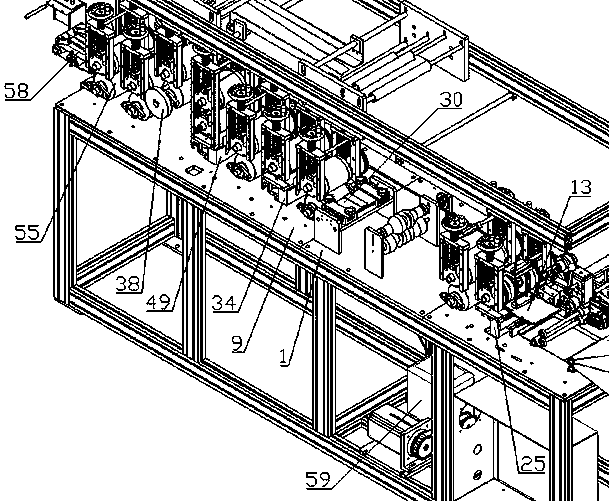

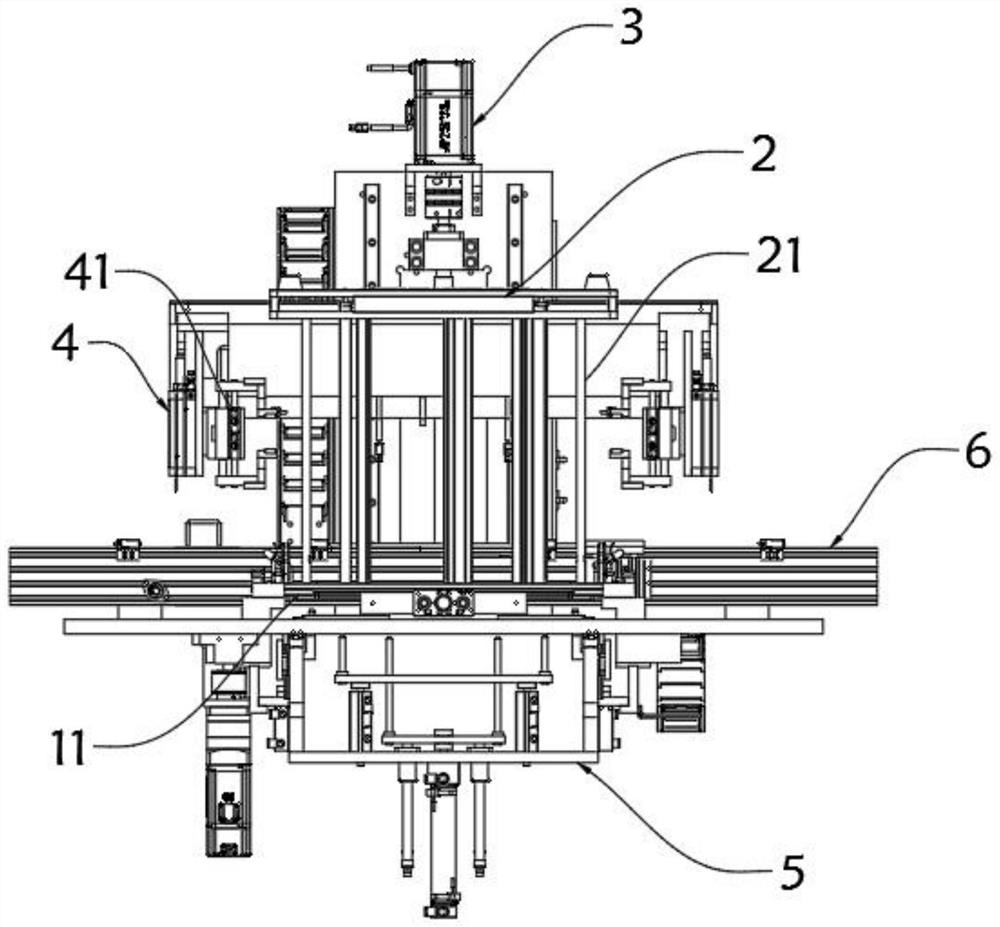

Automatic cable plugging machine

ActiveCN112828571AFast transferGuaranteed no deviation in insertionFinal product manufactureMetal working apparatusStructural engineeringAssembly line

The invention discloses an automatic cable plugging machine. A PCB assembly line, an XYZ three-axis movement mechanism, a cable stripping mechanism, a material receiving transfer mechanism and a cable plugging mechanism are arranged on a workbench. According to the automatic cable plugging machine, orderly feeding and conveying of cables are realized through a cable feeding module, threading is convenient, cable feeding and cable withdrawing are relatively stable, multi-cable conveying can be realized, and the efficiency is high; the cutting and stripping of insulating layers on the surfaces of the cables are realized through the cable stripping module, the cutting of metal wires of the cables can also be realized, and the pluggable cables of which the metal wires are exposed at the two ends are automatically obtained. The stripped cables on the cable stripping module are clamped and received through cable clamping claws of the material receiving module; and then the cables are inserted into all work stations of a transfer module, and the cables are conveyed to the cable plugging mechanism through the transfer module after full plugging, so that circulating and rapid transfer of the cables is realized, and the efficiency is high. The pluggable cables can be quickly and orderly plugged onto a PCB through the cable plugging mechanism, and a guiding structure assists in plugging during plugging, thereby ensuring that the cables are plugged in place without deviation, and ensuring the product quality.

