Patents

Literature

289 results about "Metal evaporation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In really general terms, “evaporation” means “turns into gas”; you heat a (solid) metal enough, it melts (liquid), then evaporates (gas).

Hybrid polymer film

InactiveUS6083628AFine surfaceLow costFixed capacitor dielectricSynthetic resin layered productsThermoplasticCross-link

A hybrid film, comprising a first polymer film having a plasma-treated surface and a second polymer film having first and second surfaces, with the first surface of the second polymer film being disposed along the first plasma-treated surface of the first polymer film, has superior thermal and mechanical properties that improve performance in a number of applications, including food packaging, thin film metallized and foil capacitors, metal evaporated magnetic tapes, flexible electrical cables, and decorative and optically variable films. One or more metal layers may be deposited on either the plasma-treated surface of the substrate and / or the radiation-cured acrylate polymer. A ceramic layer may be deposited on the radiation-cured acrylate polymer to provide an oxygen and moisture barrier film. The hybrid film is produced using a high speed, vacuum polymer deposition process that is capable of forming thin, uniform, high temperature, cross-linked acrylate polymers on specific thermoplastic or thermoset films. Radiation curing is employed to cross-link the acrylate monomer. The hybrid film can be produced in-line with the metallization or ceramic coating process, in the same vacuum chamber and with minimal additional cost.

Owner:SIGMA LAB OF ARIZONA

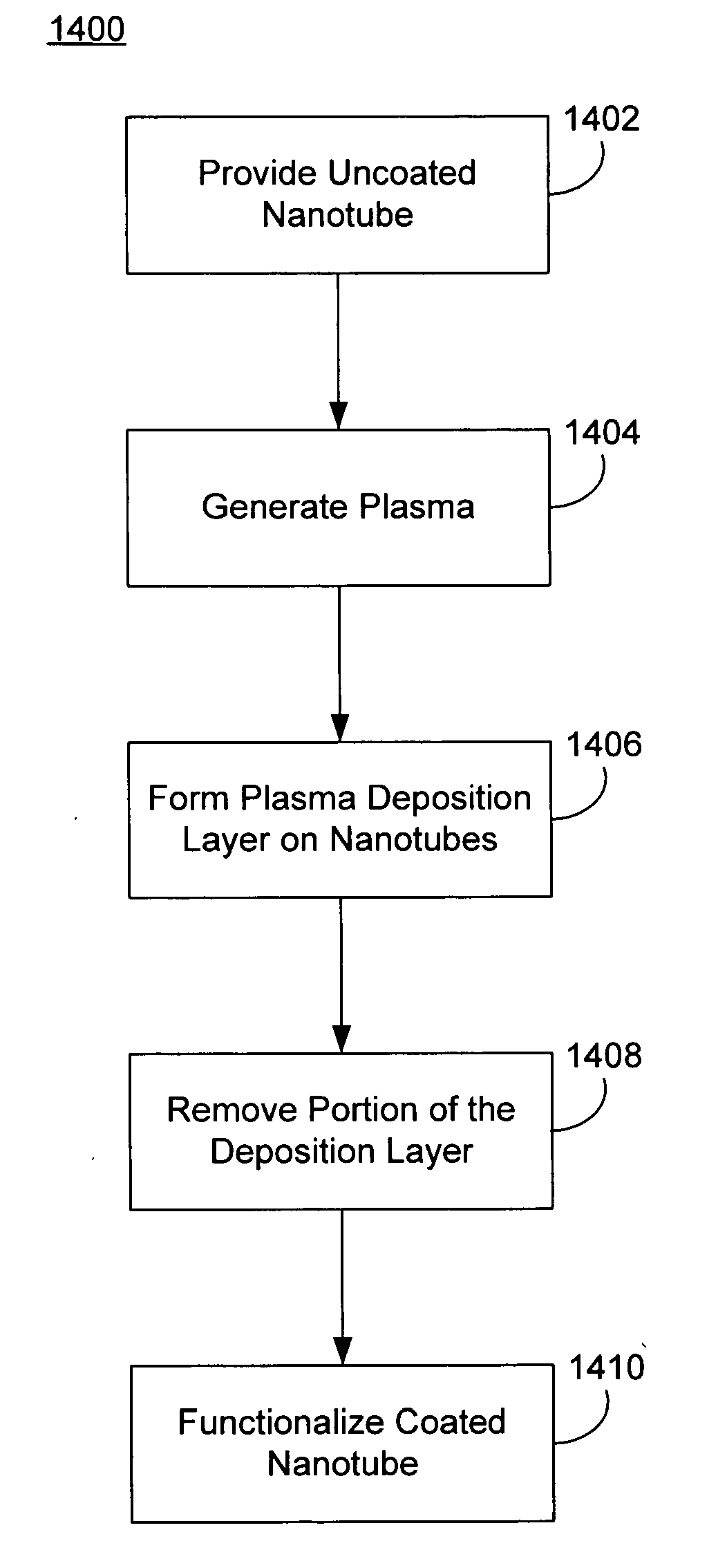

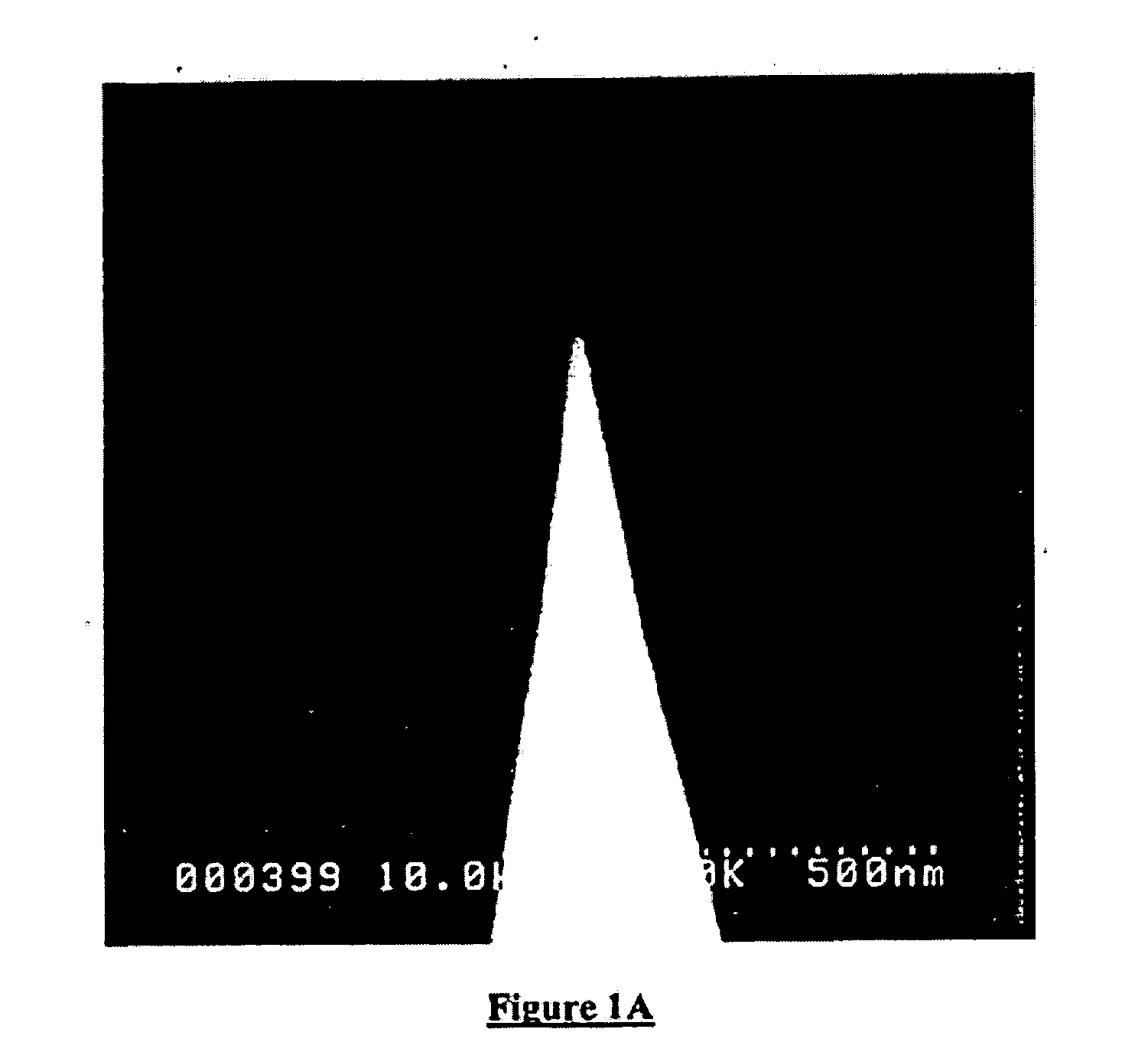

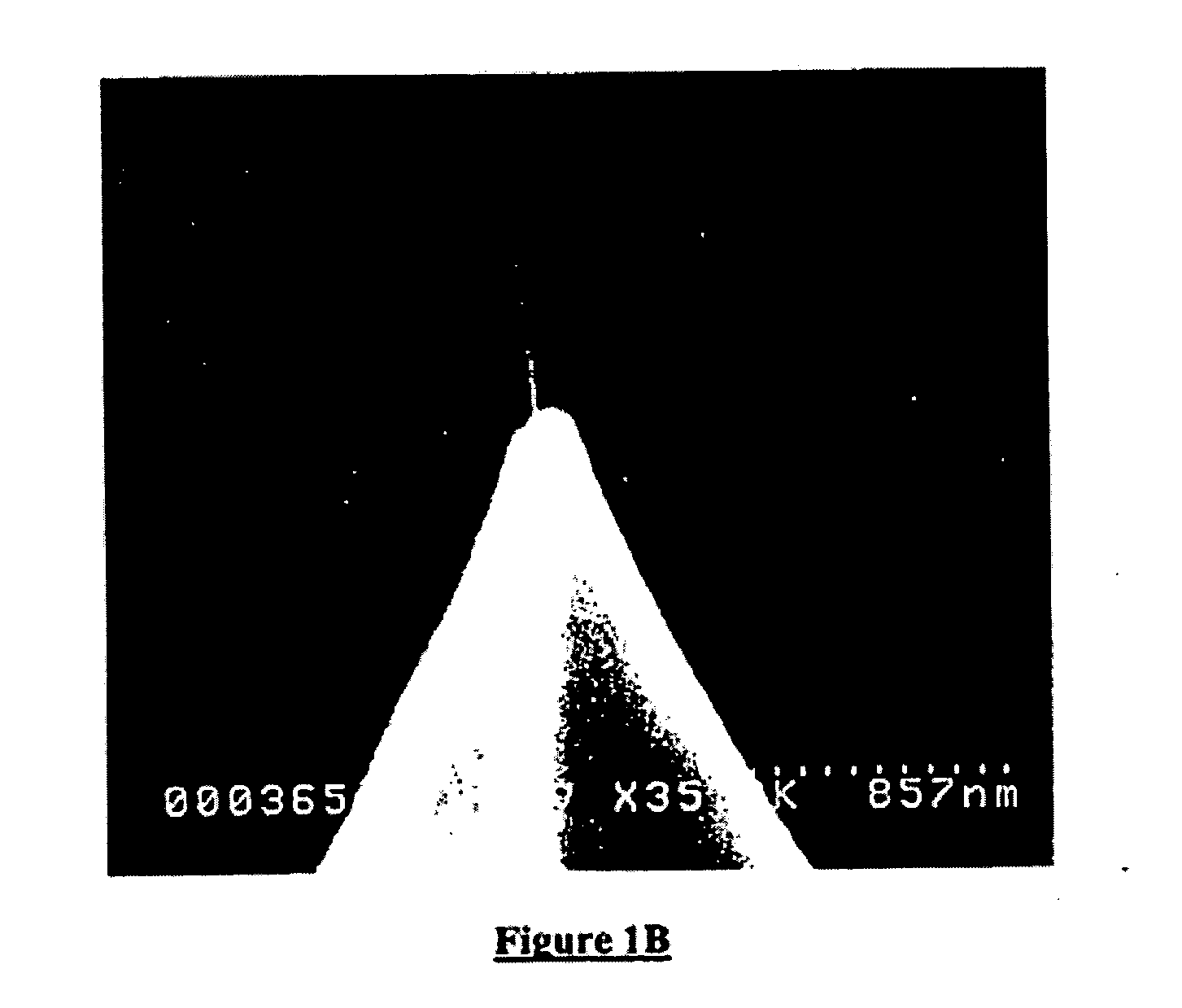

Coatings for carbon nanotubes

A coated nanotube that includes an inner nanotube having an exterior surface, and a plasma deposited layer covering at least part of the exterior surface of the inner nanotube. Also, a method of making a coated nanotube, the method where the method includes the steps of generating a plasma from a coating precursor, and exposing an inner nanotube to the plasma, where a plasma deposited layer is formed on at least a portion of the inner nanotube. Additionally, a method of making a coated nanotube that includes the steps of providing an inner nanotube, and evaporating a metal into the inner nanotube, where the metal forms a coating layer on at least a portion of the inner nanotube.

