Patents

Literature

45results about How to "Promote boiling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

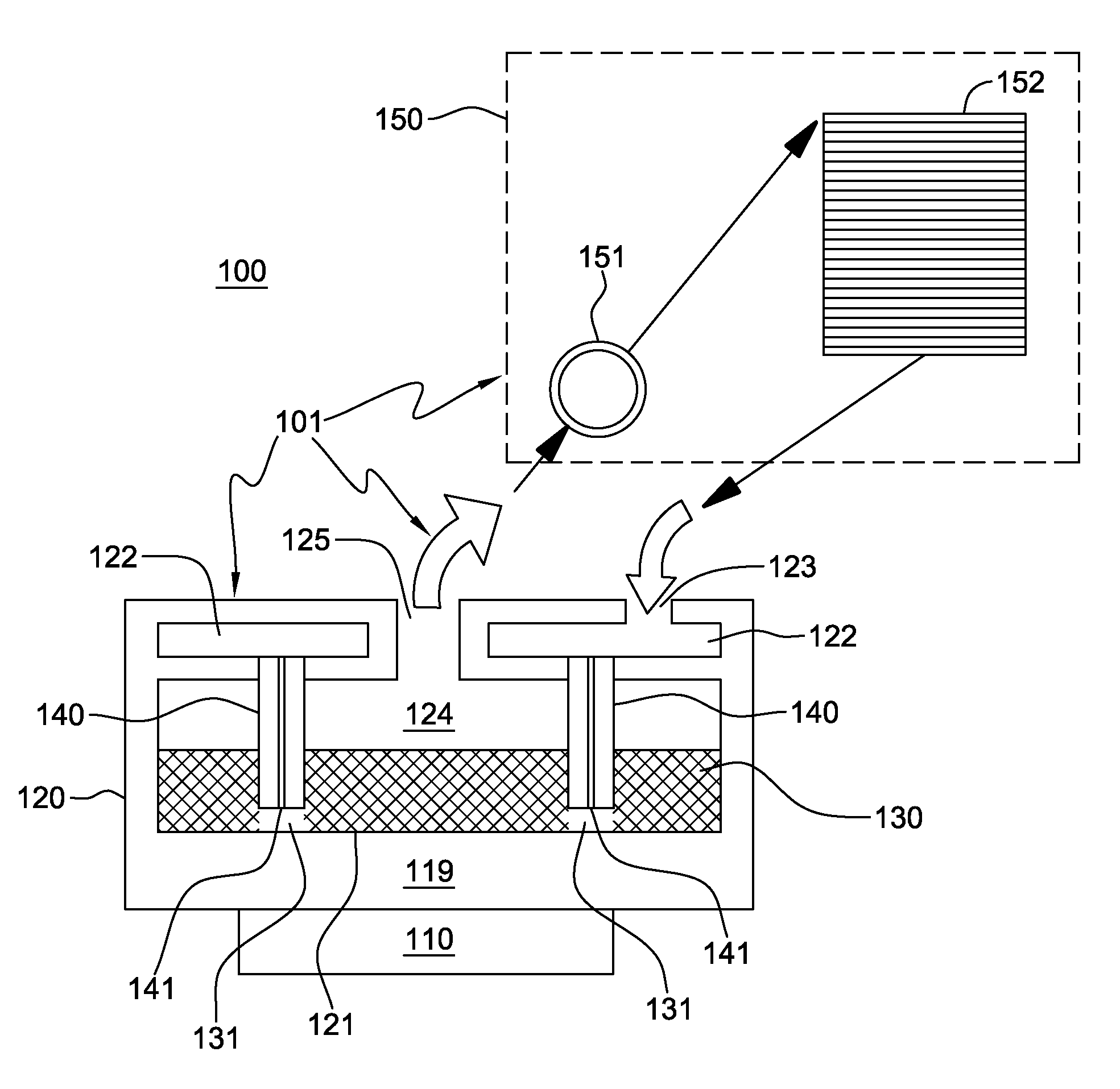