Owner:良忠城精密科技(苏州)有限公司

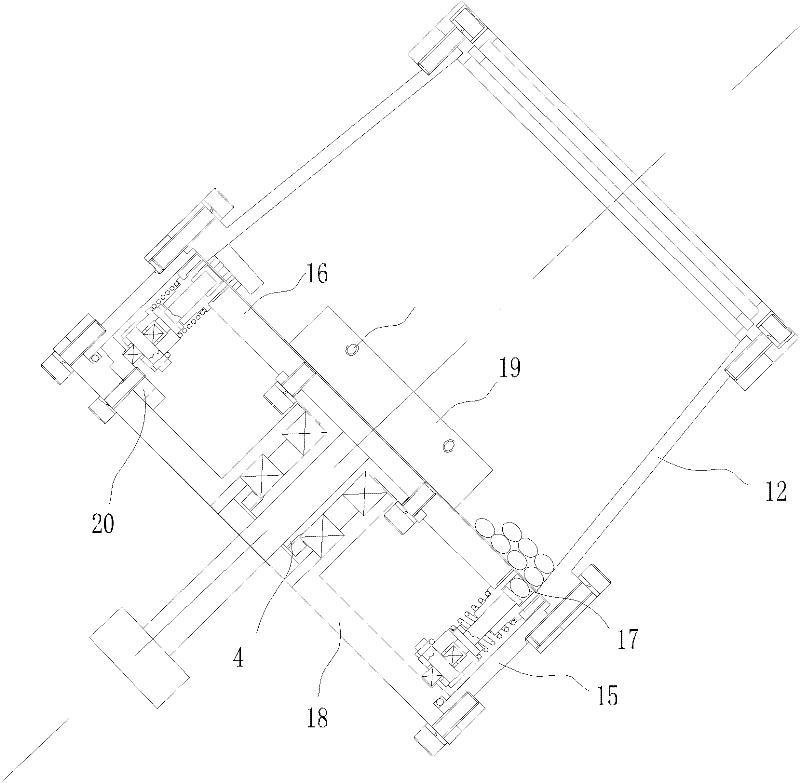

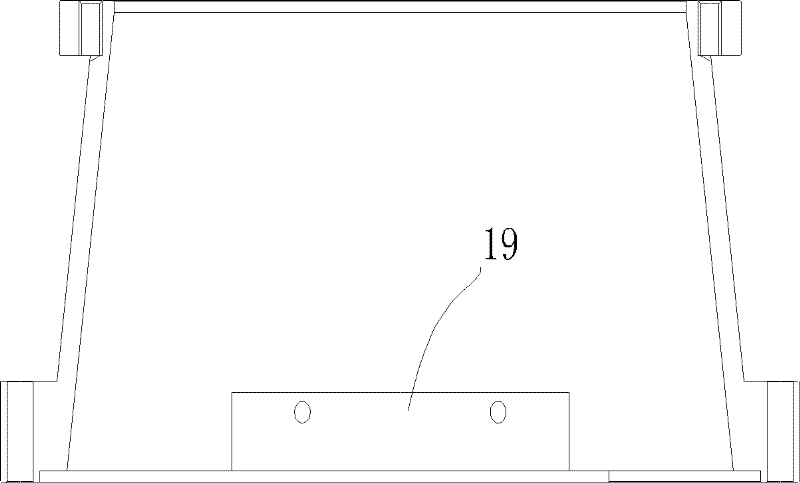

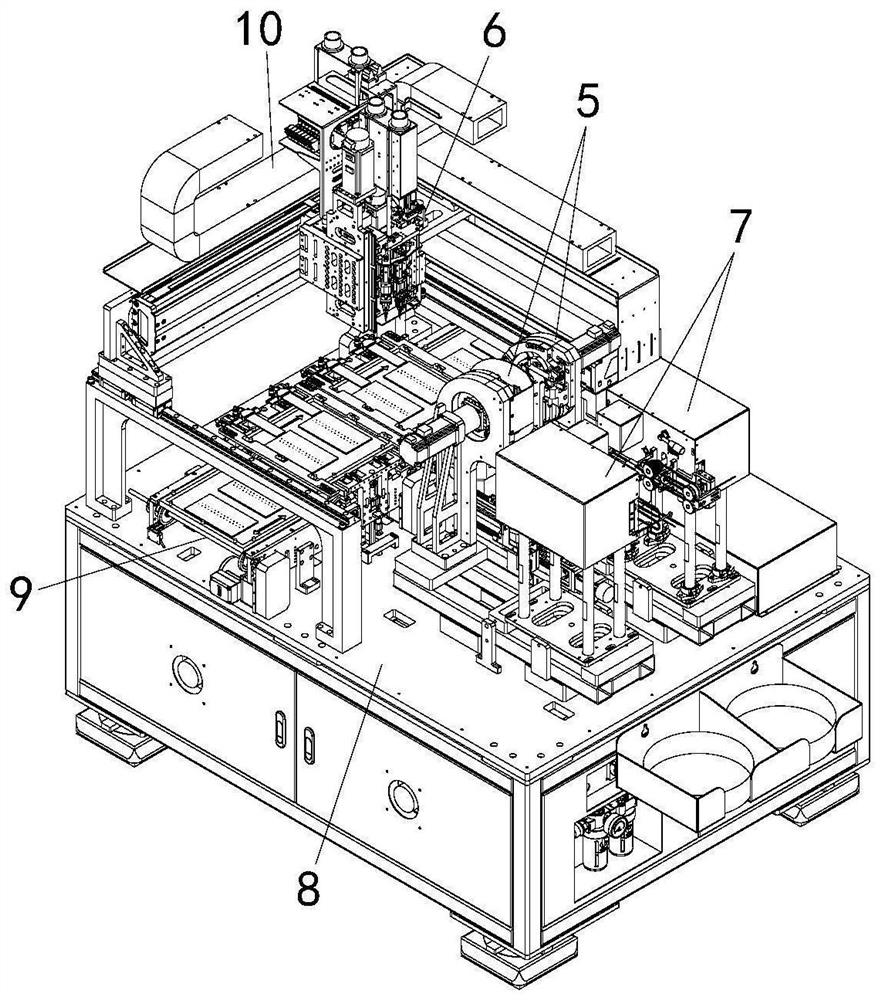

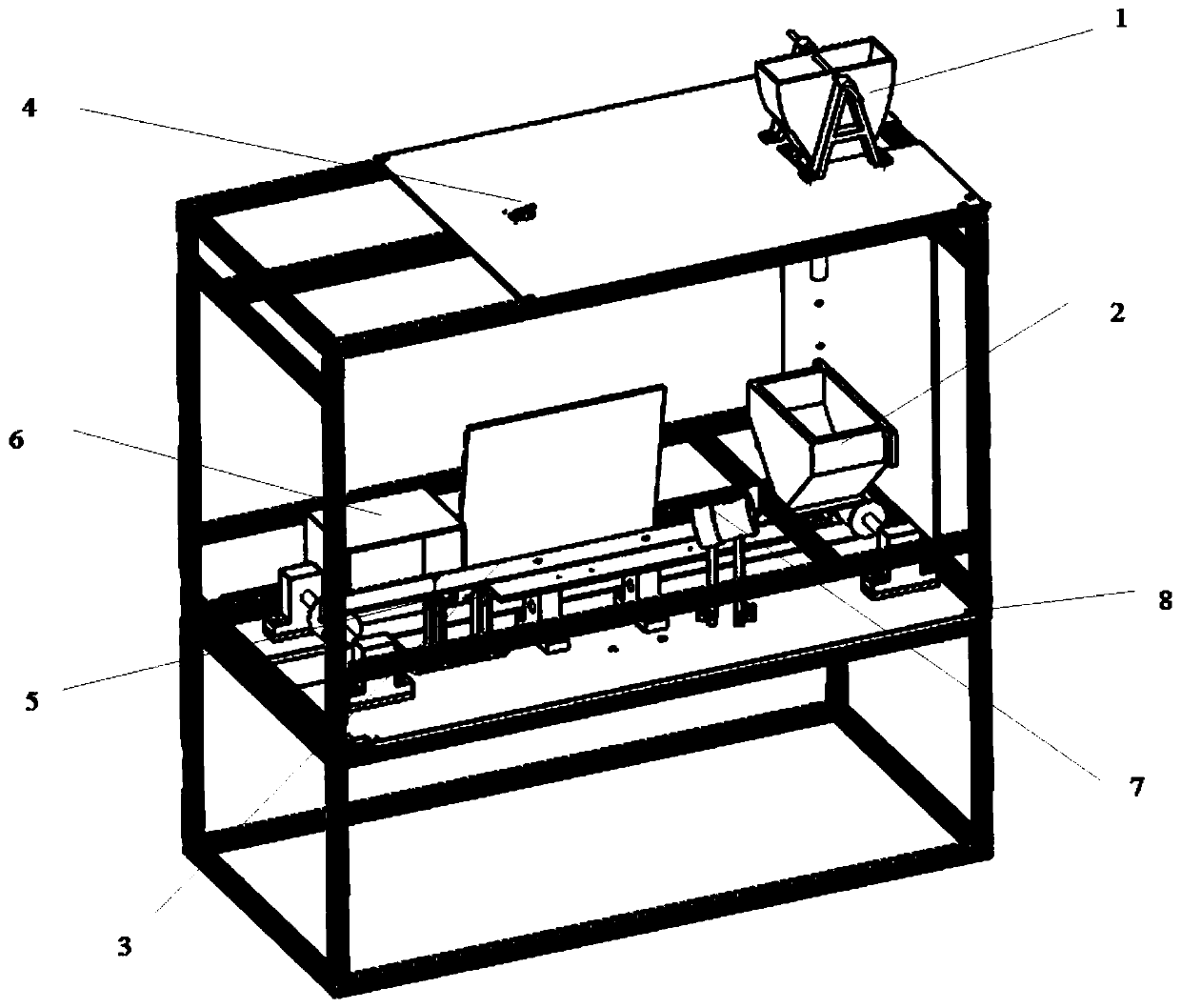

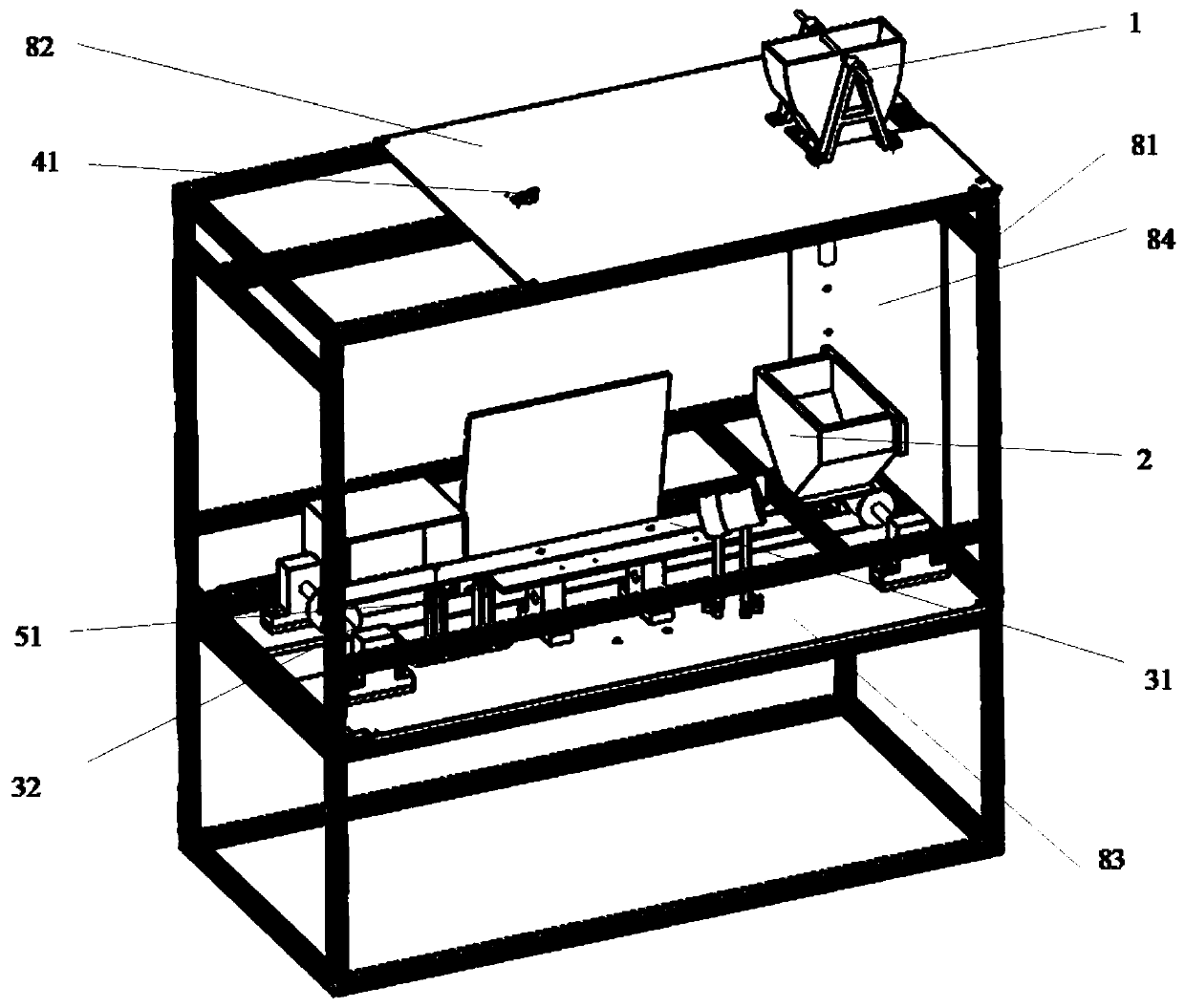

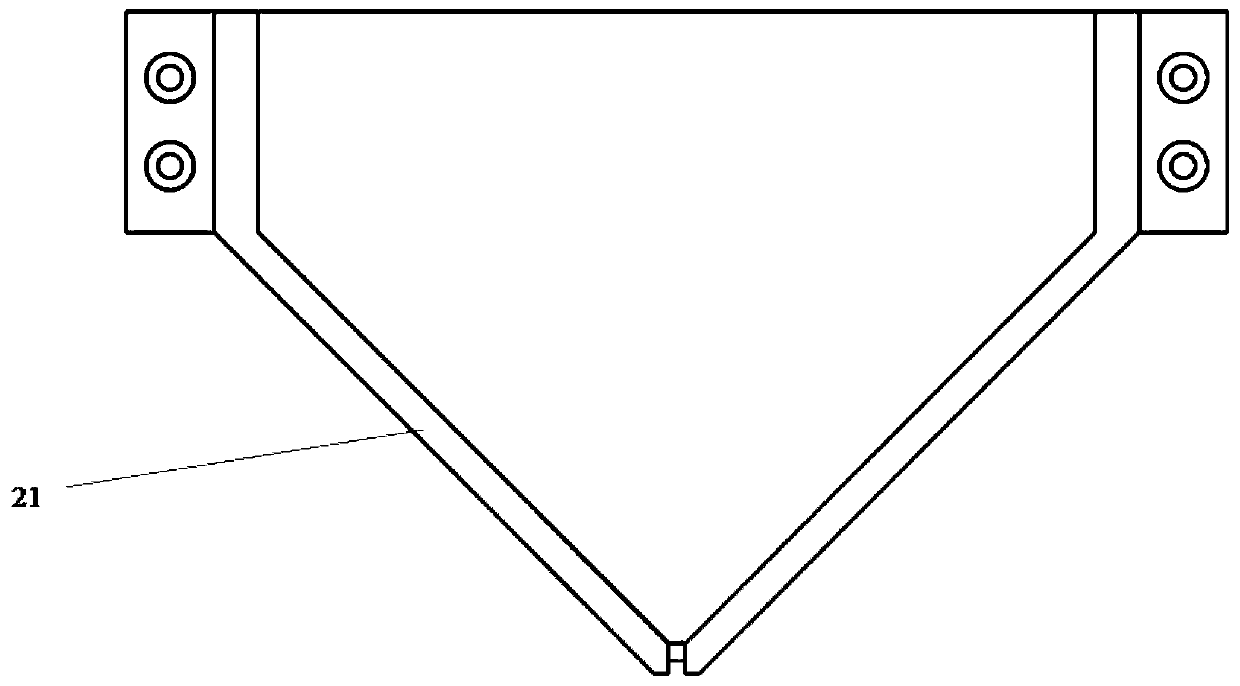

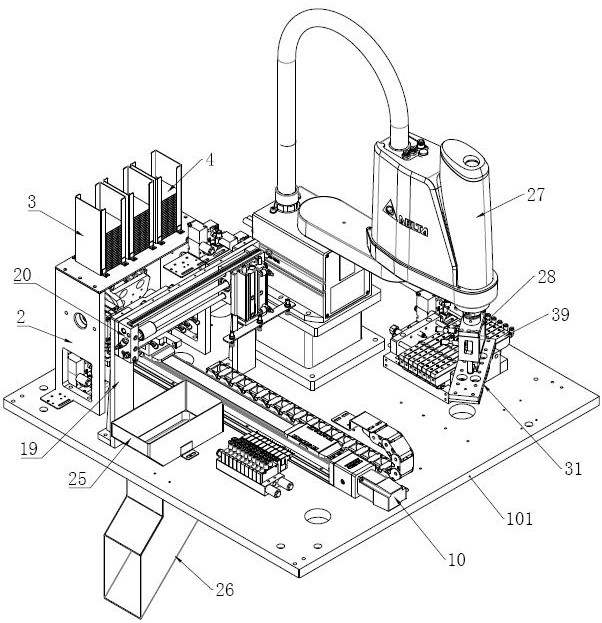

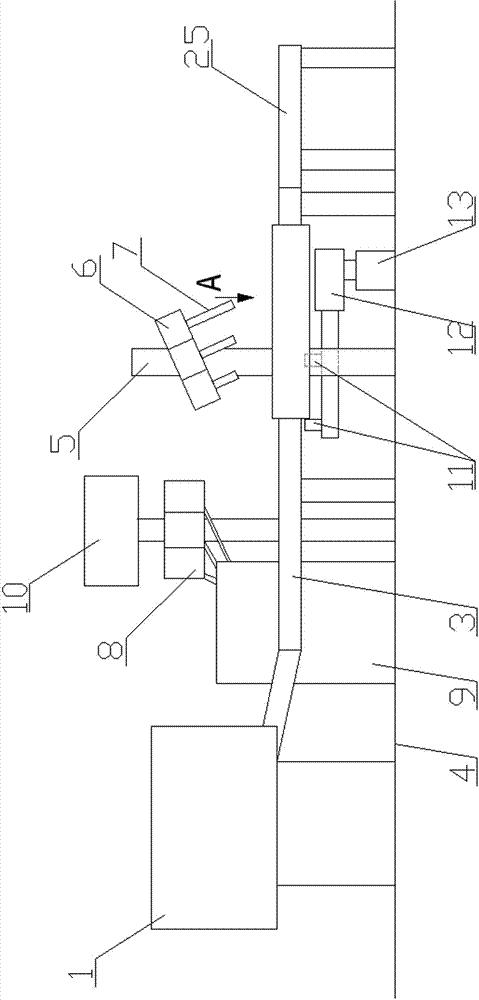

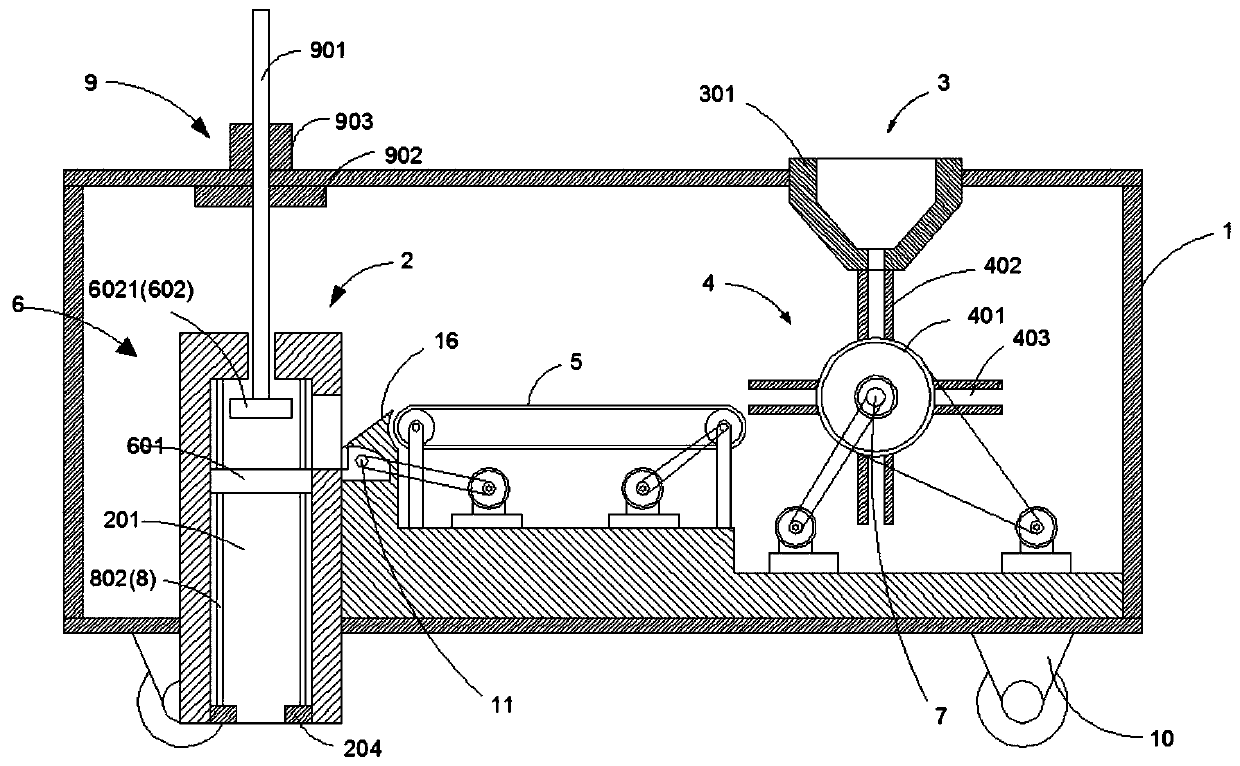

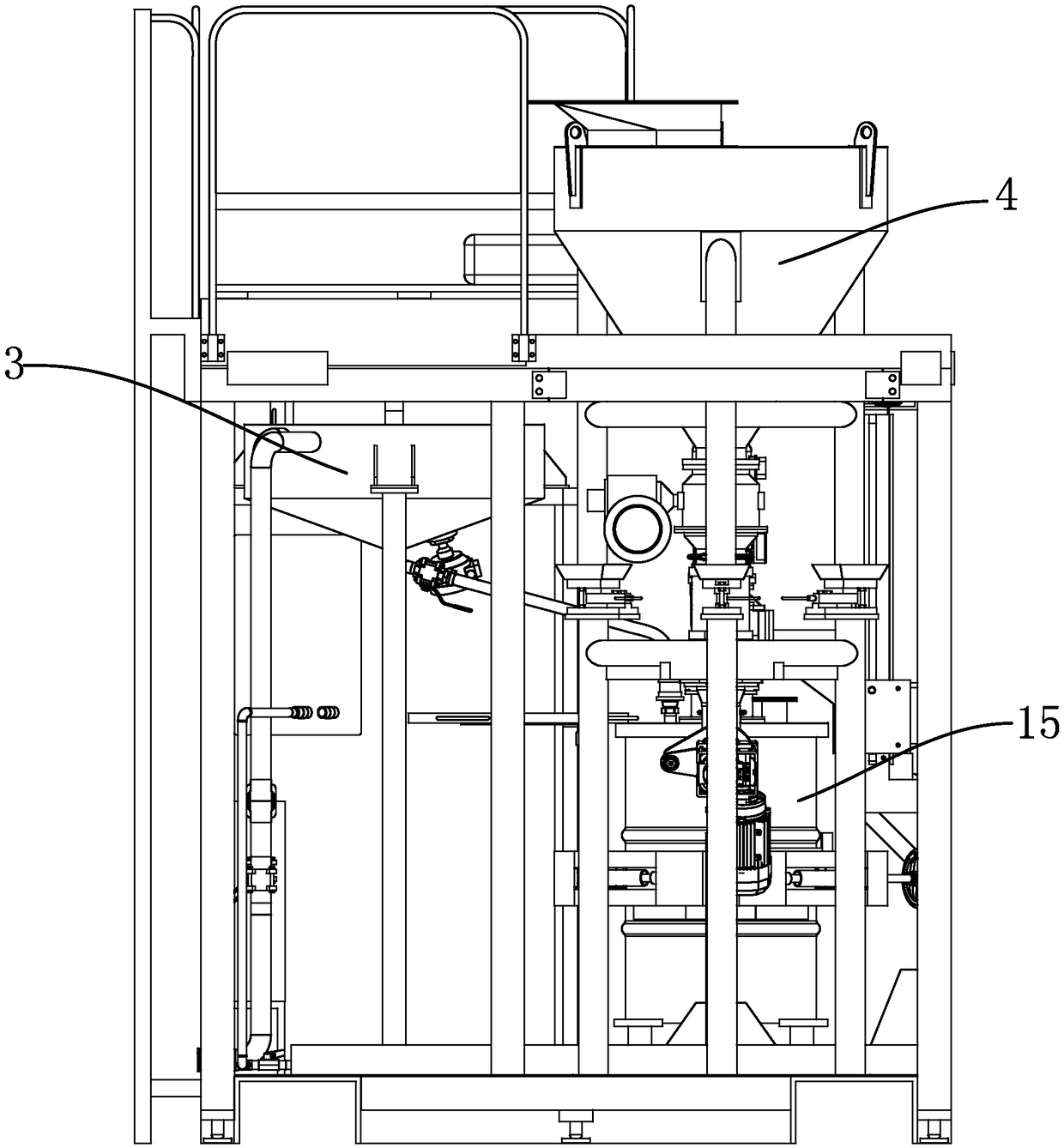

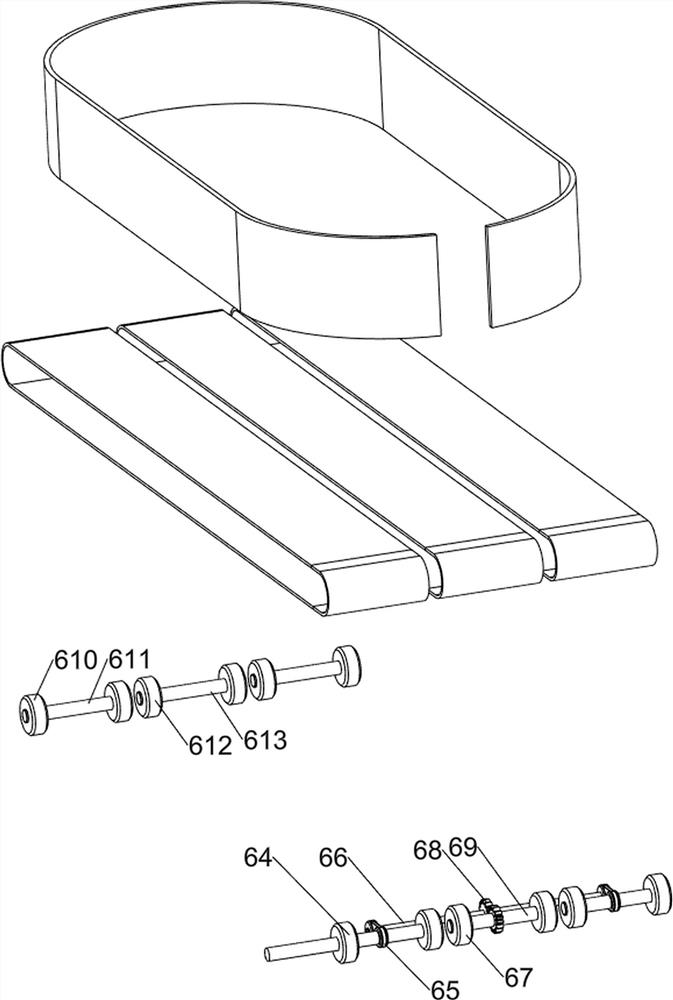

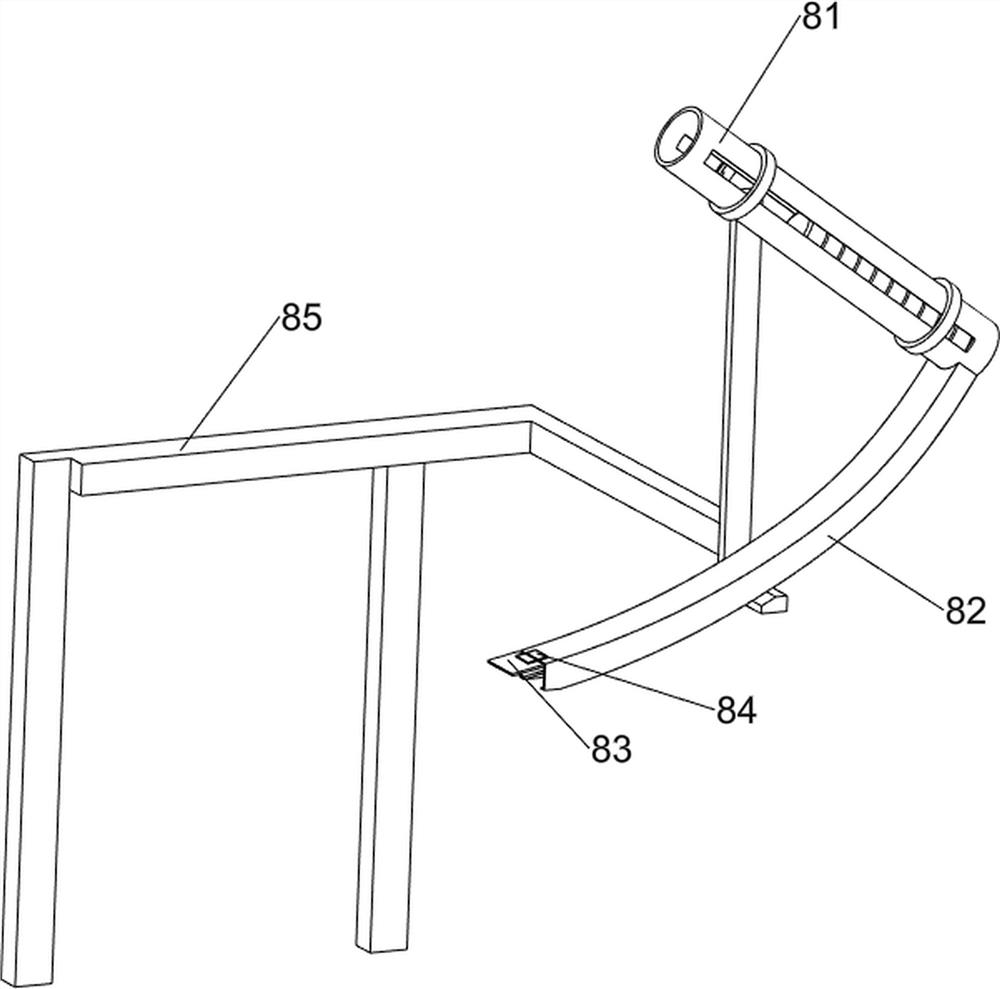

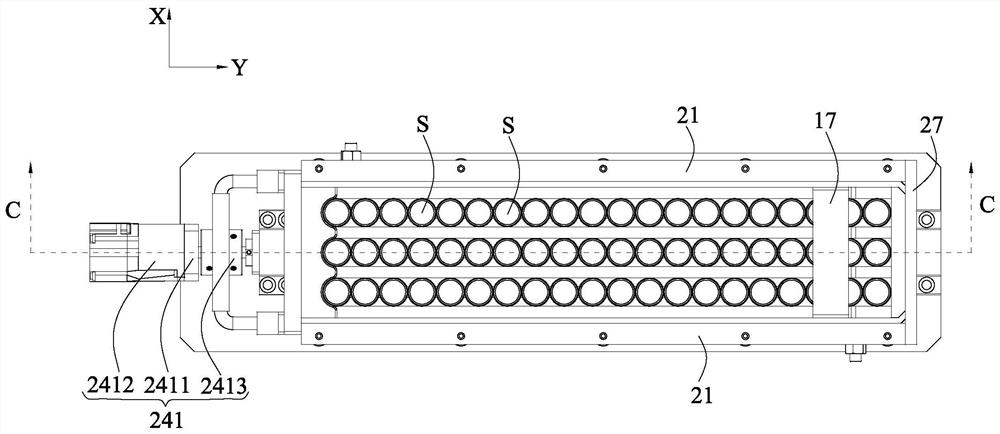

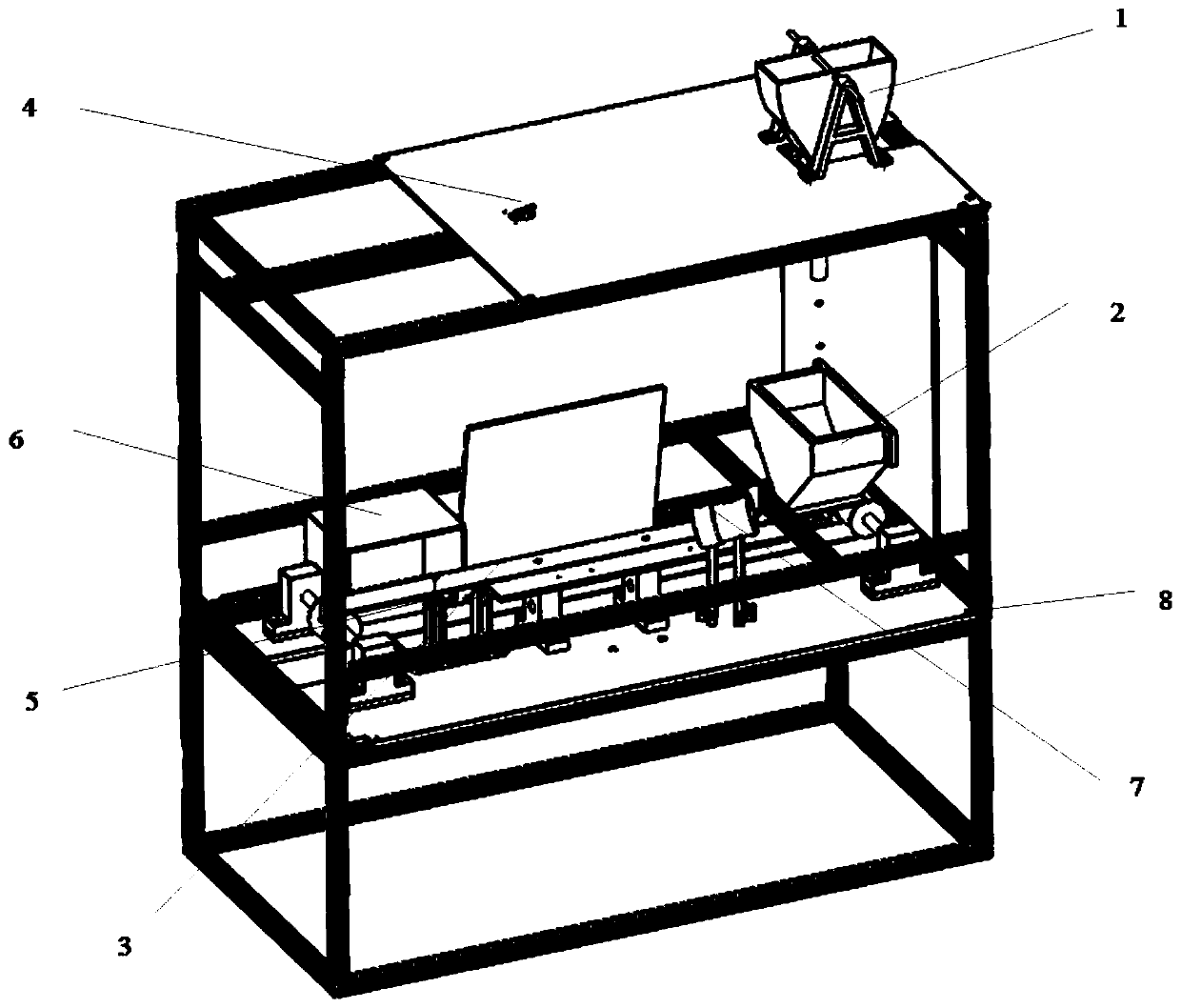

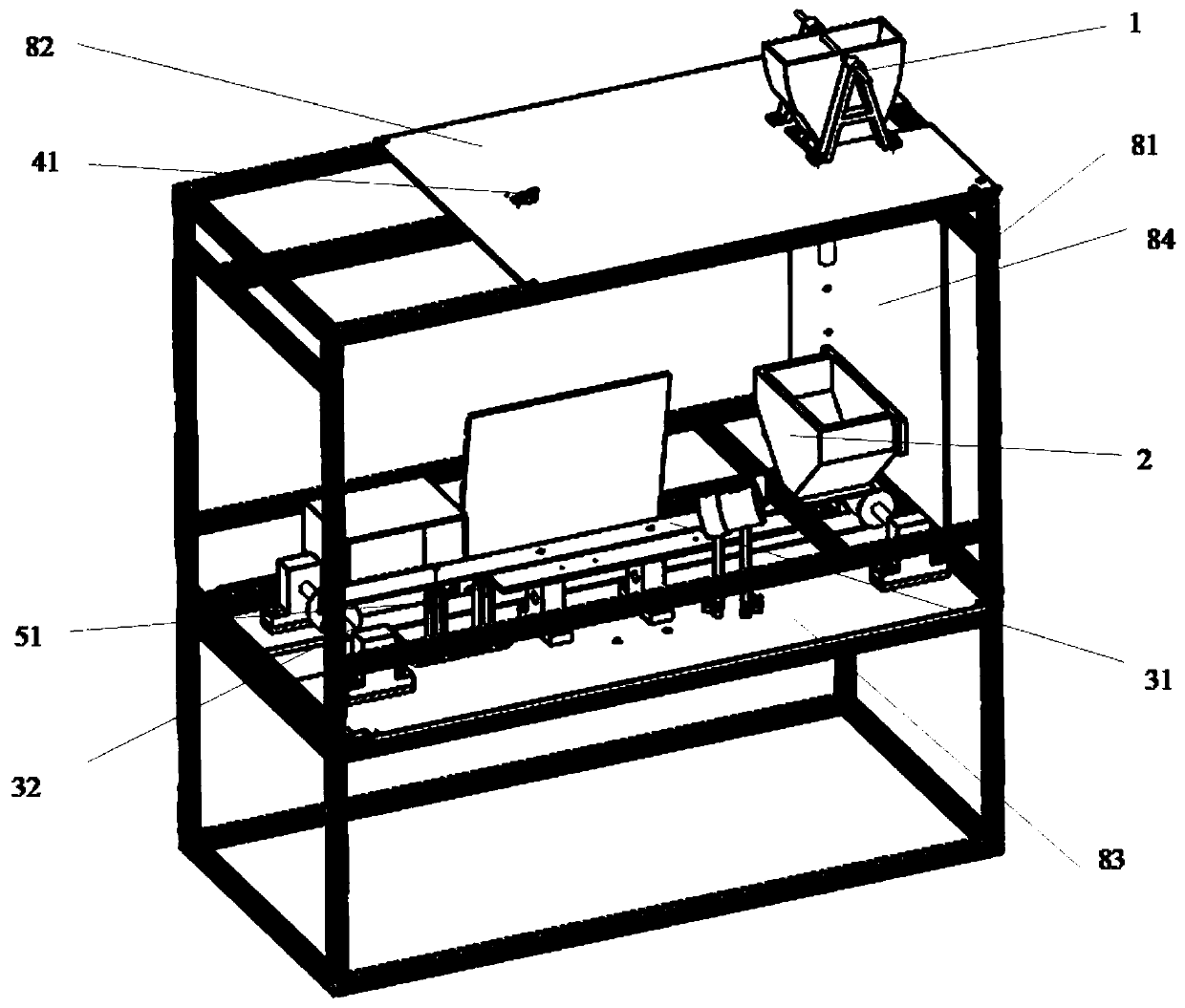

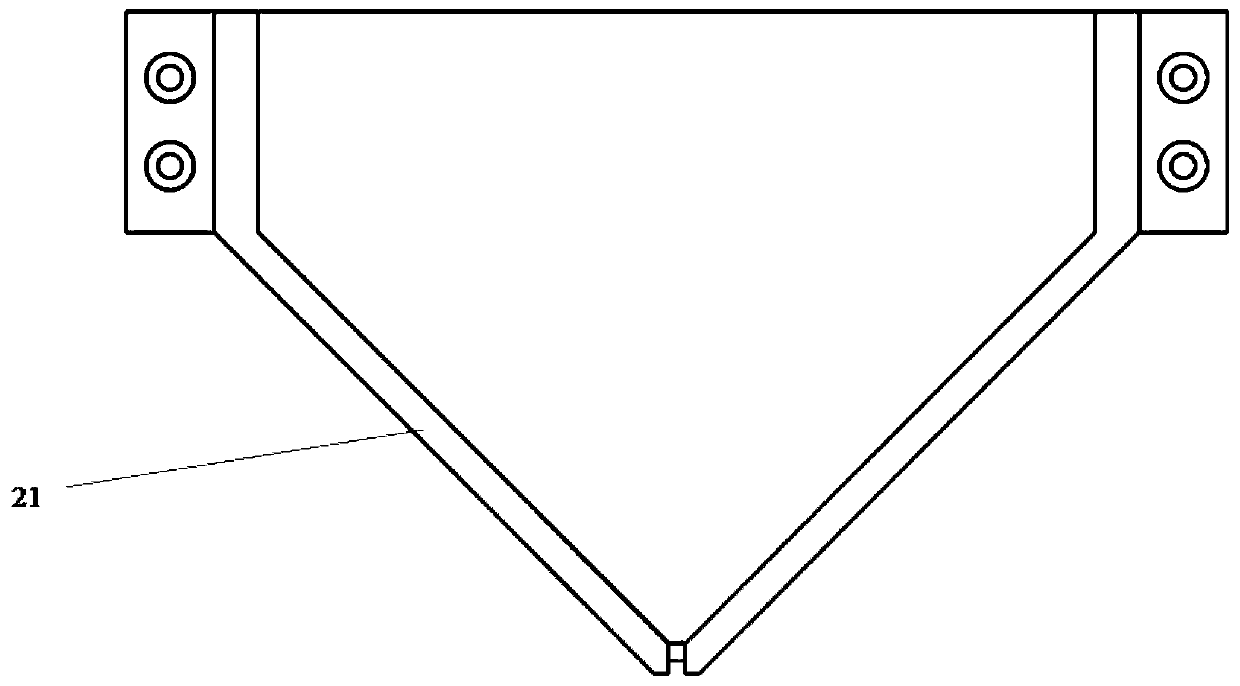

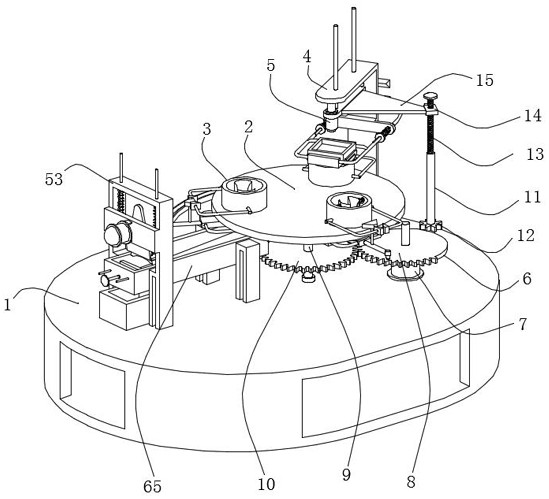

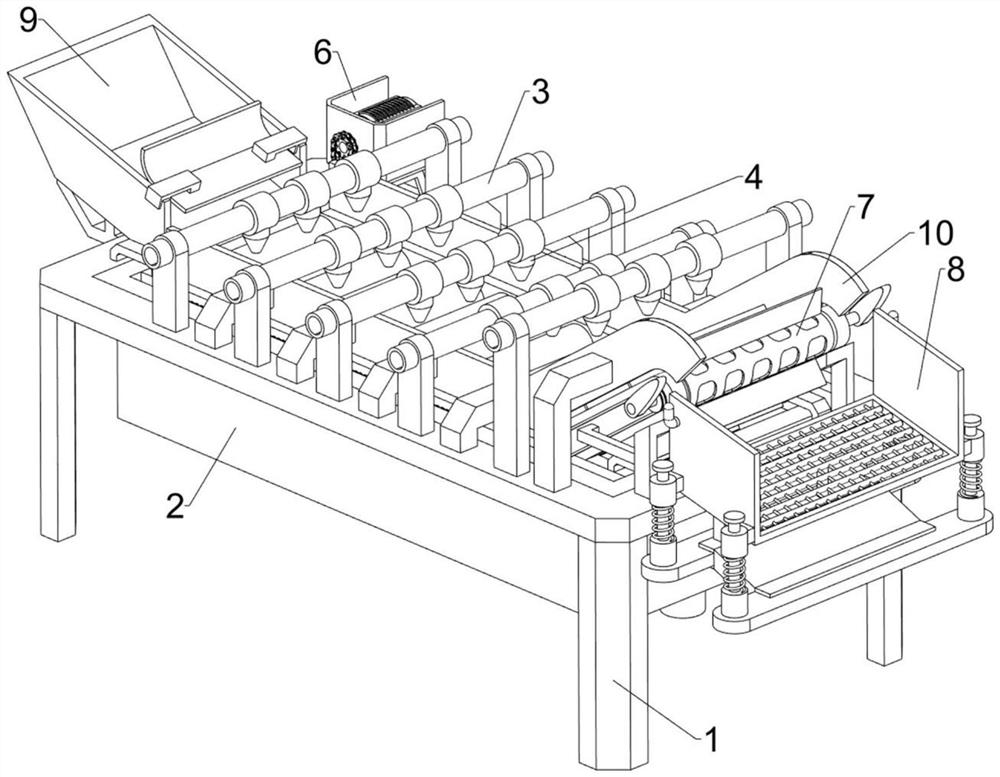

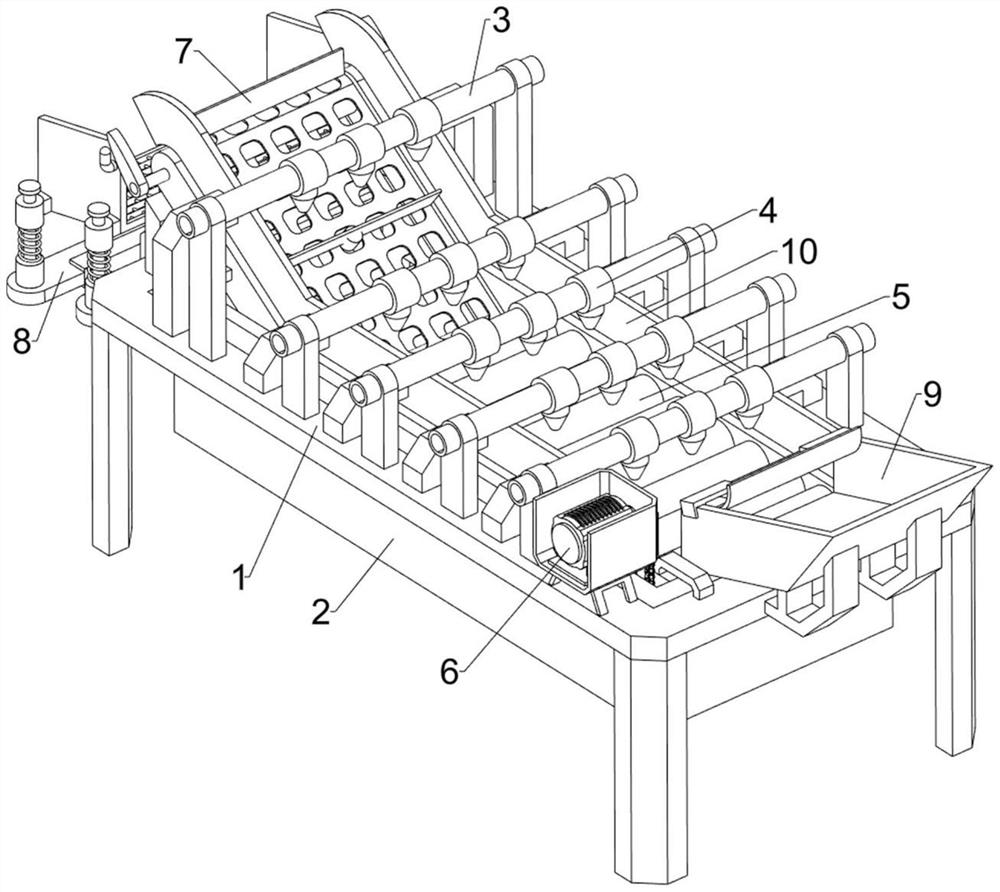

Fluorescent marker rice seed sorting mechanism and method

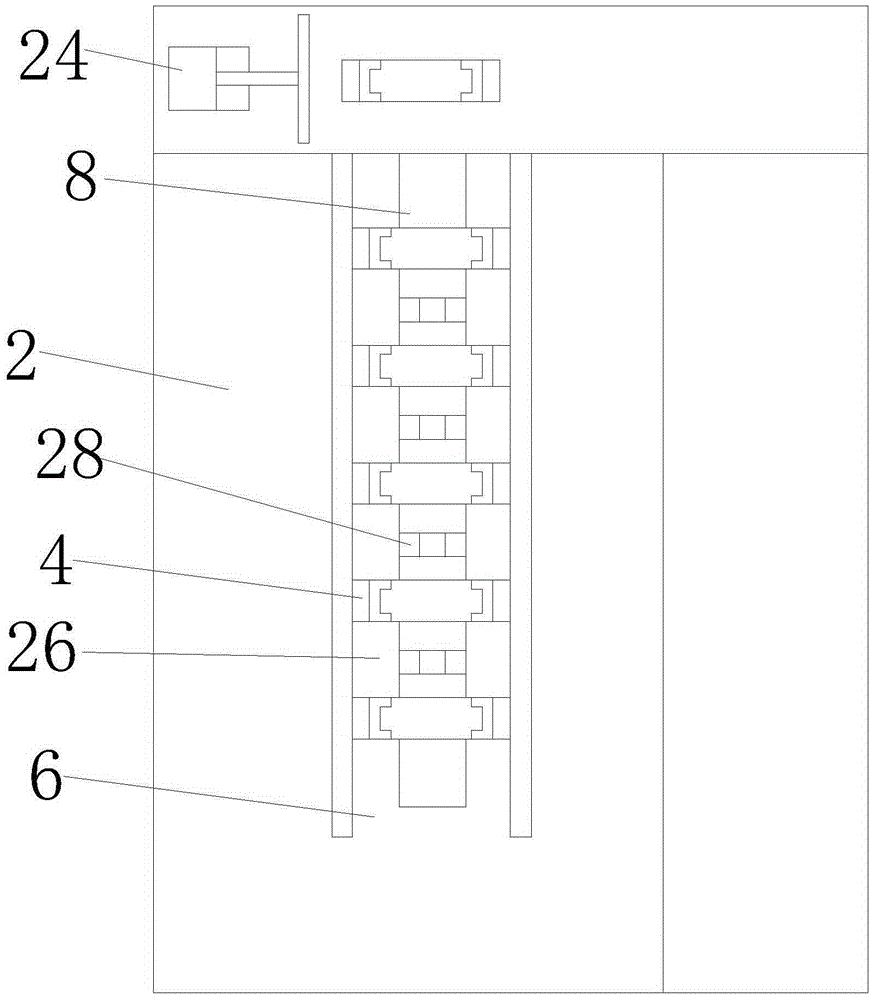

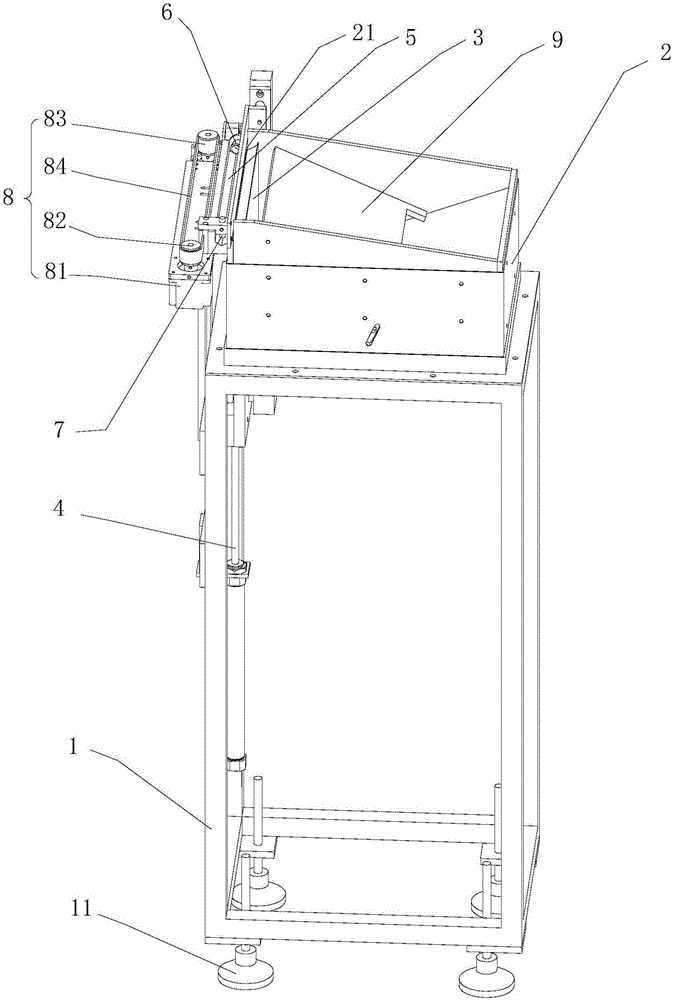

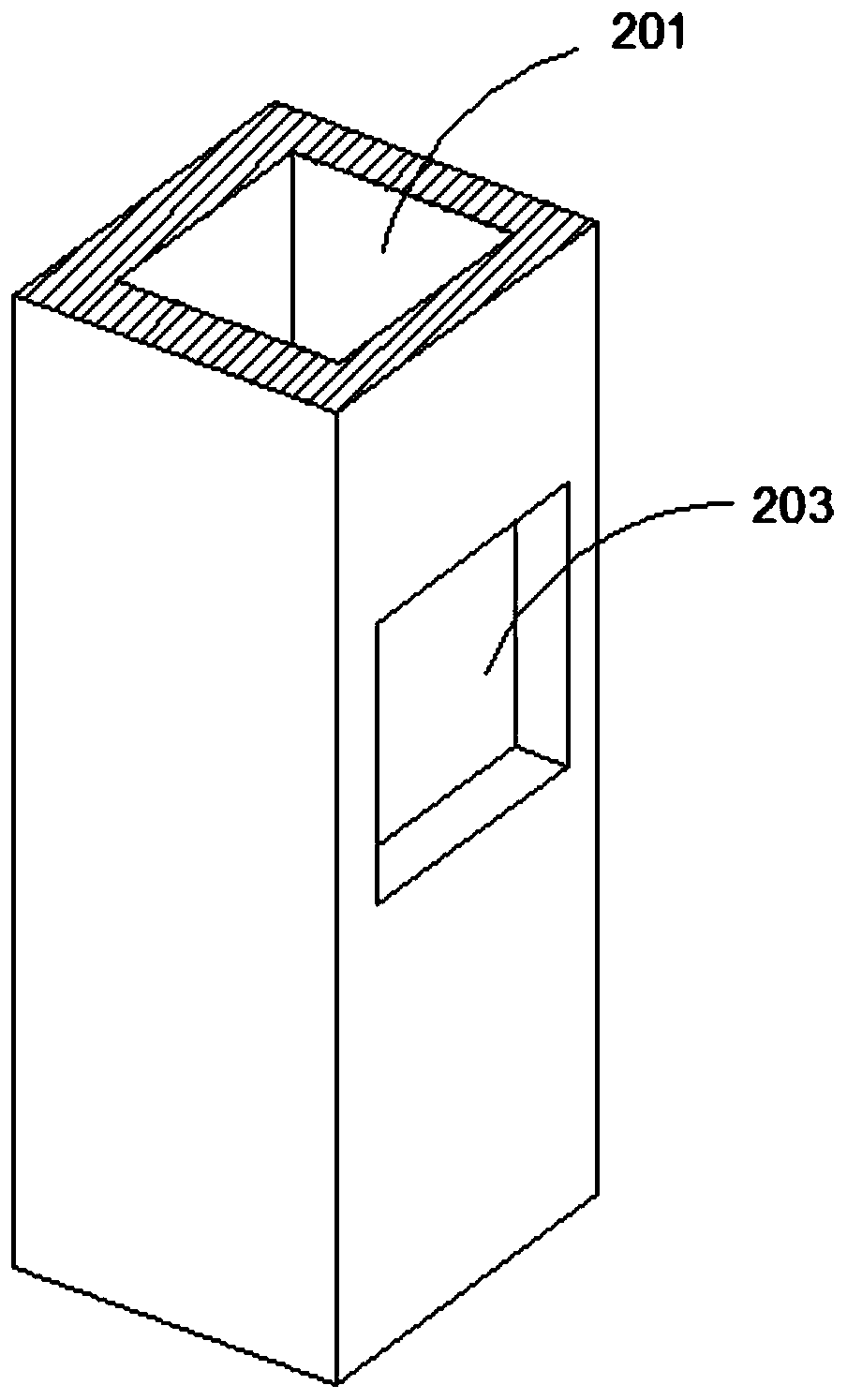

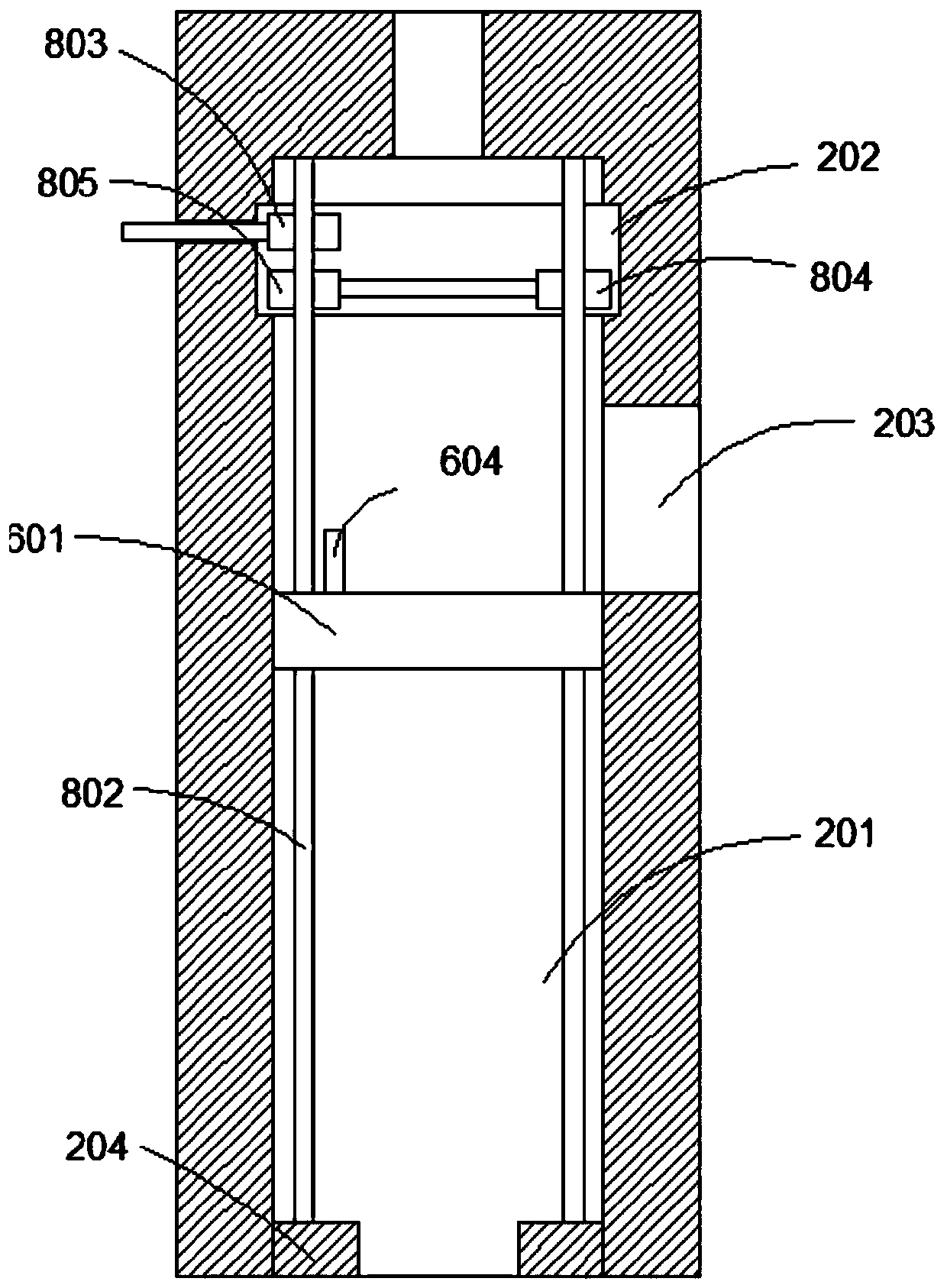

The invention provides a fluorescent marker rice seed sorting mechanism and method. The fluorescent marker rice seed sorting mechanism comprises a blanking mechanism (1), a profiling positioning mechanism (2), a conveying mechanism (3), a detection device (4), an injection mechanism (5), a collecting channel (6), a light source (7) and a frame (8), wherein the frame (8 )comprises a support frame (81), an upper positioning plate (82), a middle positioning plate (83) and a side positioning plate (84), the detection device (4) and the injection mechanism (5) in the conveying mechanism (3) are correspondingly provided with a detection station and an injection station, the collecting channel (6) is aligned with the injection station, and the light source (7) is aligned with the detection station. The fluorescent marker rice seed sorting mechanism is simple and compact in structure, convenient to use and capable of stably, uniformly and orderly loading and transporting the seeds, the detection area is wide, multiple times of detection can be carried out, and the precision of seed sorting is greatly improved.