Owner:CALIFORNIA INST OF TECH

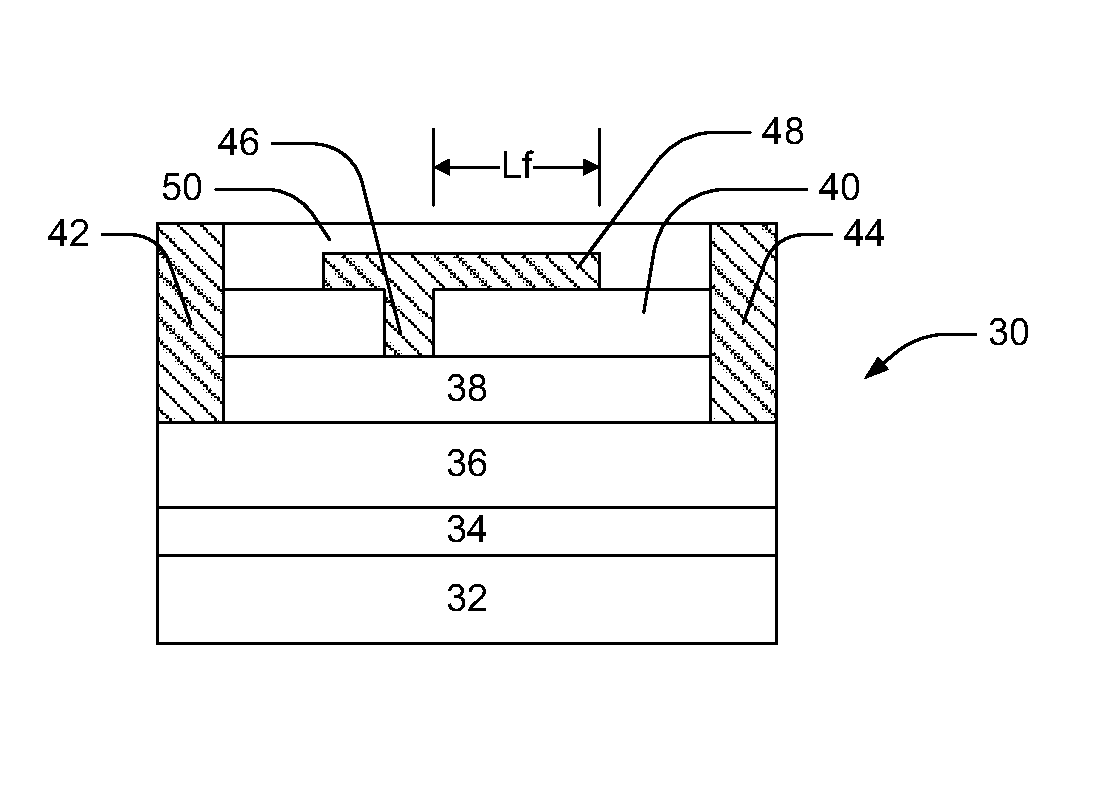

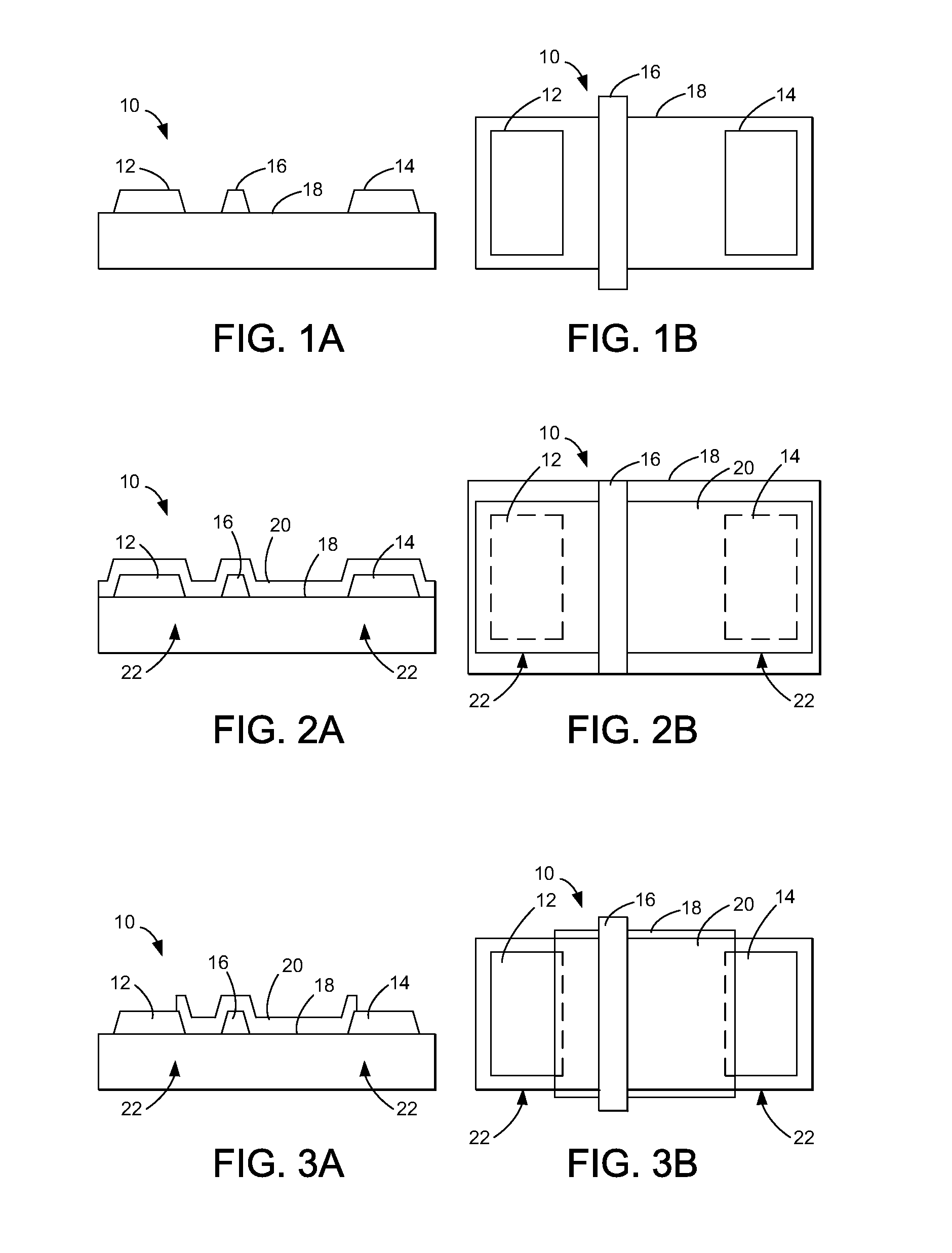

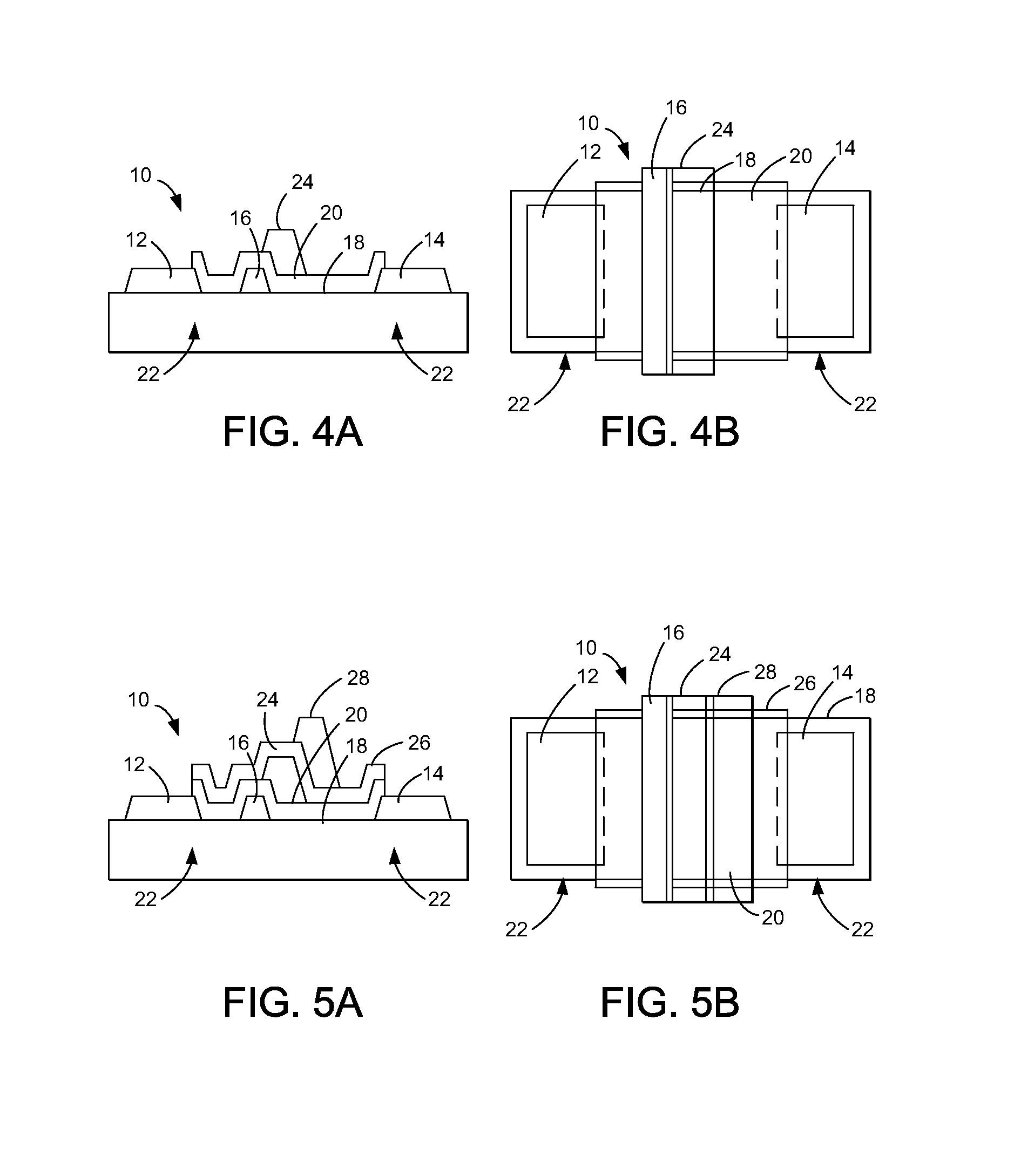

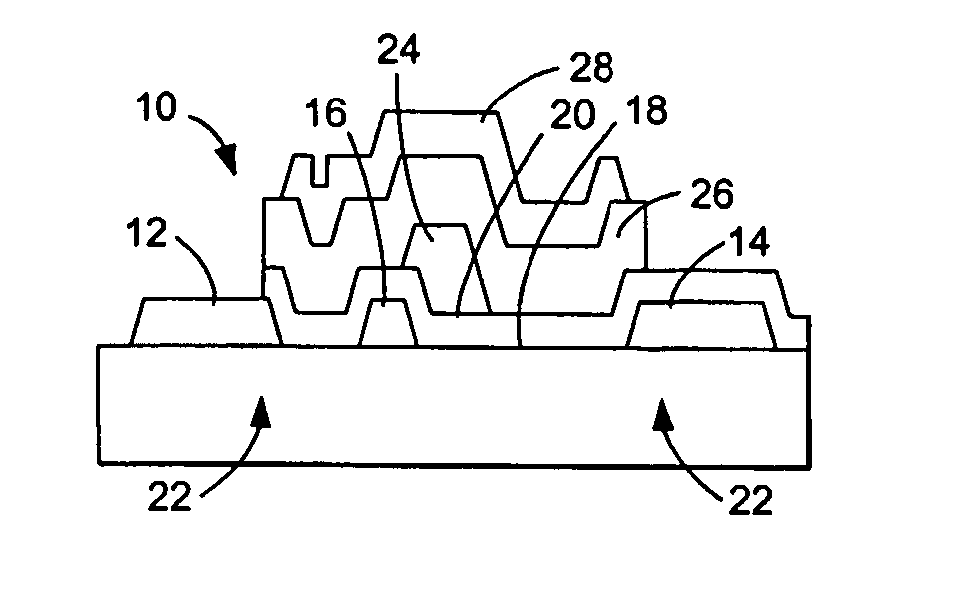

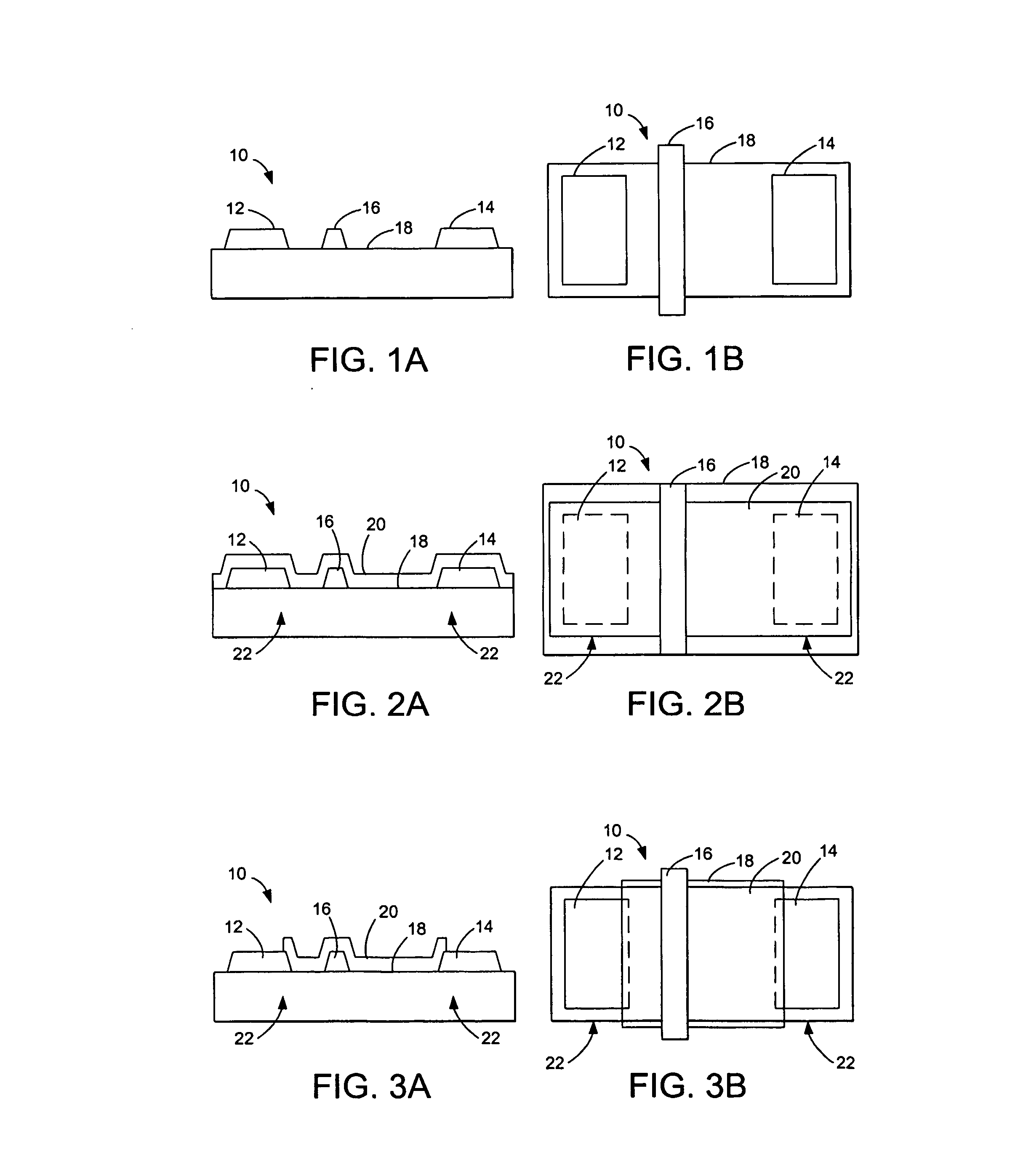

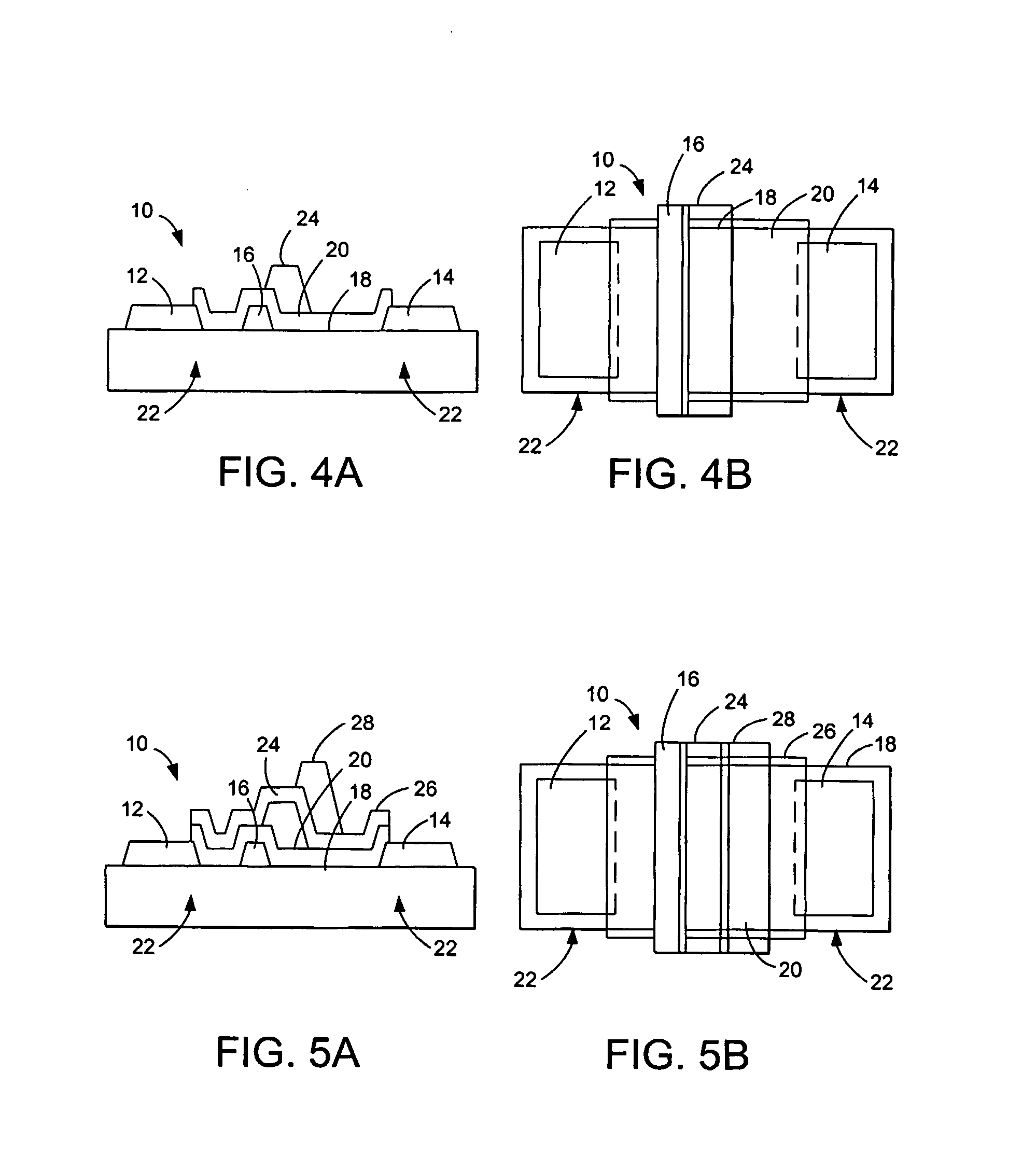

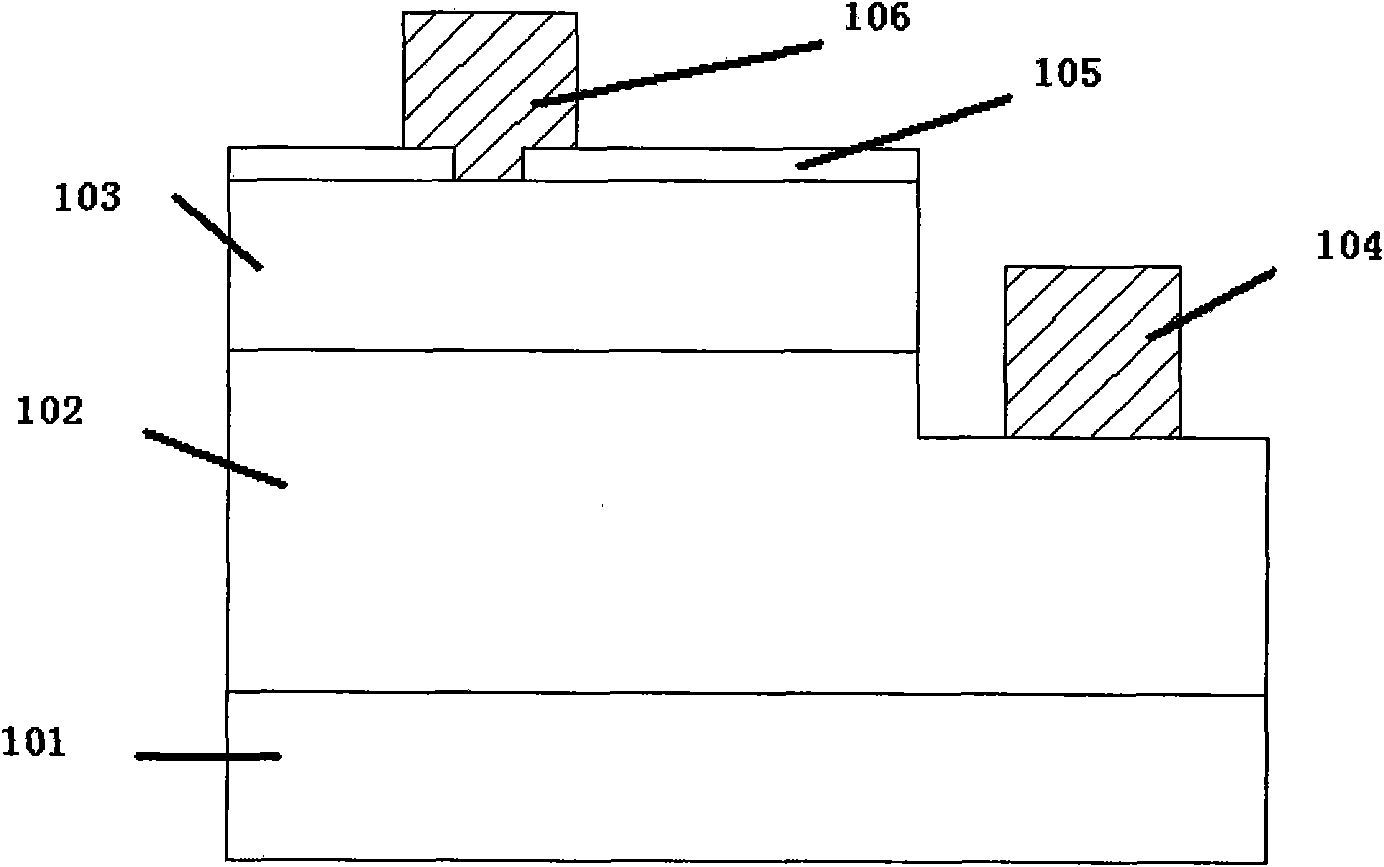

Fabrication of single or multiple gate field plates

ActiveUS7812369B2Strict controlLower gate resistanceSolid-state devicesSemiconductor/solid-state device manufacturingDielectricManufacturing technology

A process for fabricating single or multiple gate field plates using consecutive steps of dielectric material deposition / growth, dielectric material etch and metal evaporation on the surface of a field effect transistors. This fabrication process permits a tight control on the field plate operation since dielectric material deposition / growth is typically a well controllable process. Moreover, the dielectric material deposited on the device surface does not need to be removed from the device intrinsic regions: this essentially enables the realization of field-plated devices without the need of low-damage dielectric material dry / wet etches. Using multiple gate field plates also reduces gate resistance by multiple connections, thus improving performances of large periphery and / or sub-micron gate devices.

Owner:RGT UNIV OF CALIFORNIA +1

Fabrication of single or multiple gate field plates

ActiveUS20070059873A1Strict controlMaximum performanceSolid-state devicesSemiconductor/solid-state device manufacturingDielectricField effect

A process for fabricating single or multiple gate field plates using consecutive steps of dielectric material deposition / growth, dielectric material etch and metal evaporation on the surface of a field effect transistors. This fabrication process permits a tight control on the field plate operation since dielectric material deposition / growth is typically a well controllable process. Moreover, the dielectric material deposited on the device surface does not need to be removed from the device intrinsic regions: this essentially enables the realization of field-plated devices without the need of low-damage dielectric material dry / wet etches. Using multiple gate field plates also reduces gate resistance by multiple connections, thus improving performances of large periphery and / or sub-micron gate devices.

Owner:RGT UNIV OF CALIFORNIA +1

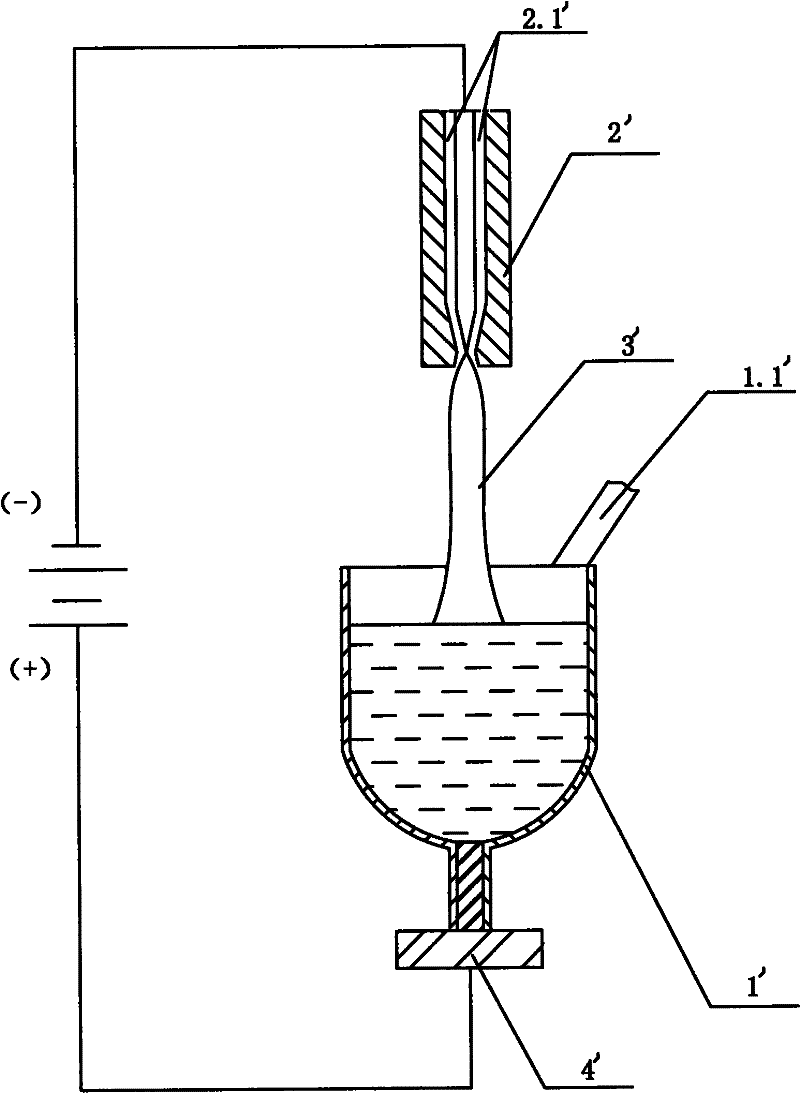

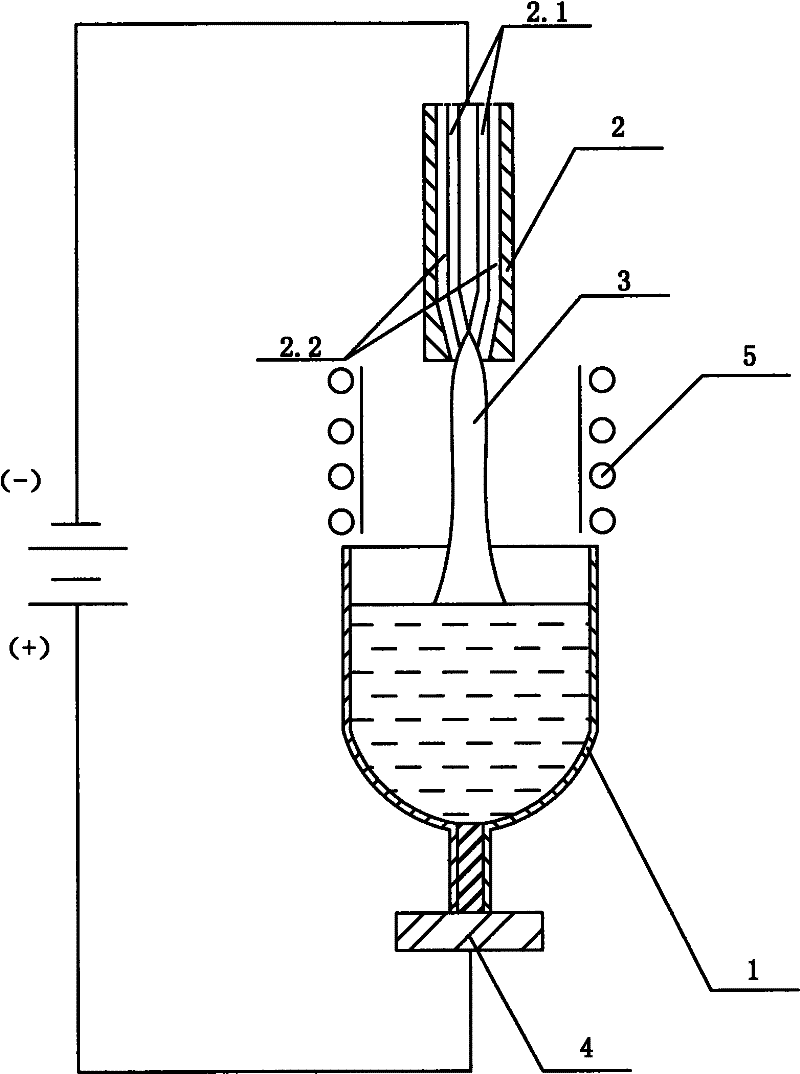

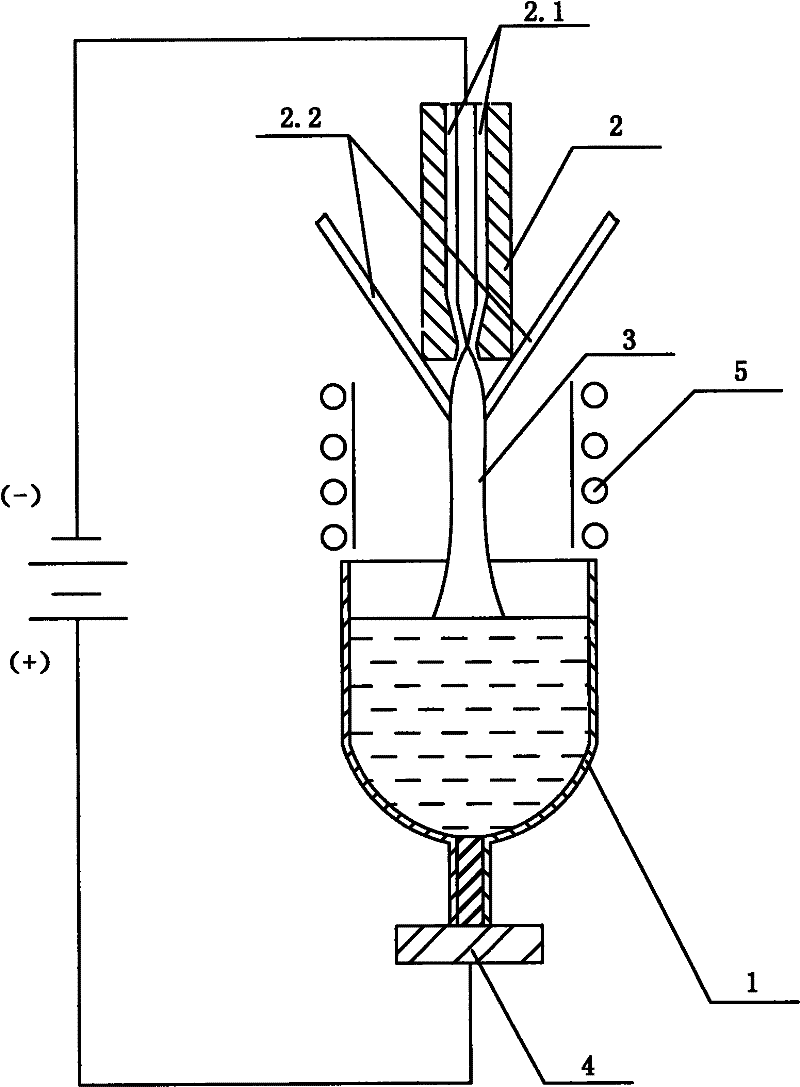

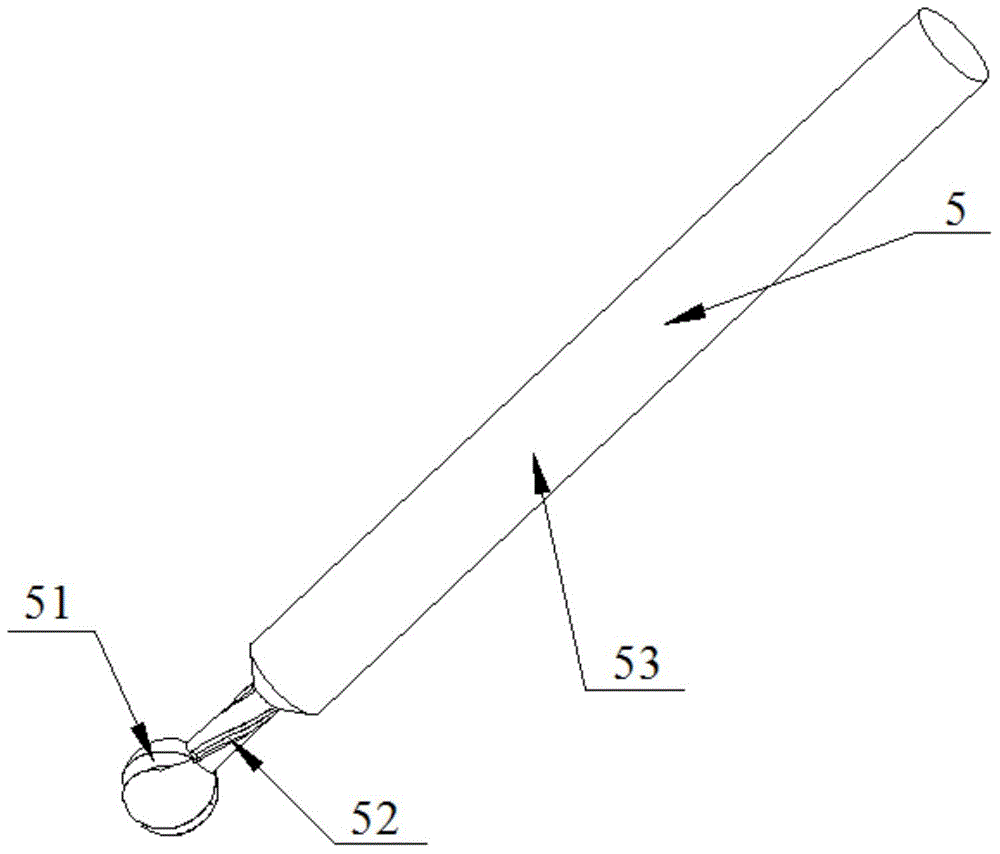

Metal evaporating device and method for preparing ultrafine metal powder by using same

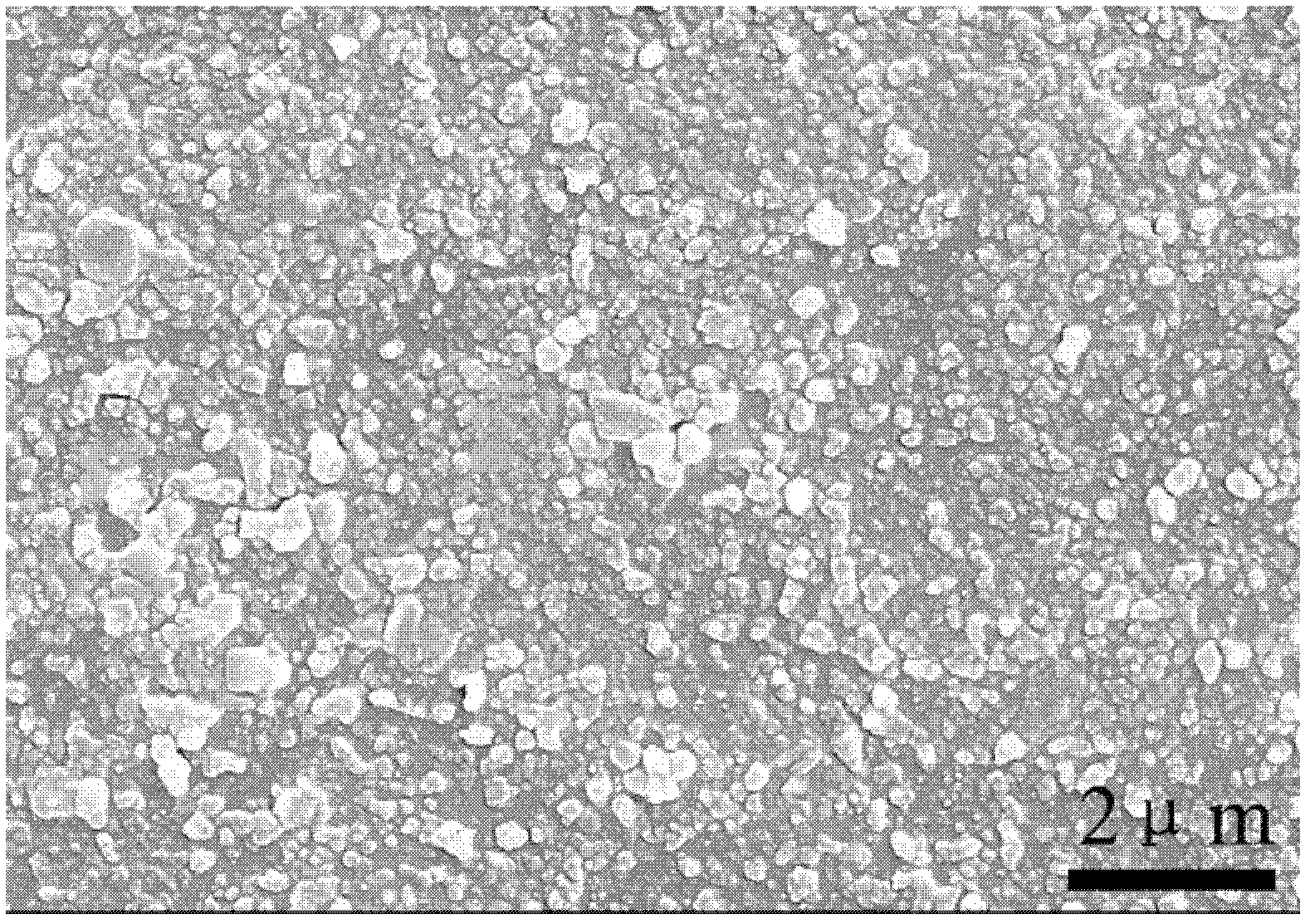

The invention discloses a metal evaporating device and a method for preparing ultrafine metal powder by using the same. The device comprises a crucible (1), a plasma transferred arc torch (2), a plasma transferred arc (3), a graphite (4), a power supply and a lead, which form an electric loop, wherein an air inlet pipe (2.1) from which air enters, is arranged in the plasma transferred arc torch (2); the plasma transferred arc (3) is arranged between the plasma transferred arc torch (2) and the crucible (1); the graphite (4) is arranged on the bottom of the crucible (1); and a feed pipe (2.2) which is used for feeding metal raw materials is arranged above the plasma transferred arc (3). The structure of the metal evaporating device has the advantages that the energy of the plasma transferred arc is fully utilized, the metal output and the metal evaporating efficiency are increased, the energy consumption is lowered, and the ultrafine metal powder which has uniform particle size and is free from large particle metal residual is acquired.

