Flat heat pipe liquid suction core provided with fins and embedded grooves and manufacturing method thereof

A technology of a flat heat pipe and a manufacturing method, which is applied to indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of uncontrollable groove-hole structure shape, poor boiling heat transfer performance, small capillary radius, etc., and achieve improved boiling Effects of heat transfer performance, reduction of penetration resistance, and reduction of capillary radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the accompanying drawings and examples; however, the flat heat pipe wick with fins and embedded grooves and its manufacturing method of the present invention are not limited to the examples.

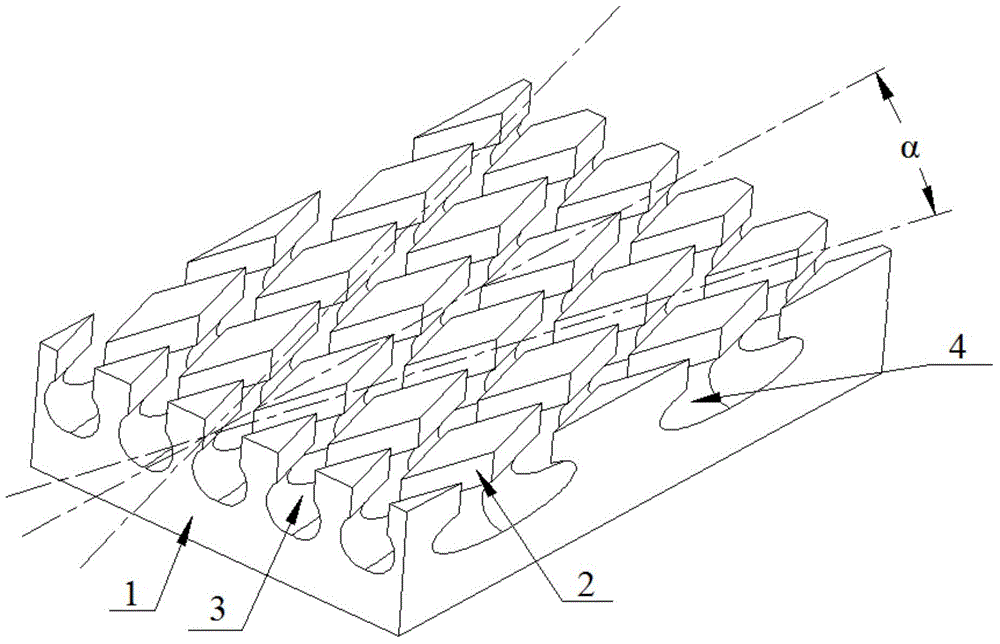

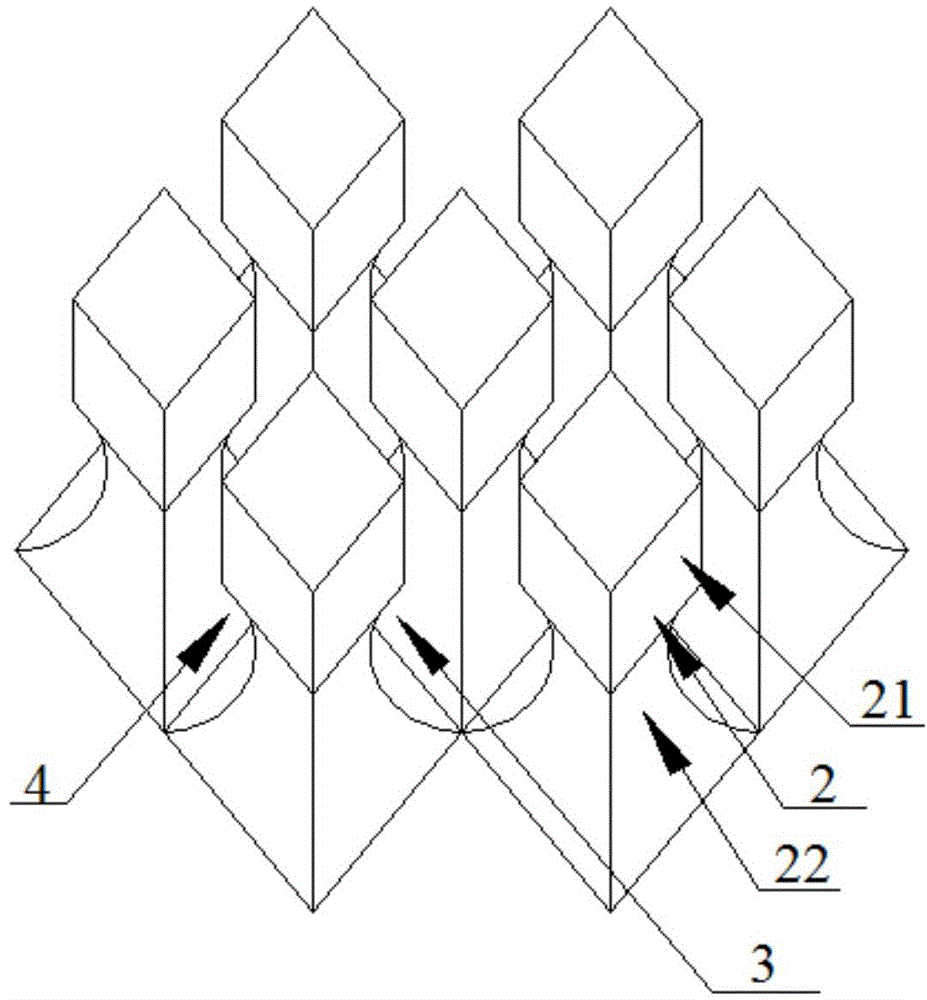