Owner:SHANGHAI JIAO TONG UNIV

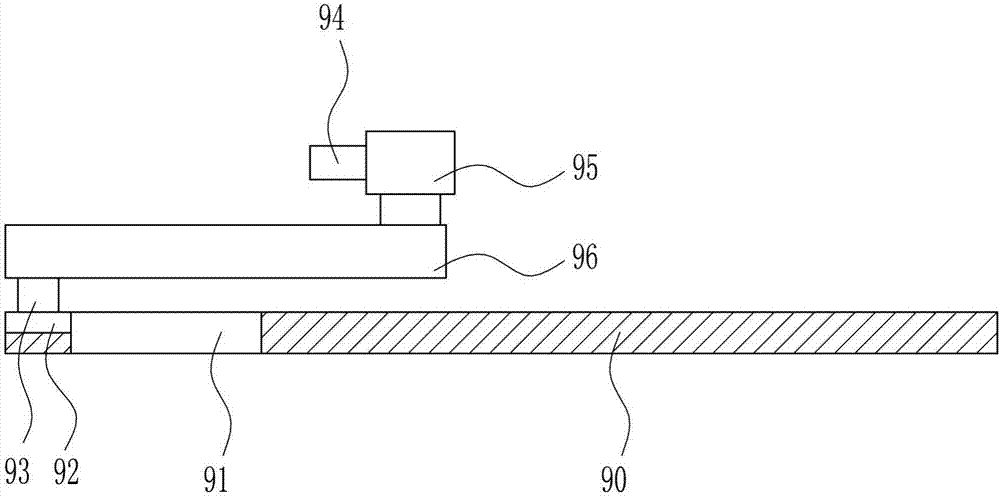

Conductive strip feeding device for junction box patch production

ActiveCN105406315AImprove efficiencyQuality improvementLine/current collector detailsDrive motorEngineering

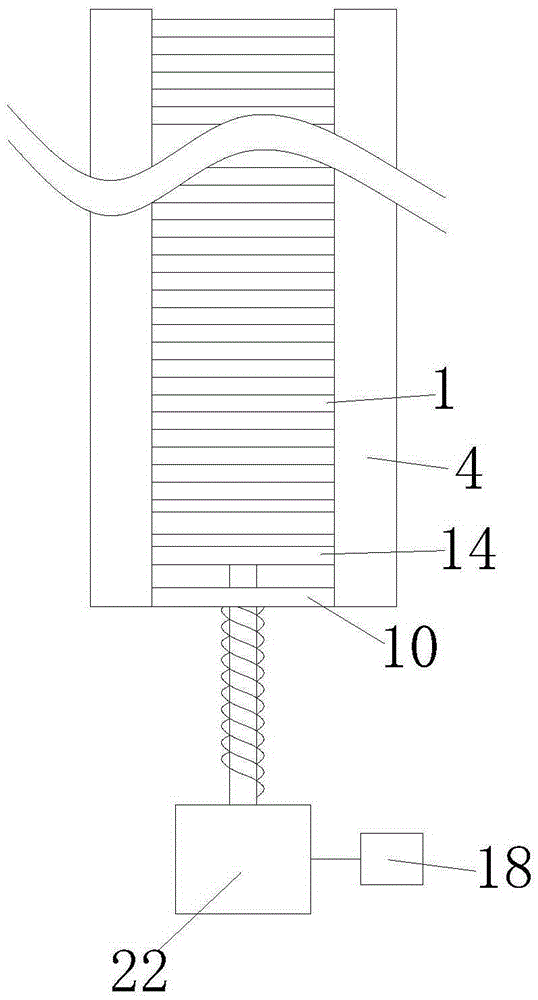

The invention provides a conductive strip feeding device for junction box patch production. The conductive strip feeding device comprises a feeding table and a material storage tool used for placing conductive strips by means of stacking single pieces of the conductive strips up and down, wherein the feeding table is provided with a loading station and a feeding station; the feeding table is provided with a push component used for pushing the material storage tool to the feeding station from the loading station; the material storage tool comprises a base and two clamping bases vertically installed on the base; the bottom surface at the inner side of the base is provided with a push plate; a pushing hole is arranged, wherein the pushing hole penetrates through the bottom surface of the outer side and the bottom surface of the inner side of the base; the feeding station is provided with a pushing mechanism; and the pushing mechanism includes a lead screw and a drive motor used for driving the lead screw to rise and fall, wherein one end of the lead screw can penetrate through the pushing hole and then lean against the push plate. According to the conductive strip feeding device for junction box patch production provided by the invention, by setting the material storage tool and the pushing mechanism, the automatic feeding of the conductive stripe for junction box patch production can be finished, and the conductive strip feeding device has the characteristics of being simple in structure, convenient in use, multiple in one-time storage of the material storage tool and fast in feeding, and after the conductive strip feeding device is used, the production efficiency and quality of the junction box patch can be greatly improved.

Owner:SUZHOU SUOLIWANG NEW ENERGY TECH CO LTD

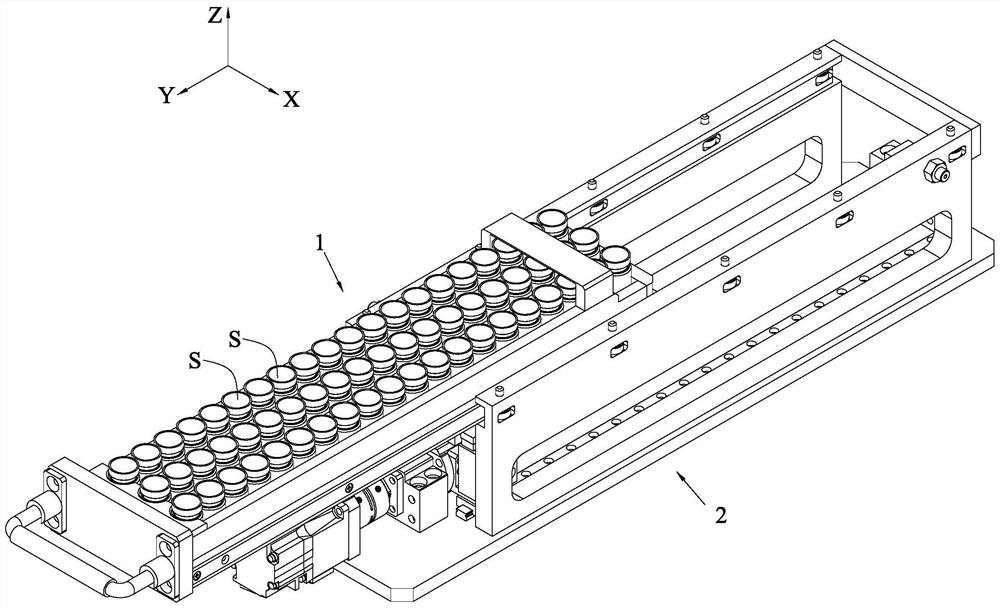

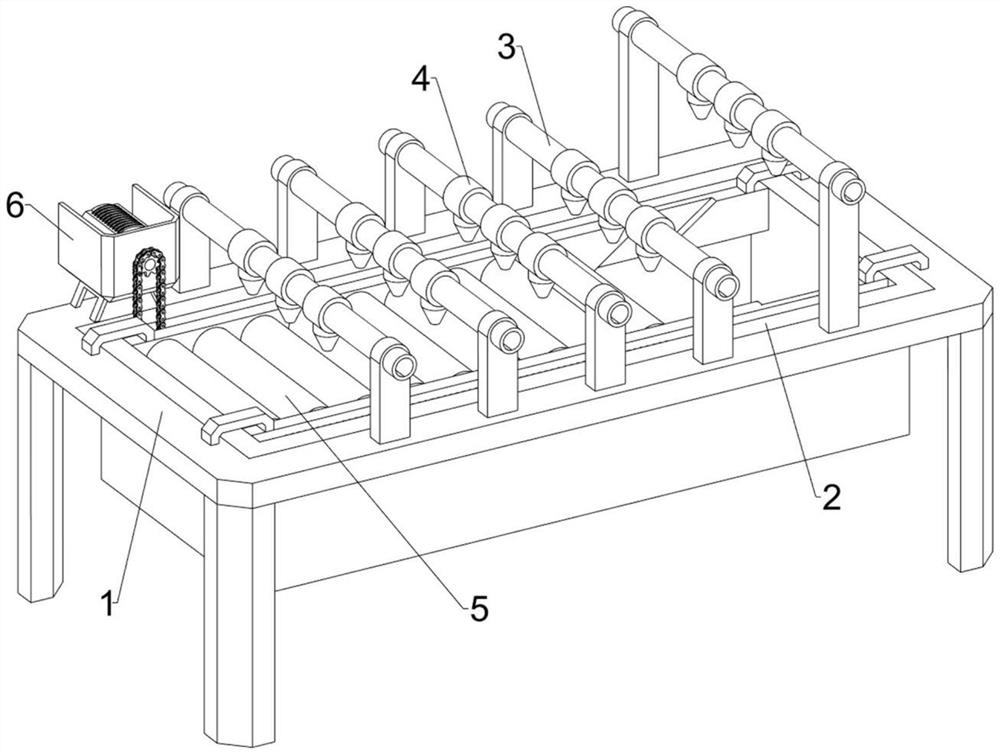

Roller feeding device

Owner:KUNSHAN AODELU AUTOMATION TECH

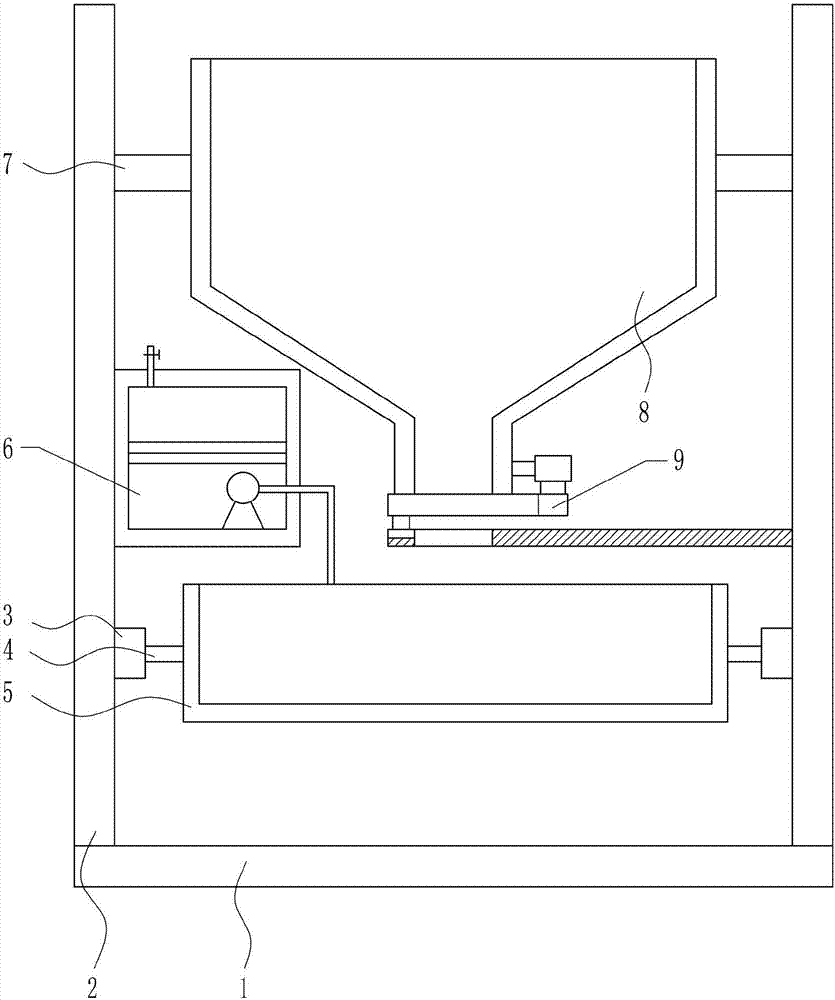

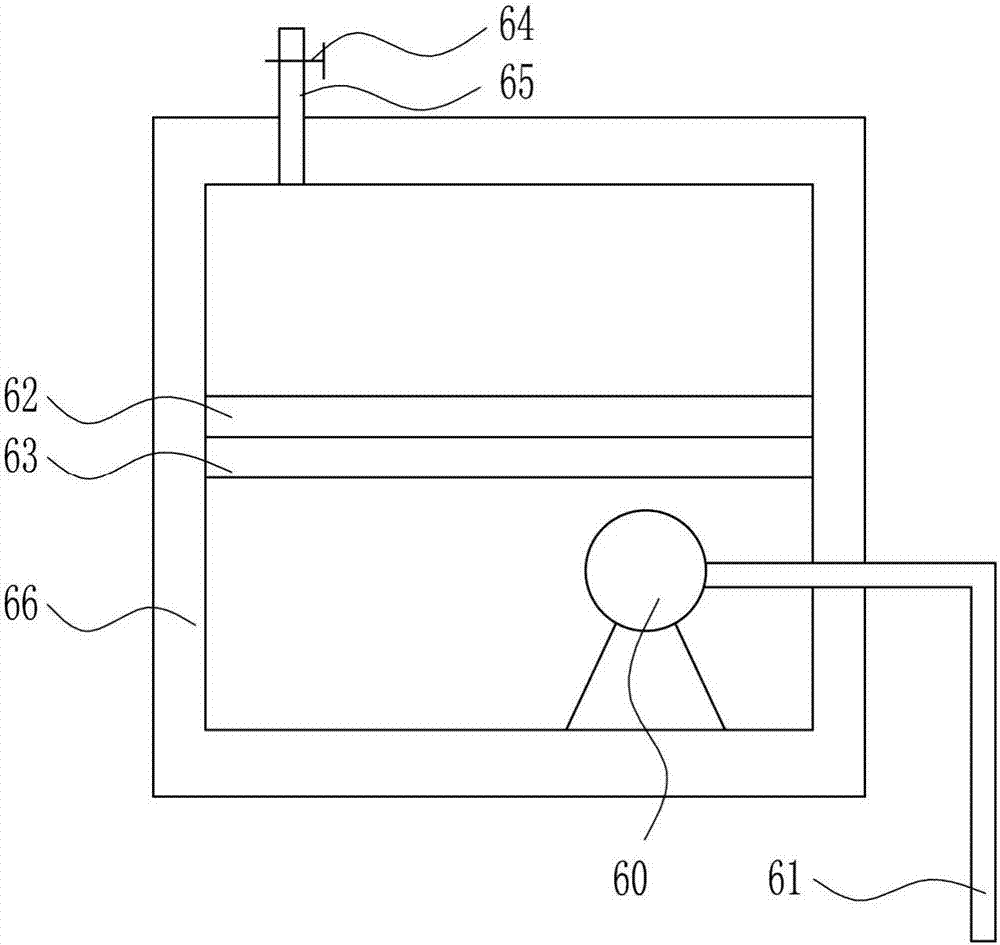

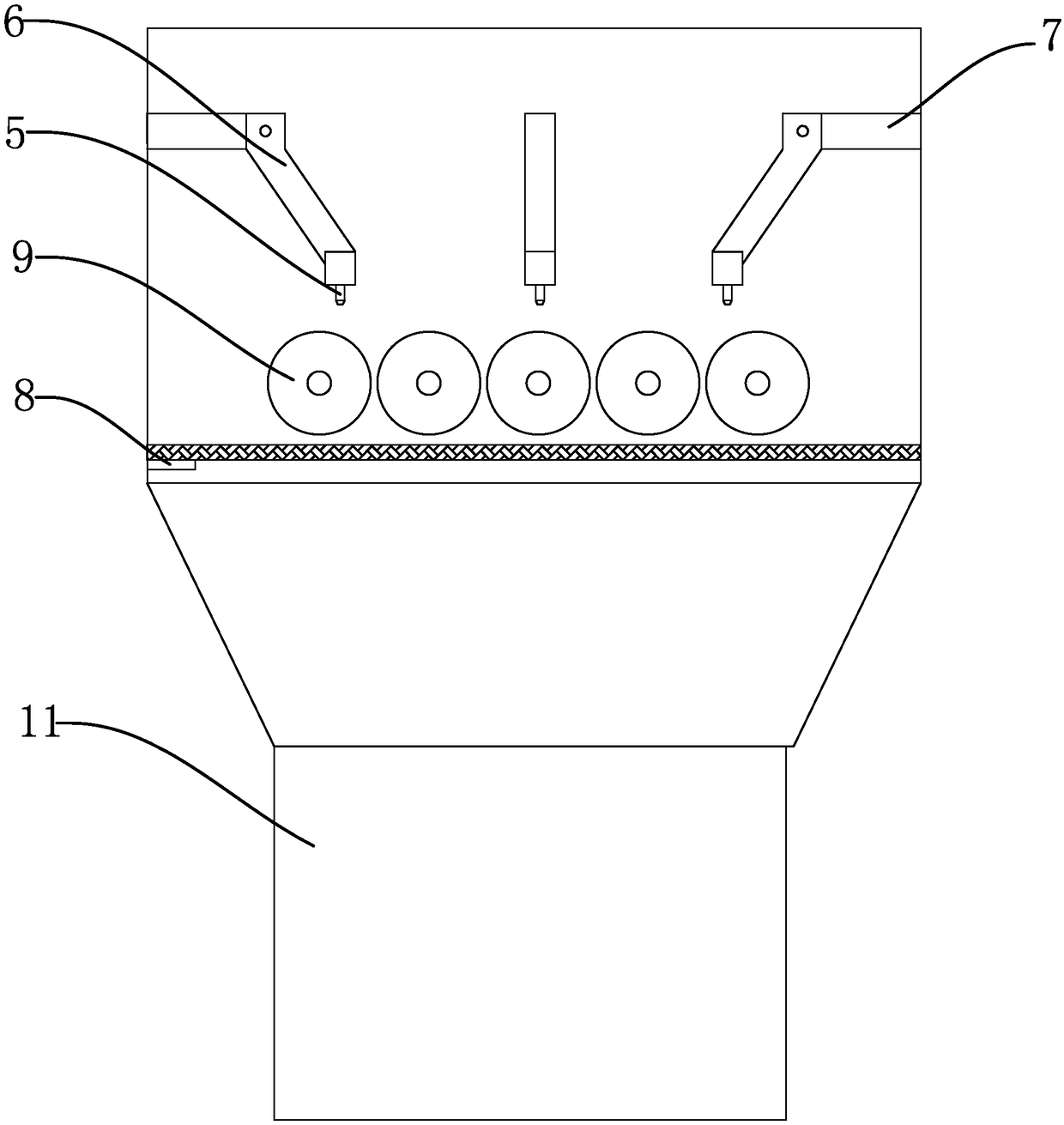

Hot pressing equipment for foam plastic recycling

The invention relates to hot pressing equipment, in particular to hot pressing equipment for foam plastic recycling. The technical problem to be solved by the invention is to provide the hot pressing equipment for the foam plastic recycling which is ordered in feeding and uniform in heating. In order to solve the technical problem, the invention provides the hot pressing equipment for the foam plastic recycling, which comprises a first bearing seat, a first bevel gear, a second bevel gear, a first rotating shaft, a first belt pulley, a second bearing seat, a first connecting rod, a slide way, a valve and the like; the bottom in a mounting frame is connected with a sliding rail, a first guide sleeve and a third bearing seat in sequence from left to right in a bolt connecting mode; the top of the sliding rail is connected with sliding blocks in a sliding manner; and the sliding blocks are in sliding fit with the sliding rail. According to the hot pressing equipment for the foam plastic recycling, a material in a molten state in a forming mould is pushed leftwards by shaking a rocking handle, and finally, is extruded from the forming mould to form a strip-shaped material; the specific gravity is greatly increased; and the space occupied in transportation is greatly reduced.