Owner:JIANGSU BOQIAN NEW MATERIALS

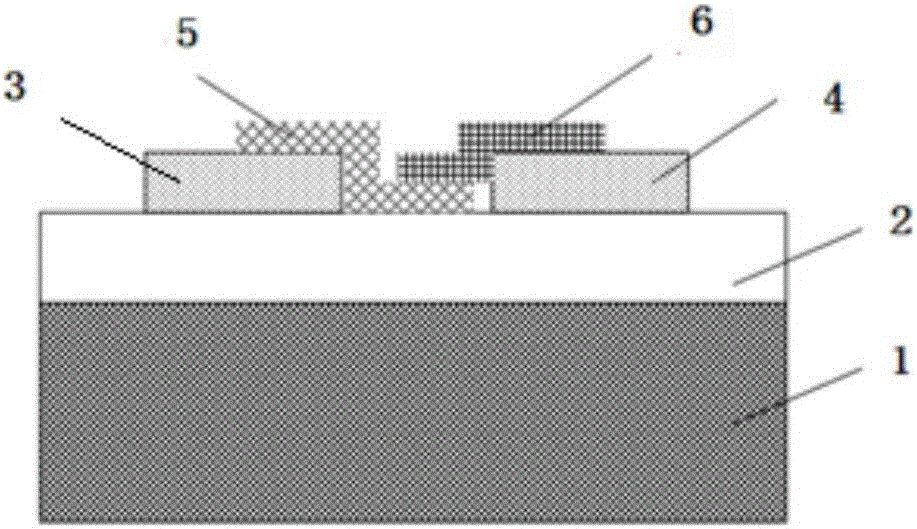

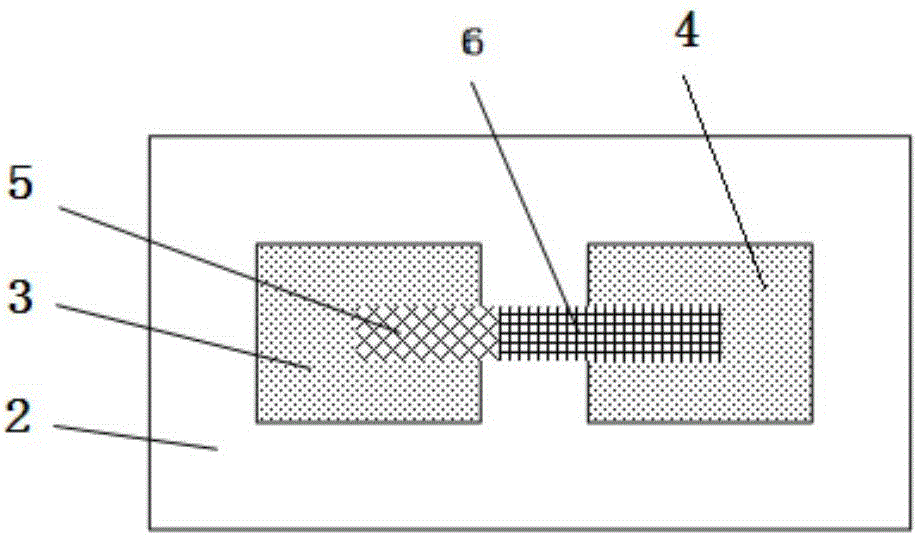

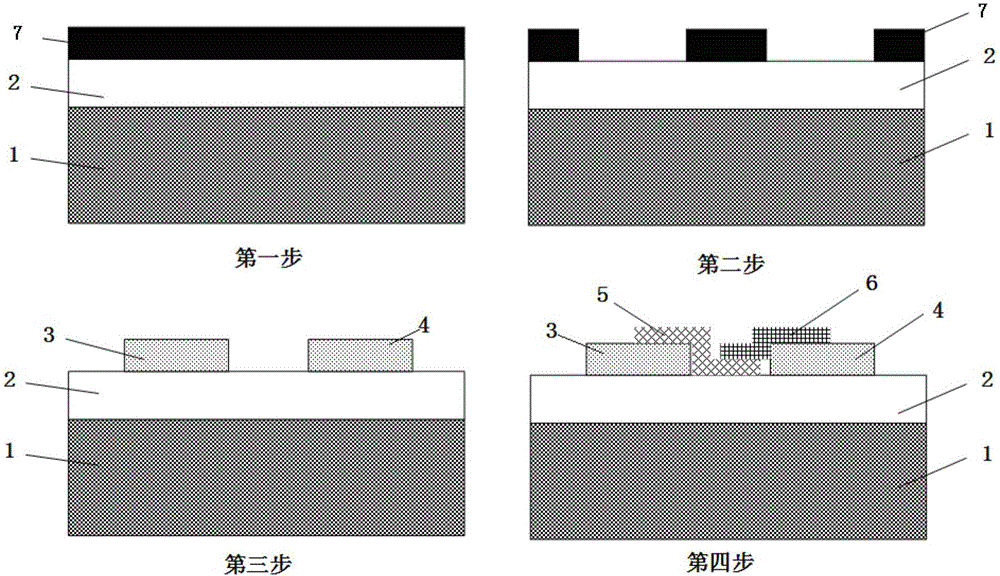

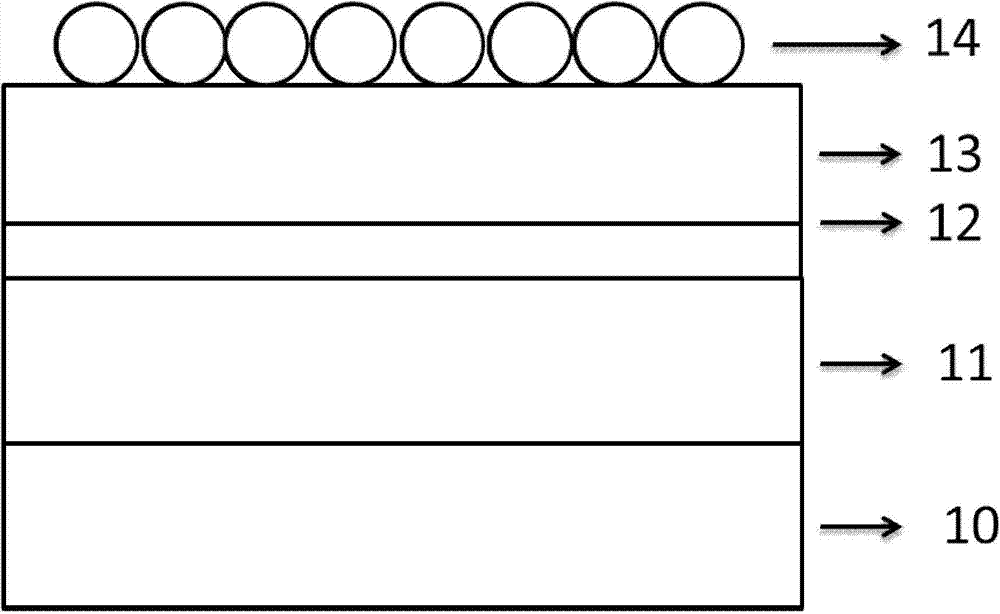

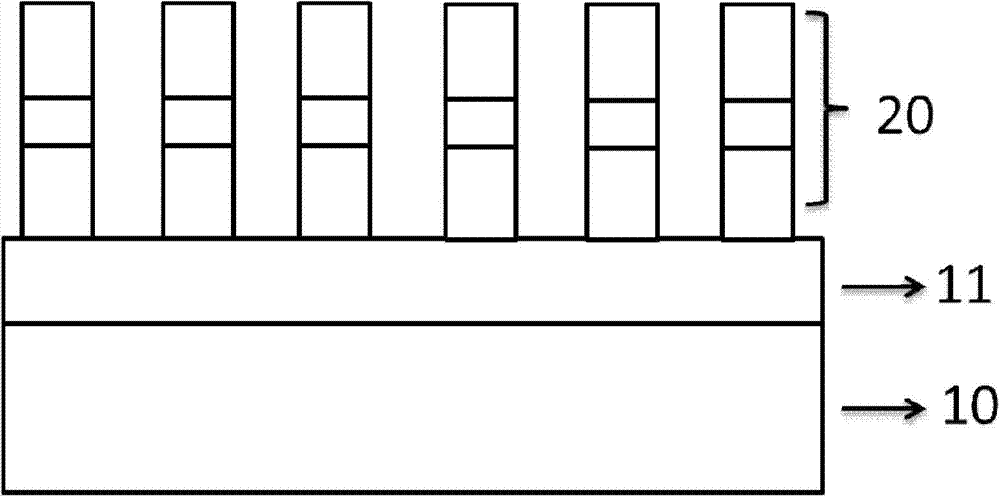

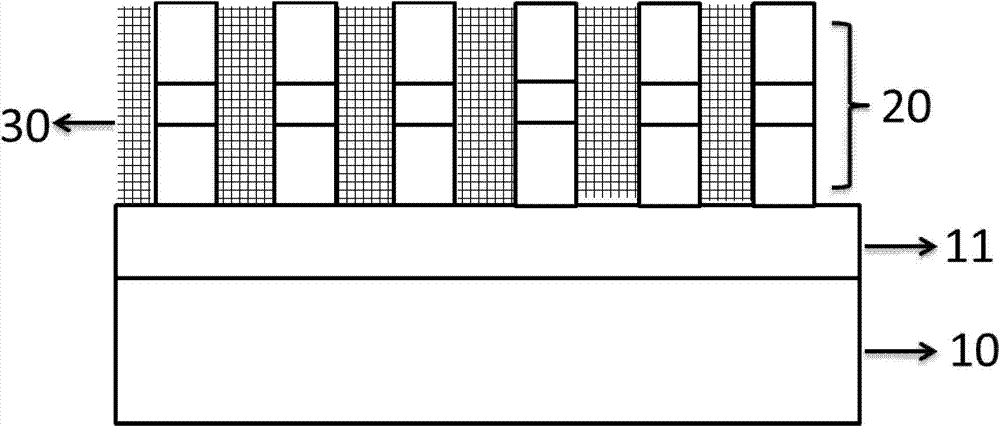

Two-dimensional material heterojunction field effect transistor, preparation method thereof and transistor array device

ActiveCN106206710AImprove output characteristicsLow costSemiconductor/solid-state device manufacturingSemiconductor devicesTransistor arrayOhmic contact

The invention provides a two-dimensional material heterojunction field effect transistor, a preparation method thereof and a transistor array device. The transistor comprises a conductive substrate, an insulating dielectric layer, a source electrode, a drain electrode, a first two-dimensional material layer and a second two-dimensional material layer, wherein the insulating dielectric layer is arranged on the conductive substrate; the source electrode and the drain electrode are arranged at two ends of the insulating dielectric layer respectively and a channel region is arranged between the source electrode and the drain electrode; the first two-dimensional material layer is arranged on the source electrode and the channel region connected with the source electrode; the second two-dimensional material layer is arranged on the drain electrode and one part of first two-dimensional material layer on the channel region; the first two-dimensional material layer is different from the second two-dimensional material layer in material; the first two-dimensional material layer, the second two-dimensional material layer, the source electrode and the drain electrode can form ohmic contact. The transistor provided by the invention has good properties of output characteristics and the like and is low in cost. The preparation method of the transistor provided by the invention is high in substrate utilization rate and high in preparation efficiency; the damage of metal evaporation to a two-dimensional material can be avoided; and the array device can also be prepared.

Owner:科睿唯安(佛山)新能源科技有限公司

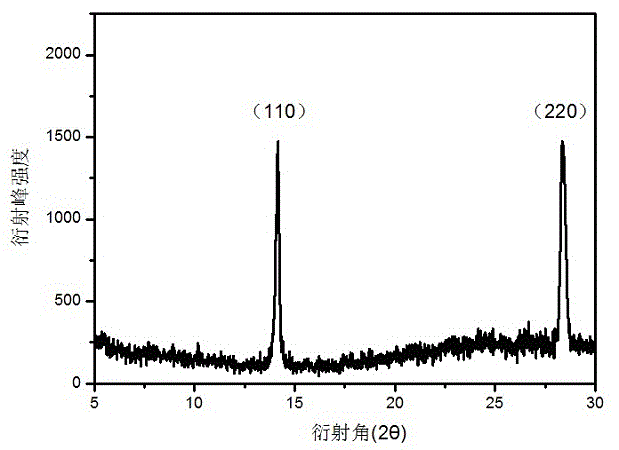

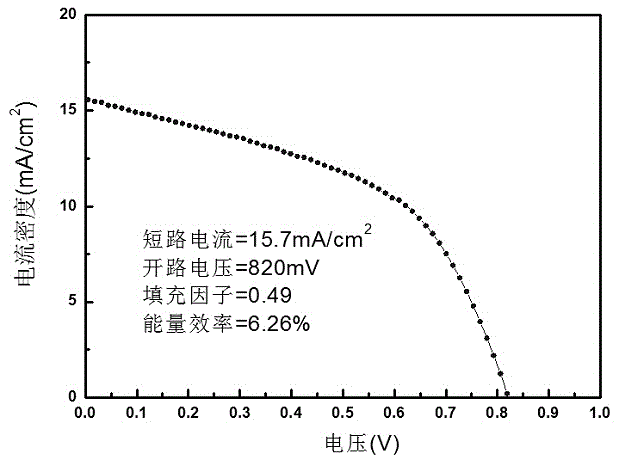

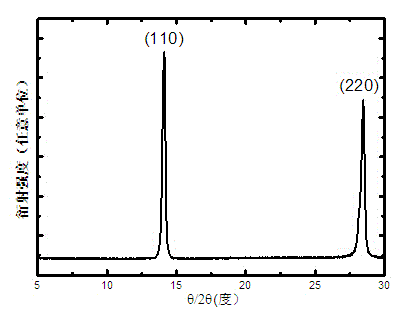

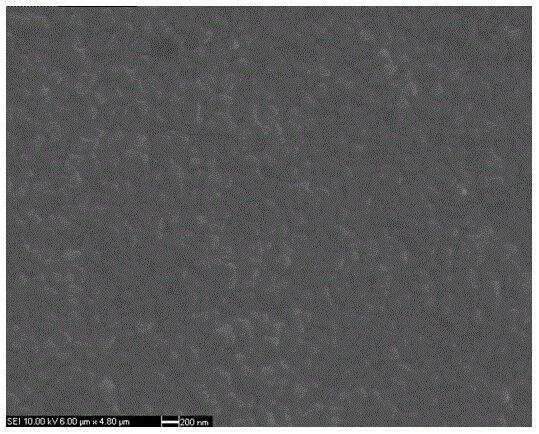

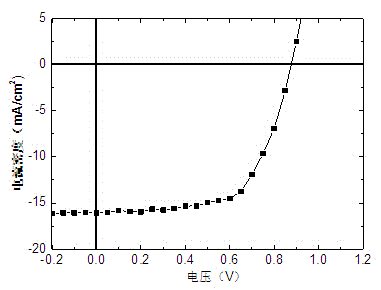

Preparation method of organic and inorganic hybridization perovskite material growing by single-source flash evaporation method and plane solar cell of material

InactiveCN104134720AEase of mass productionEasy to operateFinal product manufacturePhotovoltaic energy generationManufacturing technologyPhysical chemistry

The invention relates to a preparation method of an organic and inorganic hybridization perovskite material growing by a single-source flash evaporation method and a plane solar cell of the material, and belongs to the field of novel material device manufacturing technologies. A preparation method of an organic and inorganic hybridization perovskite film comprises the step of rapidly heating a metal evaporation boat to be above 1000 DEG C by taking a perovskite material solution as a single evaporation source within 1s to prepare the organic and inorganic hybridization perovskite film with accurate components. The organic and inorganic hybridization perovskite film prepared by the single-source flash evaporation method has the characteristics that the film is high in evaporation rate and cavity-free, and is suitable for preparing a plane device. TiO2 or ZnO serving as an n-type material, Spiro-OMeTAD serving as a p-type material and the i-type organic and inorganic hybridization perovskite film form a p-i-n-type plane solar cell device; and the device with efficiency of 6.26% can be obtained after preparation condition optimization.

Owner:SHANGHAI UNIV

Method for producing film metal fine device on PDMS surface

InactiveCN101509130AEasy to integrateLow costLiquid/solution decomposition chemical coatingChemical platingChemical reaction

The invention provides a method for preparing a film metal micro device on the surface of PDMS by chemical plating. The method comprises: a layer of polyacrylic acid (PAA) is selectively grafted to be formed on a designated area of the surface of PDMS through the photochemical reaction by adopting photolithographic masks; after a series of surface chemical reactions such as amination, absorption, reduction and the like, a nano-scale gold particle catalytic center required by chemical plating is formed in an area irradiated by UV light; finally, by selectively carrying out chemical plating on metal by means of nano-gold catalysis, the metal film device is formed on the surface of the PDMS irradiated by the UV light. By the method, the integrated metal film is prepared on the surface of the PDMS sheet and on the inner surface of the channel / cavity of the PDMS in order to prepare such micro devices as a micro-heater, a microelectrode, a microsensor, a micro shielding device and the like, which take the PDMS as a substrate, and to integrate circuits. The method is characterized in that the process is simple and easy to practice and clean laboratories and high-cost metal evaporation and deposition processes are unnecessary. The prepared metal device has the advantages of high accuracy and low cost.

Owner:ZHEJIANG UNIV

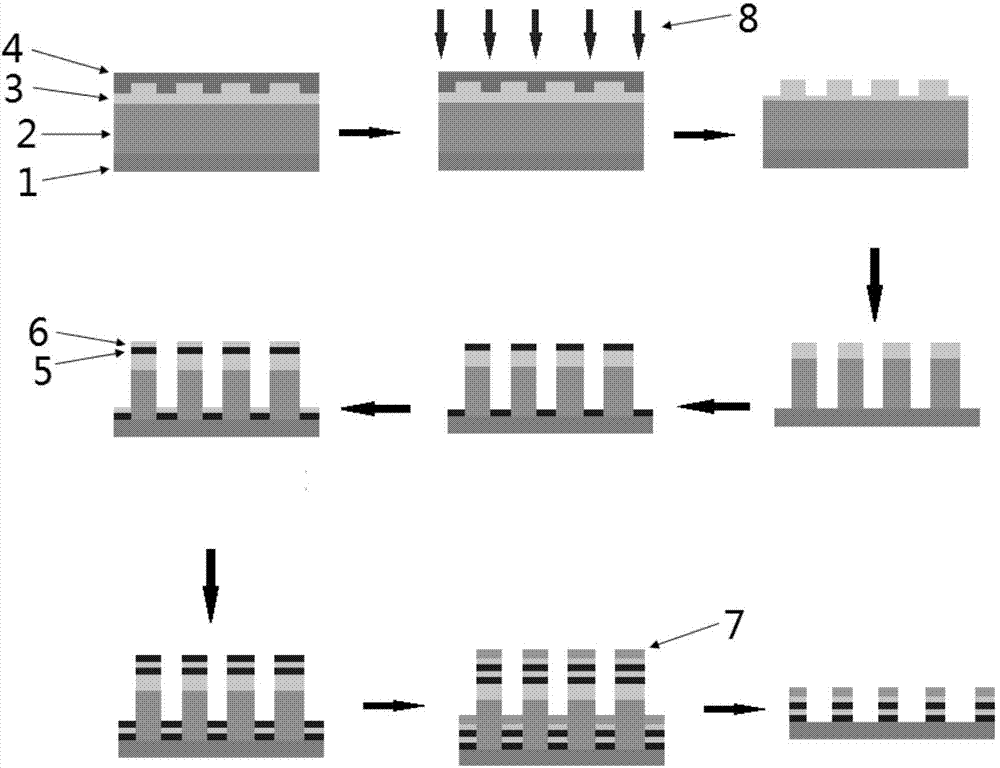

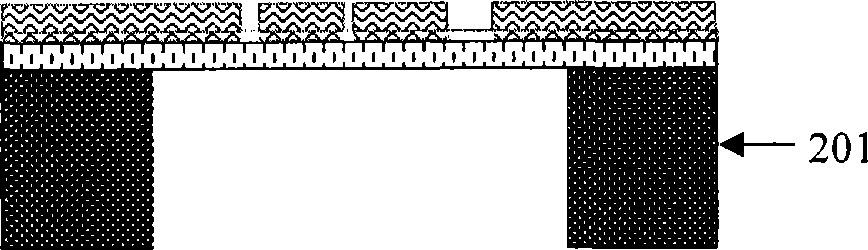

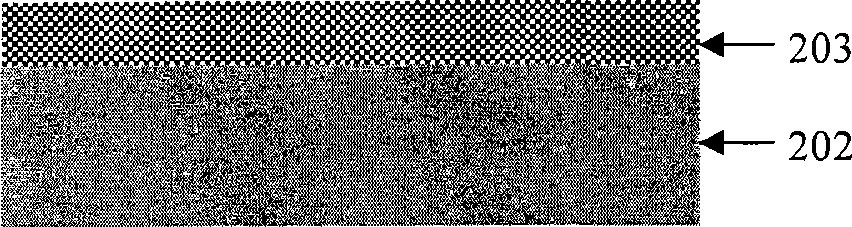

Multilayer structure surface enhanced Raman scattering base and preparation method thereof

ActiveCN103575721ACoordination compatibilityOverall structure coordinationRaman scatteringNano structuringBiocompatibility Testing

The invention belongs to the technical field of nano-imprinting and spectra, and in particular relates to a multilayer structure surface enhanced Raman scattering base and a preparation method thereof. The surface enhanced Raman scattering base is simple in process, high in efficiency, high in enhancement factor and biocompatible. The base consists of a substrate and a periodic nano columnar structure which is positioned on the substrate, wherein the nano columnar structure is a multilayer structure; the multilayer structure consists of alternation layers and a gold layer; the alternation layers consist of silver and media; the gold layer is positioned on the topmost layer. A nano-imprinting technology is used as a core technology, and a reactive ion etching process, a metal evaporation process, a silicon dioxide plating process, a metal peeling process and the like are combined to prepare a multilayer nano structure, so that the technical problems that a silver structure base is not biocompatible and a gold structure base is low in enhancement factor are solved; on the basis of ensuring biocompatibility, the enhancement factor of the base is greatly improved, the detection is efficient and sensitive, and the base can be applied to biological detection after further treatment.

Owner:WUXI IMPRINT NANO TECH

Avalanche photodiode and manufacturing method thereof

ActiveCN104465853AImprove signal-to-noise ratioReduce dark currentSemiconductor devicesEtchingSignal-to-noise ratio (imaging)

The invention discloses an avalanche photodiode and a manufacturing method of the avalanche photodiode. The avalanche photodiode comprises a buffering layer at least having epitaxial growth on a substrate, an N-type ohmic contact layer, a light absorption layer, an avalanche multiplication and a P-type ohmic contact layer. The light absorption layer is made of superlattices of an InAs layer and a GaSb layer which are different in thickness and can adsorb infrared from a short wave to a long wave, meanwhile, dark current can be reduced by AlGaAsSb, the device is manufactured through mesa etching, passivation and metal evaporation, the device can respond to the infrared from the short wave to the long wave and provide certain gain, and therefore the signal-to-noise ratio of a detector can be increased.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

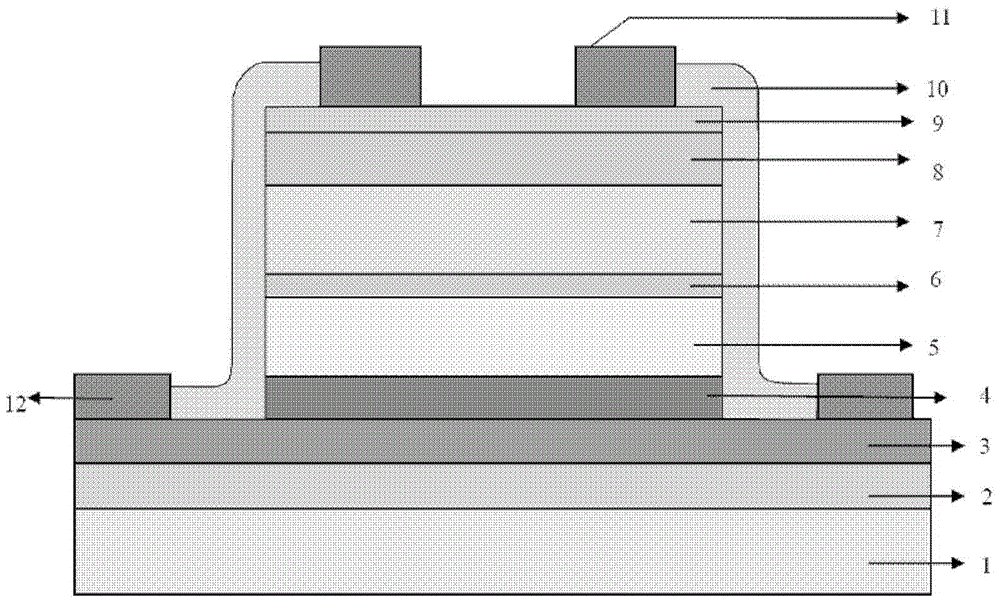

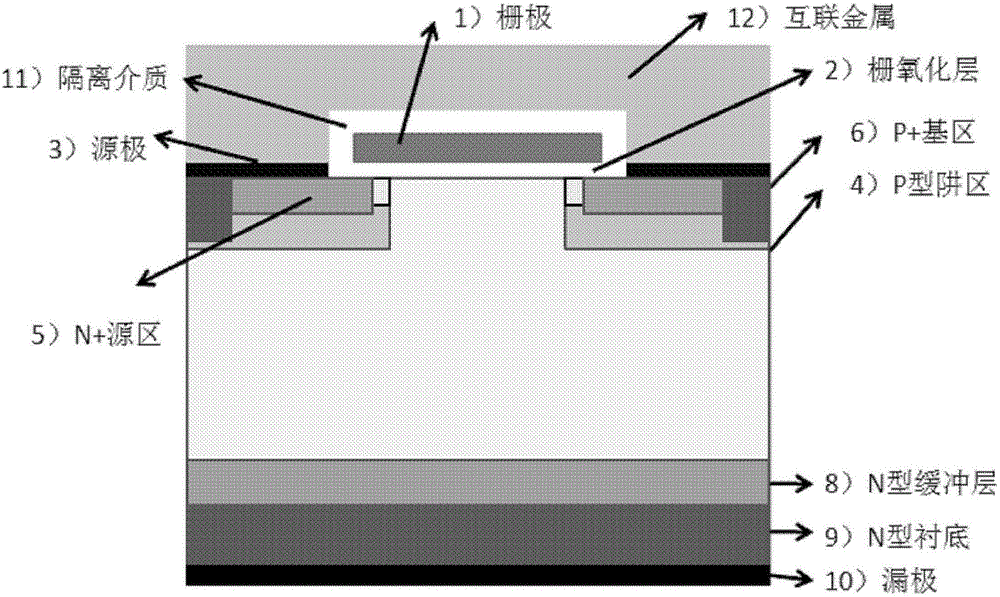

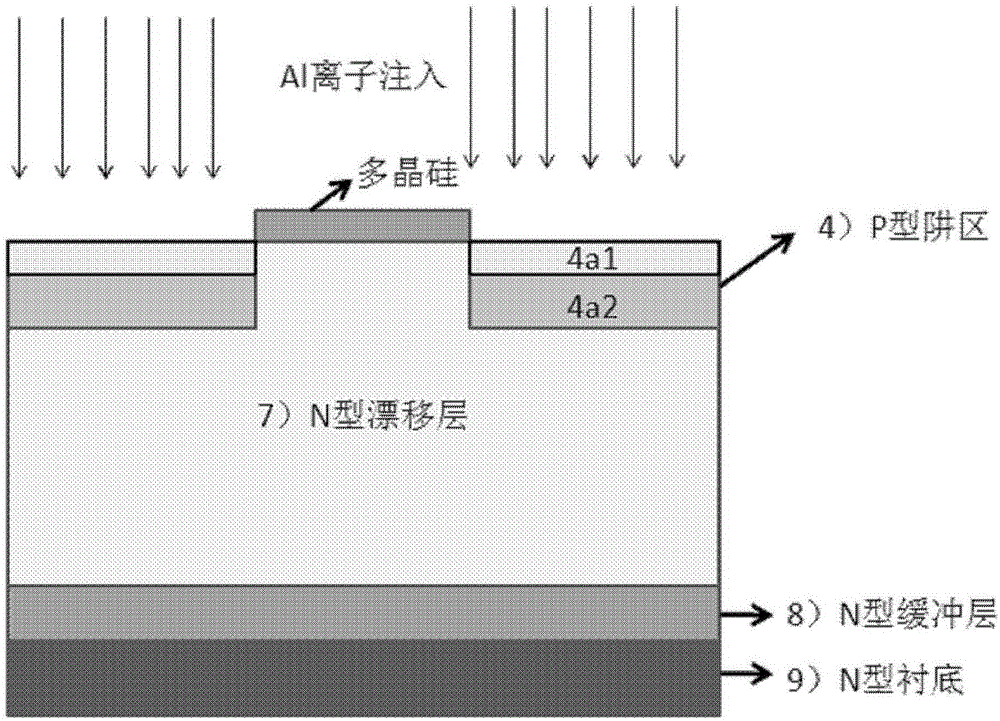

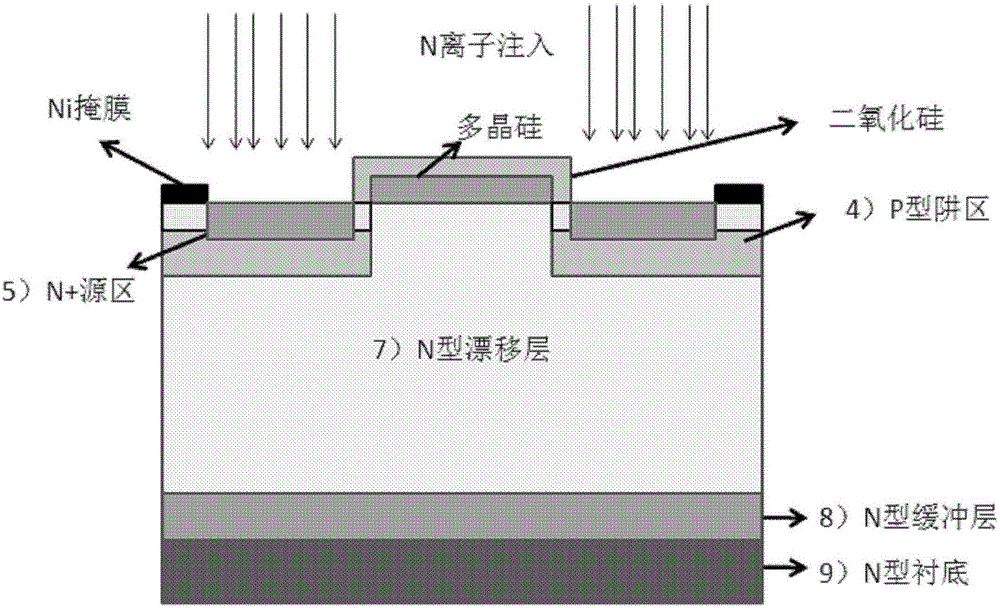

SiC metal-oxide-semiconductor field-effect transistor (MOSFET) device and fabrication method thereof

ActiveCN105810722AShort processReduce the number of photolithographySemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETInterconnection

The invention discloses a SiC metal-oxide-semiconductor field-effect transistor (MOSFET) device and a fabrication method thereof. The SiC MOSFET device comprises a plurality of cells, wherein the cells are connected through interconnection metal (12), each cell comprises a grid, a grid oxide layer, two sources, an N-type drift layer, an N+ buffer layer, an N+ substrate, a drain and an isolation medium. According to the process step disclosed by the invention, in a photoetching plate subjected to tapping in a contact region, contact metal evaporation and stripping, a source electrode region is provided with a pattern, and a pattern also exists in a pad region of the grid.