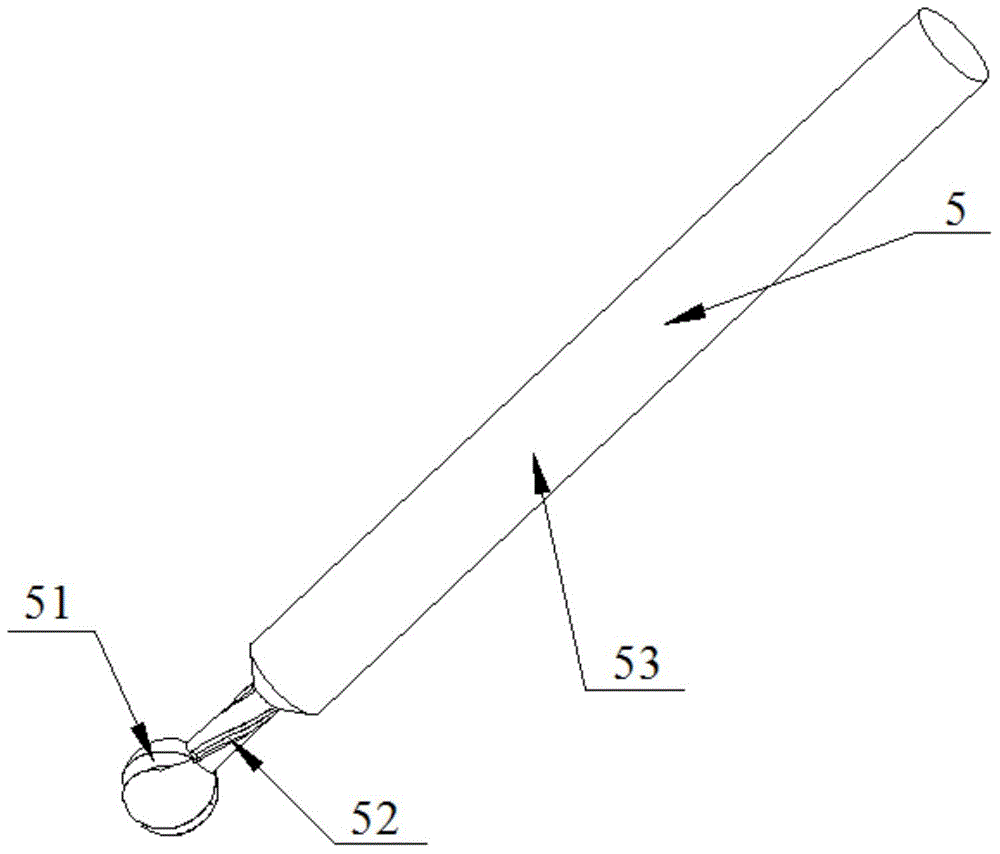

[0032] Examples, see Figure 1-Figure 3 As shown, a flat heat pipe liquid-absorbing wick with fins-embedded grooves of the present invention includes a metal evaporation plate 1, and the evaporation surface of the evaporation plate 1 is provided with a plurality of parallel intervals along the first direction. The first embedded groove 3, a plurality of second embedded grooves 4 arranged in parallel and at intervals along the second direction, and a plurality of fins 2 distributed in an array; the first embedded groove 3 and the second embedded groove 4 One by one intertwined. The first embedded groove 3 and the second embedded groove 4 respectively comprise upper and lower parts, the upper part is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com