Owner:乳山市沣润水产养殖有限公司

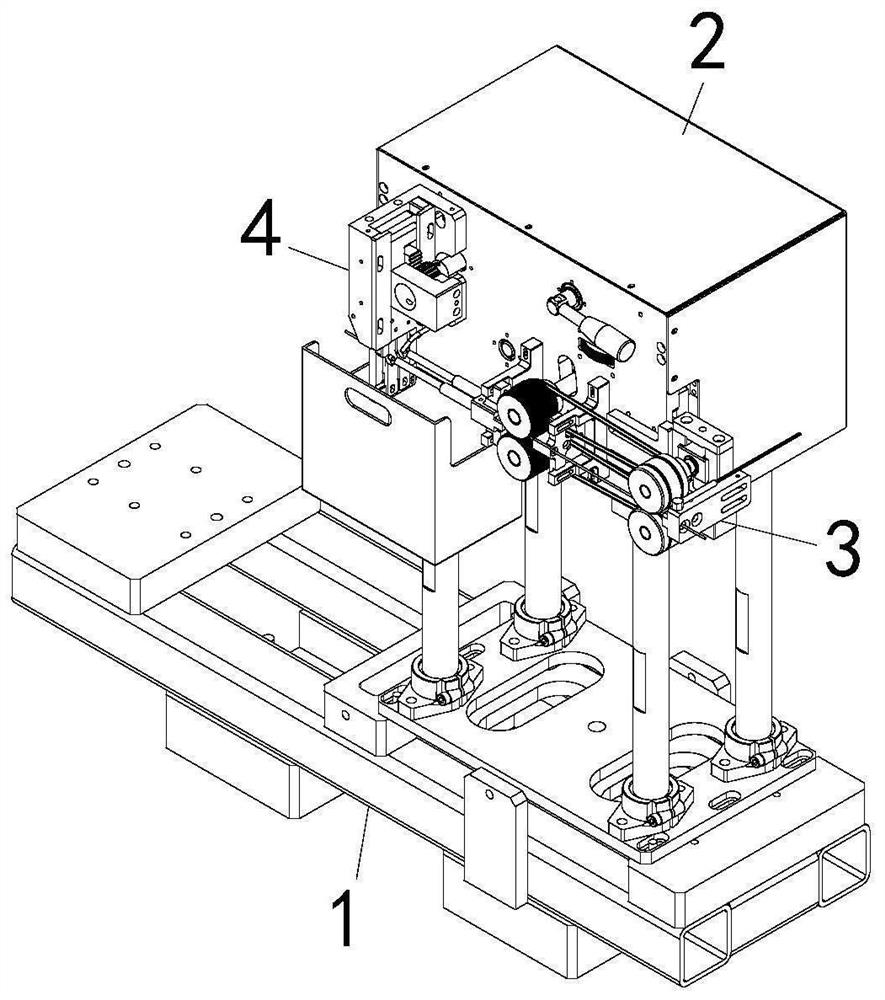

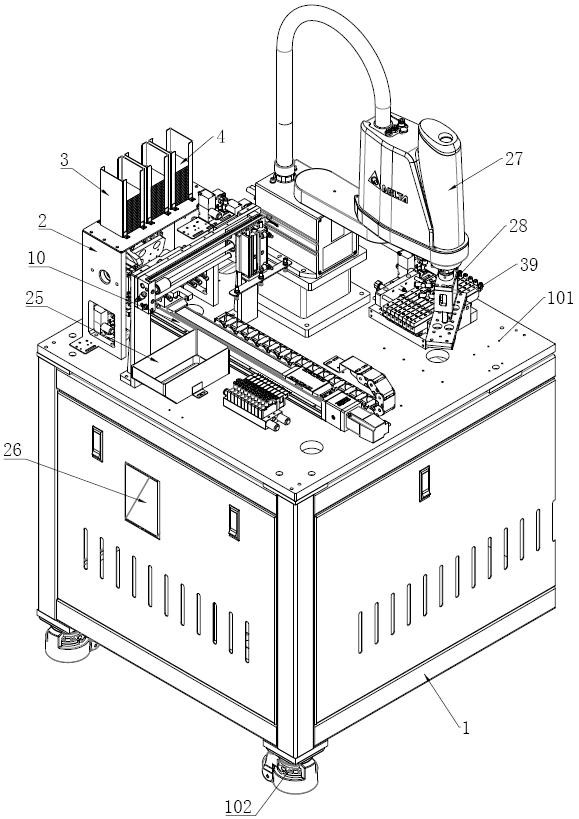

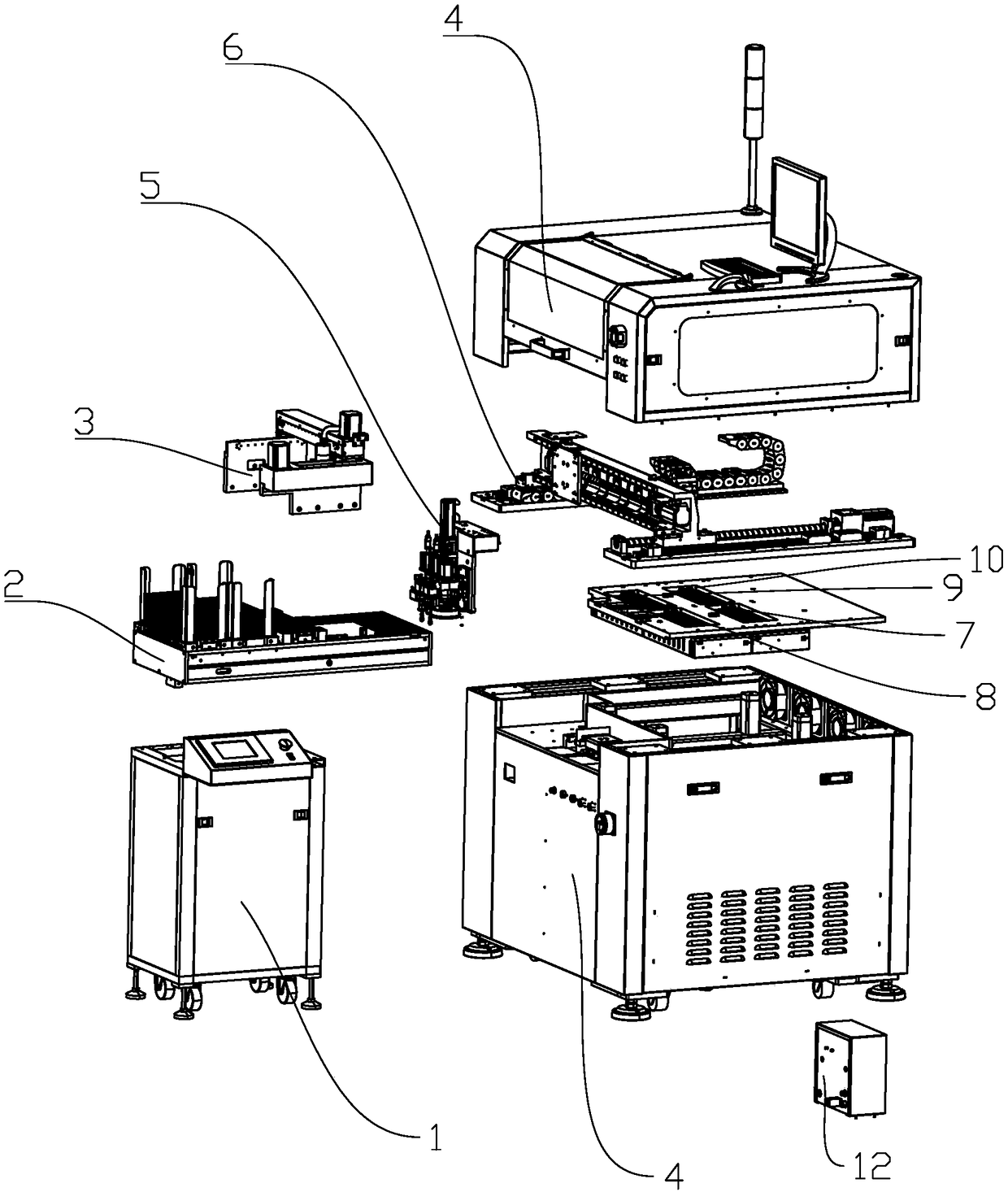

Automatic hydrogel slide feeding and patching device

The invention belongs to the technical field of micro-nano patching, and provides an automatic hydrogel slide feeding and patching device. The automatic hydrogel slide feeding and patching device comprises a machine frame, wherein a slide placing frame driven by an electric cylinder is arranged on a workbench of the machine frame, a slide positioning mechanism is arranged on the slide placing frame, and a slide bin and a film tearing mechanism are sequentially arranged on a workbench in the sliding direction of the slide placing frame; a slide feeding mechanism is correspondingly arranged below the slide bin; and a patching mechanical arm and a material sheet placing table are further arranged on the workbench, the material sheet placing table is located on one side of the patching end ofthe electric cylinder, the patching mechanical arm is located between the electric cylinder and the material sheet placing table, and a material taking and placing mechanism used for taking and placing material sheets is arranged at the end of a working shaft of the patching mechanical arm. According to the invention, automatic processing of hydrogel slide feeding, release film tearing and lamination of the material sheets on the hydrogel slide can be realized, so that the patching efficiency and the patching quality are greatly improved, the sanitation of the material sheets is not influencedin the processing course, and the produced patching product is ensured to meet the production requirement of sanitation standard.