Owner:ZHEJIANG XINKE SEMICON CO LTD

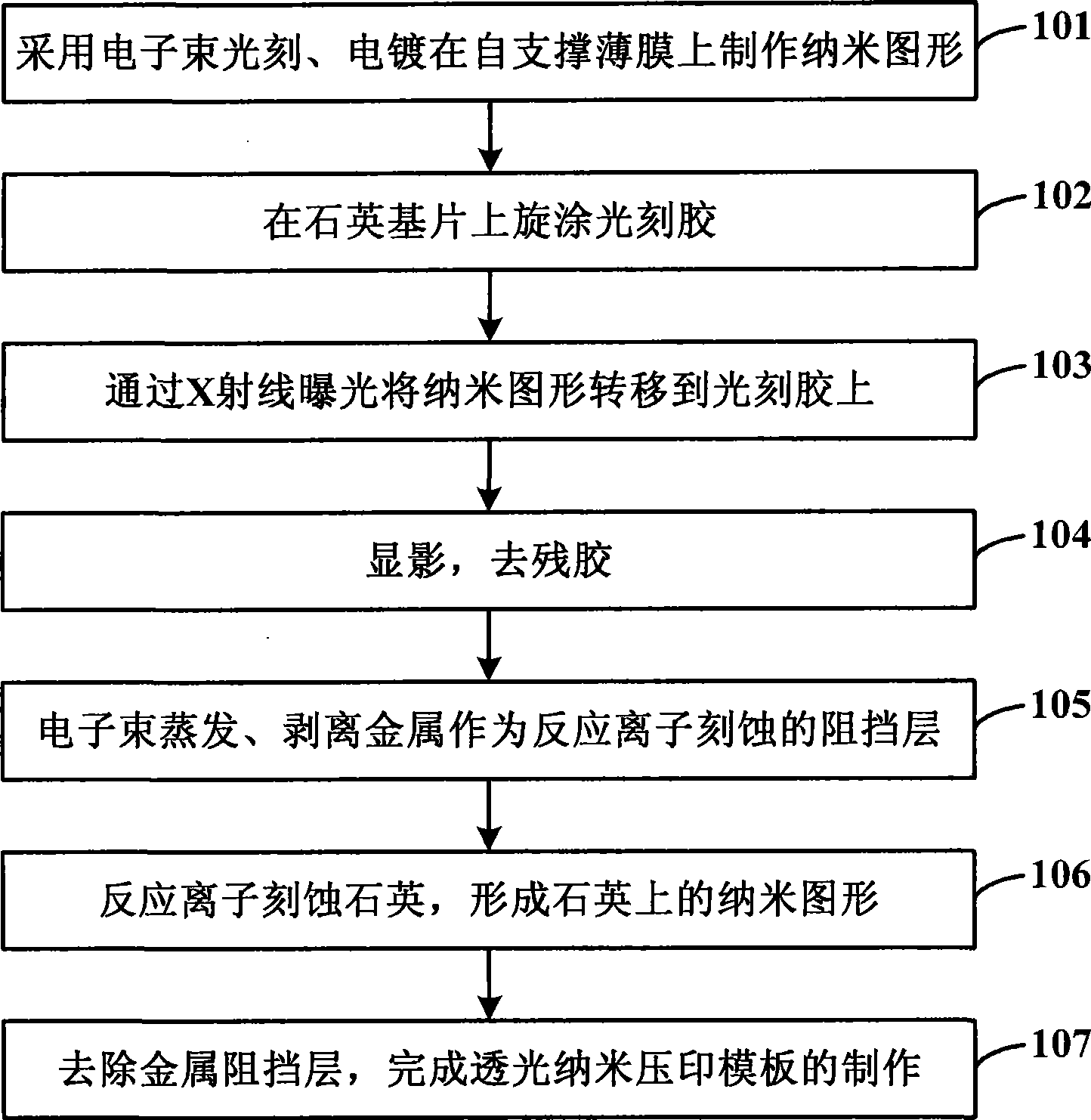

Method for preparing transparent nano imprinting template based on X-ray exposure technology

ActiveCN101520600AEasy alignmentPhotomechanical coating apparatusPhotosensitive material processingX-rayReactive-ion etching

The invention discloses a method for preparing a transparent nano imprinting template based on an X-ray exposure technology. The transparent nano imprinting template is a nano X-ray exposure template prepared by the electron beam lithography. In the method, with the X-ray exposure, nano patterns are transferred onto a photoresist which adopts non-conductive quartz as a substrate. After development, metal nano patterns on the quartz substrate are obtained with a metal evaporation and stripping technology. As metal is adopted as a barrier layer and reactive ions are used for etching the quartz, the nano patterns on the quartz are obtained and the preparation of the transparent nano imprinting template is completed after the removal of the metal. The invention solves the problem that high resolution patterns cannot be obtained on a non-conductive substrate through the electron beam lithography. Simultaneously, the invention realizes the transparent nano imprinting template and provides a convenient alignment means for nano imprinting, which renders ultraviolet treating nano imprinting possible.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

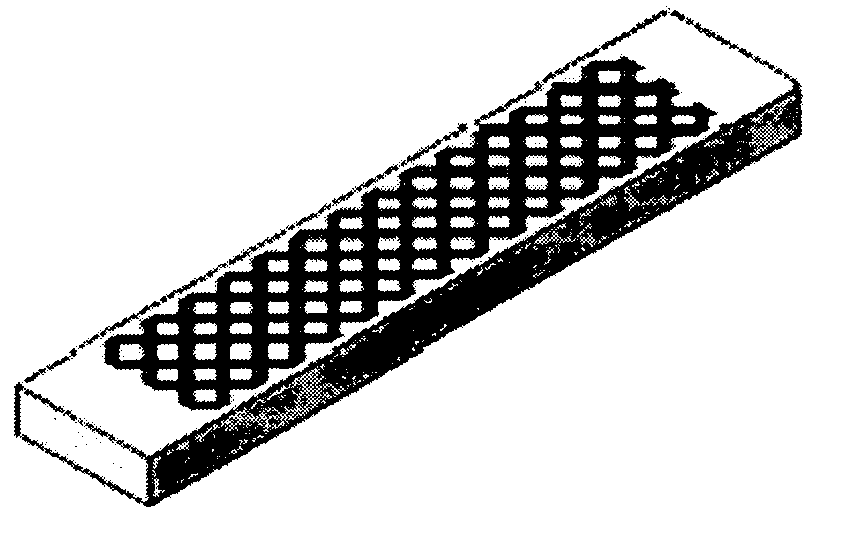

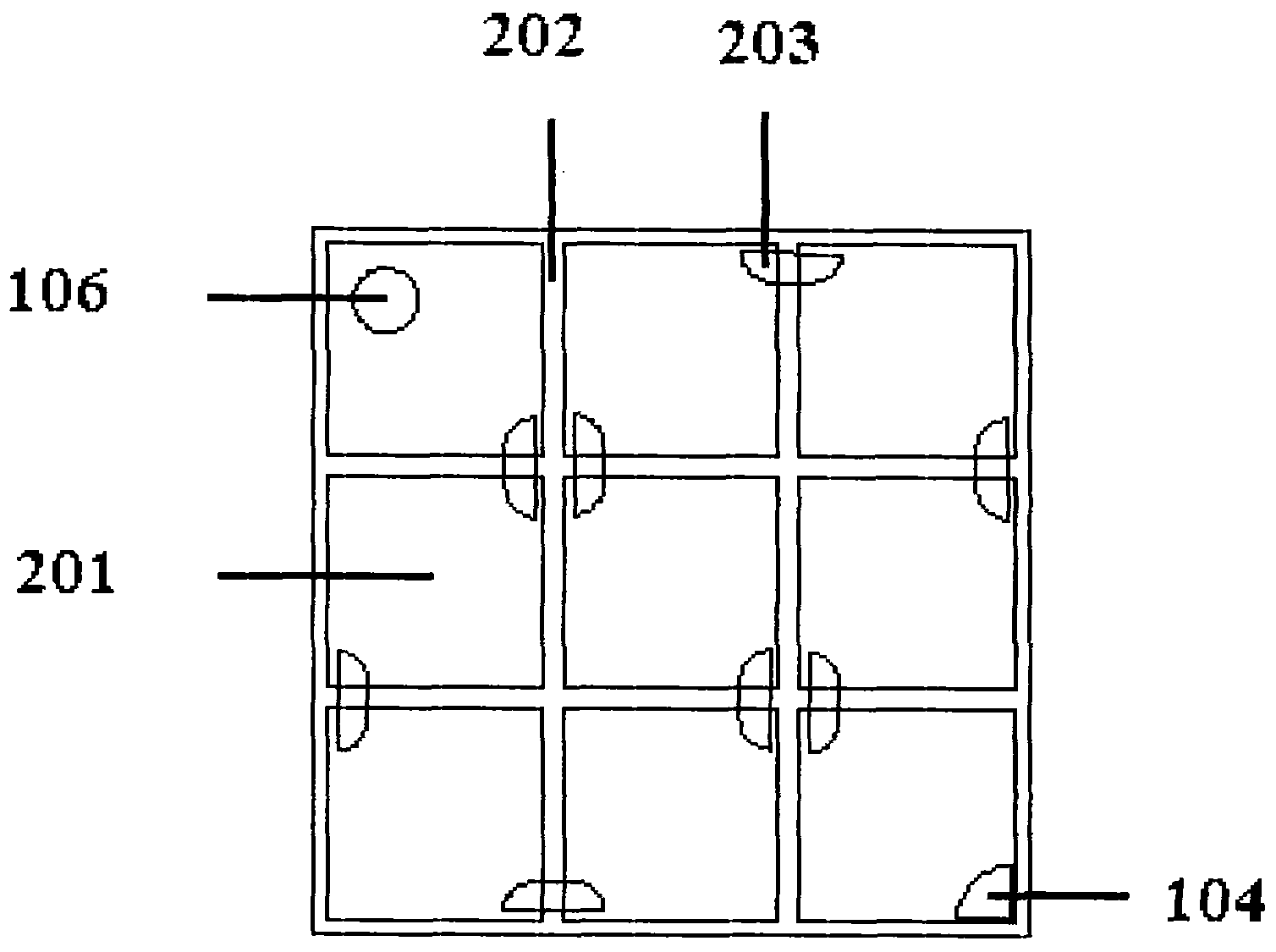

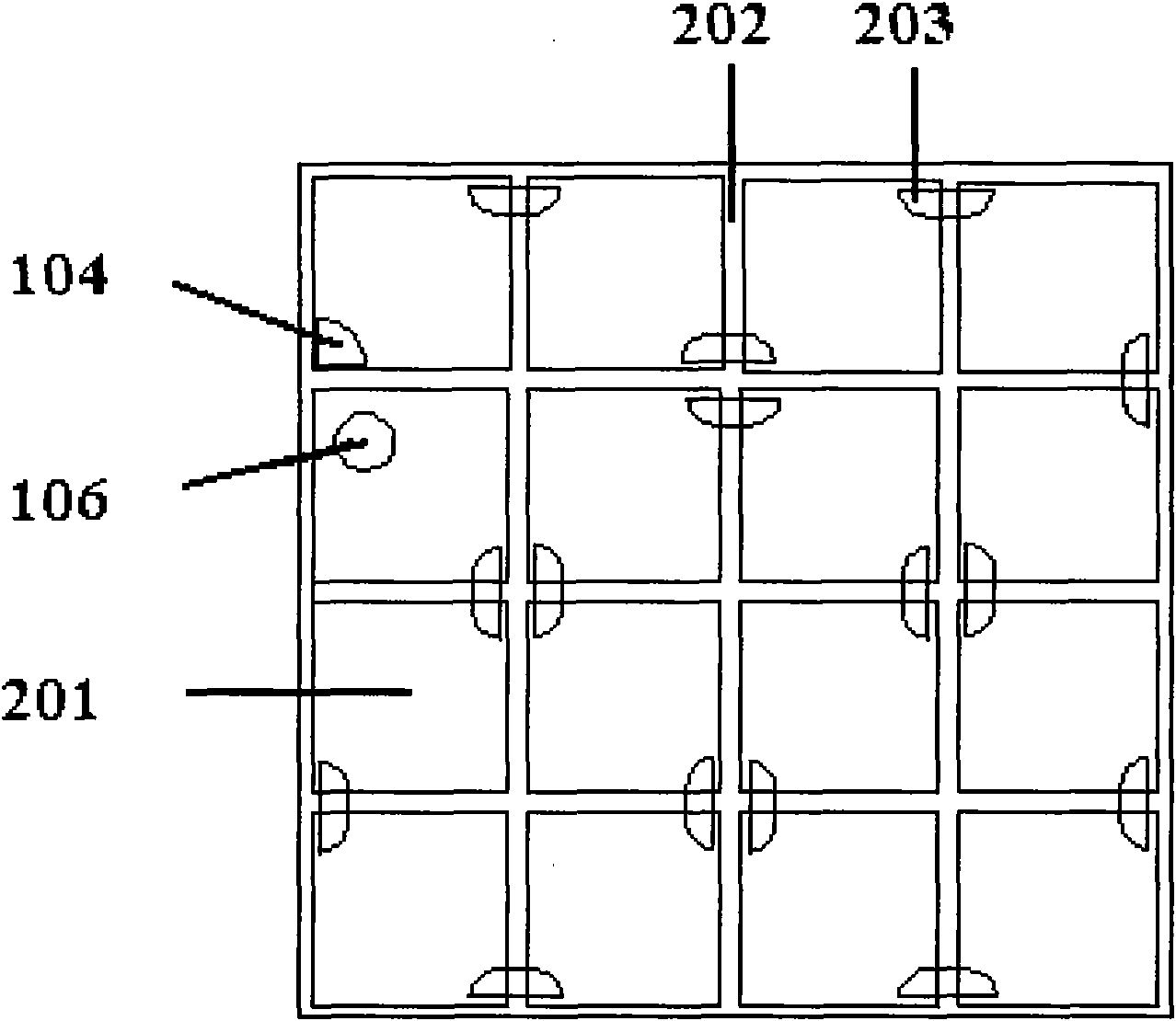

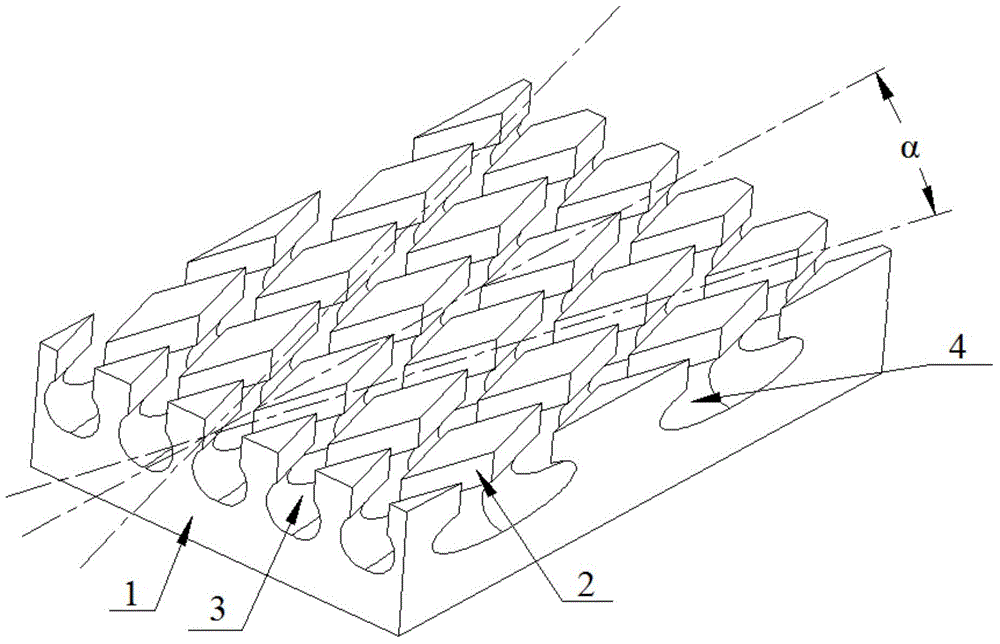

Container for evaporation of metal and method to manufacture thereof

A refractory container for evaporating metals, having improved useful life and corrosion resistance properties, the evaporation surface of the container having a plurality of grooves formed at the bottom surface. The grooves have either a depth of at least 1.2 mm, a width of at least 1.75 mm, or an interval spacing of at least 2.2 mm between adjacent grooves (or centers of adjacent grooves), and combinations thereof.

Owner:GENERAL ELECTRIC CO

Integrated light-emitting diode array chip and production method thereof

InactiveCN102376735AHigh luminous intensityImproved current spreadSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringGallium nitride

The invention relates to a production method of an integrated light-emitting diode array chip based on a gallium-nitride-based light-emitting diode. The production method comprises the following steps of: arranging 9 or 12 light-emitting diode units in an array manner to form a 3*3 or 3*4 matrix, and integrating the matrix in a chip; in the integrated chip, etching an insulating sapphire substrate layer through an etching technology to completely separate gallium nitride layers among the units; filling gaps among the units by using an insulating material, and covering the whole chip; opening electrode ports of the units on an insulating layer; connecting the electrode ports of the units in a metal evaporation manner so that the units in the whole chip form a circuit in a serial connection manner; and making P and N routing disc ports at both ends of the chip for accessing other circuits when the capsulation is carried out. The integrated chip produced by the production method has the advantages of high light-emitting strength and high photoelectric conversion efficiency and is beneficial to the capsulation and the design of a drive circuit. The production method is mainly applied to an illumination field.

