Conductive strip feeding device for junction box patch production

A technology of conductive sheets and junction boxes, which is applied in the direction of line/collector components, circuits, connections, etc., can solve the problems of low manual loading efficiency, affecting the efficiency and quality of SMT products, and many subjective factors of loading, etc. Achieve the effect of simple structure, fast feeding and orderly feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

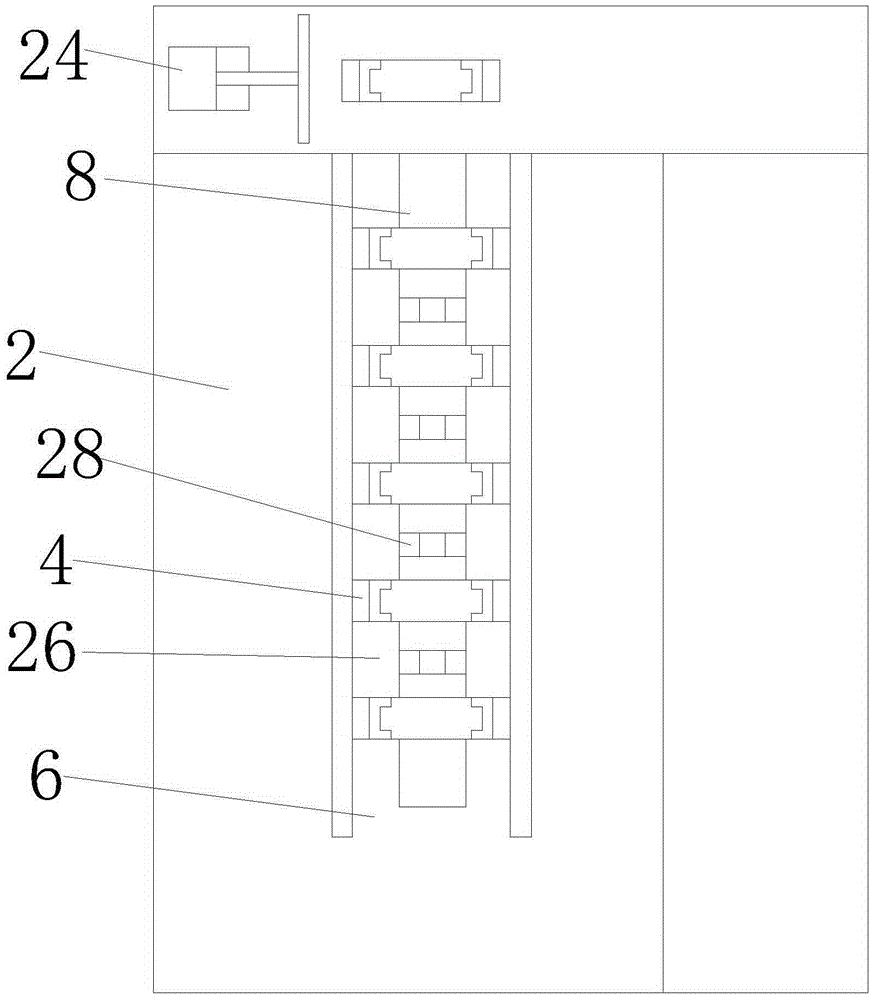

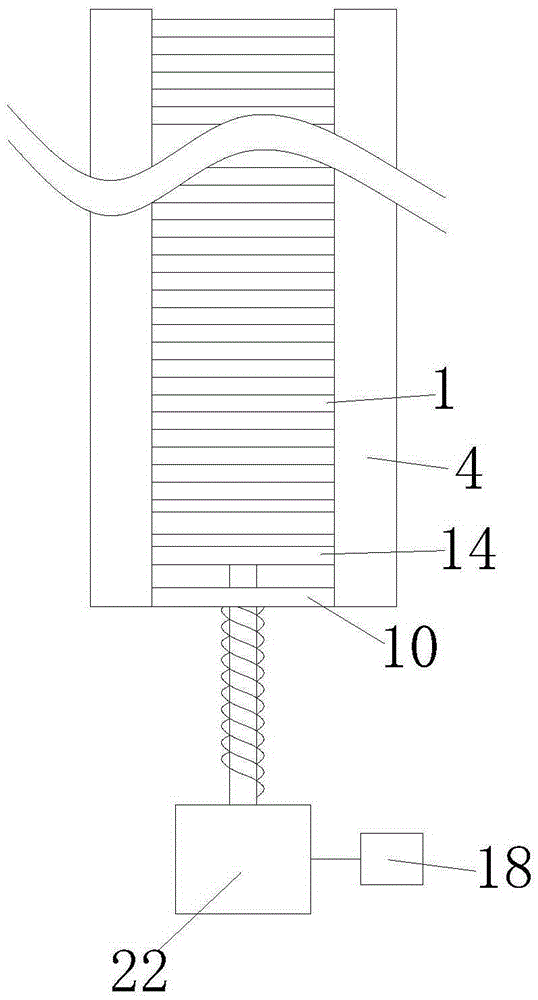

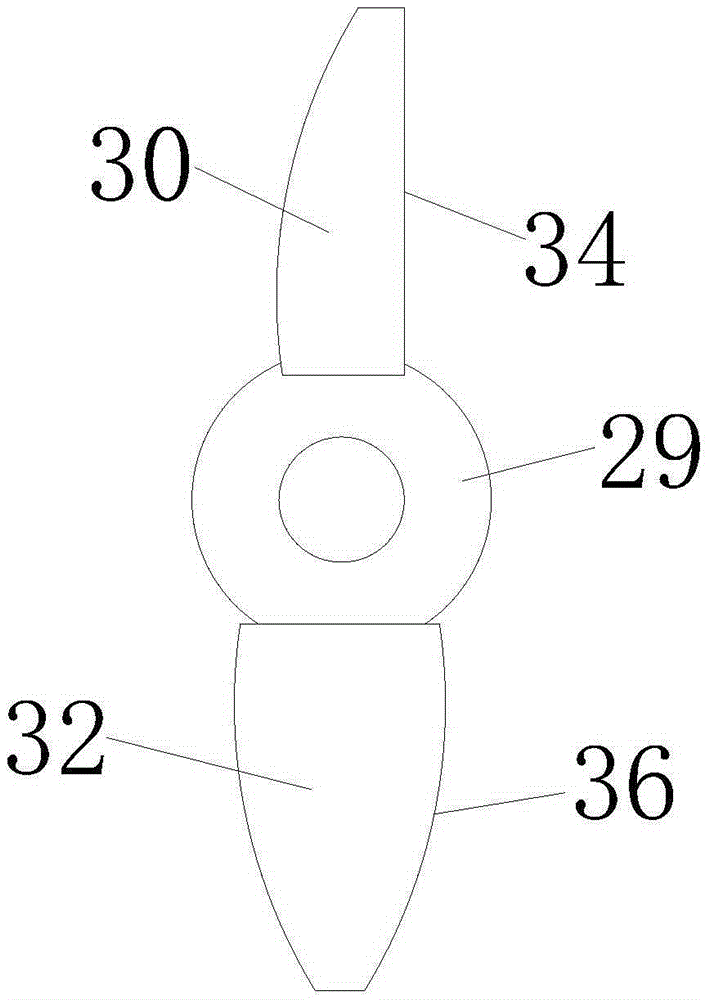

[0019] Such as figure 1 , 2 , 3, and 4, this embodiment discloses a conductive sheet feeding device for junction box patch production, including a feeding table 2 and a storage tool 4 for stacking the conductive sheets up and down in a single-piece manner, and the feeding The table 2 is provided with a feeding station 6 and a feeding station 8, and the feeding table 2 is provided with a push assembly for pushing the storage tool 4 from the feeding station 6 to the feeding station 8, The material storage tool 4 includes a base 10 and two clamping seats 12 installed vertically on the base 10. The inside bottom surface of the base 10 is provided with a stack of push plates 14 for placing the conductive sheets 1. A push hole 15 is provided from the outer bottom surface of the base 10 to the inner bottom surface thereof, and a push mechanism is provided on the feeding station 8, and the push mechanism has one end that can pass through the push hole and then press against Connect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com