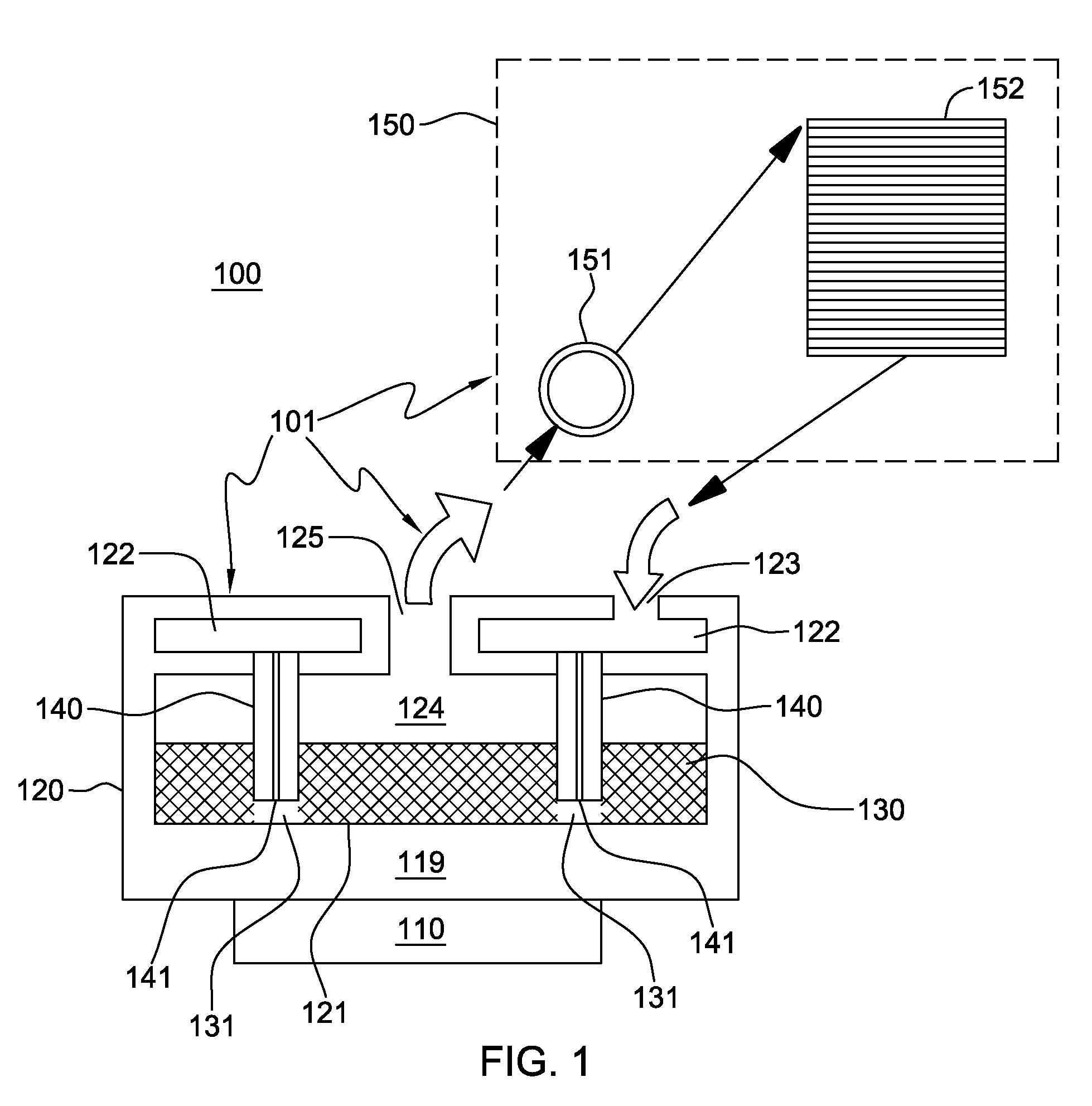

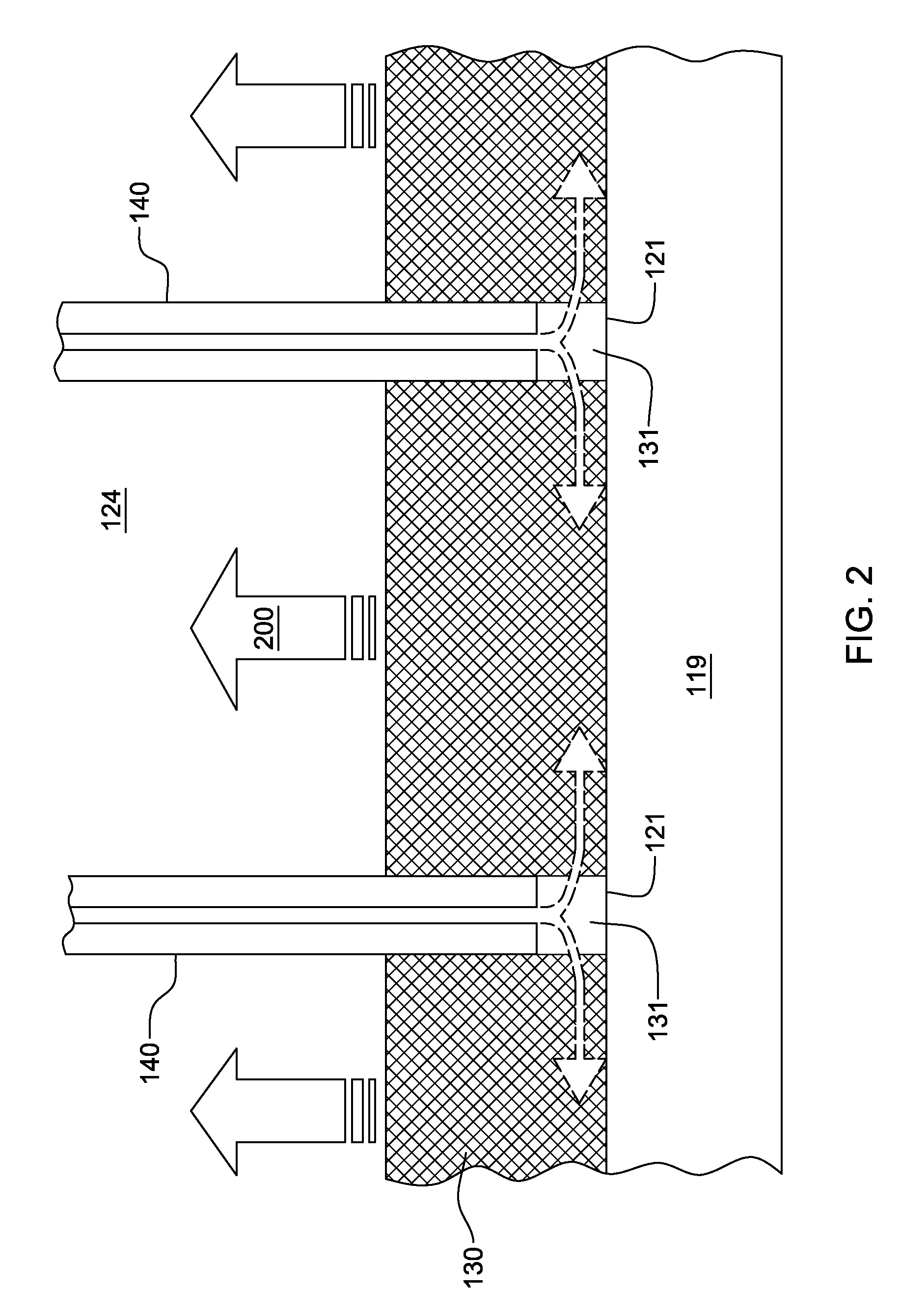

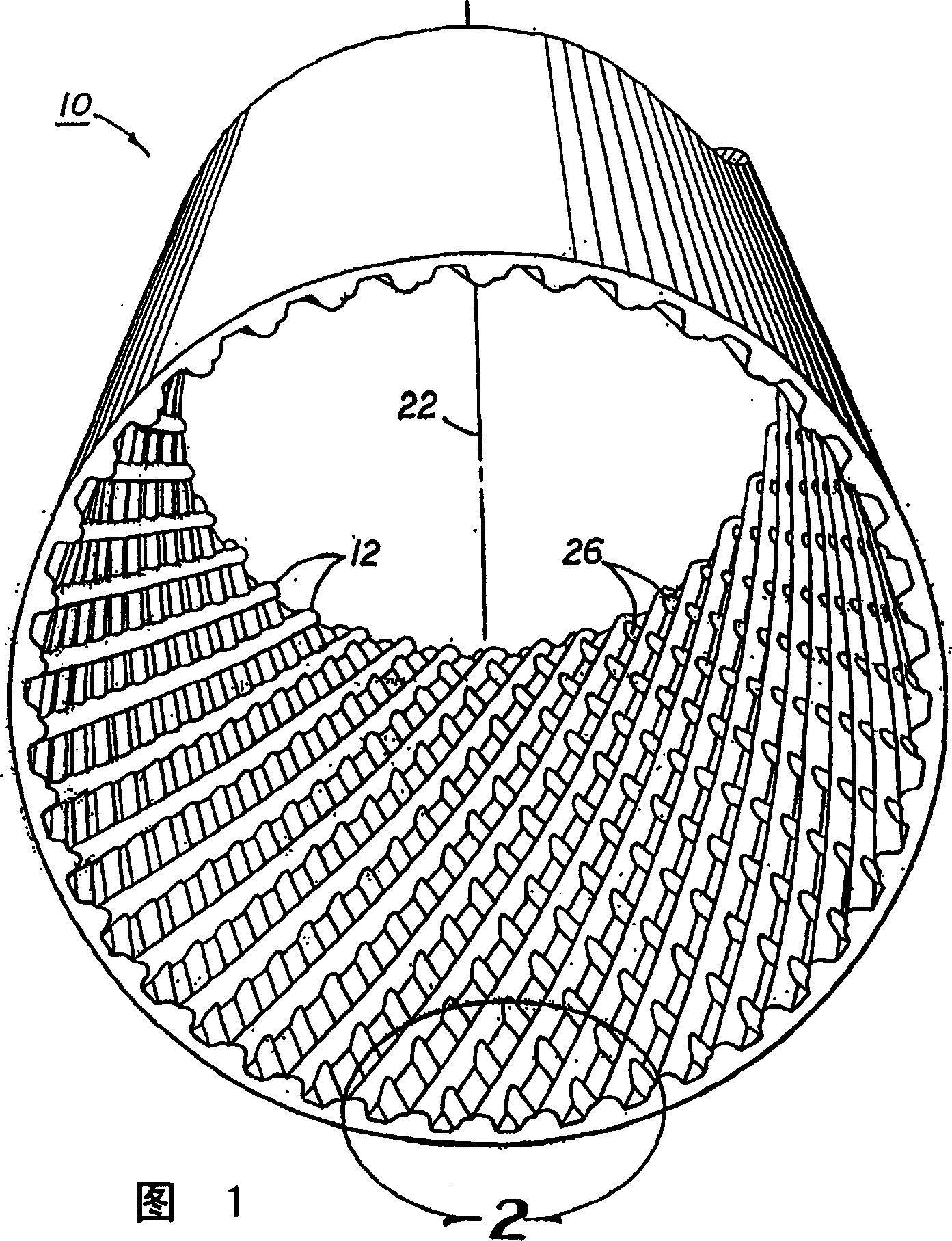

Cooling apparatus with thermally conductive porous material and jet impingement nozzle(s) extending therein

ActiveUS8081461B2Facilitates jet impingementOvercomes shortcomingDigital data processing detailsSemiconductor/solid-state device detailsThermal contactMetal foam