Owner:DALIAN MEIMING EPITAXIAL WAFER TECH

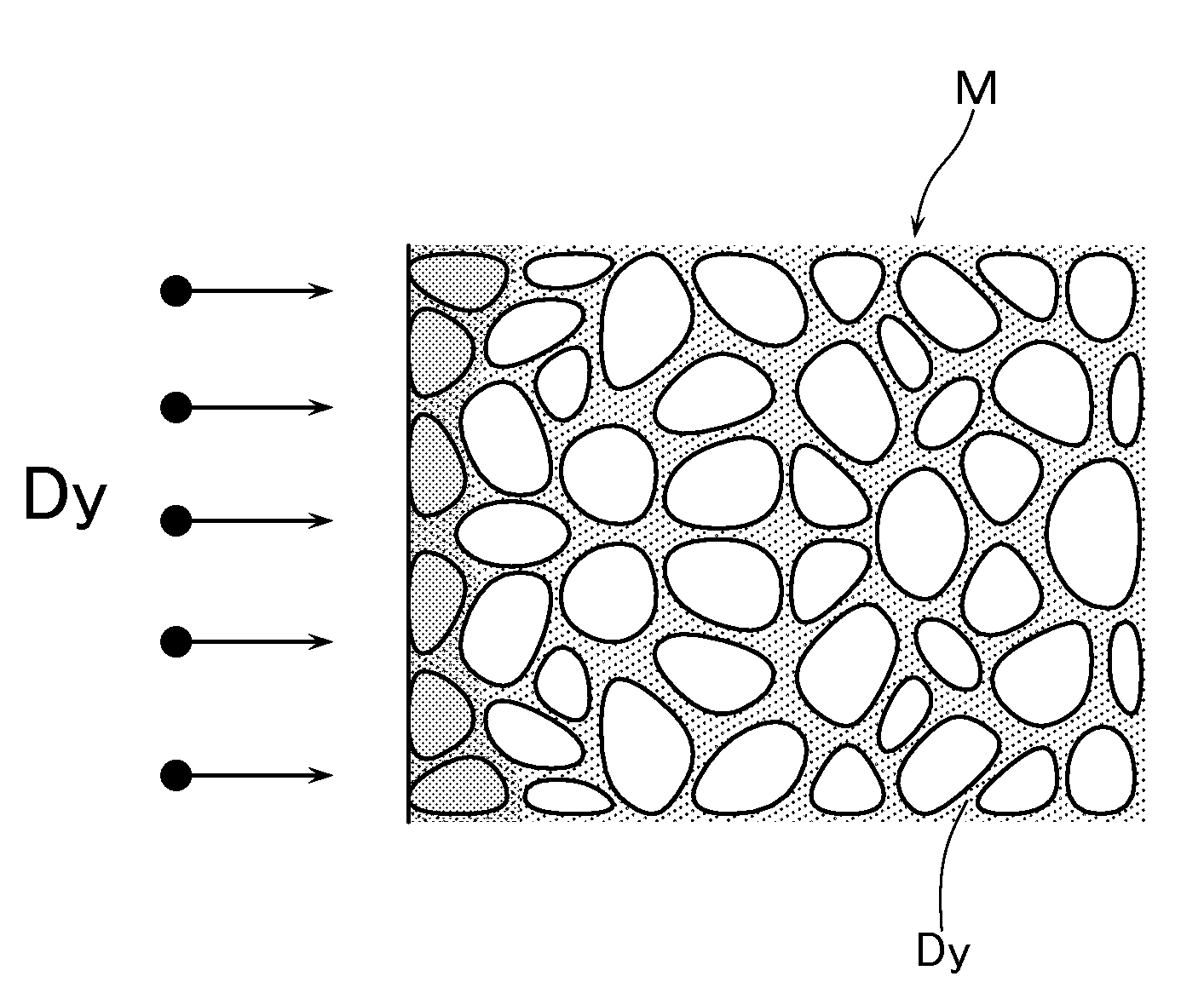

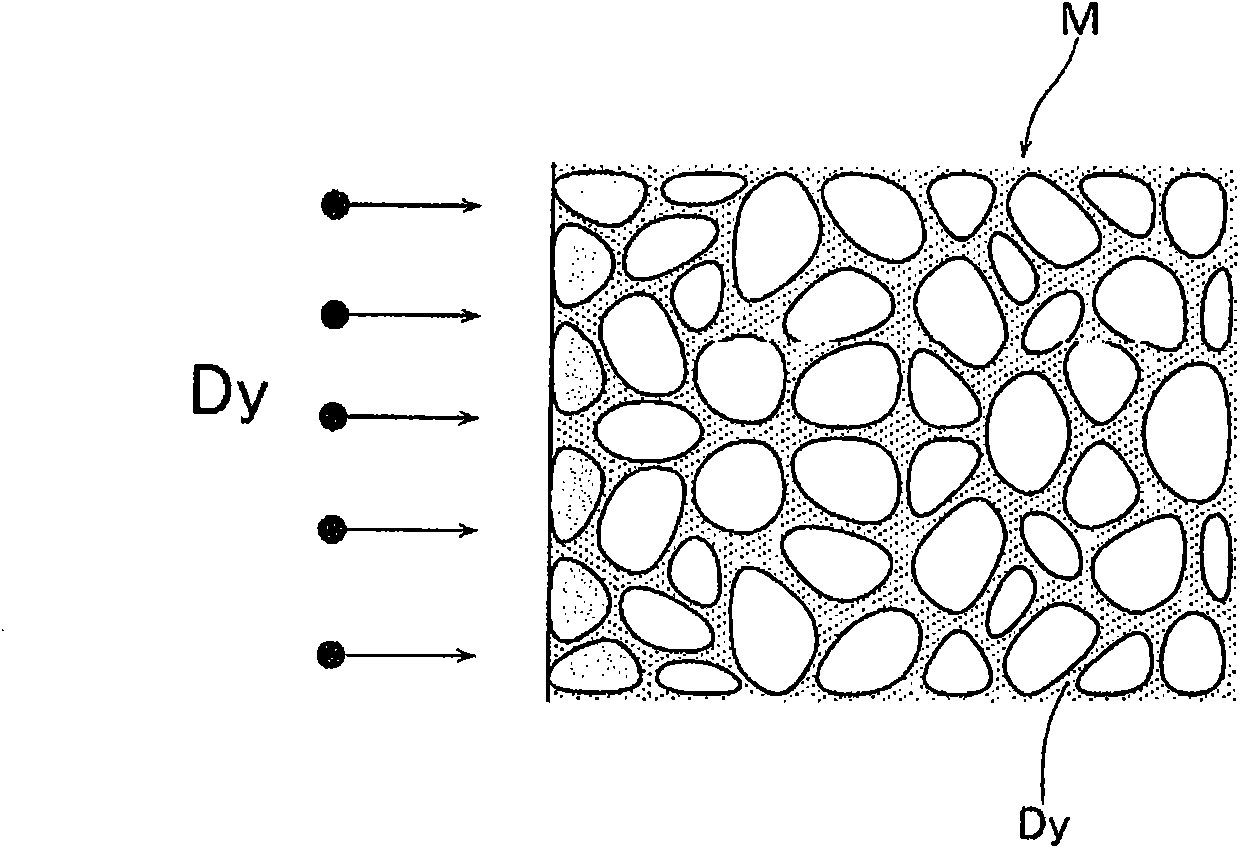

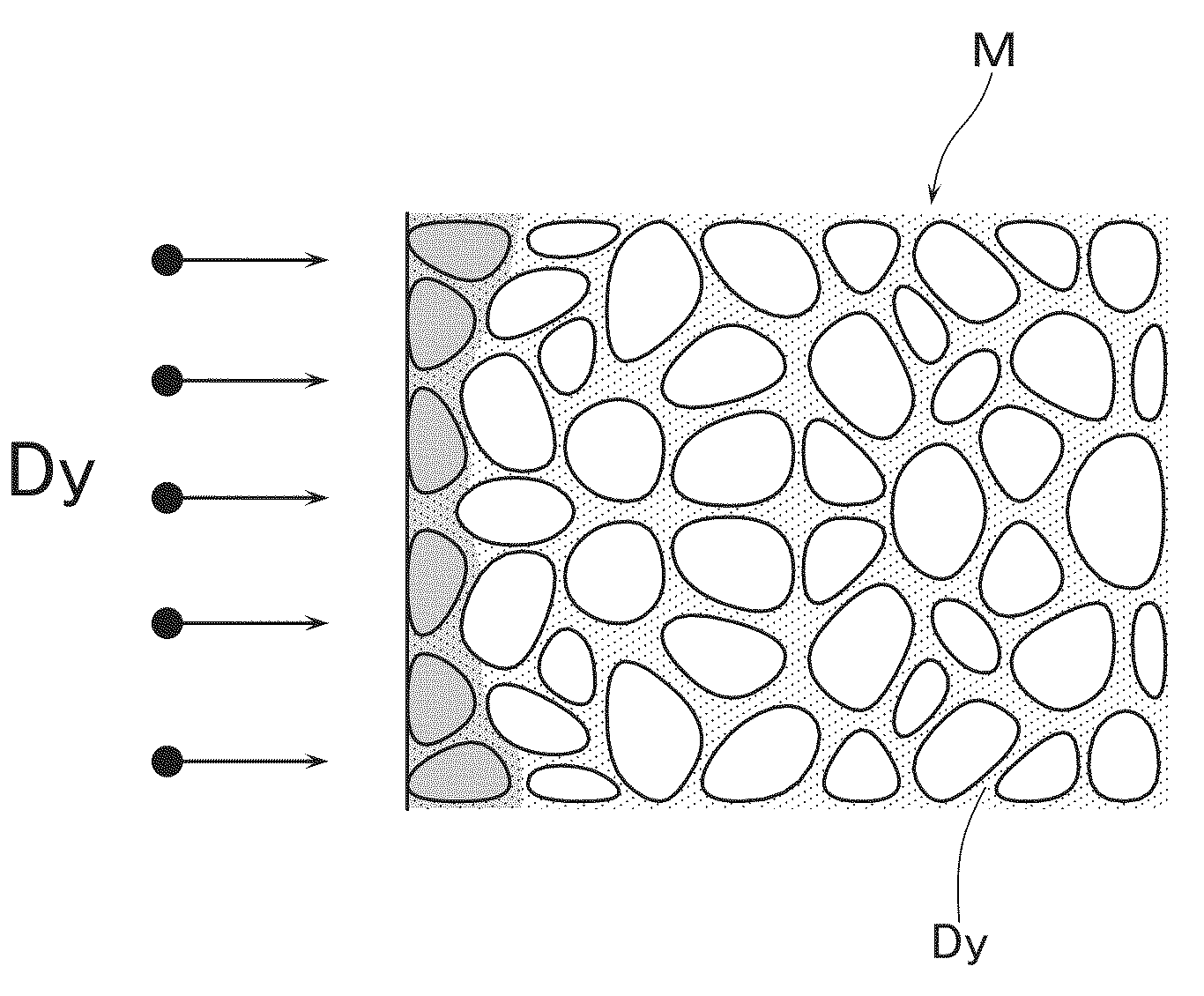

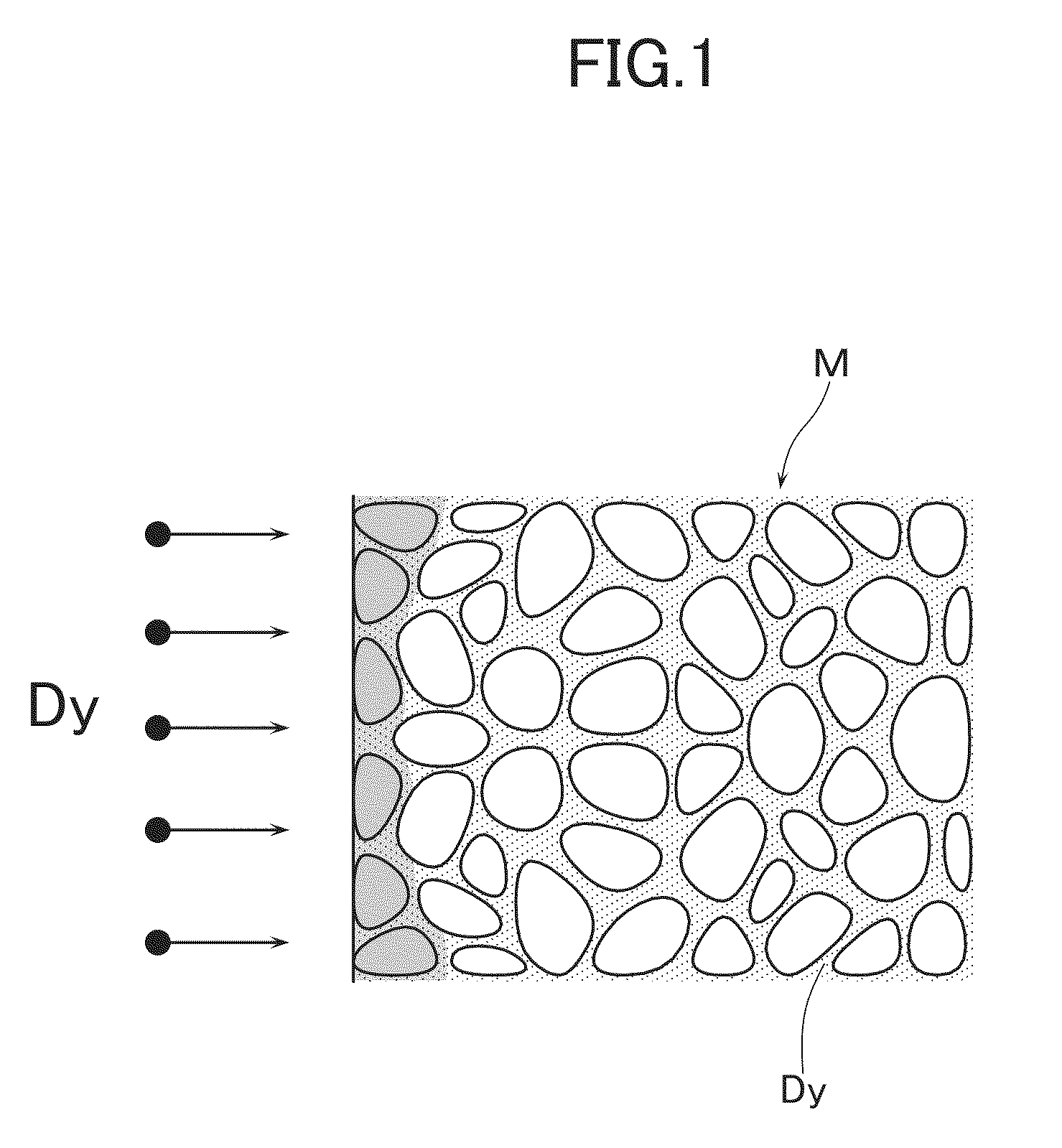

Method of recycling scrap magnet

InactiveUS20110052799A1Improve productivityImprove magnetic propertiesVacuum evaporation coatingSputtering coatingSintered magnetsRare earth

The method has the steps of: grinding a recovered scrap magnet which is an iron-boron-rare earth-based sintered magnet, thereby obtaining a scrap-derived recovered raw material powder; obtaining a sintered body from the scrap-derived recovered raw material powder by a powder metallurgy method; and processing the sintered body. The processing includes the steps of: heating the sintered body disposed in a processing chamber; evaporating a metal evaporating material containing at least one of Dy and Tb in which the metal evaporating material is disposed in the same or another processing chamber; adhering metal atoms evaporated in the evaporating step to a surface of the sintered body while controlling a supply amount of the evaporated metal atoms; and diffusing the adhered metal atoms into grain boundaries and / or grain boundary phases of the sintered body.

Owner:ULVAC INC

Method for preparing metal-PDMS (Polydimethylsiloxane) composite material

ActiveCN102627784AEasy to integrateLow costNanotechnologyCoatingsMetal evaporationPolydimethylsiloxane

The invention discloses a method for preparing a metal-PDMS (Polydimethylsiloxane) composite material. The method comprises the following steps of: performing a reduction reaction by taking an additive in a PDMS material as a reducing agent for a metal precursor to generate metal nanoparticle seeds on the entire or a part of the PDMS; performing an amplified reaction on the metal nanoparticle seeds by using an amplification solution which contains a metal precursor, a protecting agent and the like to generate a metal film layer; and preparing the metal-PDMS composite material. According to the method, metal films can be prepared on the surfaces of PDMS sheets, pipes, rods and other special-shaped PDMS materials and in channels of PDMS chips. The method has the characteristics of simple process, no need of performing high-cost metal evaporation and the like; and the prepared metal-PDMS composite material has the advantages of low cost and high integration degree.

Owner:INST OF CHEM CHINESE ACAD OF SCI

A cleaning method of a metal film forming mask

InactiveCN104614933AEasy to cleanLow costOriginals for photomechanical treatmentEvaporation (deposition)Organic solvent

A cleaning method of a metal film forming mask is disclosed. The method includes following three steps: S1) forming an organic layer on the surface of a mask by evaporation deposition; S2) putting the mask with the organic layer obtained in the step S1 into a metal film forming cavity, and performing metal evaporation deposition; and S3) putting the mask obtained in the step S2) into an organic solution and cleaning. The method can allow the metal film forming mask to be cleaned in a cleaning machine applying organic solvents, effectively prevents inconvenience in transportation processes, and saves the cost of delivering the mask to outside to be cleaned.

Owner:TRULY HUIZHOU SMART DISPLAY

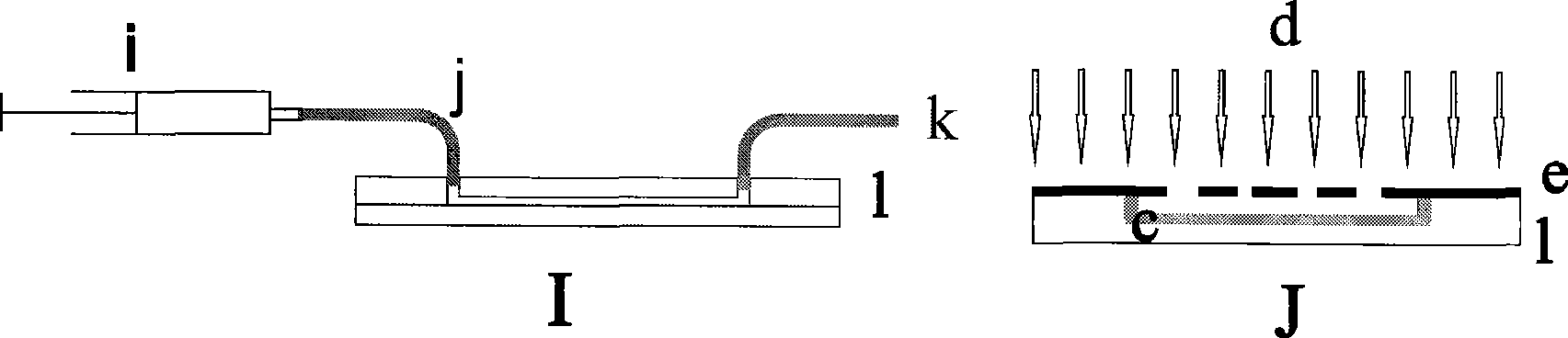

Receiving module package method for optical interconnection on chip

InactiveCN102005497AGuaranteed curing sealGood light transmissionOptical waveguide light guideSemiconductor devicesPhysicsMetal evaporation

The invention discloses a receiving module package method for optical interconnection on a chip, comprising the following steps of: transferring a ridge waveguide and a grating structure on a domain to a top silicon layer on an SOI (Silicon On Insulator) chip cleaned in advance by adopting an electron beam exposure technology; with electron beam resist as a mask, etching a submicron ridge waveguide and a grating structure by using a silicon plasma dry-method etching process; covering a silicon dioxide insulating layer on the surface of the etched graph by adopting a silicon dioxide precipitating technology; transferring a metal lead and an aligning mark graph to the silicon dioxide insulating layer by adopting a general photoetching method; producing the metal lead and an aligning mark by using a metal evaporation process; accurately backing off a photoelectric detector to the preset position on the SOI chip by using the aligning mark on the SOI chip and a flip chip bonding technology; connecting the grounded surface on the back of the photoelectric detector with a grounded wire on the SOI chip by using an interconnected gold wire; and filling setting glue between the photoelectric detector and the SOI chip for curing and sealing to finish the package of the device.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

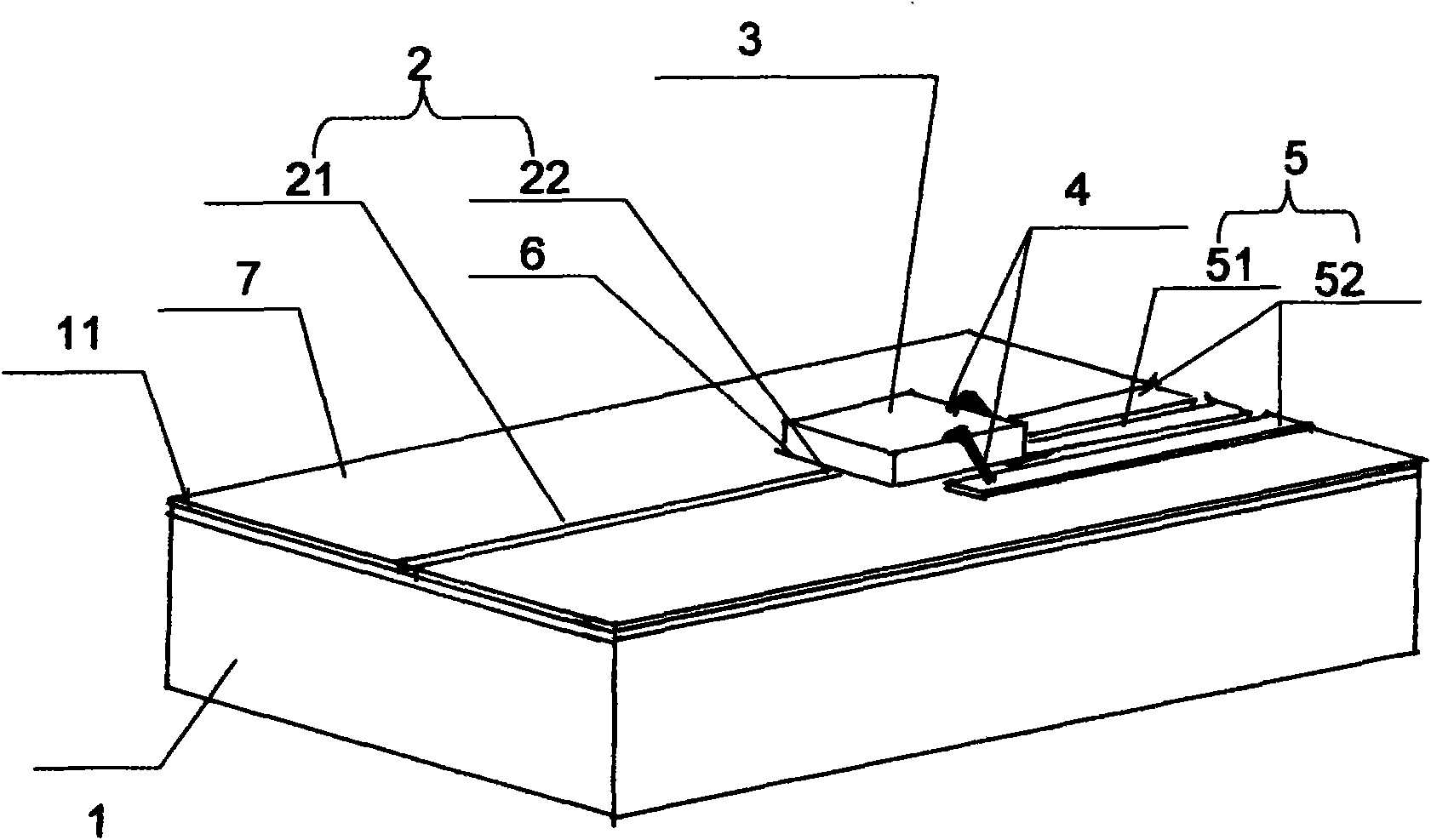

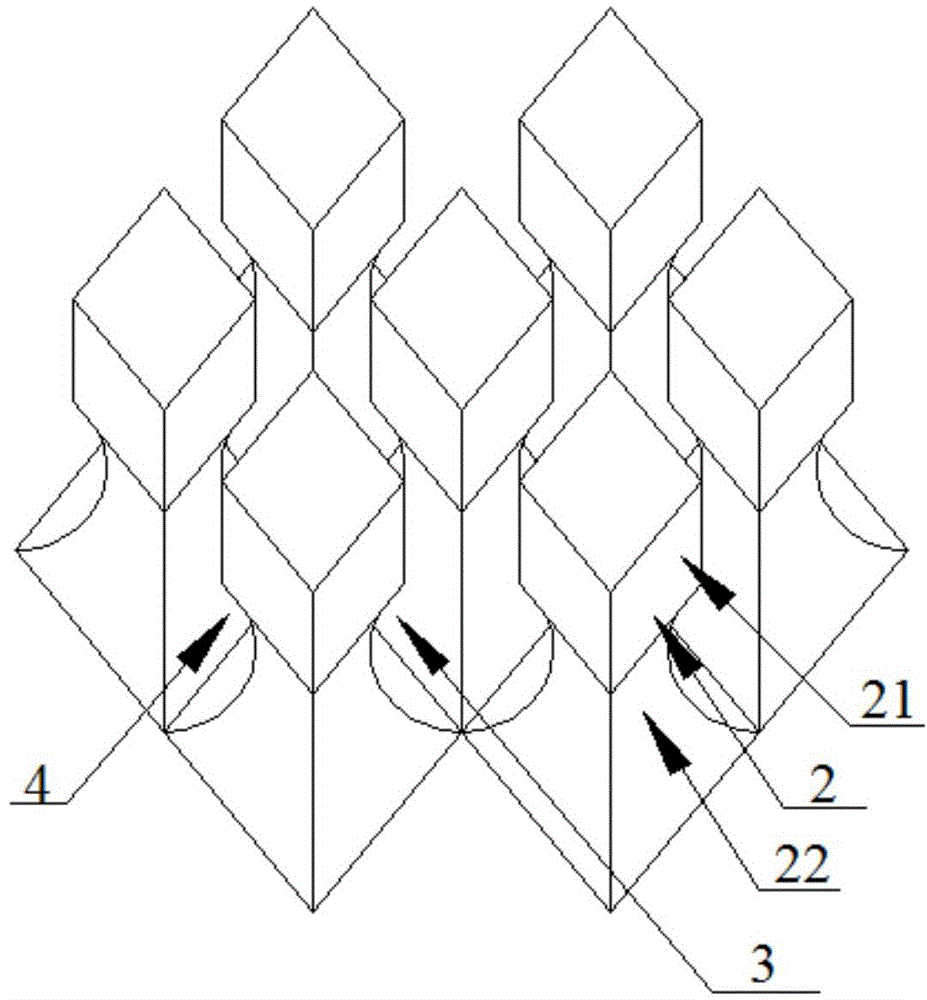

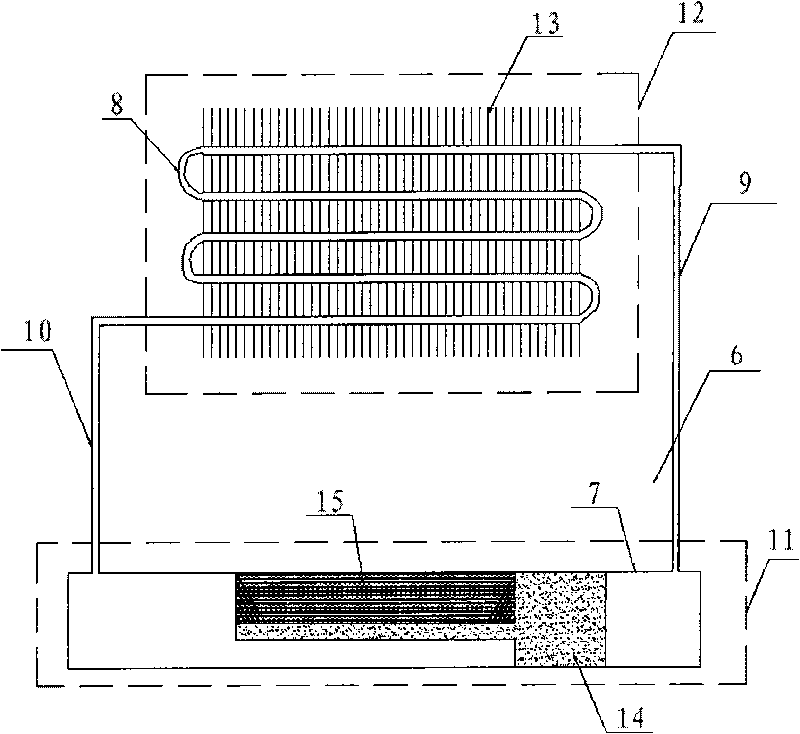

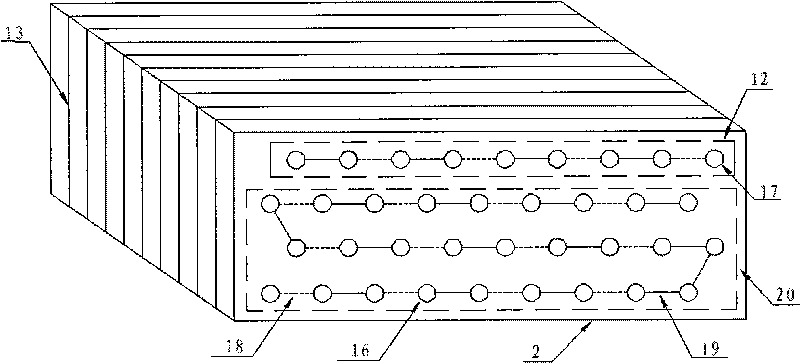

Flat heat pipe liquid suction core provided with fins and embedded grooves and manufacturing method thereof

InactiveCN104864755AIncrease disturbanceIncrease the heat exchange areaIndirect heat exchangersCapillary pressureMarine engineering

The invention discloses a flat heat pipe liquid suction core provided with fins and embedded grooves and a manufacturing method thereof. The flat heat pipe liquid suction core comprises a metal evaporation plate, wherein multiple first embedded grooves and multiple second embedded grooves which are arranged at intervals and distributed in a staggered mode in the first direction and the second direction and multiple fins distributed in an array mode are arranged on the evaporation face of the metal evaporation plate, and each first embedded groove and each second embedded groove respectively comprises a groove body forming a groove cavity and a vertical gap forming a groove opening. Each fin comprises a fin body and a supporting boss and is formed by the gaps and internal groove bodies of the corresponding first embedded groove and the corresponding second embedded groove in a staggered mode. The liquid suction core can increase heat exchange area, promote boiling for nucleus formation, enhance boiling heat transfer, improve capillary pressure and reduce backflow resistance. During manufacture, a ball-end milling cutter is utilized to mill the embedded grooves in the first direction, and a base plate is turned to mill the embedded grooves in the second direction and meanwhile form a fin structure. The flat heat pipe liquid suction core is simple in manufacturing process and low in machining cost and can remarkably strengthen heat transfer.

Owner:XIAMEN UNIV

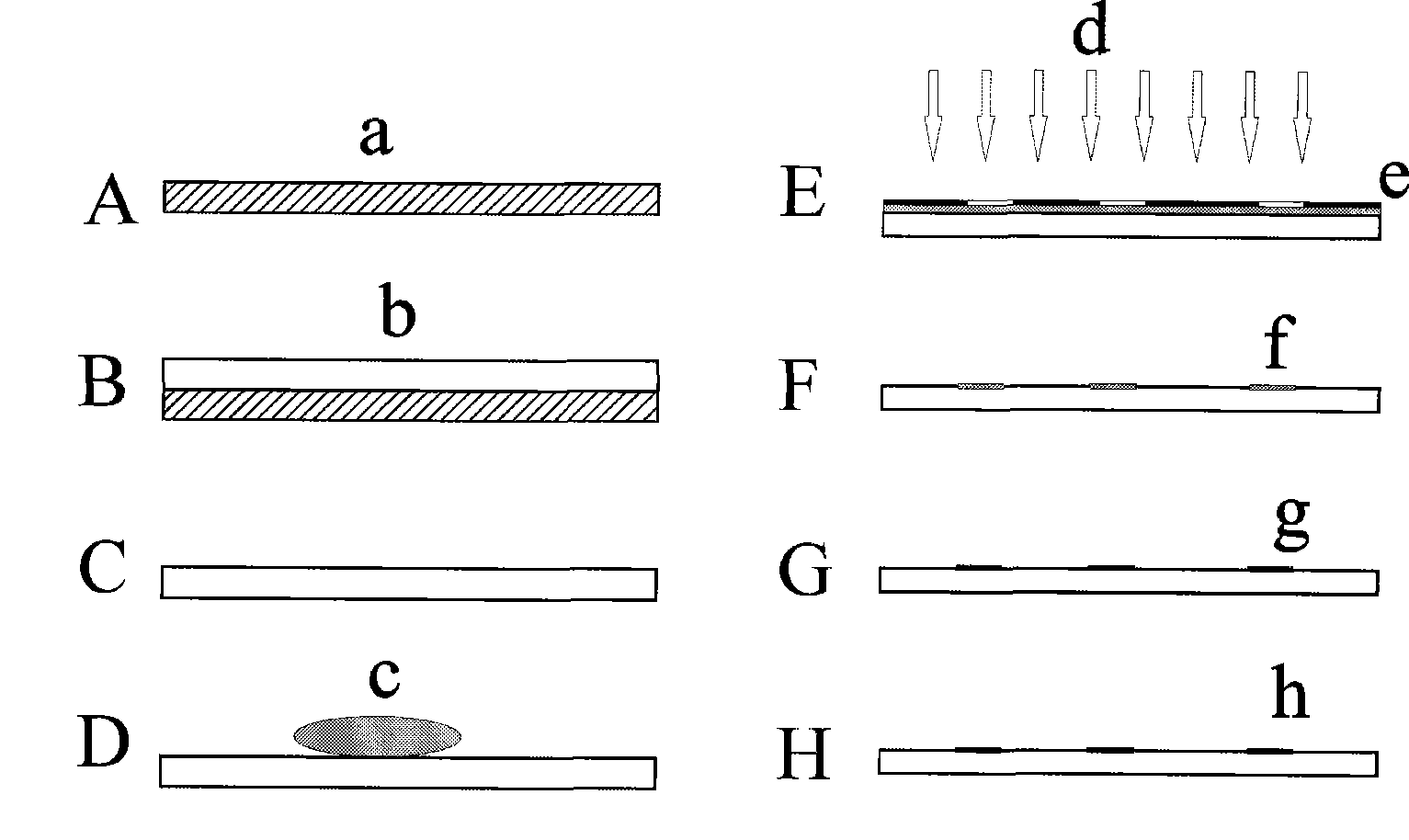

Method for deep-UV lithography making T type gate

The invention discloses a method for manufacturing a T-shaped grate by utilization of deep-UV lithography, comprising the following steps that: a substrate is cleaned and dried and then coated by chemical amplifying deep-UV photoresist; contraposition, alignment, exposure and development are performed by adoption of a deep-UV exposure machine, and a grate root photoresist window graph is formed initially; the photoresist window graph which is formed by exposure is shrunk by adoption of chemical shrinking solution; electron beam slushing compounds are coated; chemical amplifying deep-UV photoresist is coated; contraposition, alignment, exposure and development are performed by adoption of the deep-UV exposure machine; exposure and development are performed by adoption of deep-UV electron beam slushing compounds, and a grate cap photoresist window graph is formed; grate electrode metals are deposited by adoption of the metal evaporation method; the metals are peeled off and the photoresist is stripped, and then manufacture of the T-shaped grate is finished. The method makes a grate root of the T-shaped grate break through the manufacturing limit of superfine lines of a photoetching plate, saves the manufacturing cost of the photoetching plate and simultaneously can realize large-scale deep-submicron processing of compound semiconductor devices.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

CH3NH3PbI3 thin-film solar cell preparation method

InactiveCN104916785AImprove efficiencyExtend your lifeFinal product manufactureSolid-state devicesReaction rateVaporization

The invention relates to a preparation method for a CH3NH3PbI3 thin film and a solar cell thereof, which belongs to the field of novel material device manufacturing techniques. The CH3NH3PbI3 thin film preparation method comprises the steps that a CH3NH3PbI3 solution based (CH3COO)<2>Pb is used as a single evaporation source, a metal evaporation boat is heated rapidly to a temperature above 1000 DEG C in less than 1 second, and the CH3NH3PbI3 thin film with accurate components can be prepared. The CH3NH3PbI3 thin film prepared by adopting the single source reaction flash vaporization method has the advantages of fast reaction rate, fast evaporation rate, cavity-free property and long service life, and is suitable for manufacturing planar devices. Further, a p-i-n type planar solar cell deice is composed of TiO2 or ZnO which is adopted as n-type materials, Spiro-OMeTAD which is adopted as p-type materials and the i-type CH3NH3PbI3 thin film, and the device with the efficiency of 8.85% can be obtained after optimizing the preparation conditions.

