Automatic cable plugging machine

A wire insertion machine and automatic technology, which is applied in the field of automation, can solve the problems of difficulty in controlling the total length and the length of the metal wires at both ends, the difficulty of ensuring the insertion position, and the low efficiency of manual insertion, so as to save waiting time and facilitate threading , the effect of exquisite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

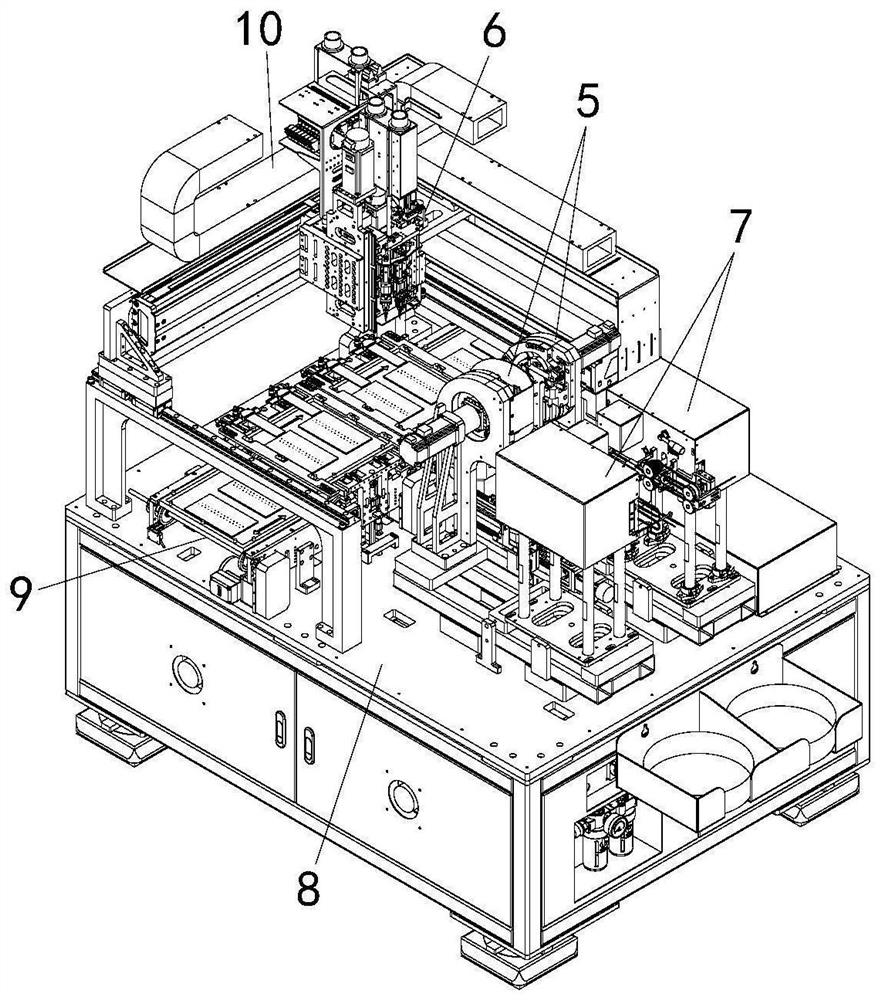

[0037] Example: such as figure 1 As shown, an automatic wire insertion machine includes a workbench 8 and a control system. The workbench 8 is provided with a PCB assembly line 9, an XYZ three-axis motion mechanism 10, a wire stripping mechanism 7, a material transfer mechanism 5 and a wire insertion mechanism 6. The wire insertion mechanism 6 is set on the XYZ three-axis motion mechanism 10, the PCB assembly line 9 and the material receiving transfer mechanism 5 are located below the stroke range of the wire insertion mechanism 6, and the wire stripping mechanism 7 is located on the side of the material receiving transfer mechanism 5 ; PCB assembly line 9, XYZ three-axis motion mechanism 10, wire stripping mechanism 7, material transfer mechanism 5 and wire insertion mechanism 6 are all electrically connected to the control system;

