Automatic mask production equipment

A technology for automatic production of masks, applied in clothing, tools for sewing clothes, clothing, etc., can solve the problems of low degree of automation, poor equipment stability, affecting the quality and production efficiency of masks, etc., to improve the overall stability and production efficiency. High efficiency and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

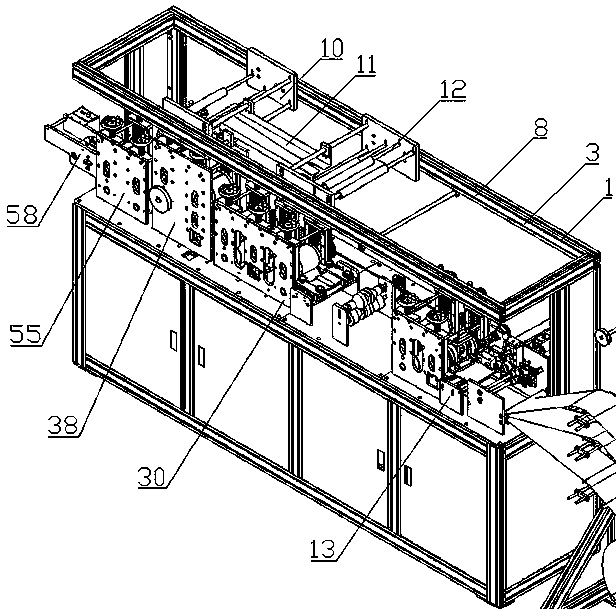

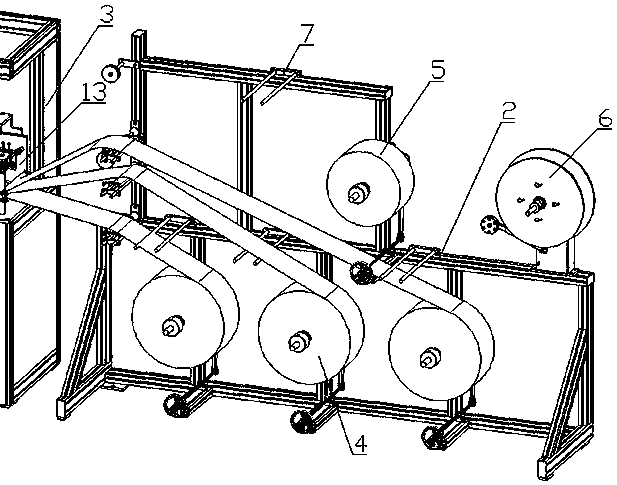

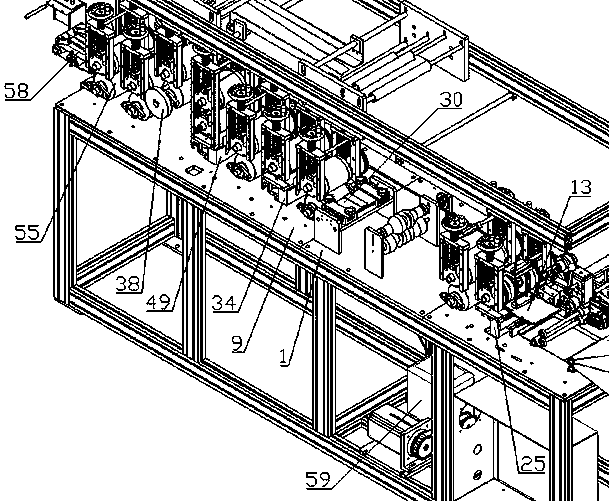

[0032] like Figure 1-12 As shown, a mask automatic production equipment includes a frame, and the frame includes a raw material feeding frame and a mask processing frame; the raw material feeding frame is located on one side of the mask processing frame. The lower part of the raw material feeding frame is provided with three cover raw material reel holders, and multiple raw material reel holders can be added according to actual processing requirements. The upper part of the raw material feeding frame is provided with an ear belt raw material reel stand and a nose bridge raw material reel stand, and the upper and lower parts of the raw material feeding frame are provided with a plurality of feeding support frames. The material of the mask body, the material of the ear loops and the material of the bridge strip play a supporting role in the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com