Owner:SHAOXING UNIVERSITY

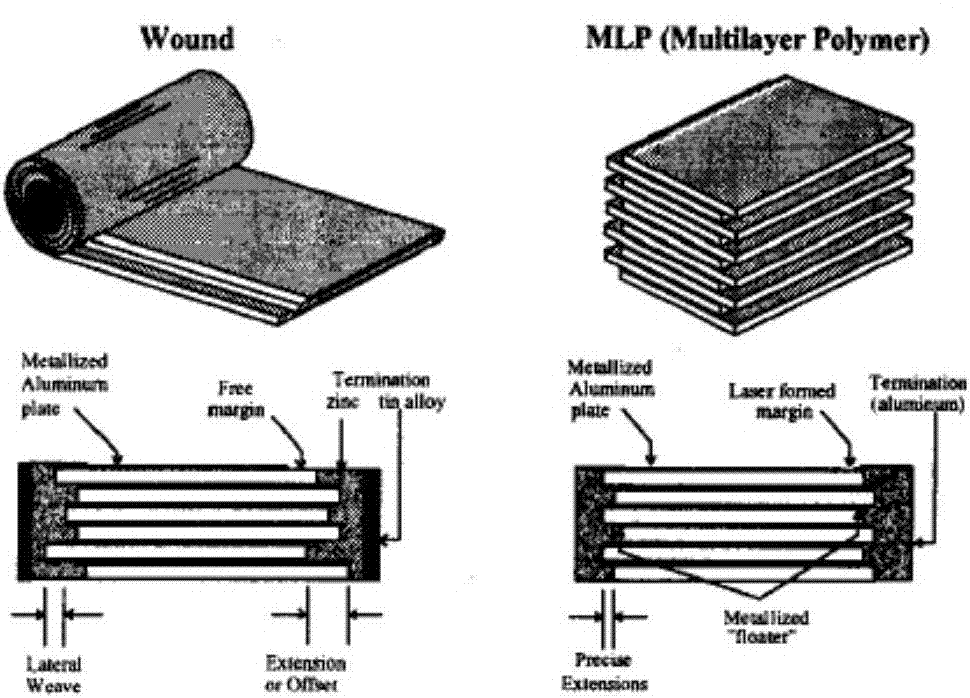

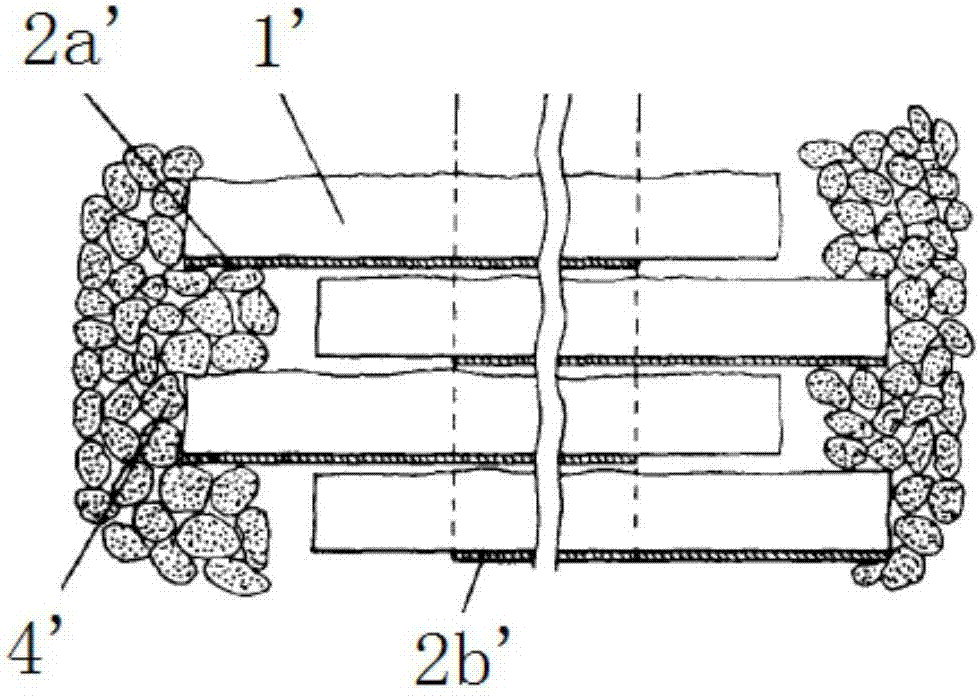

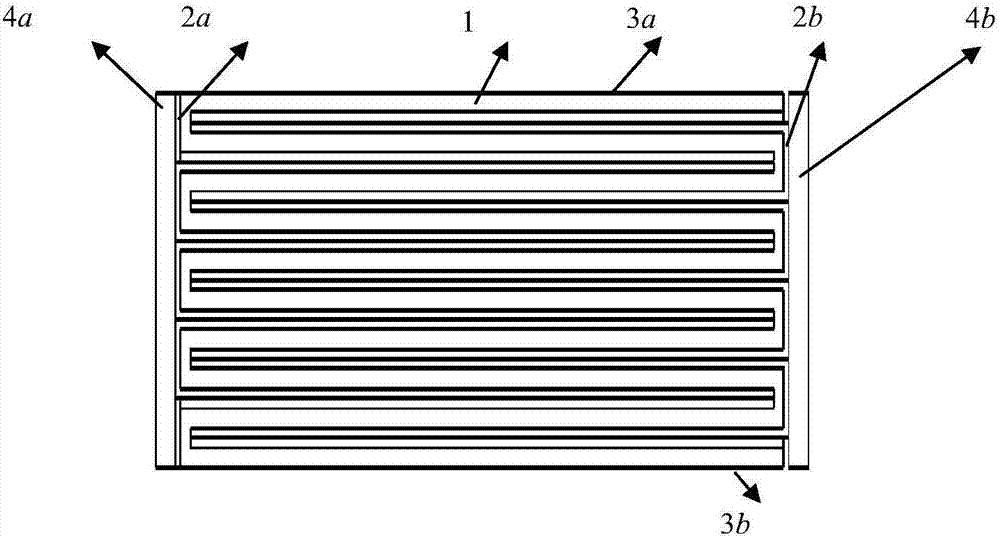

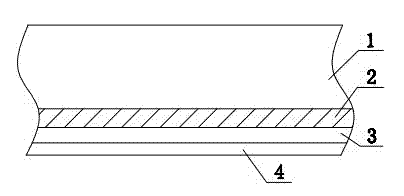

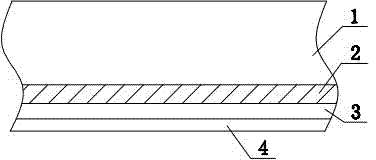

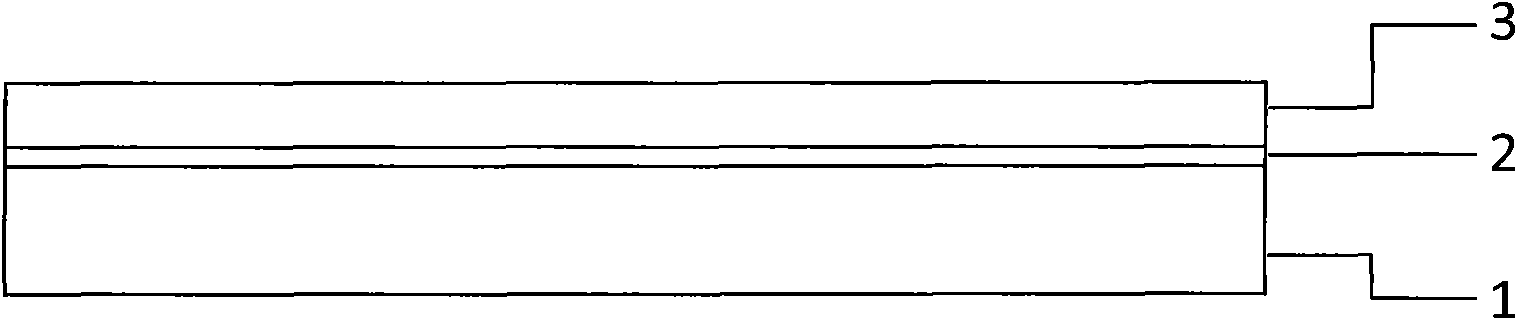

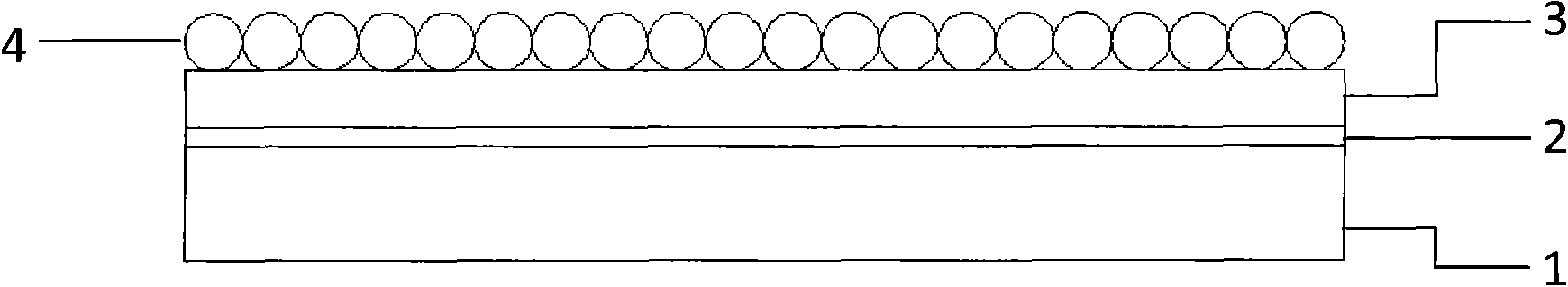

Folded thin film capacitor and fabrication method thereof

ActiveCN106935405AHigh energy storage densityInhibit sheddingThin/thick film capacitorStacked capacitorsPower flowInternal resistance

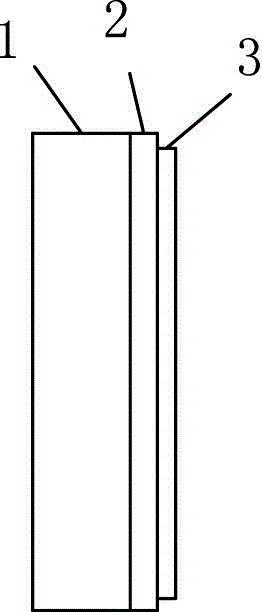

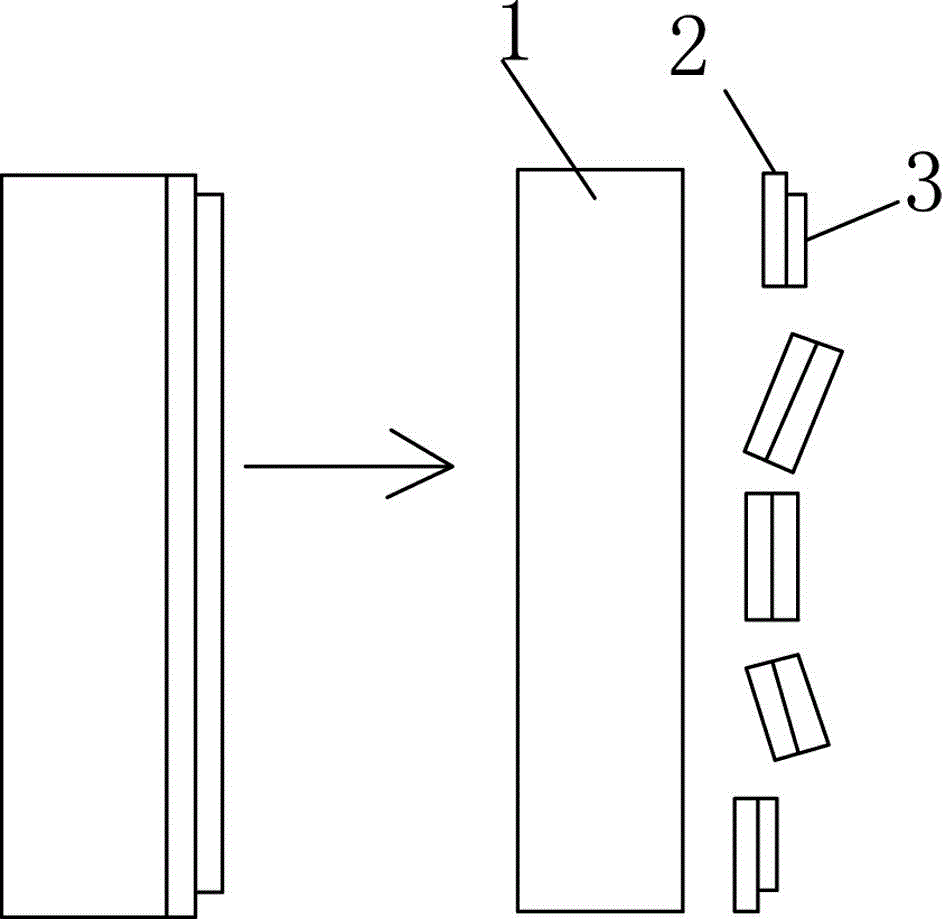

The invention provides a folded thin film capacitor and a fabrication method thereof. The folded thin film capacitor comprises a metal thin, two metal spraying layers (4a and 4b), two electrode terminals and a shell, wherein the two electrode terminals are respectively connected with the two metal spraying layers (4a and 4b), the folded thin film capacitor is characterized in that the metal film comprises a first metal evaporation film (2a), a second metal evaporation film (2b) and an electrical insulation polymer basic layer (1), the electrical insulation polymer basic layer (1) is sandwiched between the two metal evaporation films (2a and 2b), the metal film is repeatedly folded to form a cuboid block in a longitudinal direction, folded angles of the first metal evaporation film (2a) and the second metal evaporation film (2b) are superposed to respectively form a first side surface and a second side surface of the block, and the two metal spraying layers (4a and 4b) are respectively arranged on the first side surface and the second side surface. By the folded thin film capacitor and the fabrication method thereof, the problem that a metal spraying electrode at an end part of the thin film capacitor is seldom in contact with a metal film contact point is solved, heat generation of the end part of the capacitor is reduced, the internal inductance and the internal resistance of the capacitor are reduced, the lifetime of the capacitor is prolonged, and the folded thin film capacitor is particularly suitable for the field of large-current application.

Owner:SOUTHWEST JIAOTONG UNIV

Production method of semiconductor discrete device back side metal suitable for screen printing

ActiveCN102522326AWon't fall offVacuum evaporation coatingSputtering coatingScreen printingOhmic contact

The invention belongs to the semiconductor device manufacture field, concretely relating to a production method of semiconductor discrete device back side metal suitable for screen printing. Processing steps of the invention comprises: (1) pasting a film; (2) thinning a wafer through mechanical grinding; (3) removing stress corrosion; (4) carrying out wafer surface treatment before metal deposition; (5) removing a UV film pasted in step (1); (6) carrying out wafer back side metal evaporation. According to the invention, multilayer metal of a Cr / Ni / Ag structure is grown at a back side of the wafer, the multilayer metal and production technology of the above multilayer metal are different from a multilayer metal structure of a Ti / Ni / Ag structure and production technology of the multilayer metal structure of the Ti / Ni / Ag structure, since Cr is easy to form alloy with silicon at high temperature, under the premise that the metal and the silicon form ohmic contact, that the metal and the silicon do not drop off in welding is ensured, and a requirement of screen printing technology is met. According to the invention, the metal Ni can be substituted by metal NiV, and Ag can be substituted by Au.

Owner:HANGZHOU LION MICROELECTRONICS CO LTD

Manufacturing method of stress sensor based on nanorod diode piezoelectric effect

InactiveCN103794714ARealize the alarm functionPiezoelectric/electrostrictive device manufacture/assemblyForce measurement using piezo-electric devicesEtchingNanopillar

The invention discloses a manufacturing method of a stress sensor based on the nanorod diode piezoelectric effect. The method comprises the steps that an n-type layer, a multi-quantum-well active area and a p-type layer sequentially grow on a substrate, and a nanometer small ball array is assembled on the upper surface of the p-type layer; the nanometer small ball array is adopted as a mask, an LED structure is etched, the etching depth makes contact with the n-type layer, and a nanorod LED array is formed; transparent materials fill the gaps among the nanorod LED array; a metal conductive layer deposits on the surface of the nanorod LED array; part of the n-type layer is exposed through etching, and an n-type electrode and a p-type electrode are manufactured on the upper surface of the exposed n-type layer and the metal conductive layer through a metal evaporation method; a transparent rigid base plate is pressed on the part, not provided with the p-type electrode, of the surface of the metal conductive layer; the n-type electrode and the p-type electrode are communicated, and manufacturing of the stress sensor is finished.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