Owner:SHANDONG NOVOSHINE OPTOELECTRONICS CO LTD

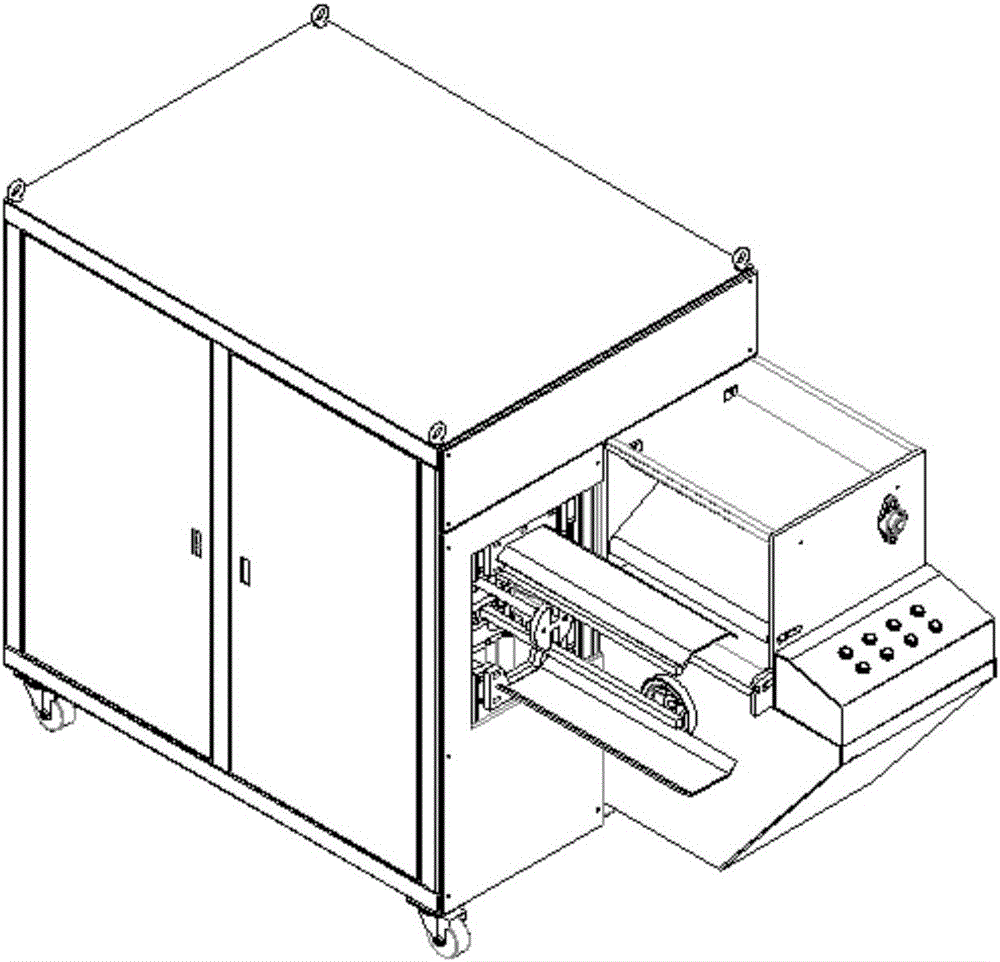

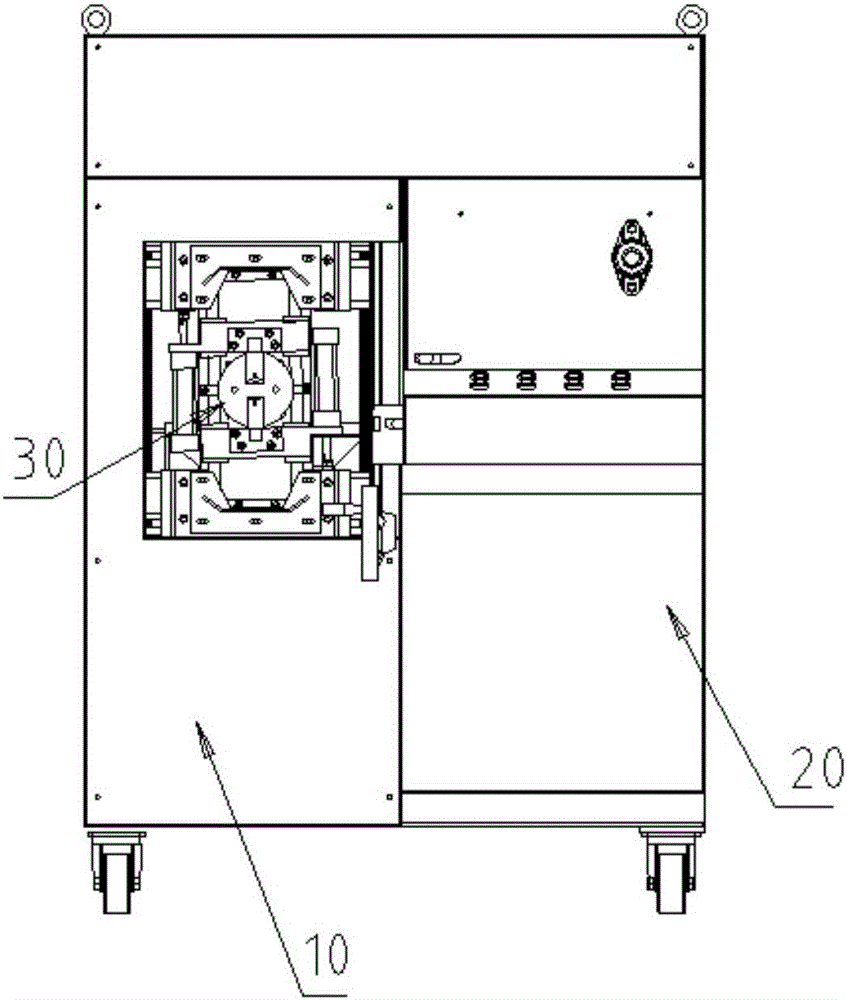

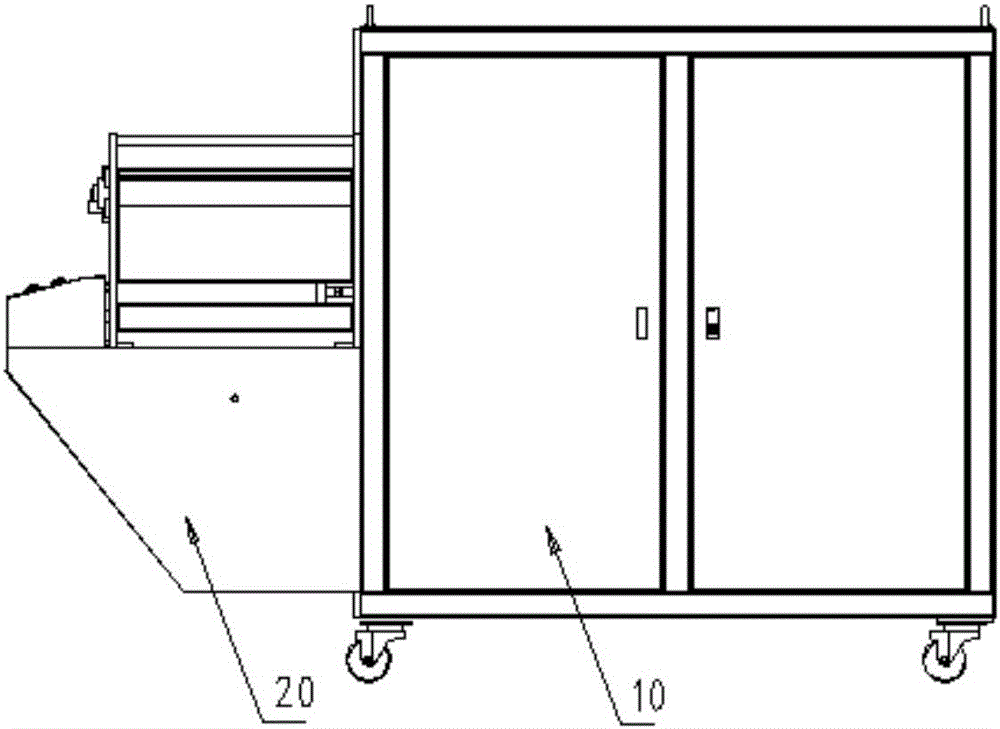

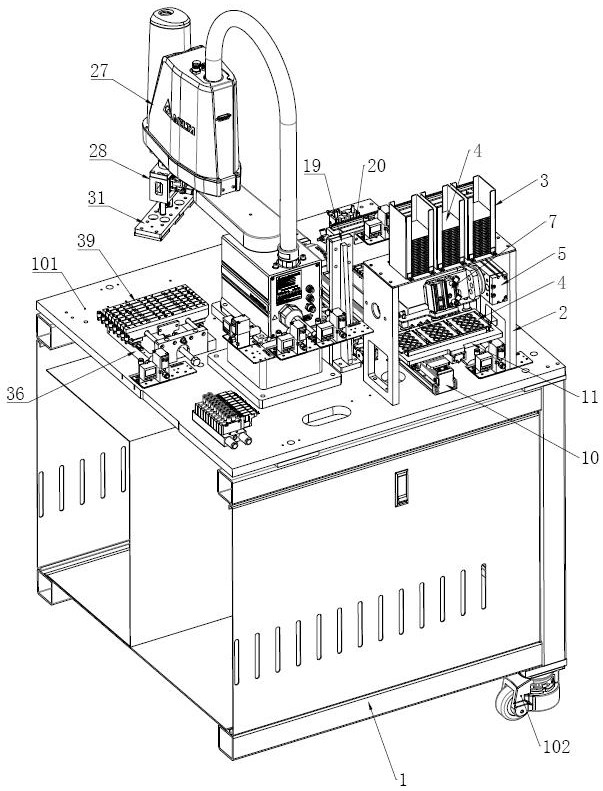

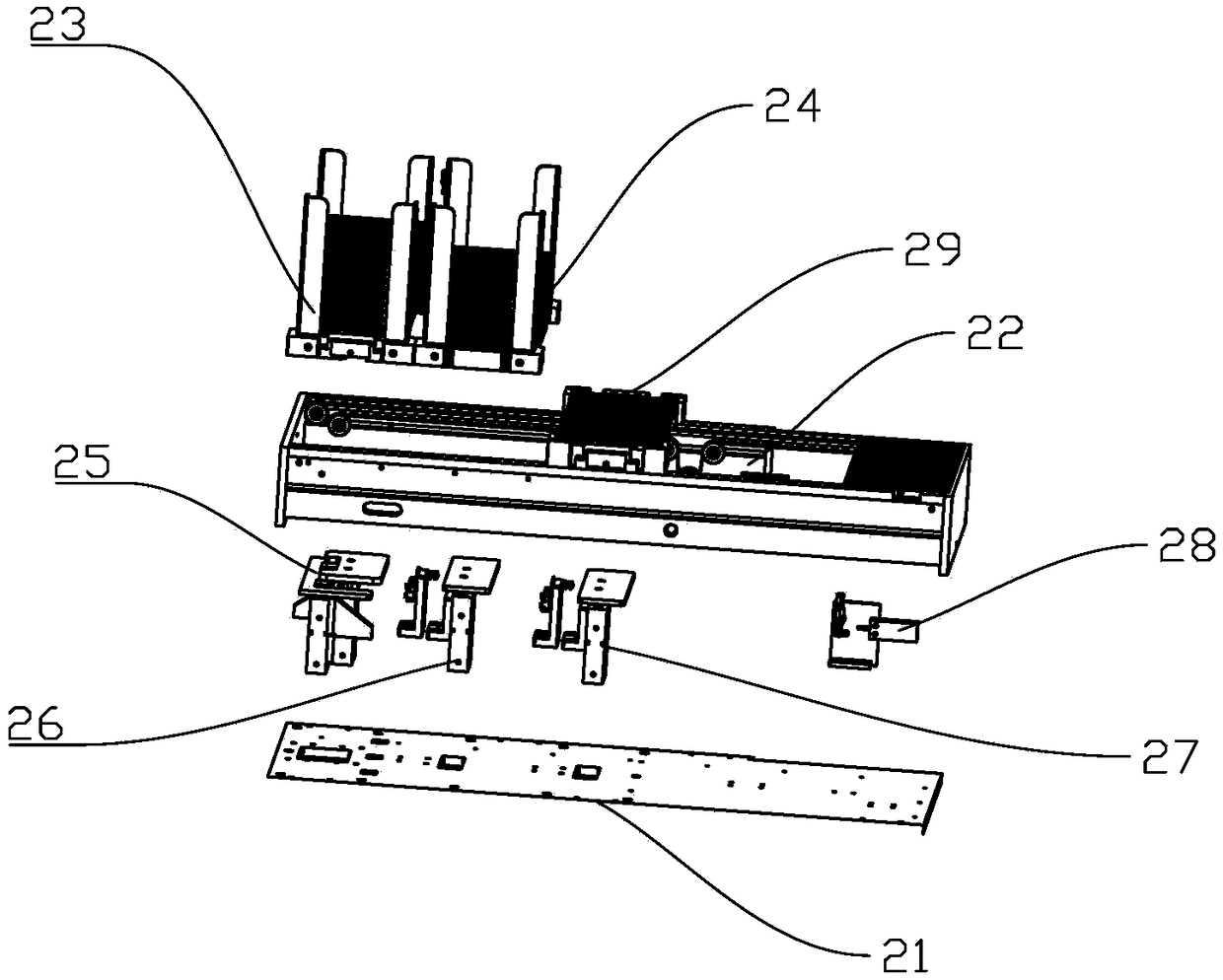

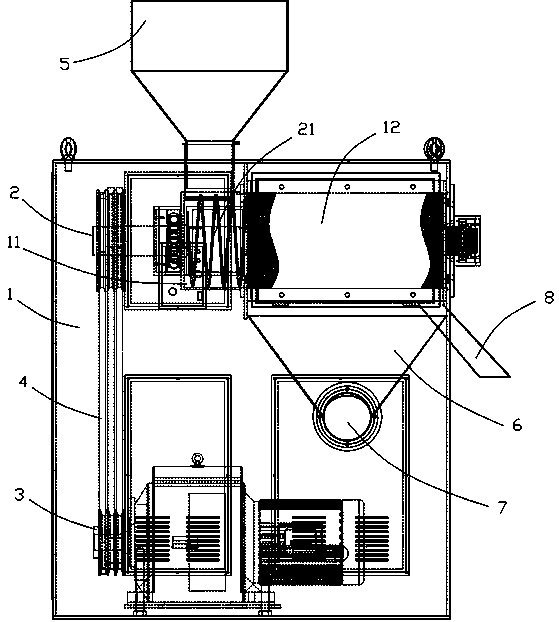

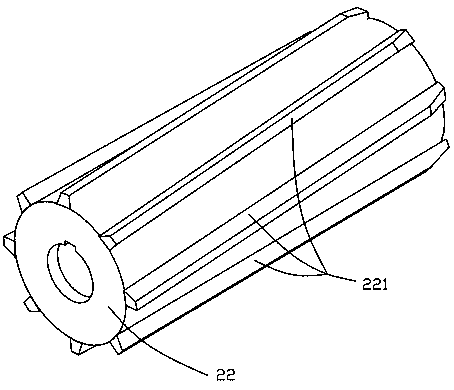

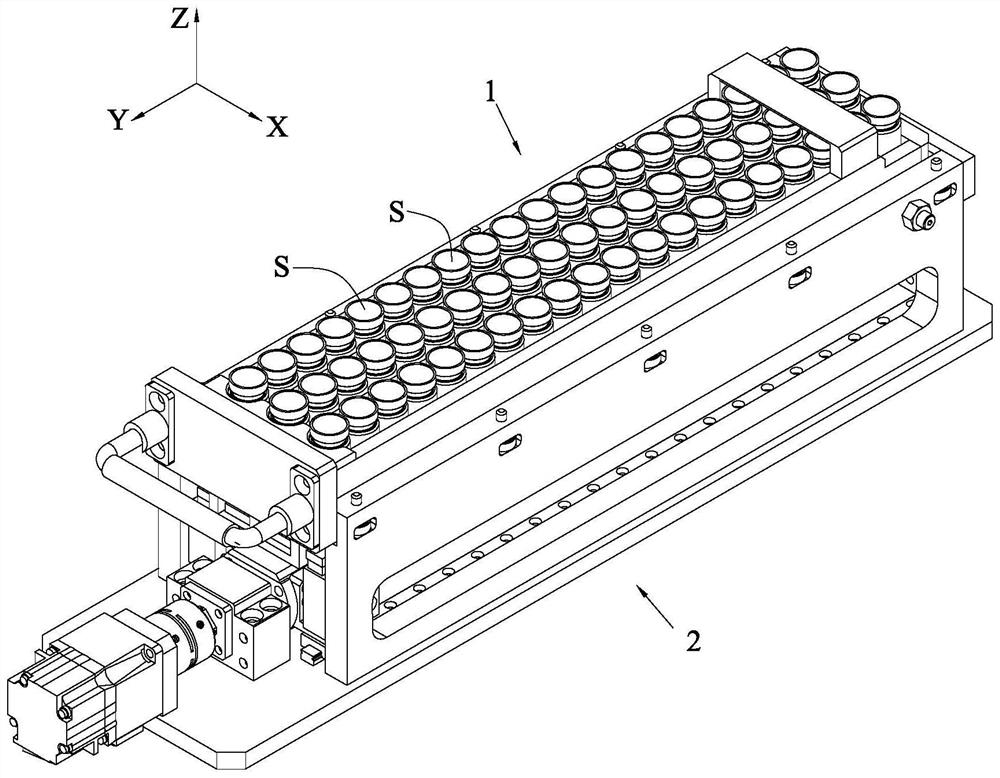

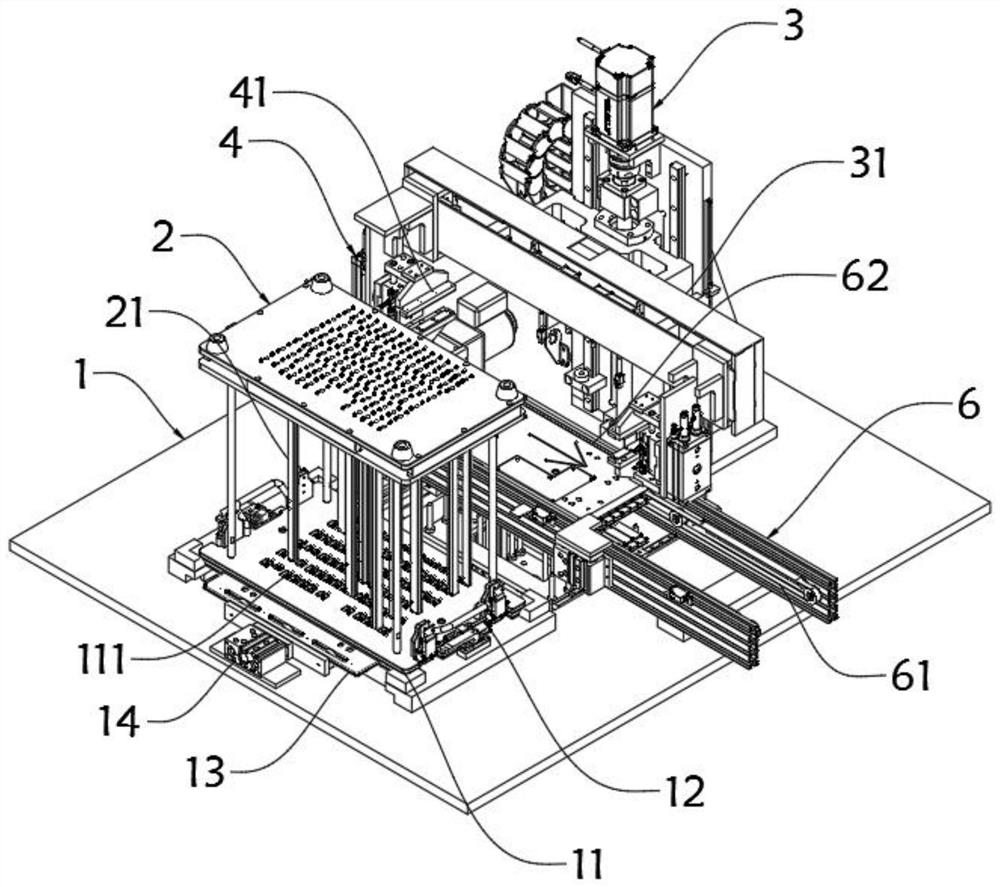

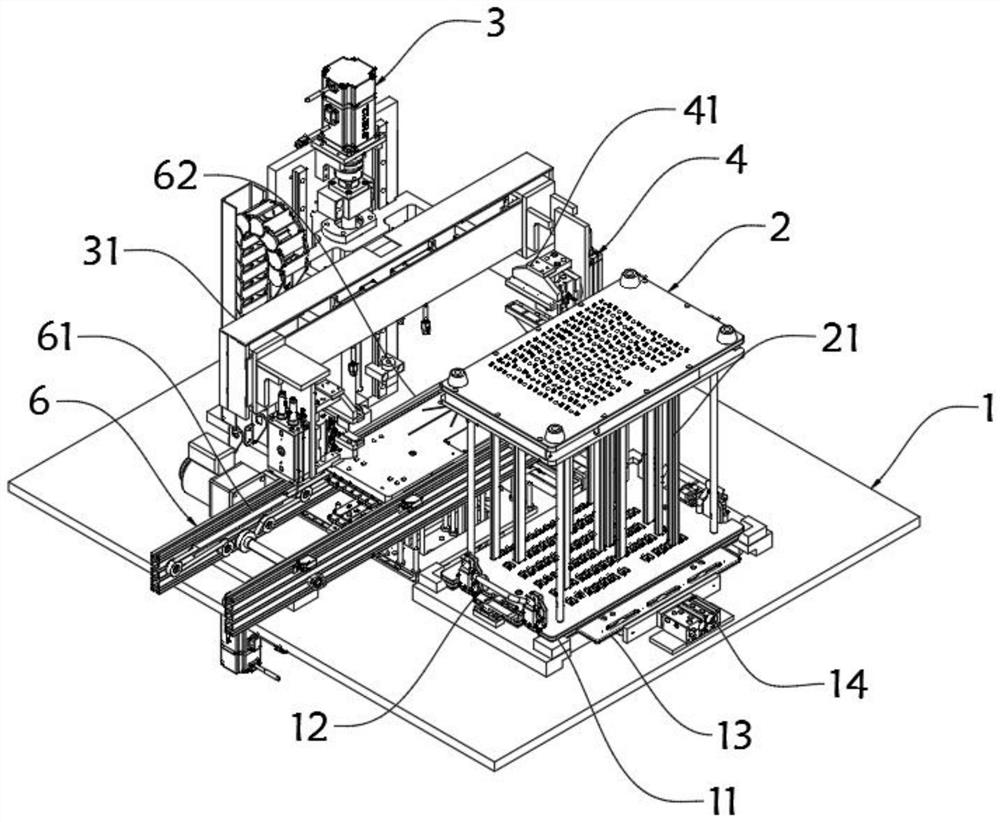

An IC chip burner

InactiveCN108987313AOrderly feedingImprove processing efficiencySemiconductor/solid-state device manufacturingConveyor partsElectrical and Electronics engineering

The invention relates to the field of chip production and manufacture. An IC chip burner comprises a feeding rack assembly and a feeding mechanism thereon. The feeding mechanism comprises a fixed baseplate, a drive belt device, a first stacking device and a first lifting device. The advantages of the IC chip burner are that material is fed in an orderly manner from material plates holding IC chips, the processing efficiency is high, and other functions are convenient to expand.

Owner:吴美珍

Camellia oleifera seed sheller thorough in milling

PendingCN108783480AGrinding and shelling thoroughlyGrind thoroughlyFatty-oils/fats productionHuskingCamellia oleiferaEngineering

The invention relates to the technical field of shelling equipment, and discloses a camellia oleifera seed sheller thorough in milling. The camellia oleifera seed sheller comprises a machine frame, arotating shaft arranged in the machine frame and a driving device for controlling the rotating shaft to rotate, wherein a spiral transmission structure is arranged on the periphery of the first end part of the rotating shaft, and is used for transmitting camellia oleifera seeds to a milling position; a sleeve which is fixed to the machine frame is arranged on the periphery of the spiral transmission structure; a roller is arranged on the periphery of the second end part of the rotating shaft, and rotates along with the rotating shaft; a plurality of ribs which extend in the length direction ofthe roller are arranged on the periphery of the roller; a spacing is generated between every two adjacent ribs; a sieving cylinder is fixedly arranged in the length region of the roller, on the machine frame; the roller penetrates in the sieving cylinder and is coaxial with the sieving cylinder; a gap is formed between the free end away from the roller, of each rib, and the sieving cylinder; thefirst end part and the second end part of the rotating shaft are connected; and the sleeve is connected with the end part of the sieving cylinder, or a gap is formed between the sleeve and the end part of the sieving cylinder. The camellia oleifera seeds are slowly transmitted to the roller through the spiral transmission structure for milling, the quantity of milled camellia oleifera seeds in unit time is relatively low, and the shelling of the camellia oleifera seeds is thorough.

Owner:HUNAN DASANXIANG TEA OIL CO LTD

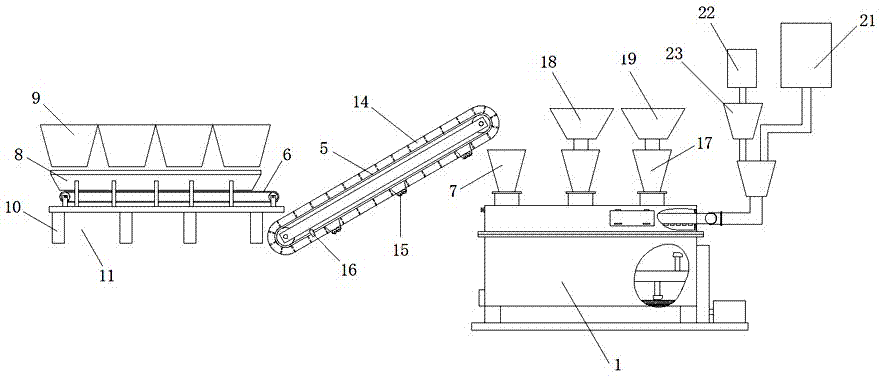

Intermittent feeding assembly device of cement mixing tank and production method thereof

PendingCN106863610AReasonable designAccurate measurementMixing operation control apparatusIngredients weighing apparatusAgricultural scienceAgricultural engineering

The invention relates to an intermittent feeding assembly device of a cement mixing tank and a production method thereof. The intermittent feeding assembly device comprises the cement mixing tank, a feed inclined belt and a horizontal belt, wherein an aggregate feed opening, a cement feed opening and a powder feed opening are formed in the top of the cement mixing tank, and a liquid inlet is formed in one side of the cement mixing tank; the feed inclined belt is arranged in an inclined mode, and the horizontal belt is horizontally arranged; and a transition bin is arranged above the aggregate feed opening, the discharge end of the feed inclined belt is located above the transition bin, the discharge end of the horizontal belt is located above the feed end of the feed inclined belt, an elongated aggregate weigh is arranged above the horizontal belt along the length direction of the horizontal belt, and a plurality of aggregate bins which are used for storing aggregate are arranged above the aggregate weigh along the length direction of the aggregate weigh. The feeding assembly device has the advantages of reasonable design, accuracy in measurement and orderliness in feeding, feeding blockage can be effectively avoided, the production efficiency is improved, and materials can be uniformly and thoroughly mixed.

Owner:FUJIAN XINDA MACHINERY

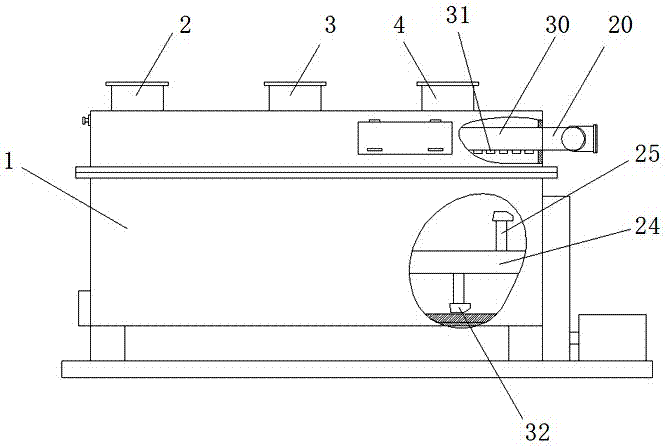

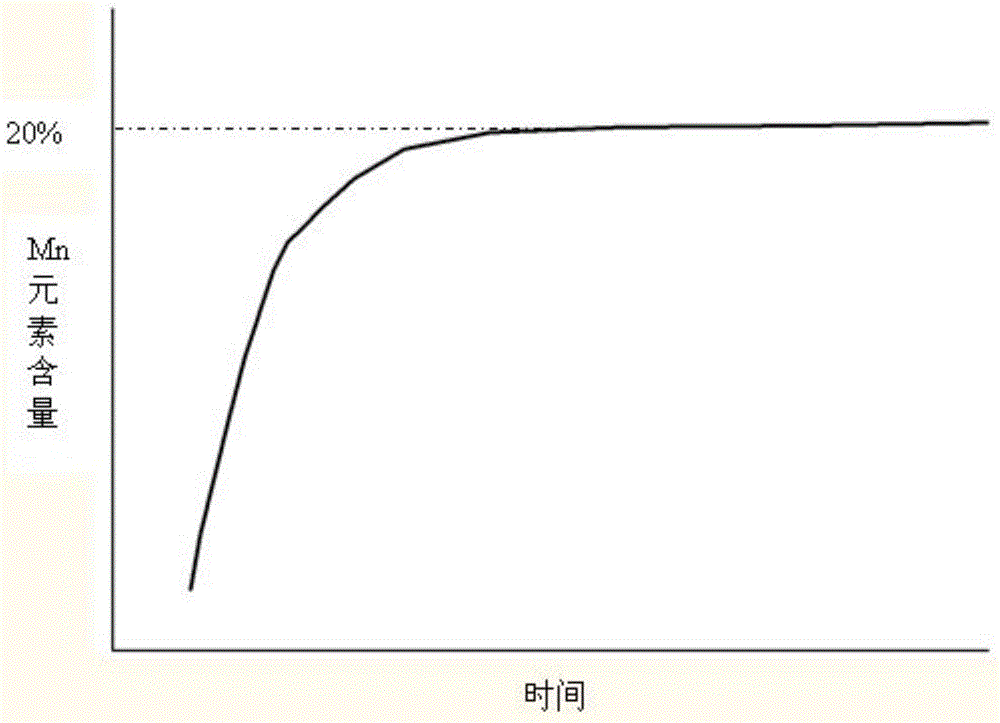

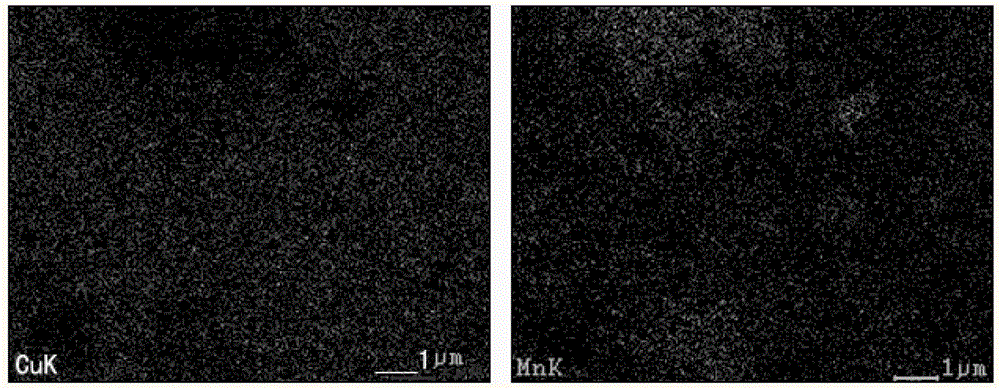

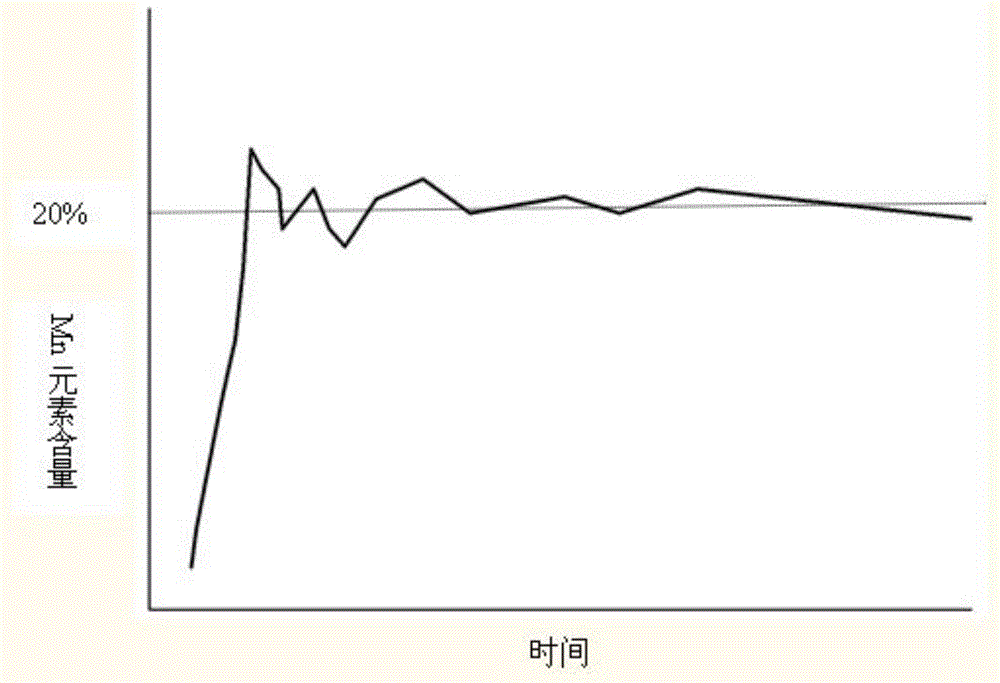

Charging method for preparing binary submicron metal alloy powder by using physical vapor deposition

ActiveCN104907575AOrderly feedingThe content of main metal elements is reducedBinary alloyRaoult's law

The invention discloses a charging method for preparing binary submicron metal alloy powder by using a physical vapor deposition method. The charging method comprises the steps that saturated vapor pressure of each metal element in the metal alloy powder in a certain temperature range is calculated, a degree of metal evaporation is judged, and according to content of each element in the metal alloy powder and the Raoult's law, the charging speed ratio of each metal element is calculated; according to charging ratio of each metal element, pure metal which contains a large proportion in the metal alloy powder serves as a main metal element and is added into a crucible inside a metal evaporating device in advance, the charging speed of small proportional metal, namely a secondary metal element and the charging speed of the main metal element are adjusted, then charging is conducted, and the submicron-class binary powder is obtained. According to the method, the binary submicron metal alloy powder which is even in ingredients can be produced effectively and continuously.

Owner:JIANGSU BOQIAN NEW MATERIALS

Artificial forcing breeding method for batrachuperus pinchonii

InactiveCN107079873AImprove multiplication efficiencyImprove survival rateAnimal feeding stuffAccessory food factorsBatrachuperus pinchoniiObserved Survival

The invention relates to a salamandrina breeding method and in particular relates to an artificial forcing breeding method for batrachuperus pinchonii. The method is technically characterized by comprising the following steps: building a culture pond; feeding breeding batrachuperus pinchonii; incubating the breeding batrachuperus pinchonii; managing the young batrachuperus pinchonii, optimizing the growth environment of the batrachuperus pinchonii, and performing scientific management. The birth and survival rate is improved at each link of the whole batrachuperus pinchonii growth process, the growing period is shortened, and the weight of an individual batrachuperus pinchonii is increased, so that the quality of the batrachuperus pinchonii is well guaranteed. According to the forcing breeding method disclosed by the invention, the fertilization rate of the batrachuperus pinchonii is increased by 30% compared with that under natural conditions, the survival rate of the batrachuperus pinchonii is improved by 50% compared with that under natural conditions, the growing period of the batrachuperus pinchonii is shortened by 150-200 days, and the weight of the individual batrachuperus pinchonii is increased by 26% year on year.

Owner:迪庆藏族自治州高原生物研究所

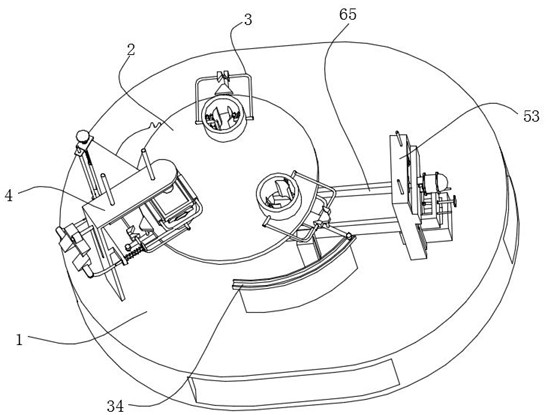

Automatic glue-injecting device for outer seal ring of power battery cap

PendingCN106953036AAvoid displacementImprove work efficiencyCell lids/coversCell sealing materialsPower batteryElectric control

The invention relates to an automatic glue-injecting device for an outer seal ring of a power battery cap. The device comprises a worktable, an electric control box, a vibrating disc, a glue injecting track, a glue box, a glue injecting pneumatic suction and drain pump, a glue injection needle, a glue injecting feeding device, a rotating limiting device, a rotating driving device and a material receiving disc. The vibrating disc, the glue injecting track, the glue tank and the glue injecting pneumatic suction and drain pump are arranged on the worktable, the vibrating disc is connected to a feeding outer seal ring at one end of the glue injecting rack, the glue injecting feeding device is arranged on the lower portion of the other end of the glue injecting track, and the rotating limiting device and the rotating driving device are separately arranged on two sides of the other end of the glue injecting track. The automatic glue-injecting device provided by the invention is compact in structure and high in degree of automation, and can quickly and stably inject glue into the outer seal ring.