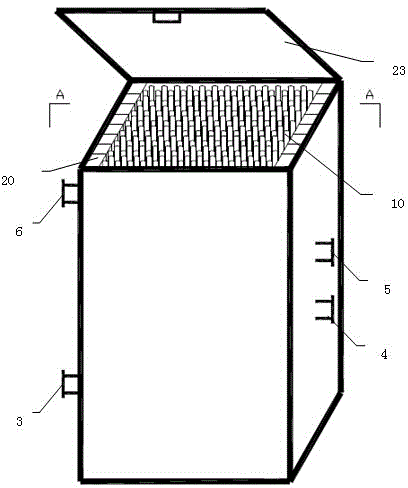

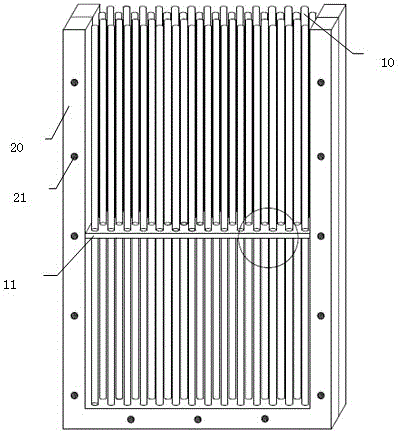

A cooling apparatus and method of fabrication are provided for facilitating cooling of an electronic device. The cooling apparatus includes a thermally conductive porous material and a liquid coolant supply. The thermally conductive porous material (such as metal foam material) is coupled to a surface of the electronic device to be cooled, or a structure coupled to the electronic device. The liquid coolant supply includes a jet impingement structure, which includes one or more jet nozzles for directing liquid coolant onto the surface to be cooled. The jet nozzle(s) extends into the thermally conductive porous material, and facilitates delivery of liquid coolant onto the surface to be cooled. The thermally conductive porous material is in thermal contact with the surface to be cooled and facilitates cooling of the electronic device by boiling of the liquid coolant passing through the porous material.

Owner:LENOVO GLOBAL TECH INT LTD

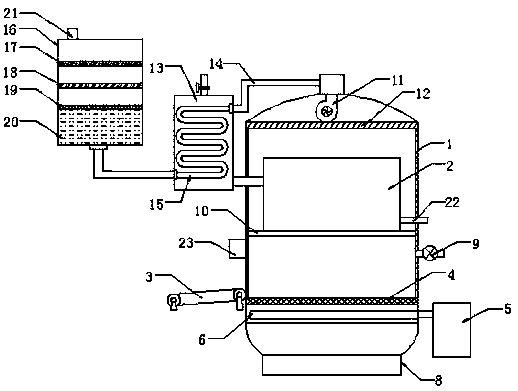

Environment friendly type industrial smoke overall treatment boiler and using method thereof

InactiveCN108645021ABurn evenlyBurn fullySolid fuel combustionCombustion technology mitigationCoalEngineering

The invention discloses an environment friendly type industrial smoke overall treatment boiler which comprises a boiler body, a heat exchange box and a purification box. A base is arranged at the bottom end of the boiler body, a burning cavity is arranged inside the boiler body, a burning separating plate is arranged at the lower end of the burning cavity, a fuel gas pipe is arranged below the burning separating plate, one end of the fuel gas pipe is connected with a fuel gas device, a feeding opening is formed in one side of the burning cavity, a conveying belt is arranged on the outer side of the feeding opening, a combustion-supporting pump is arranged on one side of the burning cavity, a supporting plate is arranged above the burning cavity and supports a water tank, and water in the water tank is heated to be discharged through a water discharging pipe; and the heat exchange box is arranged, heat of smoke in a smoke pipe is transferred to water in the heat exchange box, the waterin the heat exchange box is preheated, the water heating speed is increased, the heat energy is sufficiently used, the using amount of fire coal can be reduced, and energy conservation and emission reduction are achieved. The environment friendly type industrial smoke overall treatment boiler is reasonable in design, practical, feasible, more user-friendly and suitable for application and popularization.