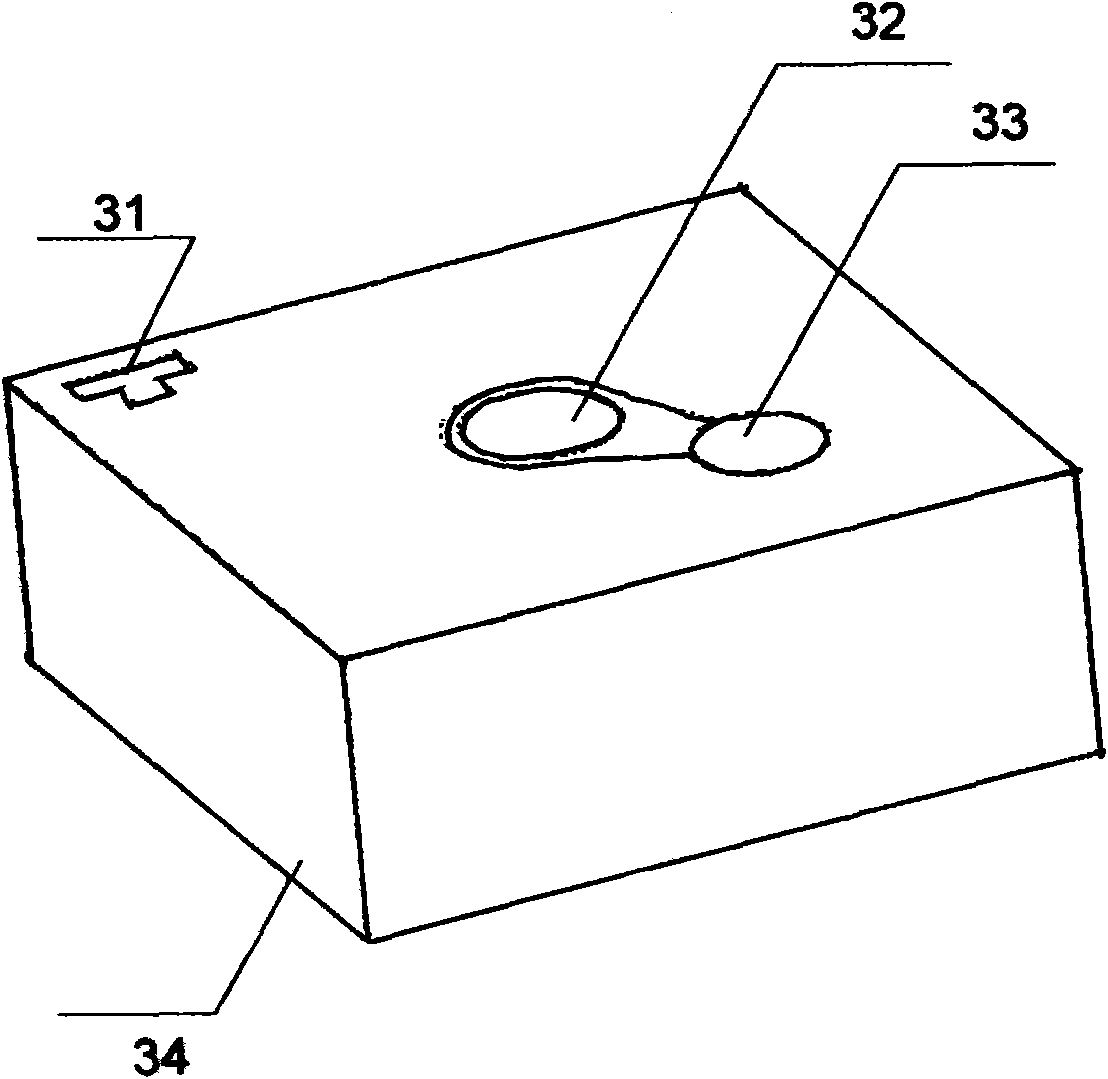

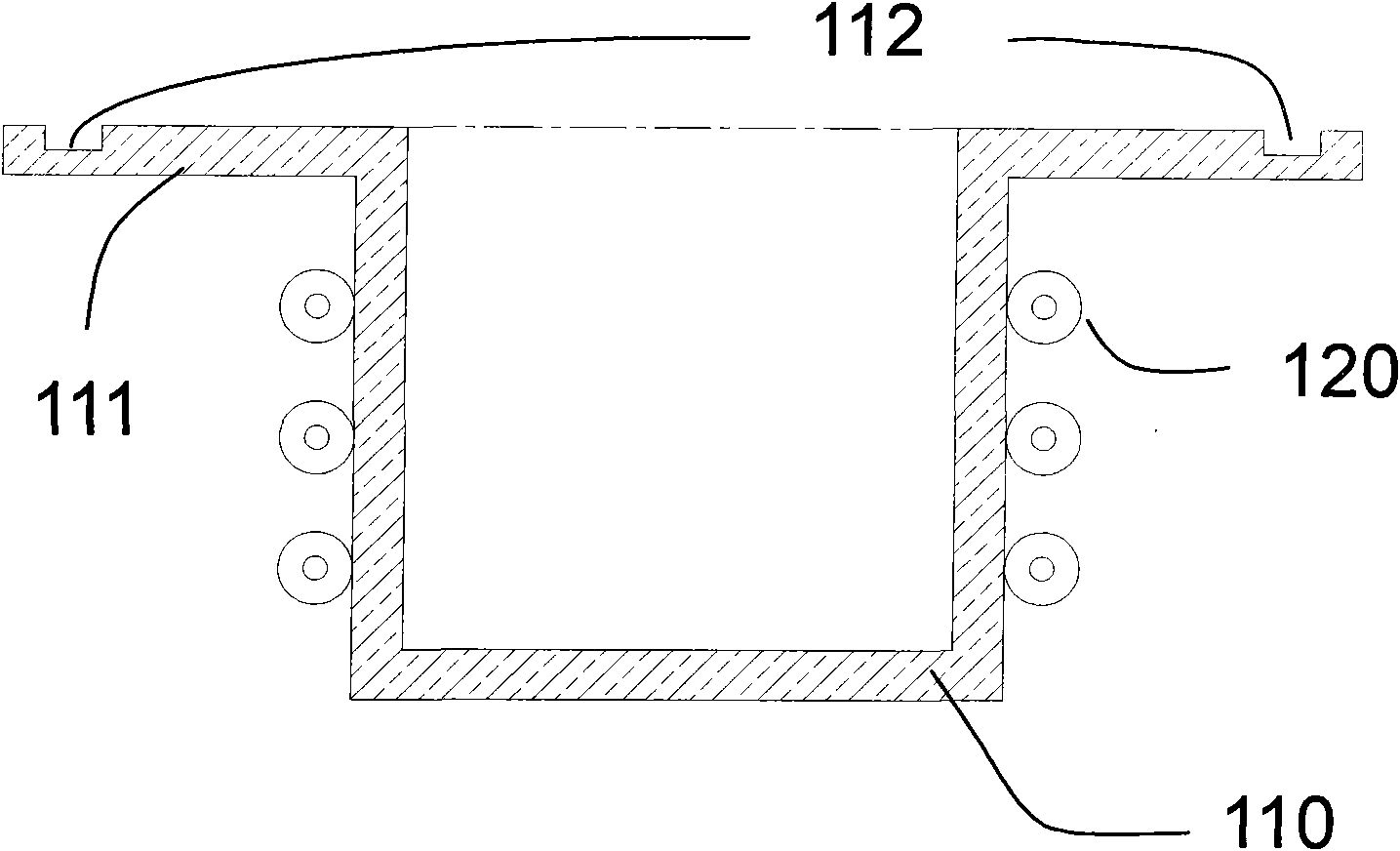

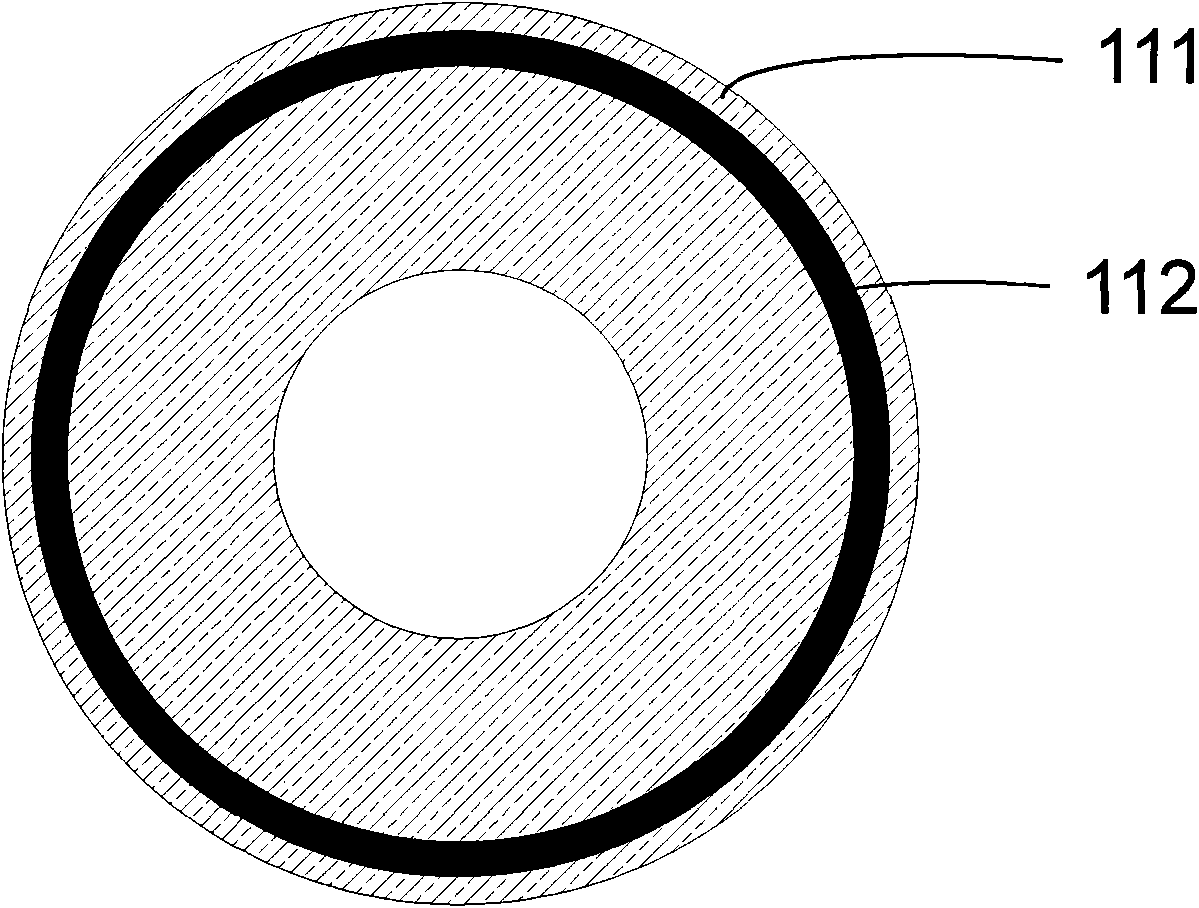

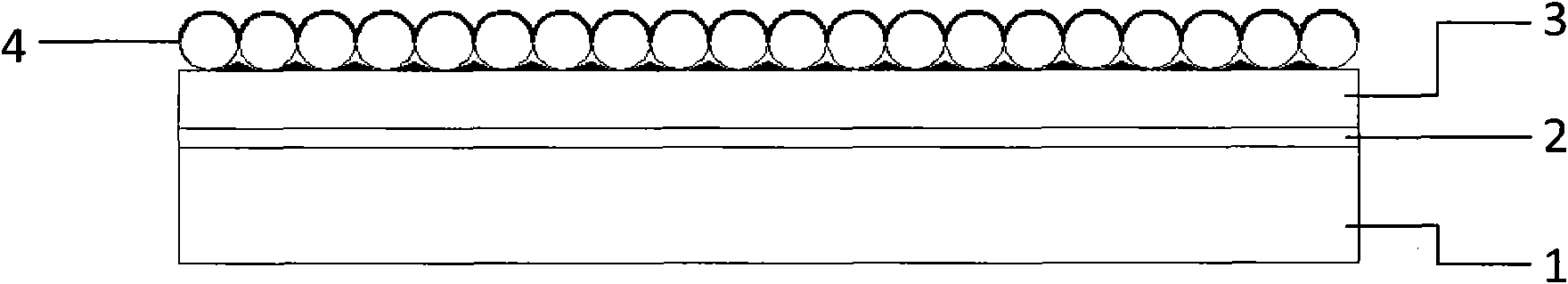

Metal evaporation crucible

InactiveCN102071398AWill not alloyMolten metal flowingVacuum evaporation coatingSputtering coatingMetal evaporationCurrent limiting

The invention relates to a metal evaporation crucible, which comprises a crucible container of which one end is open. The crucible is characterized in that: the open side of the crucible container is provided with an annular horizontal platform; the annular horizontal platform is provided with at least one annular current-limiting groove; the annular current-limiting groove is concentric with the annular horizontal platform and the crucible container and is positioned at the outer edge of the horizontal platform; the width of the annular horizontal platform is at least three times that of the cross section of a heater strip; the depth of the annular current-limiting groove is a half of the thickness of the annular horizontal platform; and the width of the annular current-limiting groove is smaller than the diameter of the heater strip. A relatively wide horizontal platform is provided, and the width of the horizontal platform is three or more times greater than the diameter of the cross section of the heater strip, so that metallic solution overflowing from the crucible body is prevented from contacting the heater strip hided below the horizontal platform after crossly surpassing the horizontal platform, and the situation of unstable heating caused by heating evaporation for the second time of the overflowing metallic solution is reduced.

Owner:INESA ELECTRON

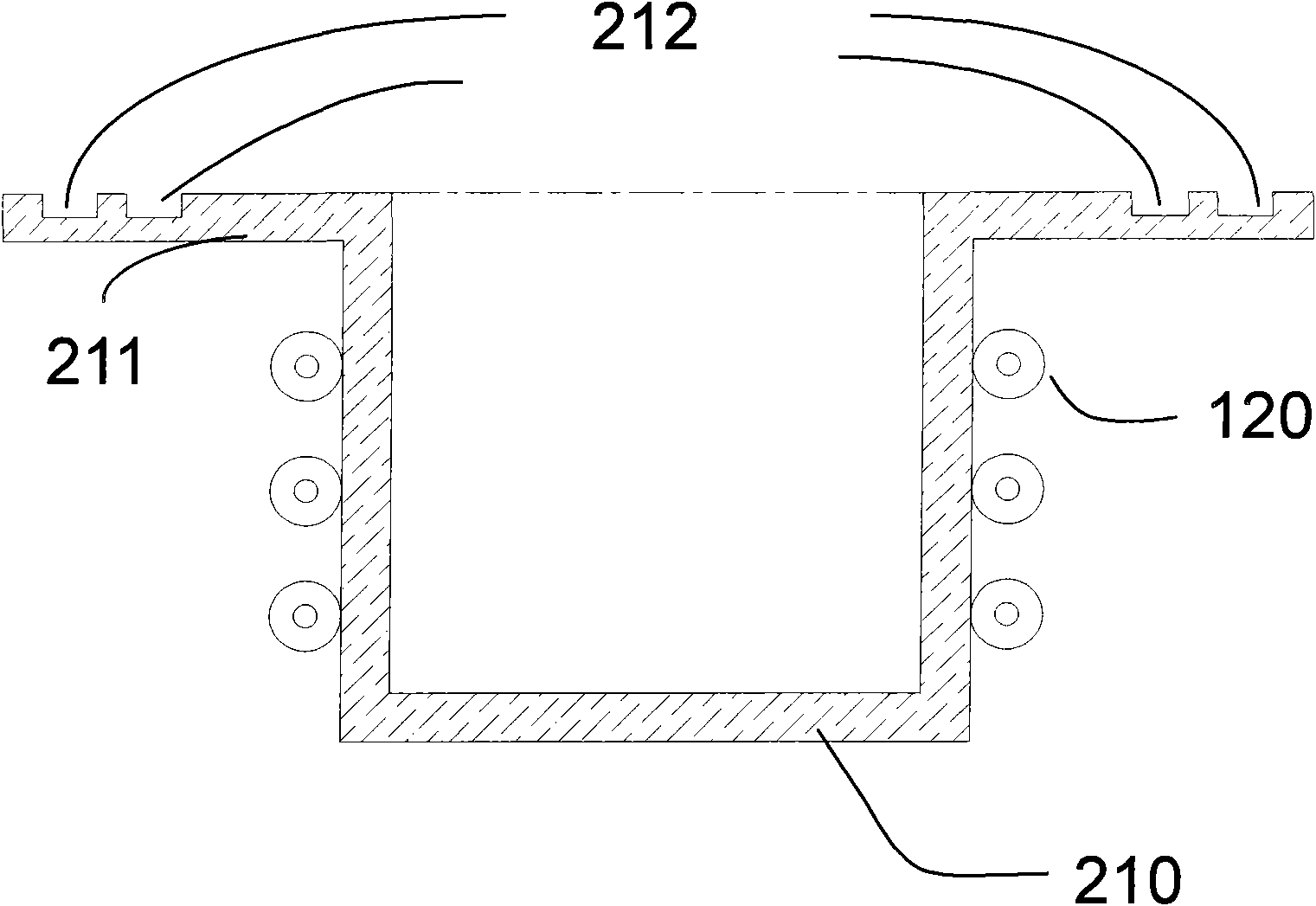

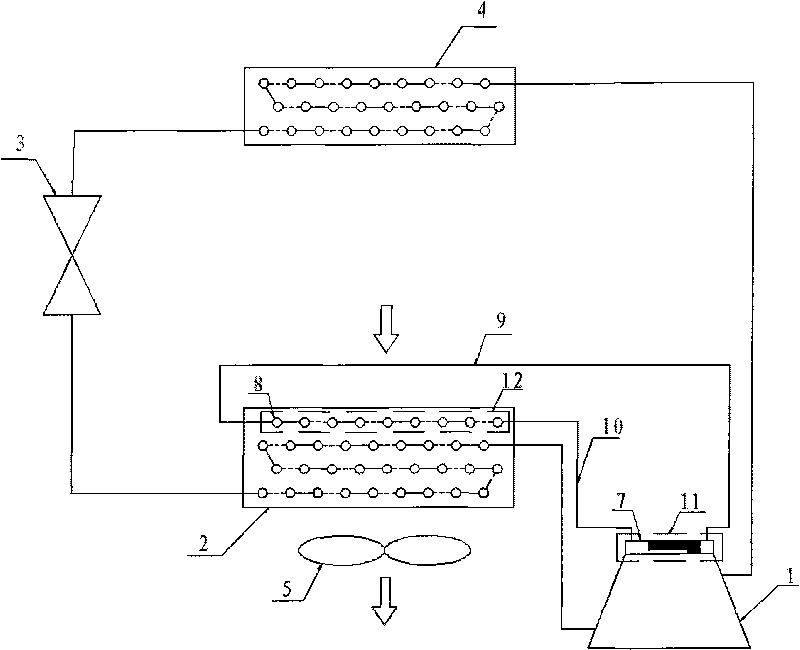

Air-cooling heat pump using excess heat of compressor for frost prevention

InactiveCN101699196AImprove performanceImprove winter coefficient of performanceCompressorHeat pumpsEngineeringExhaust pipe

The invention discloses an air-cooling heat pump using the excess heat of a compressor for frost prevention, comprising a refrigeration agent loop, a flat panel loop heat pipe and an outdoor unit fan; wherein the refrigeration agent loop is formed by the compressor, an outdoor heat exchanger, a throttling device and an indoor heat exchanger; an exhaust pipe of the compressor is connected with an inlet of the indoor heat exchanger, and an outlet of the indoor heat exchanger is connected with an inlet of the throttling device; an outlet of the throttling device is connected with an inlet of the outdoor heat exchanger, and an outlet of the outdoor heat exchanger is connected with an air suction pipe of the compressor; the flat panel loop heat pipe is formed by a metal evaporation cavity, a condensation part, a vapor phase metal pipeline, a liquid phase metal pipeline and a metal heat dissipation fin; when in heating operation in the winter, the air-cooling heat pump clings to the metal evaporation cavity on the top of the compressor to be heated under the condition of needing no extra power, a working medium inside the cavity is evaporated and vaporized, and the heat is brought to the condensation part and used for heating the air at the inlet of the outdoor heat exchanger, so that frost formation can be prevented.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing GaN-based pattern substrate template based on anodized aluminum

InactiveCN101807518AImprove orderEasy to makeSemiconductor/solid-state device manufacturingMicrosphereTemplate based

The invention relates to a method for preparing a GaN-based pattern substrate template based on anodized aluminum. The method comprises the following steps: growing a GaN-based template on a substrate; depositing an aluminium layer on the GaN-based template; laying a microsphere layer on the surface of the aluminum layer; performing metal evaporation on the substrate; removing the microsphere layer in a monolayer structure through ultrasonic vibration to obtain a patterned metal layer; etching pits on the surface of the aluminium layer by utilizing the metal layer as a mask; removing the metal layer and forming a porous aluminium oxide layer; transferring the pattern on the aluminium oxide layer to the GaN-based template by taking the porous aluminium oxide layer as the mask; and removing the porous aluminium oxide layer to obtain the GaN-based material pattern substrate template. The method for preparing a micron GaN-based pattern substrate has the characteristics of simple process, low cost and controllable size and distance of the pattern pits.

