Preparation method of organic and inorganic hybridization perovskite material growing by single-source flash evaporation method and plane solar cell of material

A perovskite material, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of unsuitability for large-scale production, complex control of dual-source methods, slow evaporation rate, etc., to achieve easy large-scale production, Reproducible, easy-to-manipulate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing an organic-inorganic hybrid perovskite material grown by a single-source flash evaporation method and a planar solar cell has the following process and steps:

[0032] (1) The transparent conductive glass SnO 2 : F as a deposition substrate, first use triton to clean the surface, then rinse off the residual triton on the surface with clear water, then use acetone to ultrasonically clean for 15 minutes, then rinse the surface with deionized water, and then use ethanol to ultrasonically clean After 15 minutes, rinse the surface with deionized water and dry it. Finally, UV-ozone treatment was used for 10 minutes.

[0033] (2) Transparent conductive glass SnO after pretreatment 2 :F, using magnetron sputtering method to deposit TiO 2 , this process uses high-purity TiO 2 As a sputtering target, first pump the sputtering chamber to 5×10 -3 Pa, and then enter Ar gas, the sputtering pressure is kept at 0.6Pa, the sputtering power is 150W, and the s...

Embodiment 2

[0039] Steps (1), (2) and (3) of this embodiment are exactly the same as in Example 1, the difference is that

[0040] (4) put CH 3 NH 3 PB 3 The solution was spread evenly on the molybdenum sheet. The air pressure in the evaporation chamber is lower than 5×10 -3 Pa, filled with nitrogen, so that the evaporation chamber pressure is maintained at 0.6Pa. Under the condition that the temperature of the sample substrate is room temperature, the perovskite film is evaporated by flash evaporation method. The temperature of the perovskite material is rapidly raised to 1000°C within 1 second, the current used is 230 amperes, and the entire evaporation time is 5 seconds.

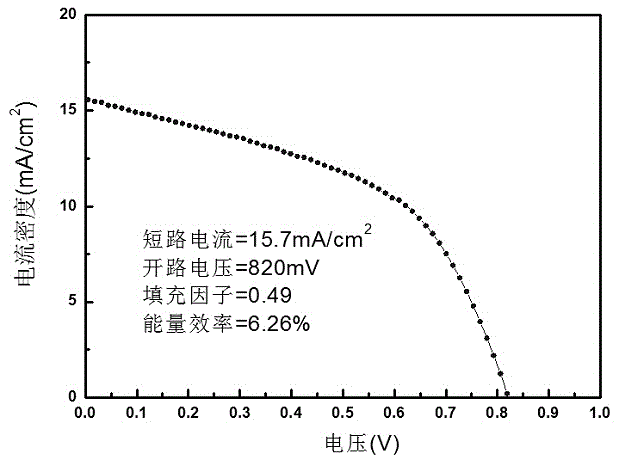

[0041] (5) Spin-coat the hole transport layer Spiro-OMeTAD on the vapor-deposited perovskite film material, and then vapor-deposit a silver electrode with a size of 2*2cm to complete the preparation of the perovskite solar cell.

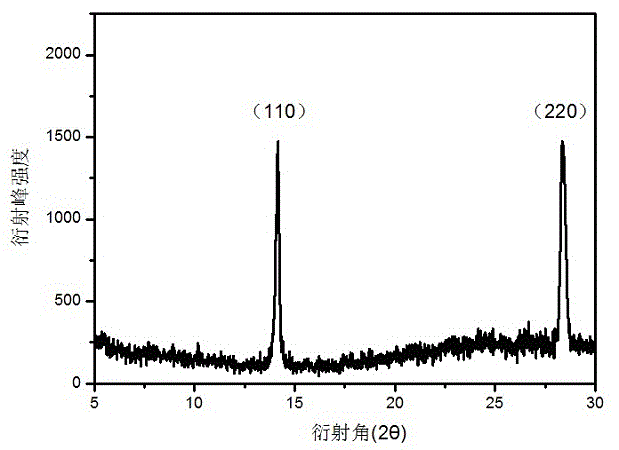

[0042] In the step (4), after passing nitrogen gas, a larger uniform organic-ino...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com