Owner:王连会

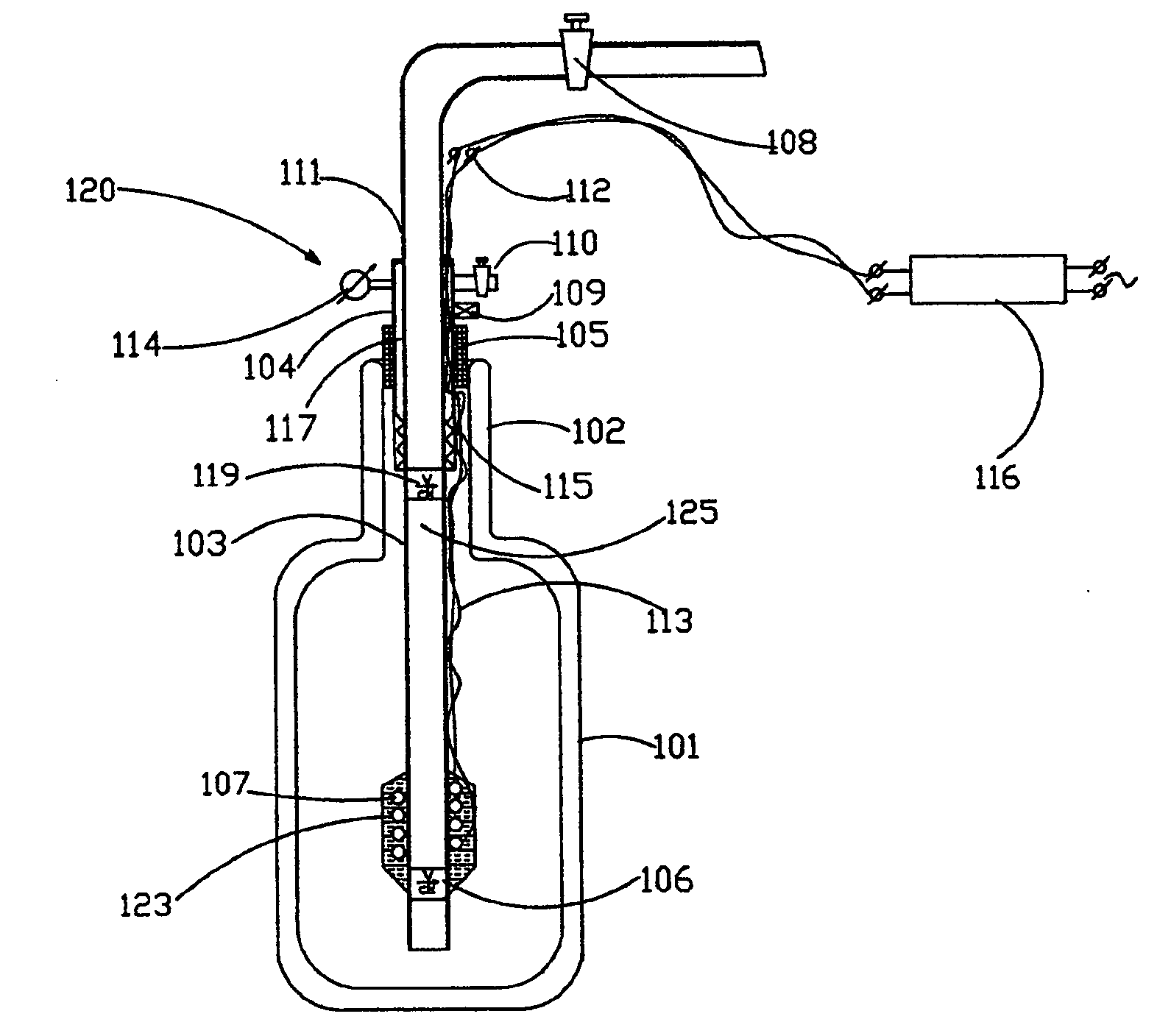