Owner:朱剑

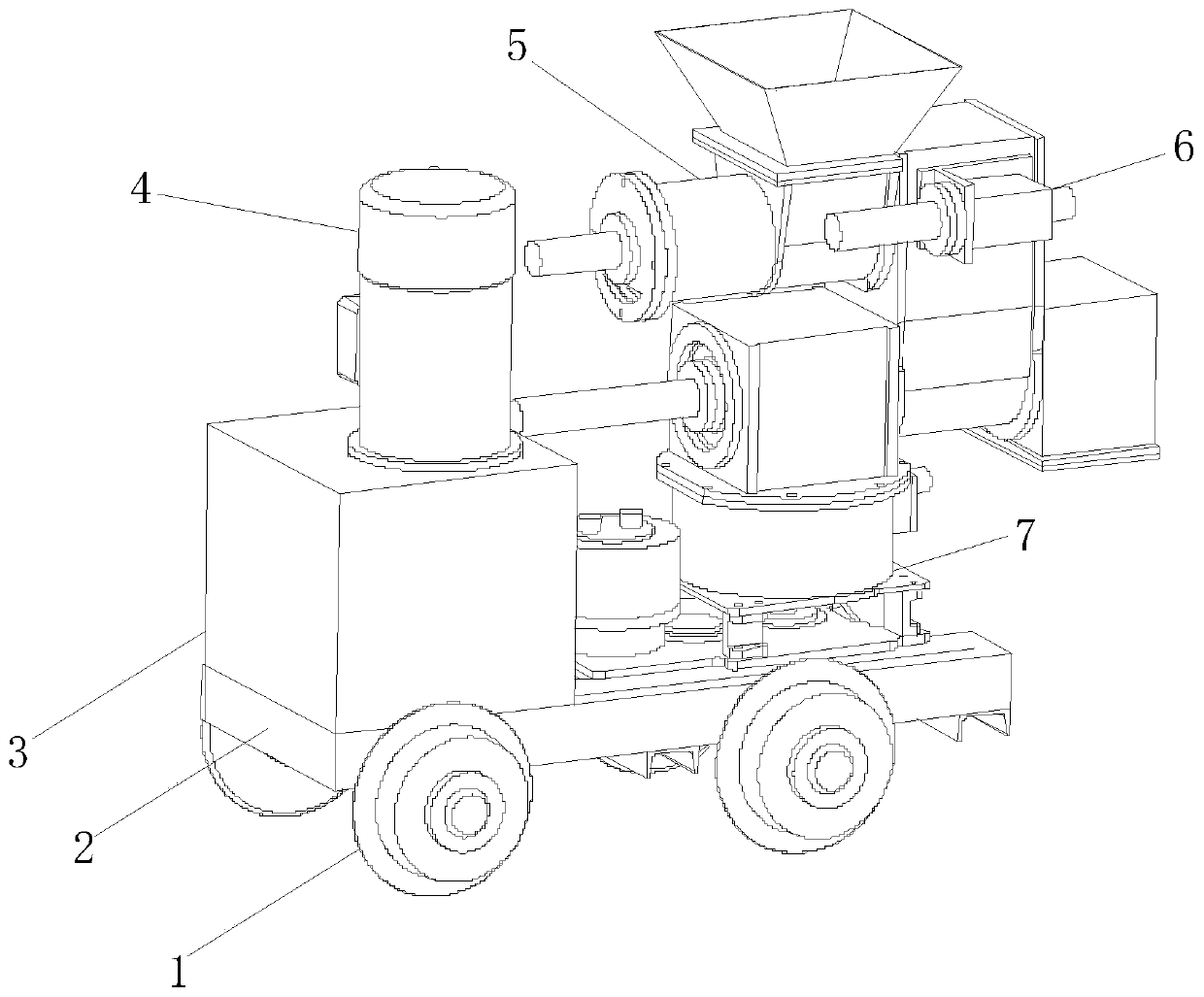

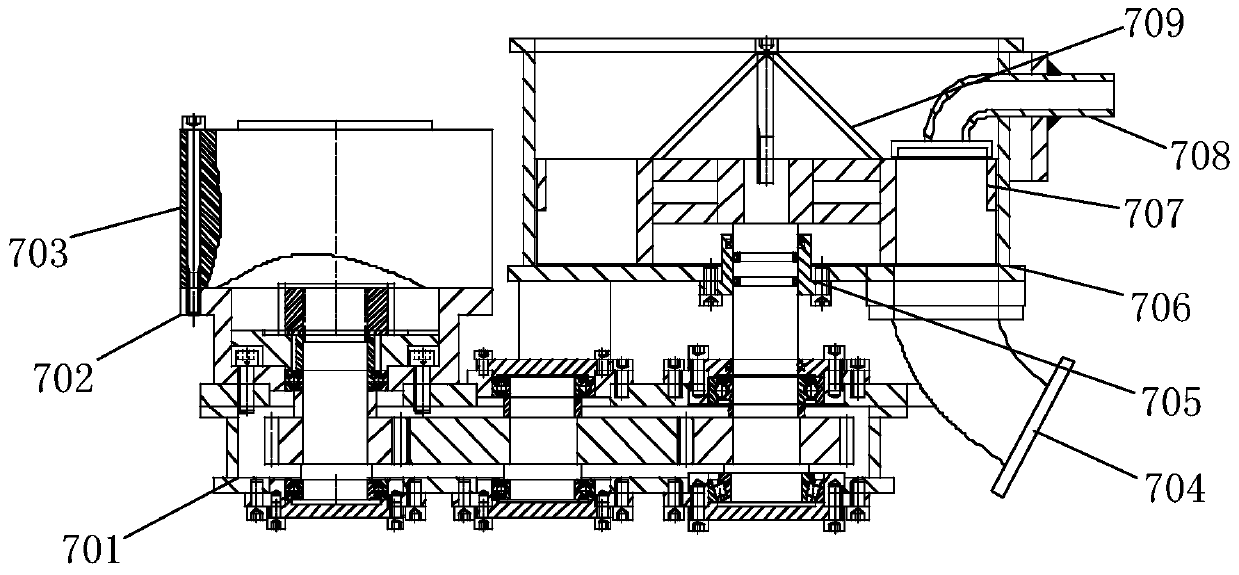

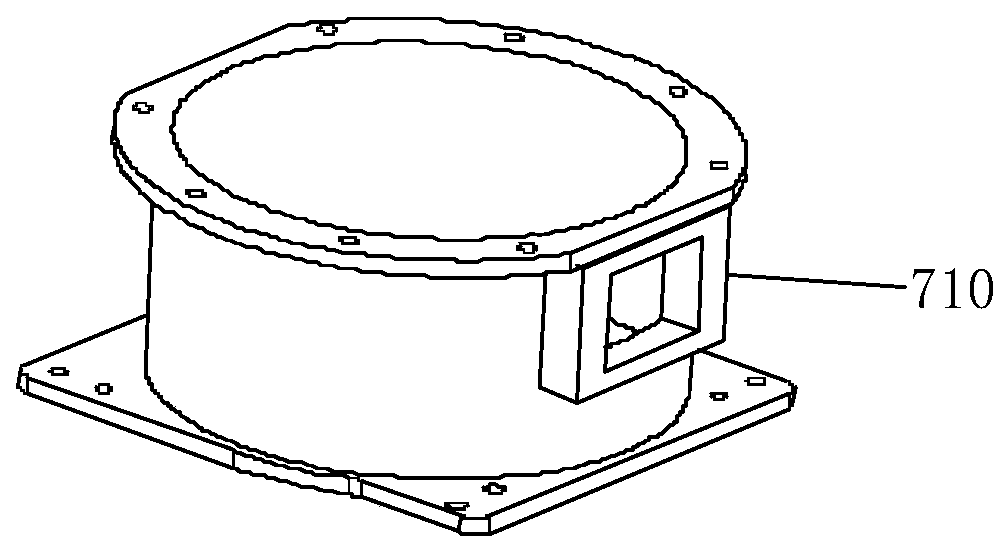

Long-distance concrete sprayer

ActiveCN111188637ACompact structureImprove sealingUnderground chambersLift valveSprayerElectric machine

The invention provides a long-distance concrete sprayer and relates to the technical field of concrete spraying equipment. The long-distance concrete sprayer comprises an underframe, a cylinder barrelmechanism, a rotor mechanism and a hydraulic system. The cylinder barrel mechanism comprises an upper cylinder barrel part and a lower cylinder barrel part. The cylinder barrel, a pushing piston, a sealing piston and a sealing box body of the sealing piston are matched one another, the sealing piston and the cylinder barrel form an end surface seal and a material collecting box is arranged on theend part of the lower cylinder barrel for collecting excess materials accumulated by the pushing piston. The rotor mechanism primarily comprises a rotor shell, a rotor and a cone-shaped distributor,and in a rotating process of the rotor, materials in stock bins are sprayed continuously. The hydraulic system comprises a hydraulic fuel tank and a motor and provides power to the sprayer. The sprayer in a form of end surface seal avoids friction between the sealing part and concrete and the cylinder barrel. The pushing piston can be a rigid piston which achieves sealing by means of the sealing piston. The rotor mechanism distributes the concrete uniformly to achieve pulse-free continuous spraying. The long-distance concrete sprayer also has the advantages of long-distance dust-free conveyance, being in long in service life and the like.

Owner:SHANDONG UNIV OF SCI & TECH

Automatic type setting machine for floor tile laying

ActiveCN110318523AFull of laying needsImprove laying efficiencyBuilding constructionsEngineeringMechanical engineering

The invention discloses an automatic type setting machine for floor tile laying. The automatic type setting machine for floor tile laying comprises a machine body, the machine body is provided with alaying channel for floor tile laying, the machine body is further provided with a feeding channel communicating with the laying channel, and a walking mechanism is arranged at the bottom of the machine body; the feeding channel comprises a rotary feeding mechanism and a belt conveying mechanism, floor tiles are conveyed into the laying channel through the rotary feeding mechanism and the belt conveying mechanism, and a laying assembly used for laying the floor tiles on the ground is installed in the laying channel; and the laying assembly comprises a bearing frame used for bearing the floor tiles and a tile pressing assembly located over the bearing frame. According to the automatic type setting machine for floor tile laying, the floor tiles can be automatically laid, labor force is saved,orderly feeding can be guaranteed when the type setting machine conducts feeding, the problem that the floor tiles are jammed in the feeding channel is effectively solved, and smooth feeding is guaranteed.

Owner:宿州学院

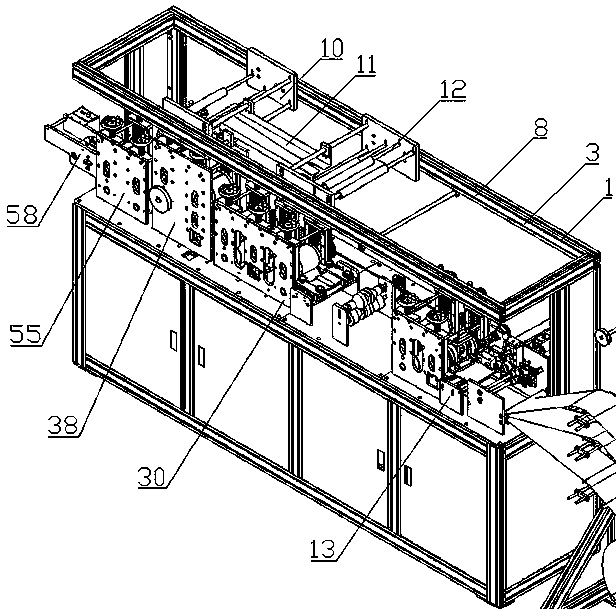

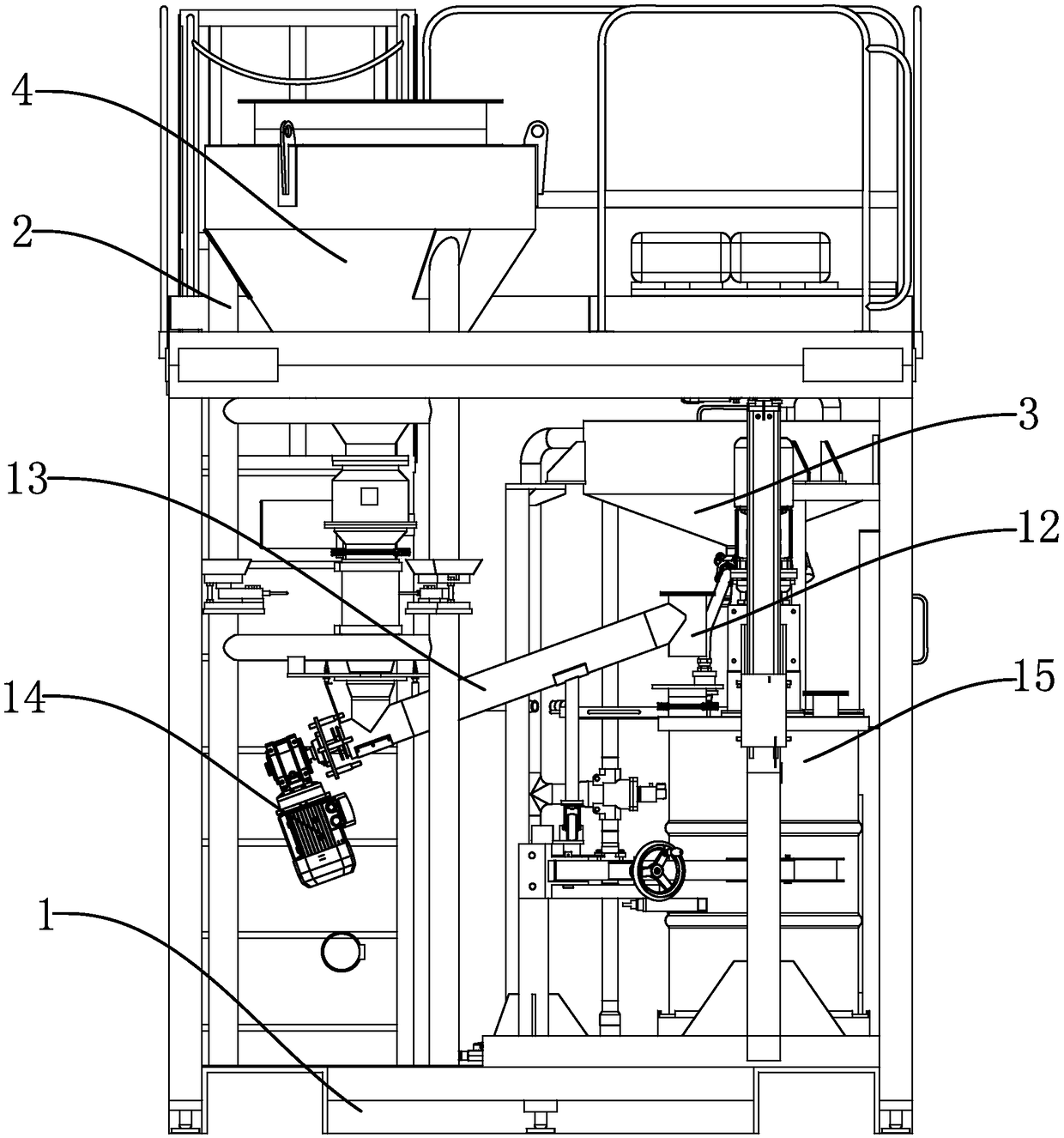

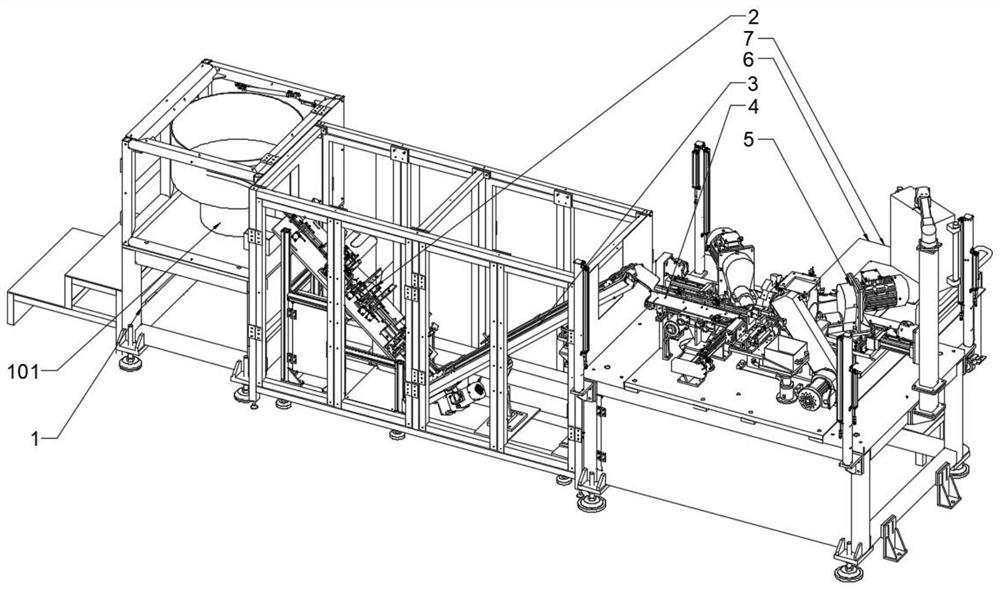

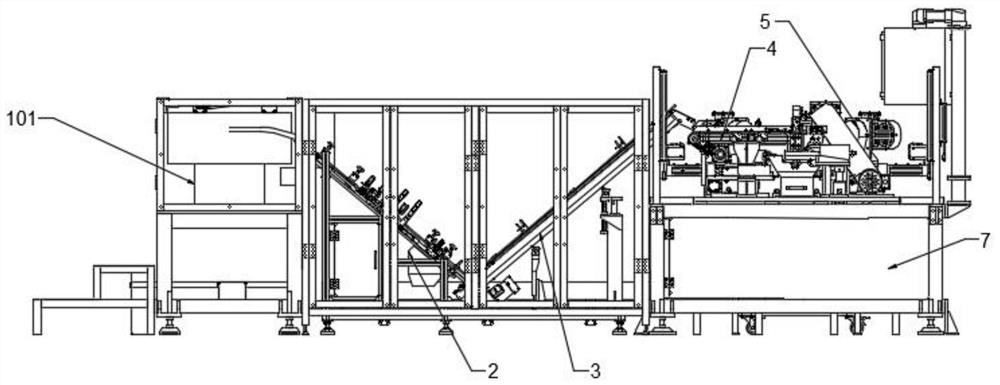

Automatic mask production equipment

PendingCN111449325AEnsure stabilityGuaranteed stabilityProtective garmentClothes making applicancesEngineeringMechanical engineering

The invention provides automatic mask production equipment. The equipment comprises a rack, and the rack comprises a raw material feeding rack and a mask processing rack; the mask processing rack comprises an upper rack and a lower rack, and the upper rack is provided with an ear belt conveying mechanism; the ear belt conveying mechanism is provided with an ear belt folding plate, and transmissionrollers are arranged on both sides of the ear belt folding plate; the lower rack is sequentially provided with a first mask processing mechanism, a second mask processing mechanism, a third mask processing mechanism, a fourth mask processing mechanism and a discharging frame base from a feeding end to a discharging end; a synchronous belt power transmission device is further arranged at the bottom of the lower rack; the ear belt conveying mechanism is located above the second mask processing mechanism and the third mask processing mechanism; and a discharging end of the ear belt conveying mechanism is connected to an ear belt feeding end of the third mask processing mechanism. According to the automatic mask production equipment, orderly and automatic feeding and discharging of processedmaterials can be achieved, good mask processing quality can be guaranteed through the multiple mask processing mechanisms, and meanwhile the whole equipment is good in stability, simple in structure and high in production efficiency.

Owner:广州英固特智能装备有限公司

Material allocation mechanism of material allocation device

The invention provides a material allocation mechanism of a material allocation device, and belongs to the technical field of machinery. The problem that material allocation quality is low in the prior art is solved. The material allocation mechanism of the material allocation device comprises a base and a machine frame fixed on the base, the material allocation mechanism is arranged on the machine frame and comprises a material allocation hopper, a feeding port is formed in the top of the material allocation hopper, and a feeding structure is arranged at the feeding port; the feeding structure comprises a plurality of feeding pipes and a plurality of material storage boxes, the feeding pipes communicate with the material storage boxes in a one-to-one corresponding manner, and the materialstorage boxes are fixed on the machine frame, and the feeding pipes are connected with material spray heads; an electromagnetic valve I and a metering valve are further arranged on each feeding pipe,the material spray heads are fixed on swing arms, and mounting frames are further fixed in the material allocation hopper; and rotating shafts are arranged at the upper ends of the swinging arms, therotating shafts are hinged to the mounting frame, motors 7 are further fixed on the mounting frame, and output shafts of the motors 7 are connected with the rotating shafts. The material allocation mechanism of the material allocation device has the advantage of improving material allocation quality.

