Charging method for preparing binary submicron metal alloy powder by using physical vapor deposition

A physical vapor deposition and metal alloy powder technology, which is applied in the field of submicron metal alloy powder preparation, can solve the problems of irregular powder shape, failure to achieve alloy structural performance, small scale, etc., and achieve stable metal element content and composition The effect of uniform distribution and large particle size span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

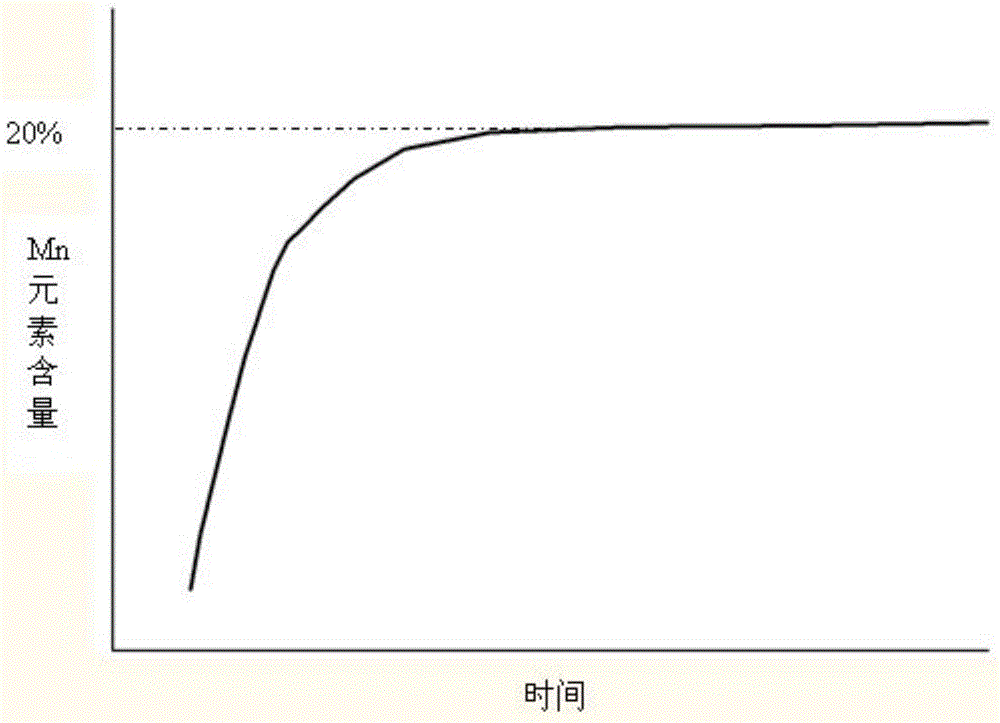

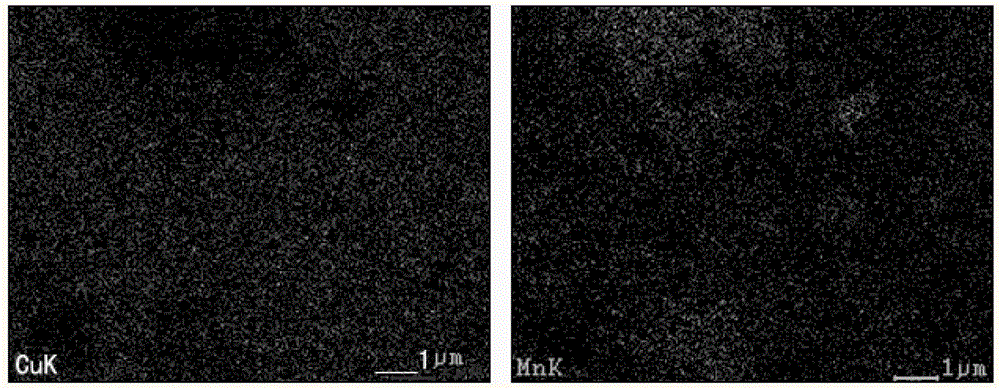

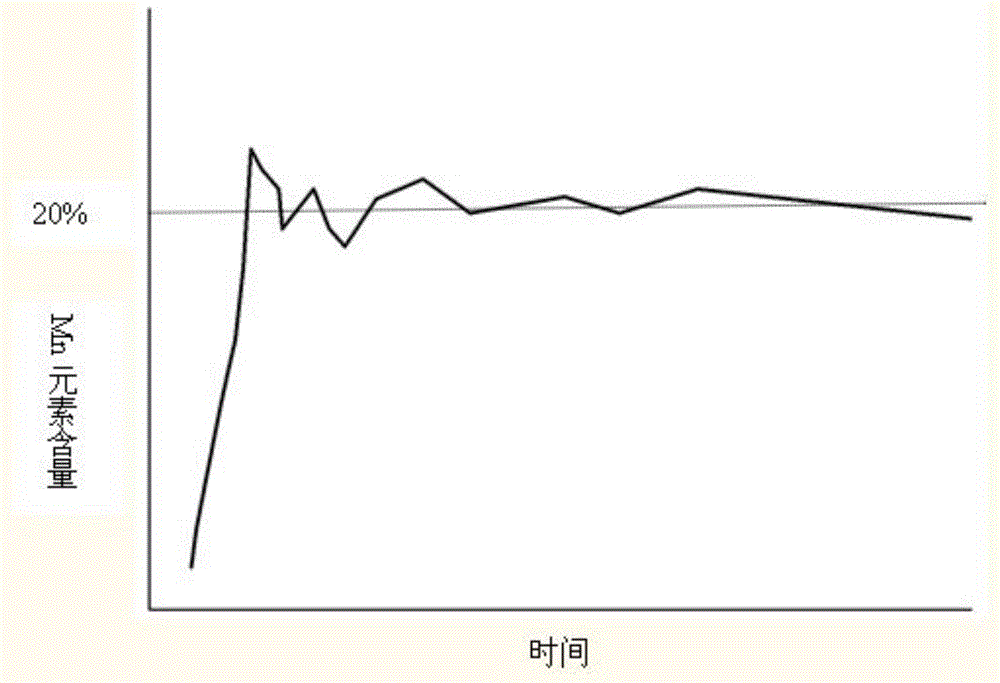

[0035] Embodiment 1, feeding design of binary submicron Cu-20%Mn (ie Cu:Mn=4:1) alloy powder

[0036] The metal is vaporized after being heated to form a metal gas. The vapor pressure of different metal gases is different, which is mainly affected by the temperature. According to the Clausius-Claiplan equation and the modification of practical application, the relationship between saturated vapor pressure and temperature is as follows:

[0037] lgp=AT -1 +BlgT+CT+D (1-1)

[0038] Among them, A, B, C, and D of various metals (this is the coefficient calculated by the saturated vapor pressure of the metal, each metal is different, can be found in the general manual, no need to explain) can be queried in the standard manual, According to the specific temperature, the saturated vapor pressure P of Cu and Mn can be calculated. a and P b . At the same time, considering that the mass ratio of Cu:Mn in the alloy is 4:1, the corresponding evaporation rate should be controlled at 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com