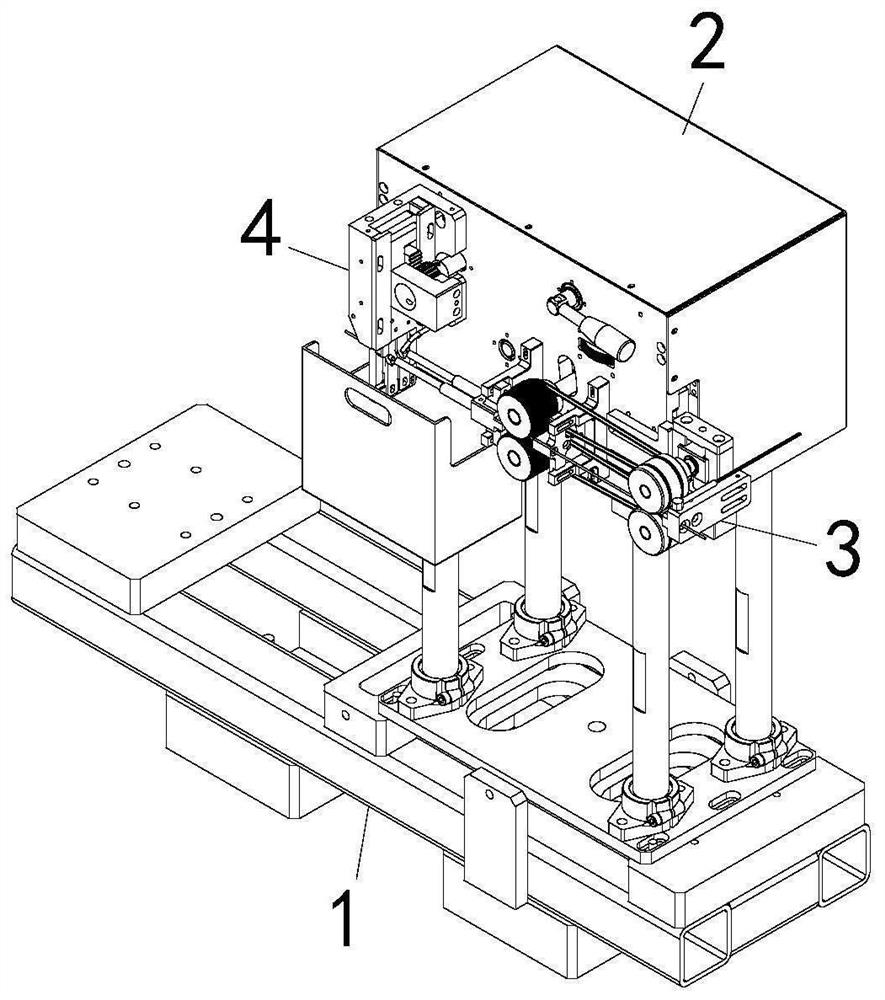

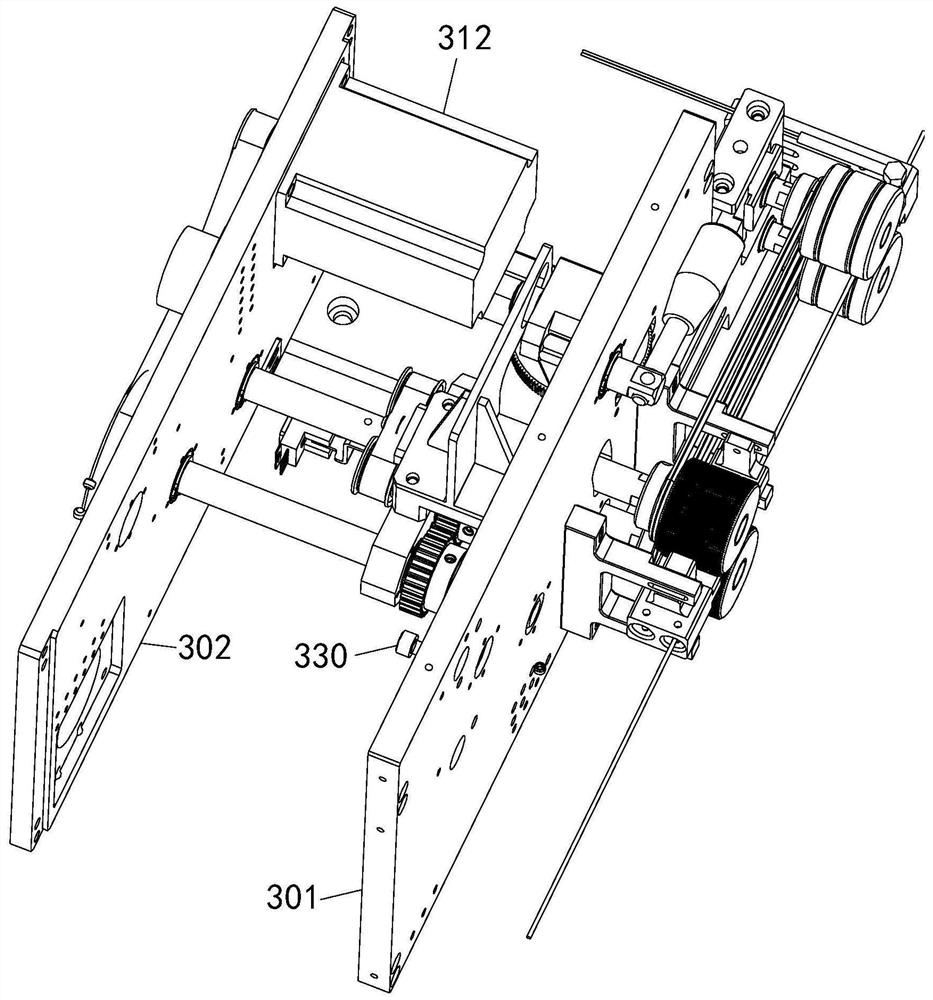

[0038] Such as Figure 2~Figure 11 As shown, the stripping mechanism 7 includes a base 1, the base 1 is provided with a mounting frame 2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com