Single multi-functional hot shear aluminum rod furnace with long and short rod line sharing

A multi-functional, rod-to-rod technology, which is applied in the field of aluminum profile processing, can solve the problems of poor thermal shearing effect and difficult extrusion of aluminum rods, and achieve the effects of reducing energy consumption, improving production efficiency, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Further description will be made below in conjunction with specific embodiments.

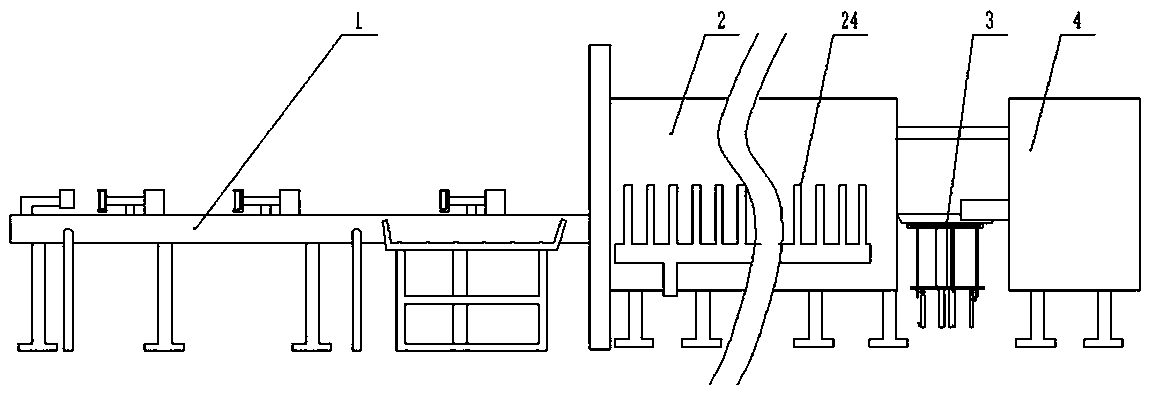

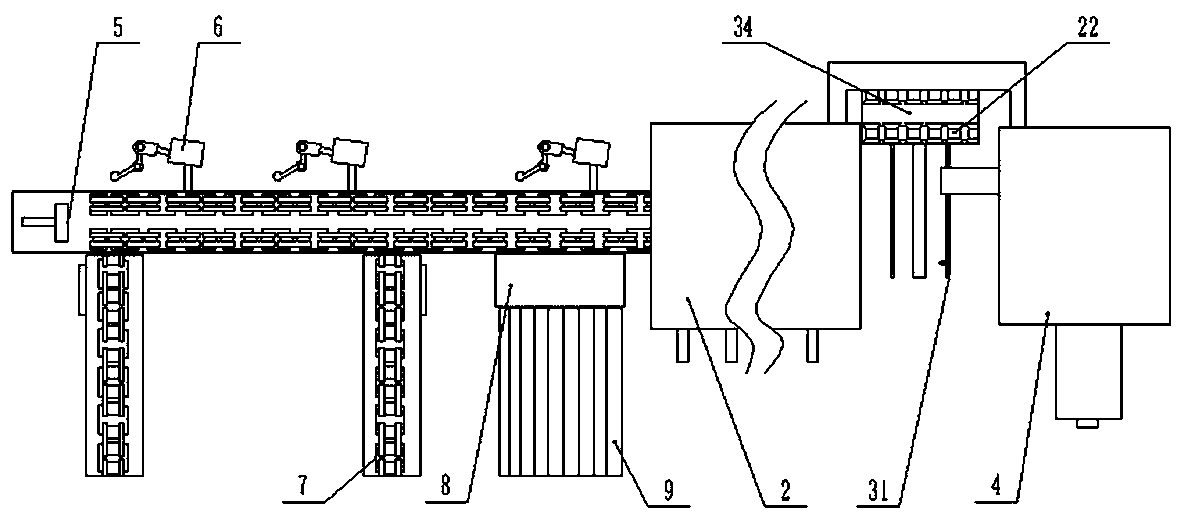

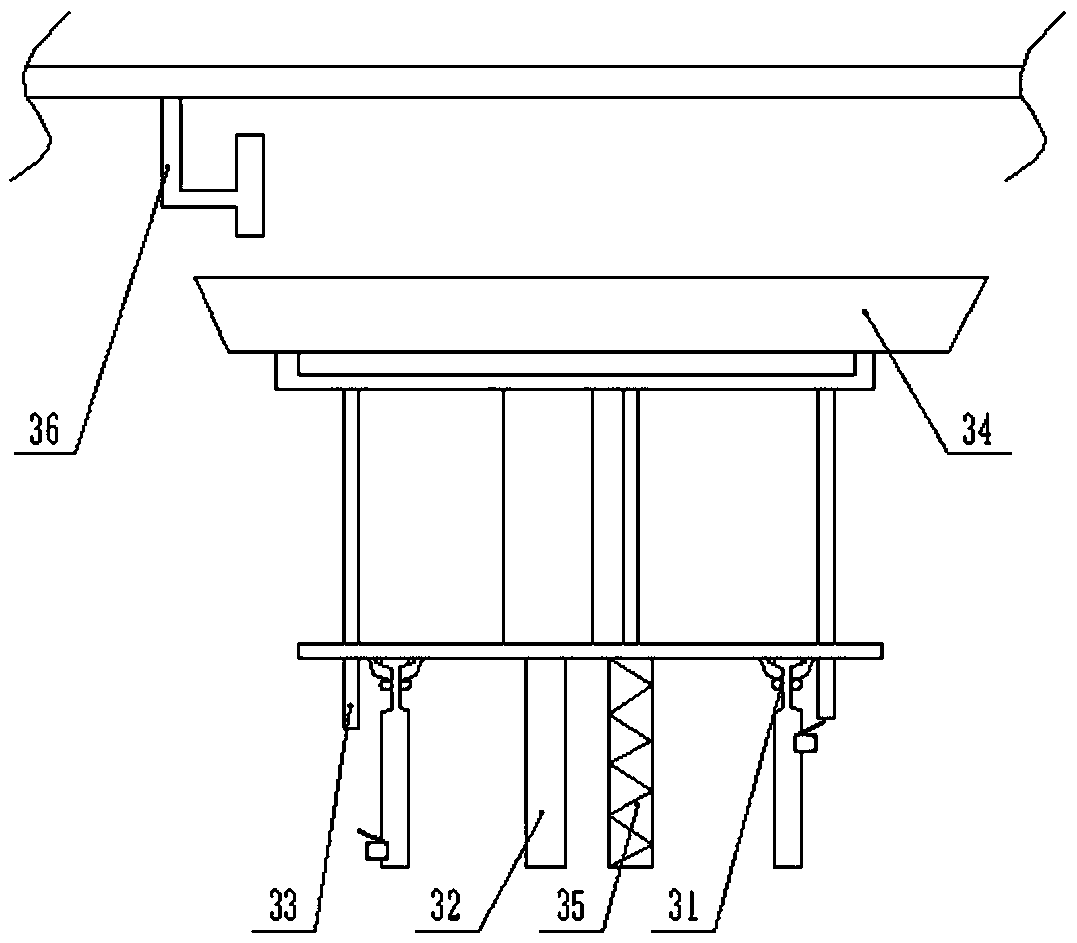

[0033] Long and short rod co-line single multi-functional hot-shearing aluminum rod furnace, including: automatic rod feeding assembly 1, heating furnace 2, lifting trolley 3, hot scissor system 4, long rod feeding rack 7, short rod automatic turning machine 8 and short rod holder 9;

[0034] One end of the automatic rod feeding assembly 1 is provided with a pusher rod 5, the other end of the automatic rod feeding assembly 1 is connected to the feeding roller 21 inside the heating furnace 2, and one side of the automatic rod feeding assembly 1 The long rod feeding rack 7 and the short rod rack 9 are arranged side by side; the short rod automatic turning machine 8 is arranged between the automatic rod feeding assembly 1 and the short rod rack 9; The hot scissors system 4 is arranged in cooperation with the heating furnace 2, and the lifting trailer 3 is arranged between the heating furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com