Owner:SUN YAT SEN UNIV

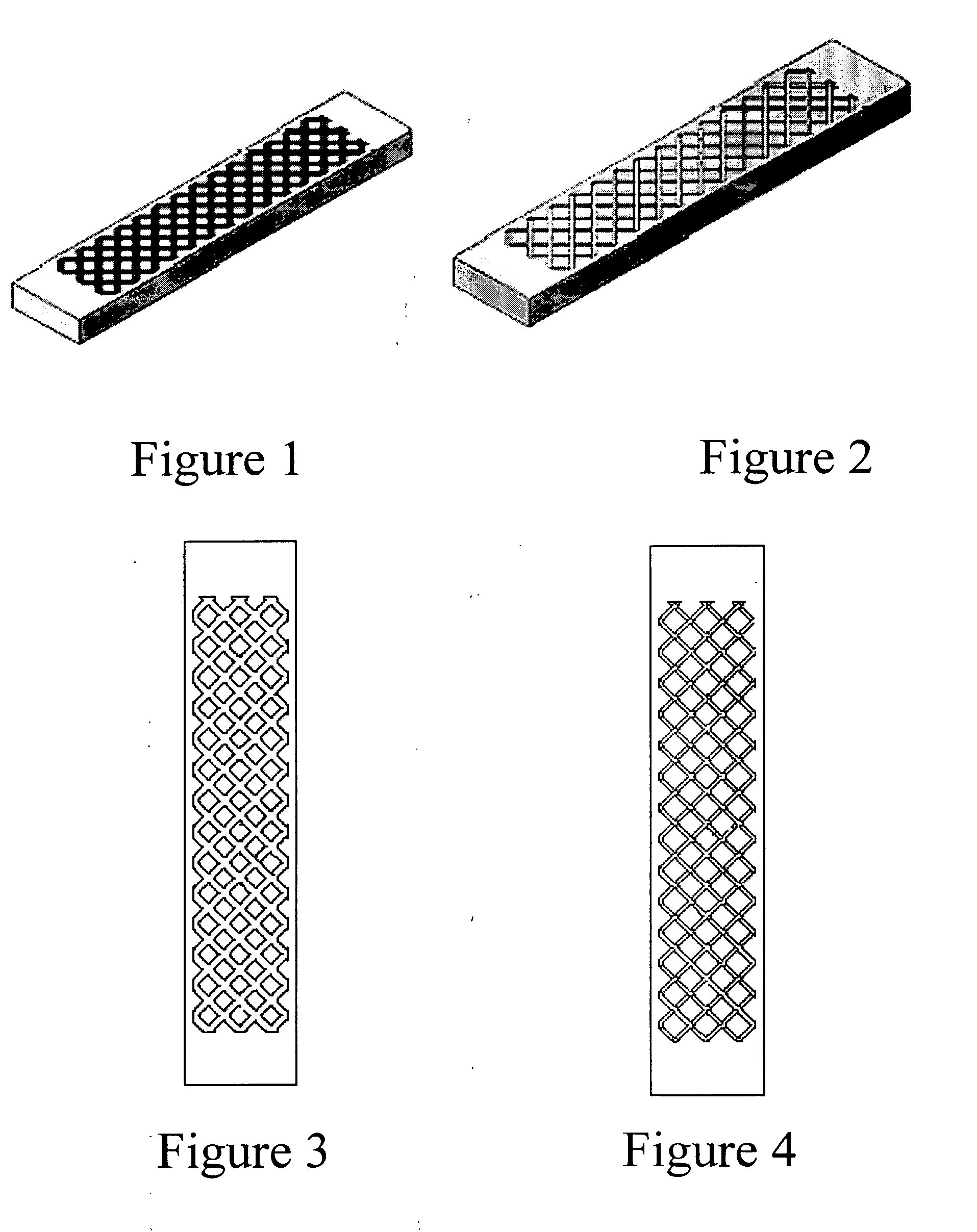

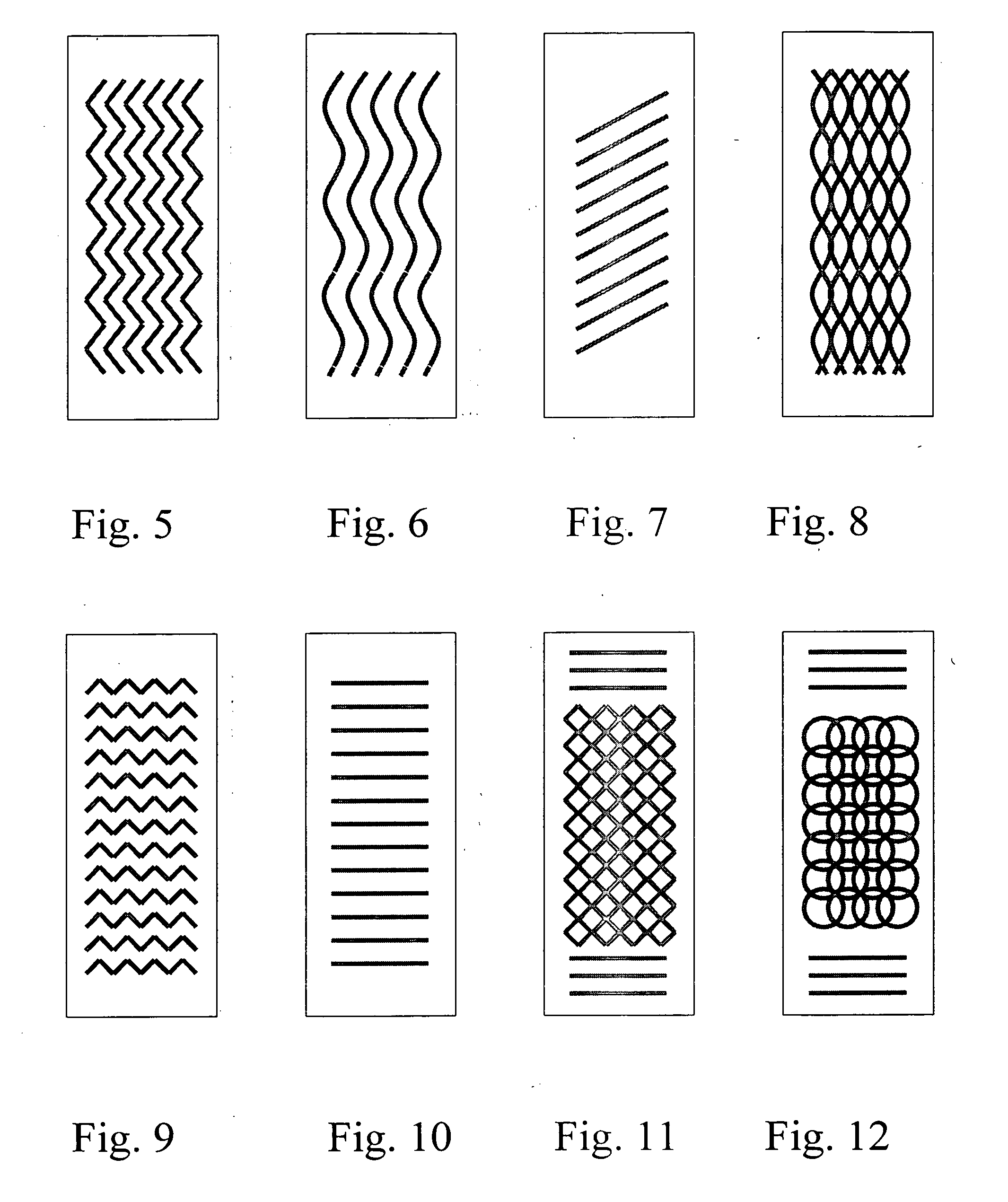

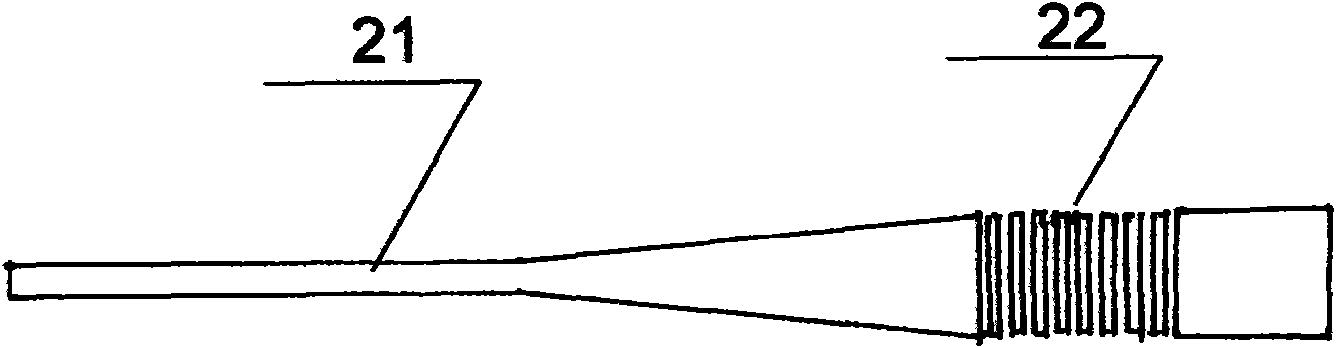

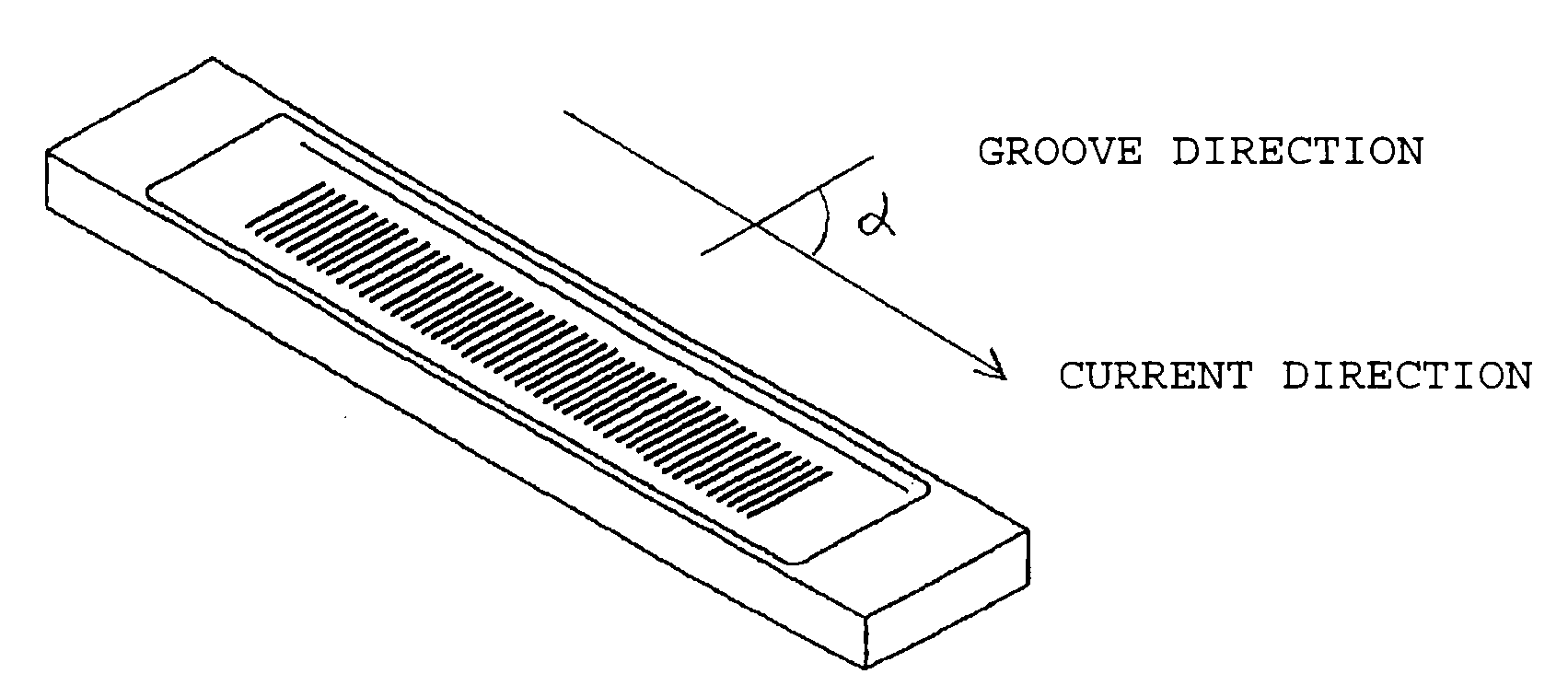

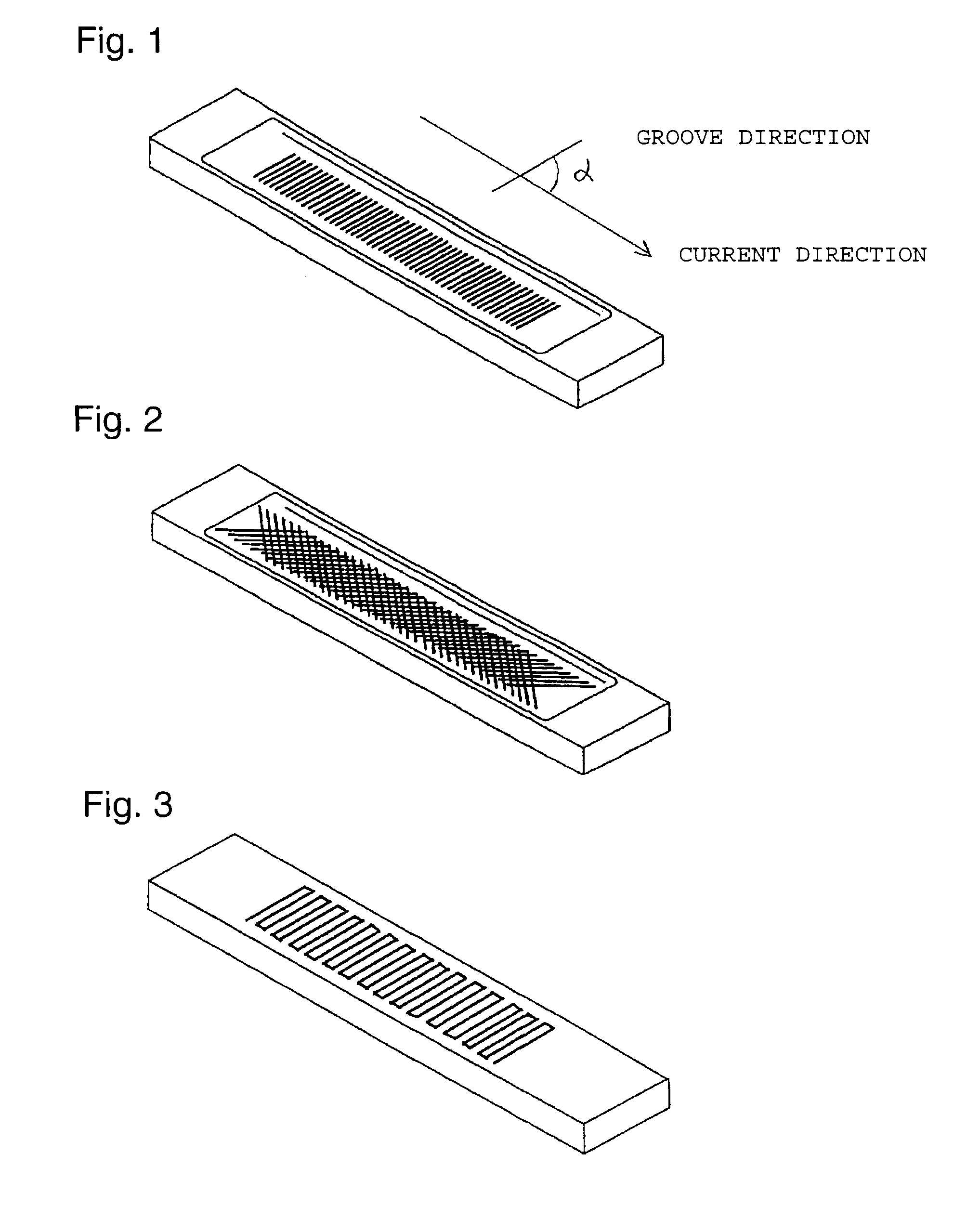

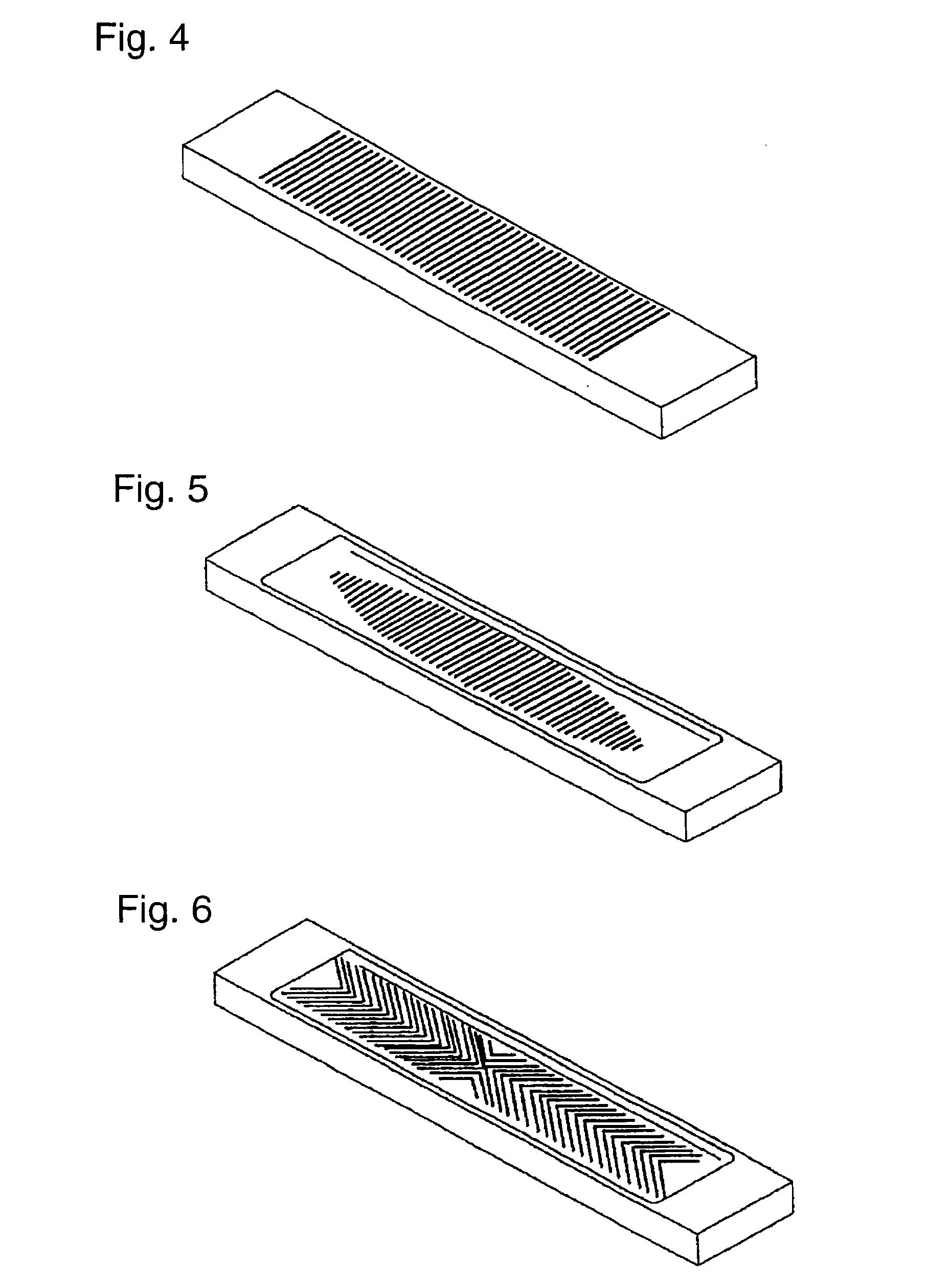

Metal Evaporation Heating Element and Method for Evaporating Metal

InactiveUS20080245305A1Improve wettabilityProlong lifeThermal drillingVacuum evaporation coatingCeramic sinteringBoron nitride

A metal evaporation boat having improved wettability to a molten metal and having a prolonged life, and a method for evaporating a metal employing it.A metal evaporation heating element characterized by having one or more grooves in a direction not in parallel with a current direction, on an upper surface of a ceramic sintered body comprising titanium diboride (TiB2) and / or zirconium diboride (ZrB2), and boron nitride (BN). It is preferred that the direction not in parallel with the current collection is from 20 to 160° C. to the current direction, that the ceramic sintered body has a cavity and the groove is formed on the bottom surface thereof, and that a predetermined pattern is drawn by a plurality of grooves on the upper surface of the ceramic sintered body and / or on the upper surface of the cavity. In addition, a method for evaporating a metal characterized by using the metal evaporation heating element and heating a metal in vacuum in a state where part or whole of the groove is in contact with the metal.

Owner:DENKA CO LTD

Method for regenerating scrap magnets

InactiveCN101952915AExcellent magnetic propertiesVacuum evaporation coatingSputtering coatingPresent methodRare earth

In an example of a conventional method, the regeneration of sintered magnets is achieved by means of a number of processes involving solvent extraction etc. As a result, productivity is poor and, since a number of solvents such as hydrofluoric acid and the like are used, the cost is high. The present method includes the following steps: a step in which scrap iron - boron - rare earth sintered magnets are recovered and pulverized and recovered raw material powder is obtained; a step in which a sintered compact is obtained from said recovered raw material powder using a powder metallurgical method and a step in which said sintered compact is arranged in a treatment chamber and heated, and a material for metal vaporization purposes containing at least one of Dy and Tb which is arranged in the same or another treatment chamber is vaporized, and vaporized metal atoms are deposited on the sintered magnet surface while the amount of said atoms which are being supplied is controlled, and the deposited metal atoms are diffused into the crystal grain boundaries and / or crystal grain boundary phase of the sintered compact.

Owner:ULVAC INC

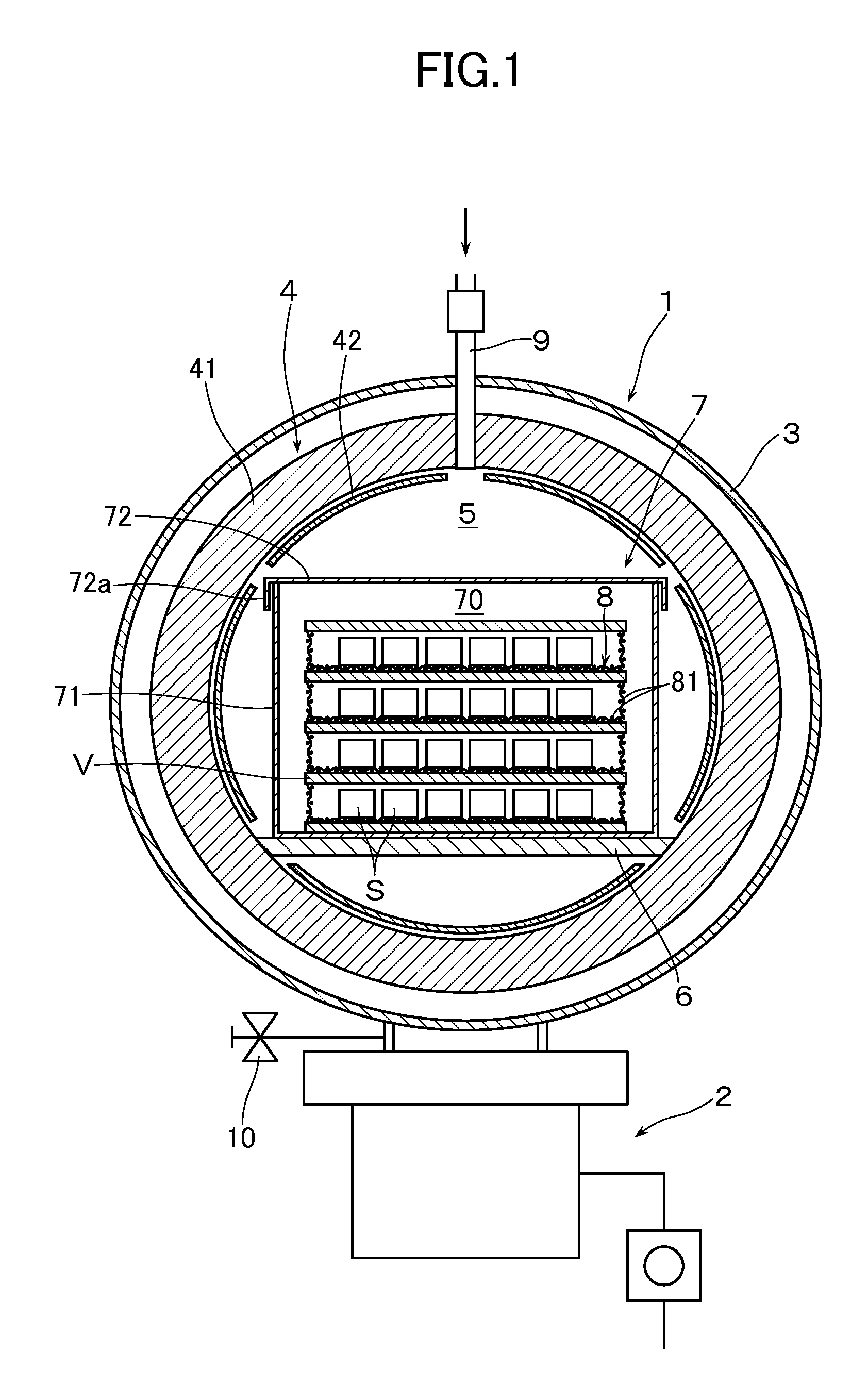

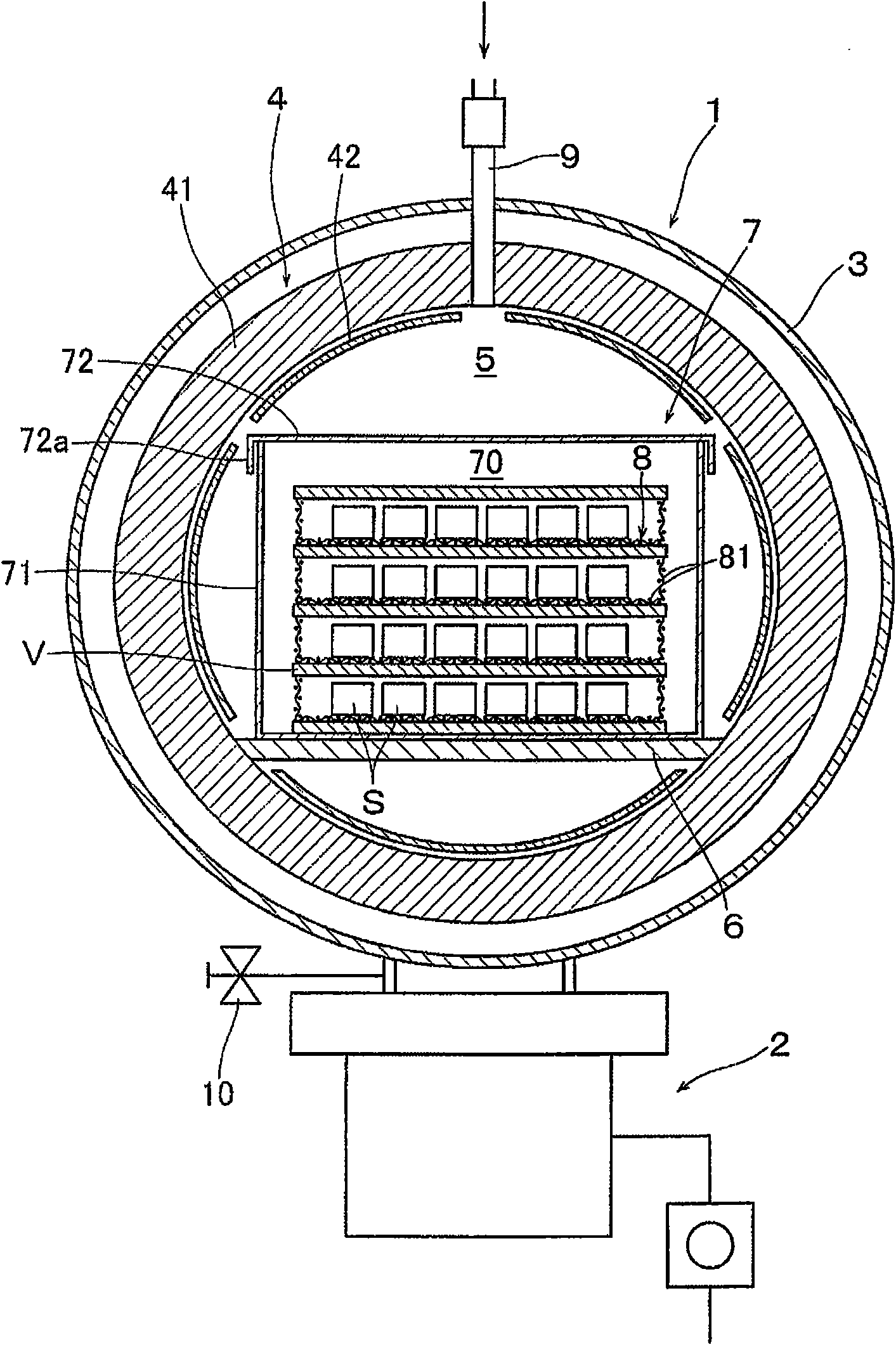

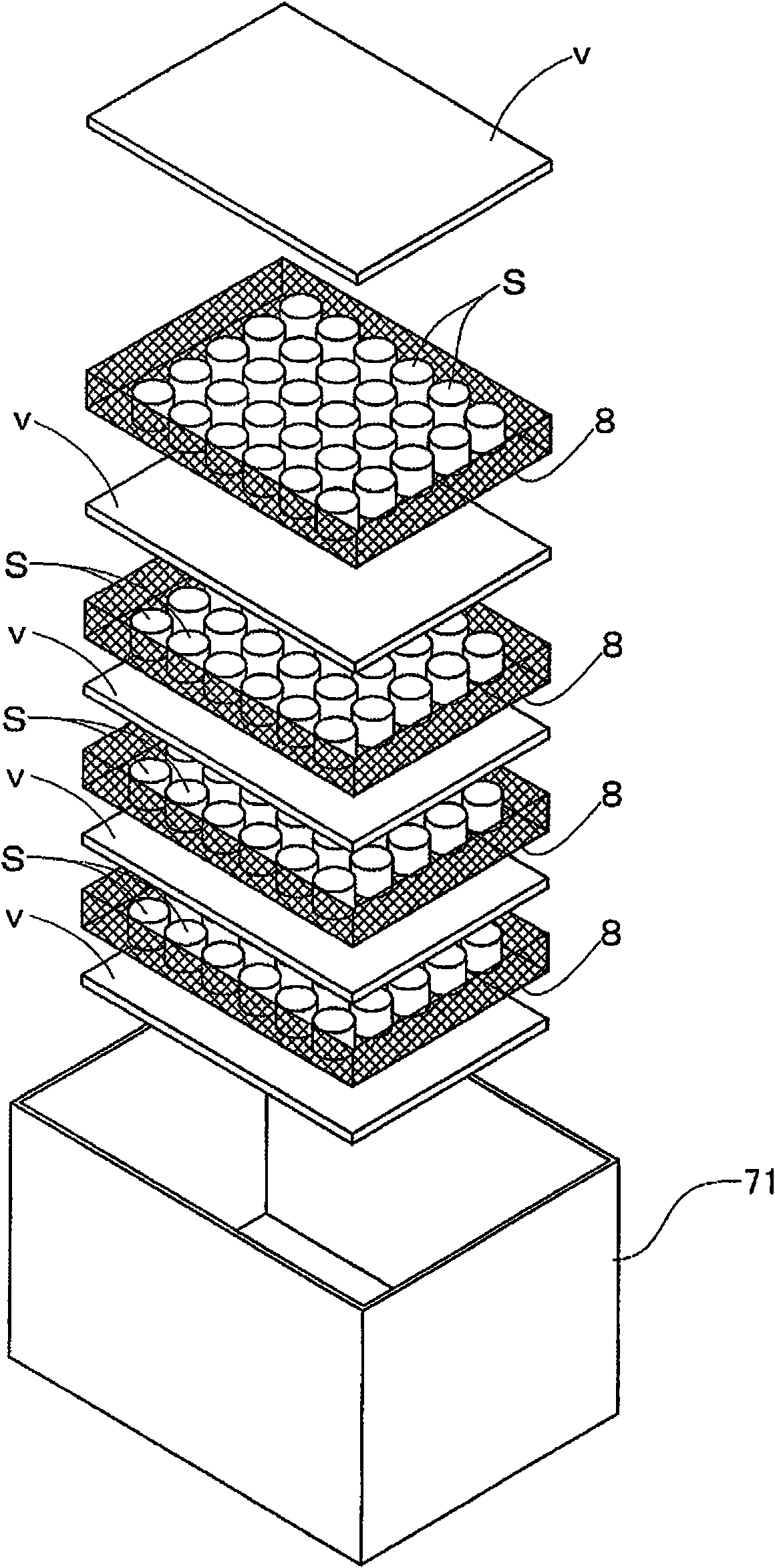

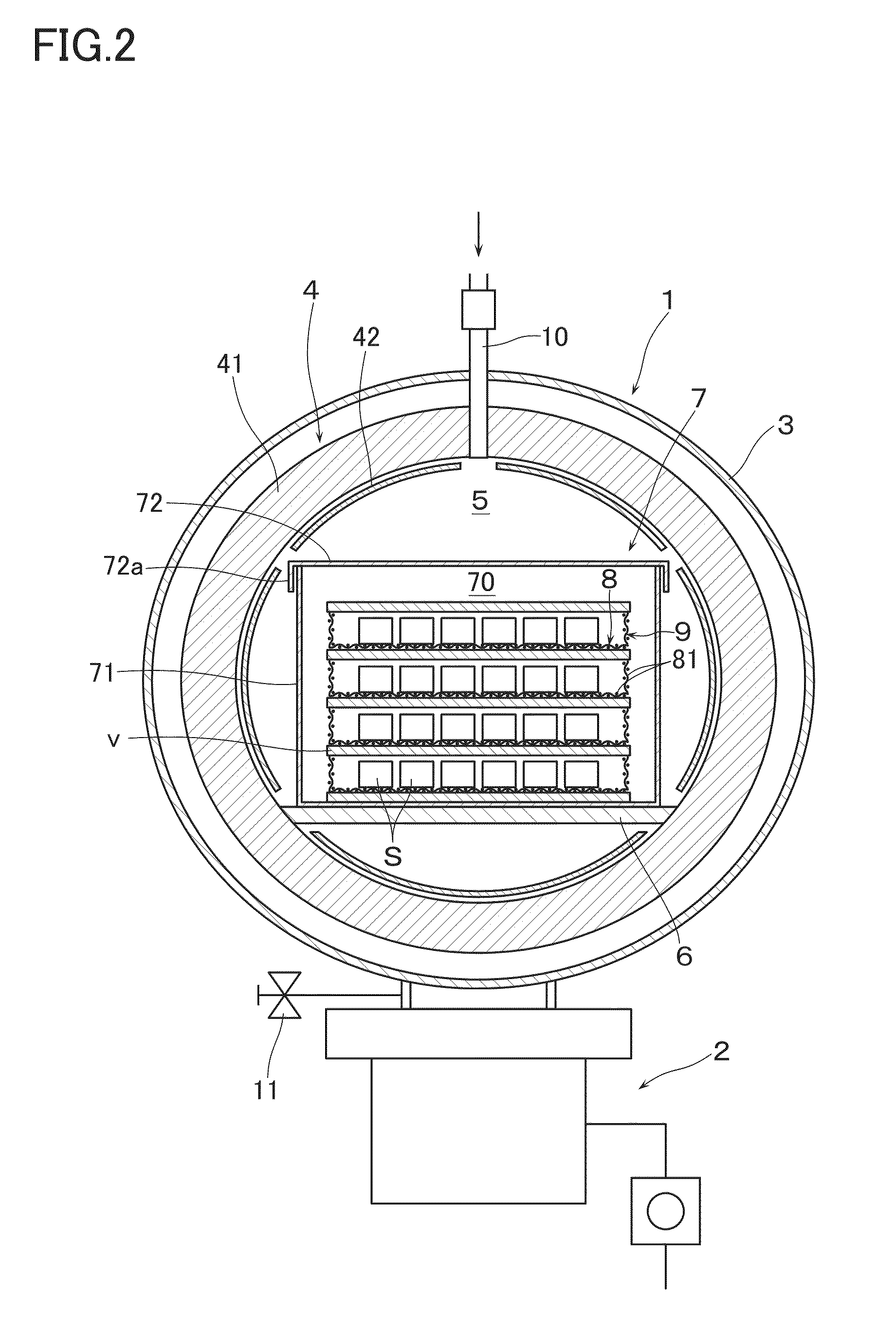

Method of manufacturing permanent magnet and permanent magnet

InactiveUS20100239878A1Effectively been improved or recoveredImprove corrosion resistanceMuffle furnacesCharge supportsSintered magnetsVacuum chamber

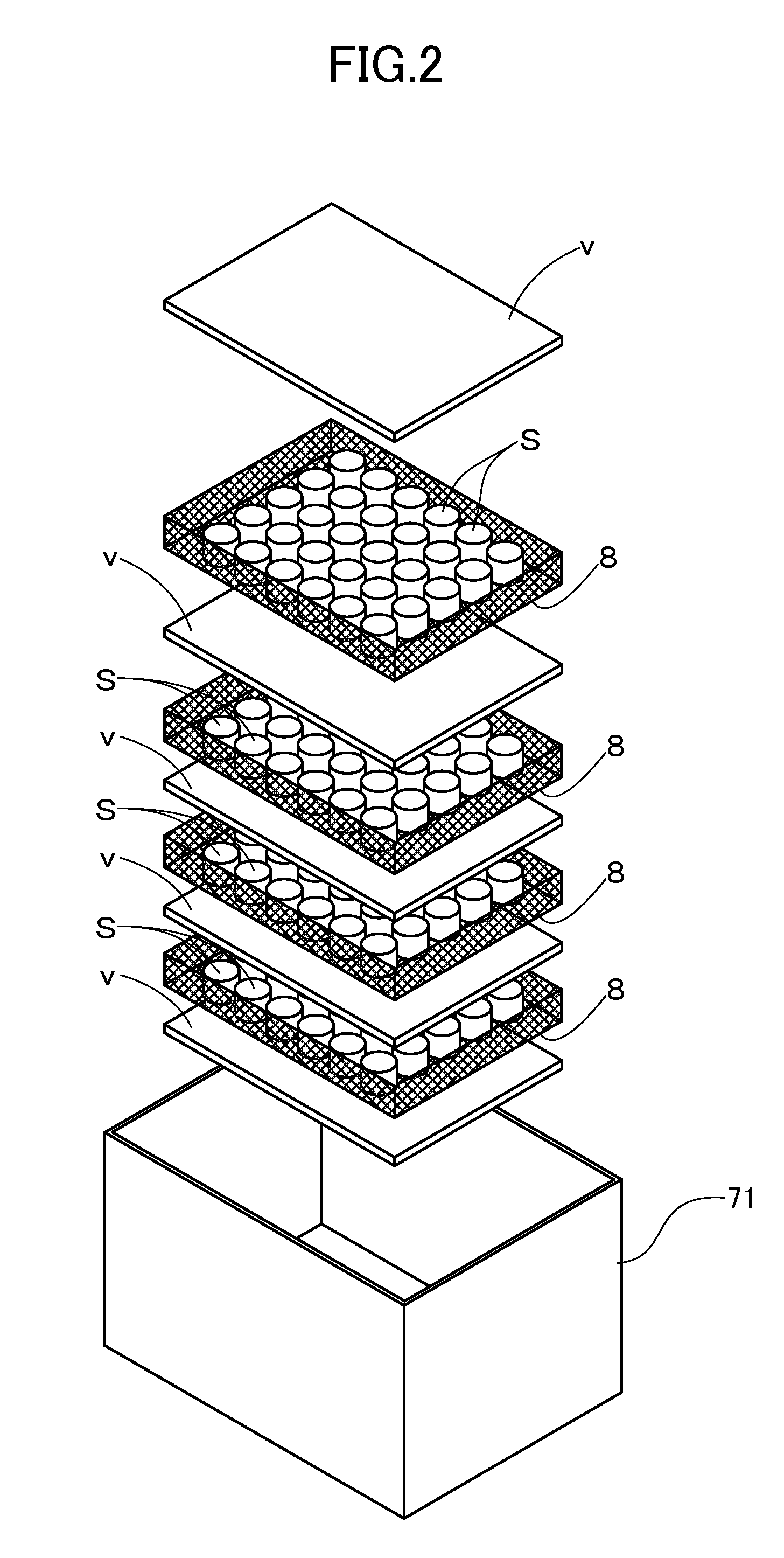

High-performance magnets are obtained by: housing metal evaporating materials (v) containing at least one of Dy and Tb and sintered magnets (S) inside a processing box; disposing the processing box inside a vacuum chamber; thereafter, heating the processing box to a predetermined temperature in a vacuum atmosphere to thereby evaporate the metal evaporating materials and cause them to be adhered to the sintered magnets. The metal atoms of the adhered Dy or Tb are diffused into grain boundaries and / or grain boundary phases of the sintered magnets. A method of manufacturing a permanent magnet is provided in which, even if the sintered magnets and the metal evaporating materials are disposed in close proximity to each other, the squareness of demagnetization curve is not impaired and in which high feasibility of mass production can be attained. While the metal evaporating materials are being evaporated, an inert gas is introduced into the processing chamber in which the sintered magnets are disposed.

Owner:ULVAC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com