Owner:海宁市冲达机械设计有限公司

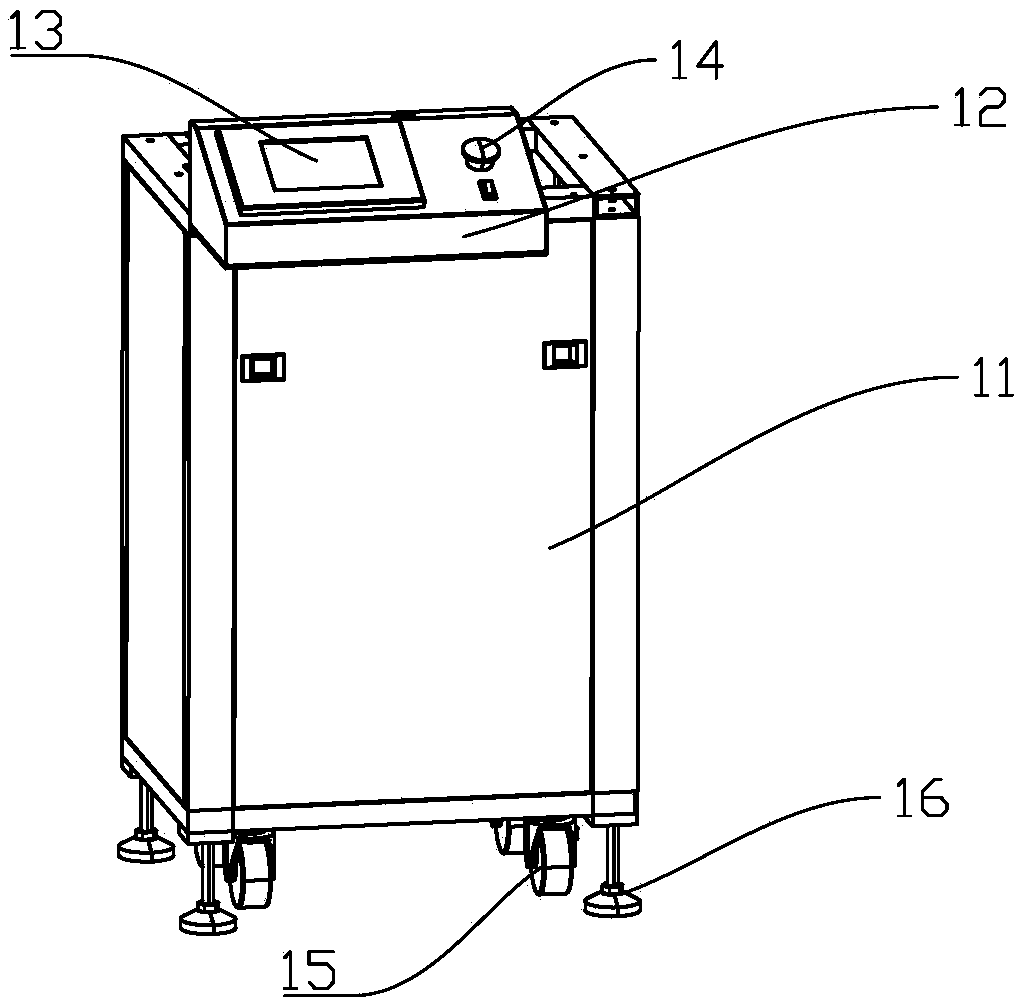

Automatic liquid shampoo canning device

PendingCN113213408ASave time on capping and pressingImprove capping and pressing efficiencyBottle-handling machinesLiquid bottlingProcess engineeringManufacturing engineering

The invention relates to a canning device, in particular to an automatic liquid shampoo canning device. The invention aims to provide the automatic liquid shampoo canning device which is simple and convenient to operate, short in spent time, high in efficiency, standard in operation and capable of avoiding bacteria breeding in the canning process. According to the technical scheme, the automatic liquid shampoo canning device comprises a machine frame, a conveying mechanism, materials and a material extruding mechanism; the machine frame is arranged on one portion of a bottom plate; the transportation mechanism is arranged on the bottom plate; the materials are placed on the conveying mechanism; and the material extruding mechanism is arranged on the machine frame. Through cooperation of a capping mechanism and a compaction mechanism, automatic capping of the materials can be achieved, meanwhile, bottle caps are automatically compacted, and the manual capping and compaction time can be saved.

Owner:张真桂

Full-automatic feeding device

ActiveCN113415617AUniform and stable feedingEfficient feeding processConveyor partsClassical mechanicsStructural engineering

Owner:华科智谷(上海)科技发展有限公司

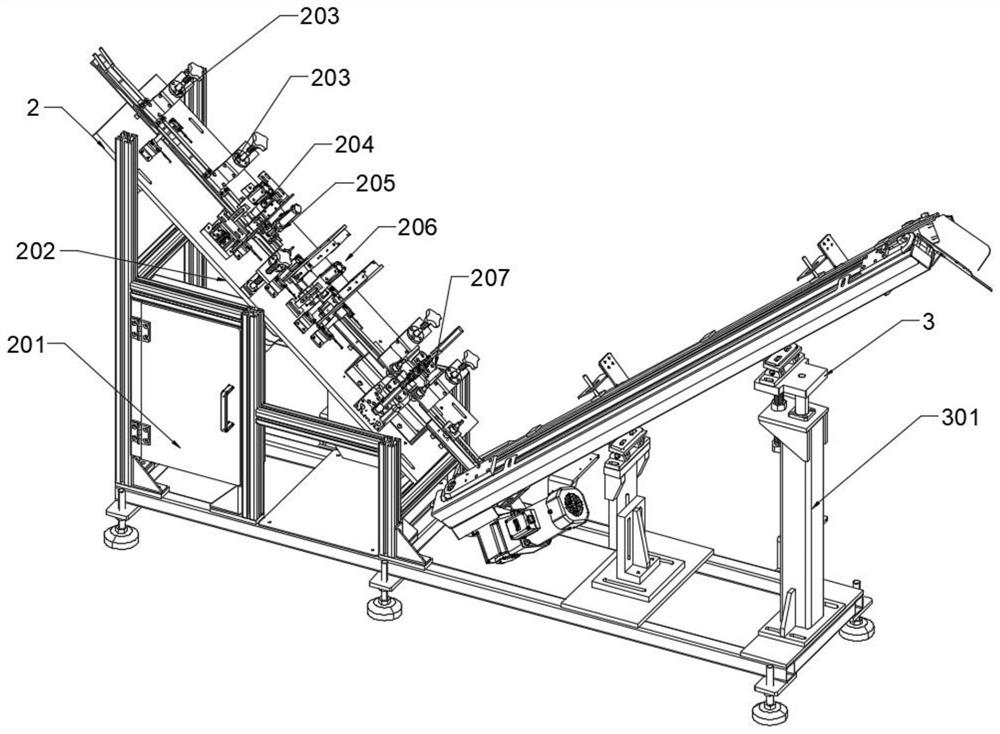

V-shaped conveying type spring conveying and chamfering equipment and using method

InactiveCN112439709AImprove work efficiencyReduce labor costsEdge grinding machinesSortingStructural engineeringMachining

The invention relates to the technical field of spring machining, and particularly provides V-shaped conveying type spring conveying and chamfering equipment. The V-shaped conveying type spring conveying and chamfering equipment comprises a machine frame, a feeding vibration disc, a V-shaped conveying line and a grinding unit are sequentially arranged on the machine frame according to the conveying line of springs, the V-shaped conveying line comprises a sliding slope unit and a climbing slope unit, and the sliding slope unit is further sequentially provided with a large end and small end detecting and discharging mechanism and a wire diameter detecting assembly from top to bottom. The V-shaped conveying type spring conveying and chamfering equipment solves the problems that in the springfeeding process of existing spring machining equipment, the springs need to be manually placed on a conveying belt one by one, so that the labor intensity of workers is high; and when the springs aretransported, screening and adjusting cannot be carried out on the large ends and the small ends of the springs, rejecting, screening and adjusting on a detection line with specific machining requirements for the diameters of the springs cannot be carried out, and unqualified springs cannot be automatically removed through screening when the springs are transported. The invention further provides ausing method of the V-shaped conveying type spring conveying and chamfering equipment. The using method is used for improving the spring chamfering efficiency.

Owner:佛山协航智能装备制造有限公司

Mechanism and method for sorting rice seeds with fluorescent labeling

Owner:SHANGHAI JIAOTONG UNIV

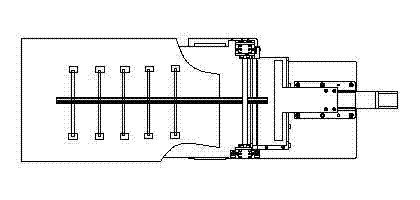

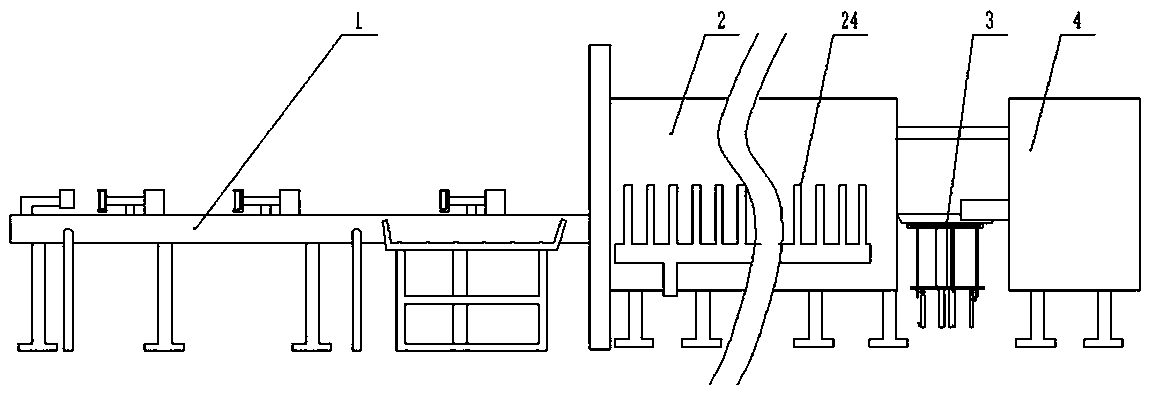

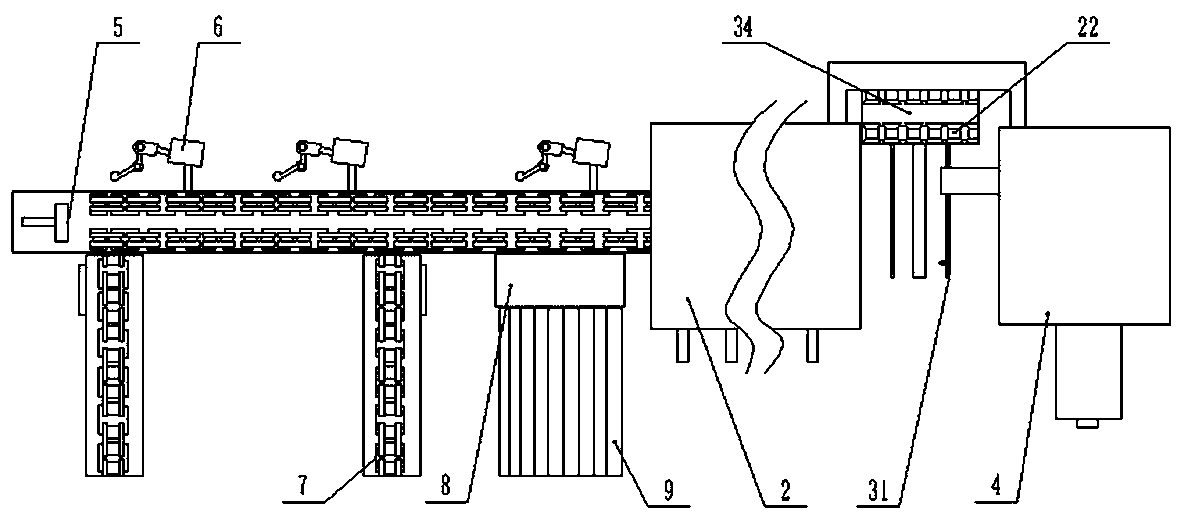

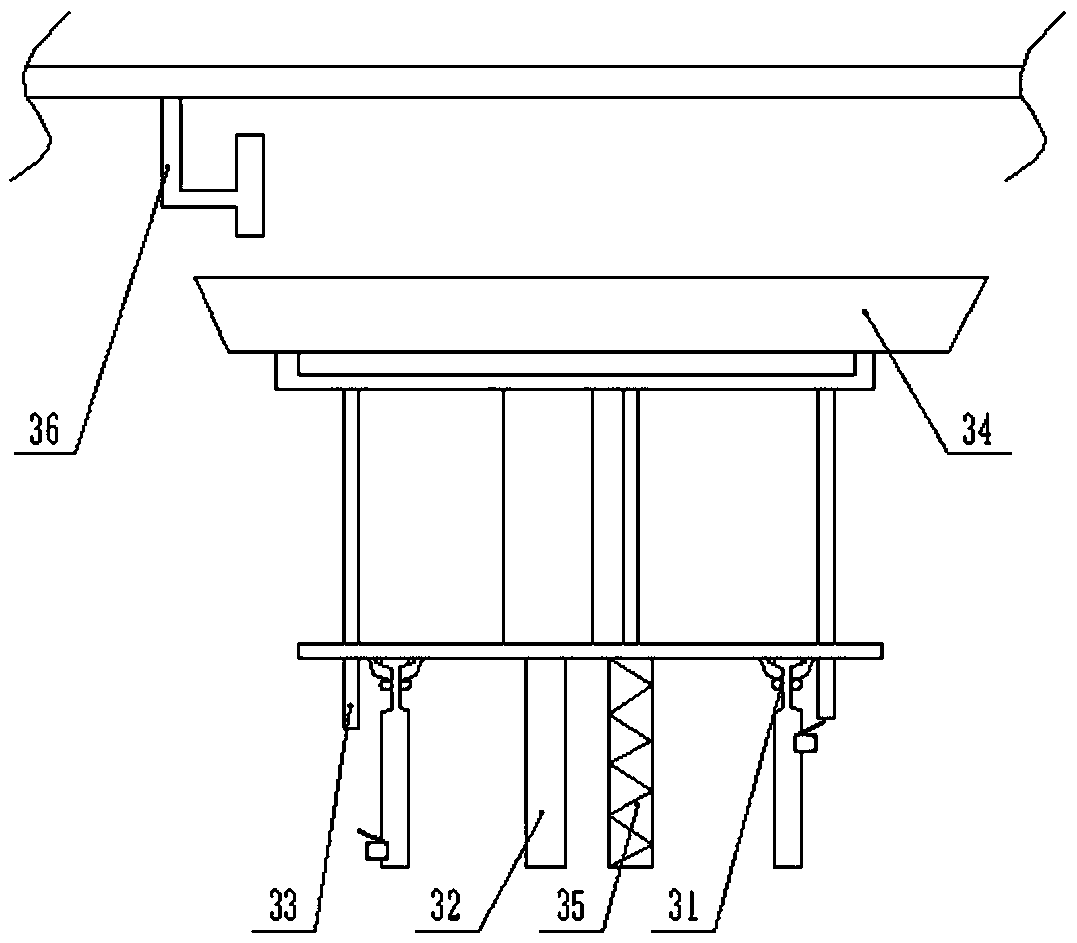

Single multi-functional hot shear aluminum rod furnace with long and short rod line sharing

The invention specifically relates to a single multi-functional hot shear aluminum rod furnace with long and short rod line sharing, and belongs to the technical field of aluminum profile machining, and aims to solve the technical problem of providing the hot shear aluminum rod furnace capable of enabling a short and round aluminum rod to be transported to the next process by keeping away from a hot scissor system. According to the technical scheme, the single multi-functional hot shear aluminum rod furnace with the long and short rod line sharing includes an automatic rod feeding assembly, aheating furnace, a lifting trailer, a hot scissors system, a long rod feeding frame, a short rod automatic overturning machine and a short rod frame; a pushing rod is arranged at one end of the automatic rod feeding assembly, the other end of the automatic rod feeding assembly communicates with a conveying roller in the heating furnace, the long rod feeding frame and the short rod frame are arranged on one side of the automatic rod feeding assembly side by side, and the lifting trailer is arranged between the heating furnace and the hot scissors system. The single multi-functional hot shear aluminum rod furnace combines the heating production line of the long and round aluminum rods and the short and round aluminum rods, the lifting trailer automatically completes the transferring of the short and round aluminum rods, and the production efficiency is improved.

Owner:山西西沙金属材料有限公司

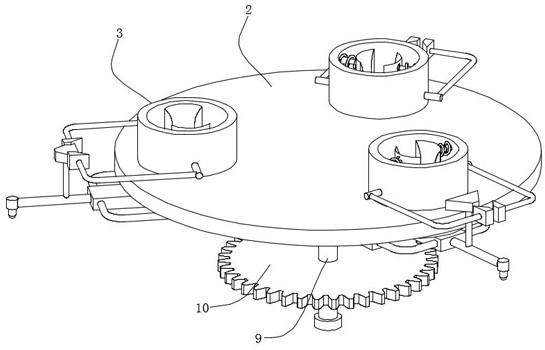

Slicing equipment for processing fruit with kernels and use method of slicing equipment

PendingCN114347117AStrong overall linkageSimple structureFruit stoningMetal working apparatusEngineeringAnnular array

The invention discloses slicing equipment for processing fruit with kernels and a using method of the slicing equipment, and belongs to the technical field of fruit processing.The slicing equipment comprises a rack, a disc is rotationally installed on the rack, three discharging mechanisms are arranged on the disc and distributed in an annular array mode, a kernel removing mounting frame is installed on the rack, and the kernel removing mounting frame is arranged on the rack; a pitting cutter cylinder is slidably mounted on the pitting mounting frame, and the three discharging mechanisms are a pitting station, a discharging station and a feeding station in sequence from the lower portion of the pitting mounting frame in the anticlockwise direction; the disc and the coring cutter cylinder are used in cooperation with the driving mechanism, the incomplete gear, the first cylindrical gear and the second cylindrical gear are used in cooperation, the coring cutter cylinder does not move when the disc rotates for feeding, the coring cutter cylinder moves when the disc does not move, fruit coring operation can be achieved, the fruit is sliced after coring is completed, and the fruit coring efficiency is improved. The slicing knife can be prevented from being damaged due to direct slicing without removing fruit kernels, the overall linkage performance is high, and the structure is simple.

Owner:洪乙辉

Convenient-to-use scissors feeding device

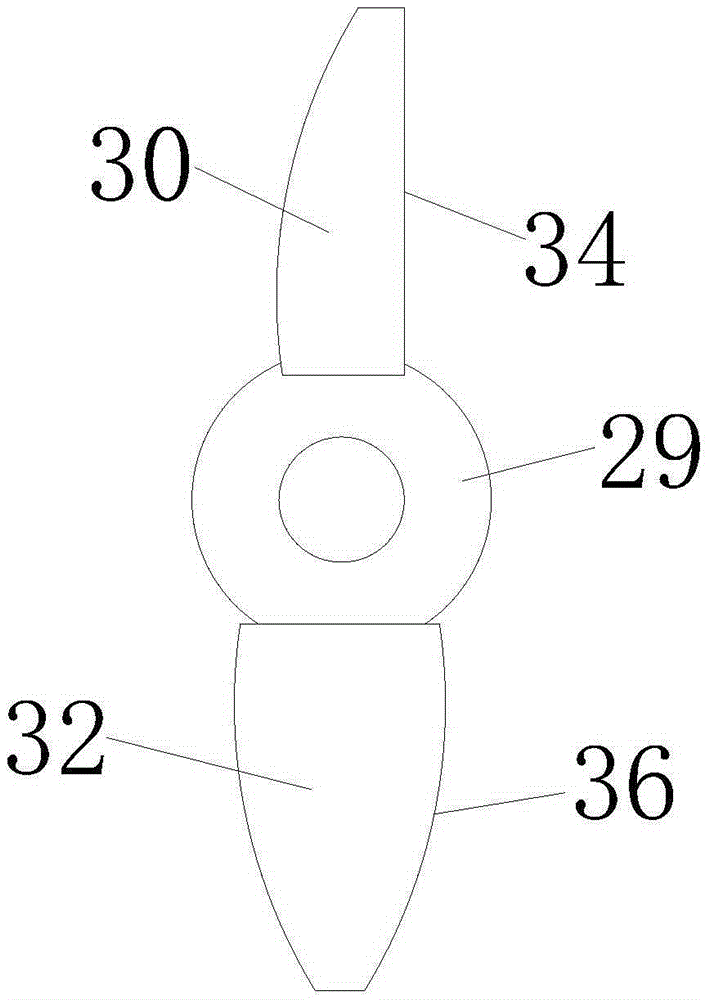

ActiveCN111792352AEasy dischargeEasy to process and produceElectric switchesConveyor partsStructural engineeringPipe

The invention relates to the technical field of keyboard machining equipment, in particular to a convenient-to-use scissors feeding device. The device comprises a platform, a stock bin separating plate is arranged at the top of the platform, the stock bin separating plate is of a hollow structure, openings are formed in the two sides of the bin separating plate, a carrier is slidably connected tothe inner side of the stock bin separating plate, a stock bin is arranged on the upper portion of the bin separating plate, a discharging opening is formed in the surface of the top of the stock bin separating plate, a plurality of material pipes are arranged between the bottom of the stock bin and the stock bin separating plate, a material distributing air cylinder is installed at the position, located on one side of the stock bin separating plate, of the top of the platform, and the output end of the material distributing air cylinder is connected with the stock bin separating plate. According to the convenient-to-use scissors feeding device, scissors structures can be separated, the scissors structures can be conveniently and sequentially discharged from materials, the scissors structures can be conveyed and fed in order through the scissors feeding device, it is guaranteed that the scissors structures cannot be extruded or collided during feeding, the scissors structures can be stably discharged in batches through a flowing channel, and machining and production of the scissors structure are facilitated.

Owner:重庆市旭宝科技有限公司

Agricultural product fruit pesticide removing device

InactiveCN114668160ANot easy to damageEasy to removeFood treatmentAgricultural sciencePesticide residue

The invention relates to a removing device, in particular to an agricultural product fruit pesticide removing device. The fruit pesticide removing device for the agricultural products is convenient for people to thoroughly remove pesticide residues on fruits and vegetables and is not easy to damage the fruits and vegetables. An agricultural product fruit pesticide removing device comprises a mounting platform, a cleaning pool, water pipes and high-pressure nozzles, the cleaning pool is fixedly connected into the mounting platform, the water pipes are fixedly connected to the top of the mounting platform at intervals, and the three high-pressure nozzles used for spraying clear water are connected to the middles of the water pipes at intervals. A water pipe is externally connected, a high-pressure spray head is started to operate, then fruits and vegetables are placed on the leftmost feeding roller, a motor is started, the feeding rollers rotate forwards to drive the fruits and vegetables to move rightwards, when the fruits and vegetables move rightwards, the high-pressure spray head sprays clear water to remove residual pesticide on the fruits and vegetables, and therefore people can conveniently and thoroughly remove the residual pesticide on the fruits and vegetables; and fruits and vegetables are not easy to damage.

Owner:FUZHOU JINXI AGRI DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com