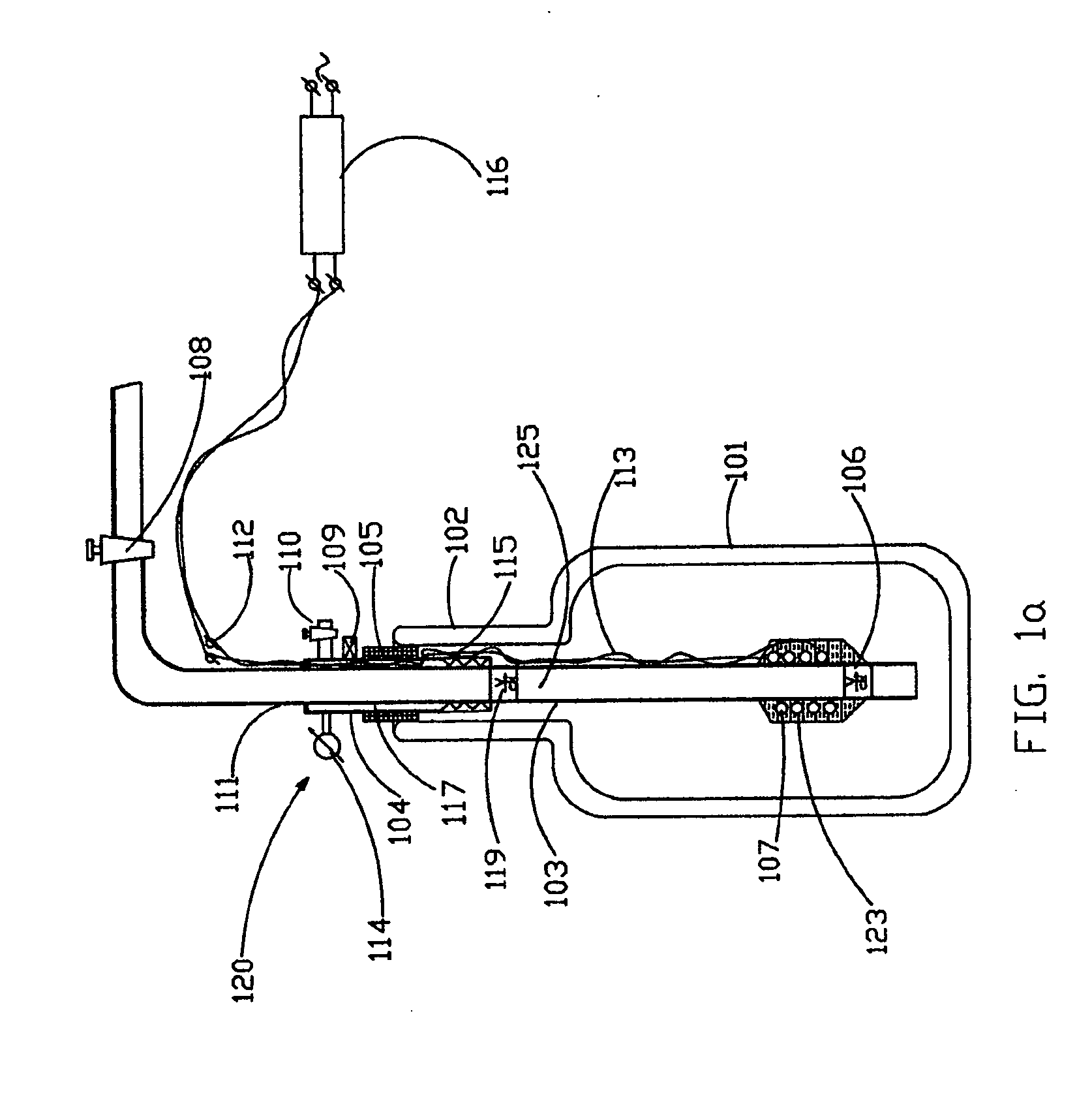

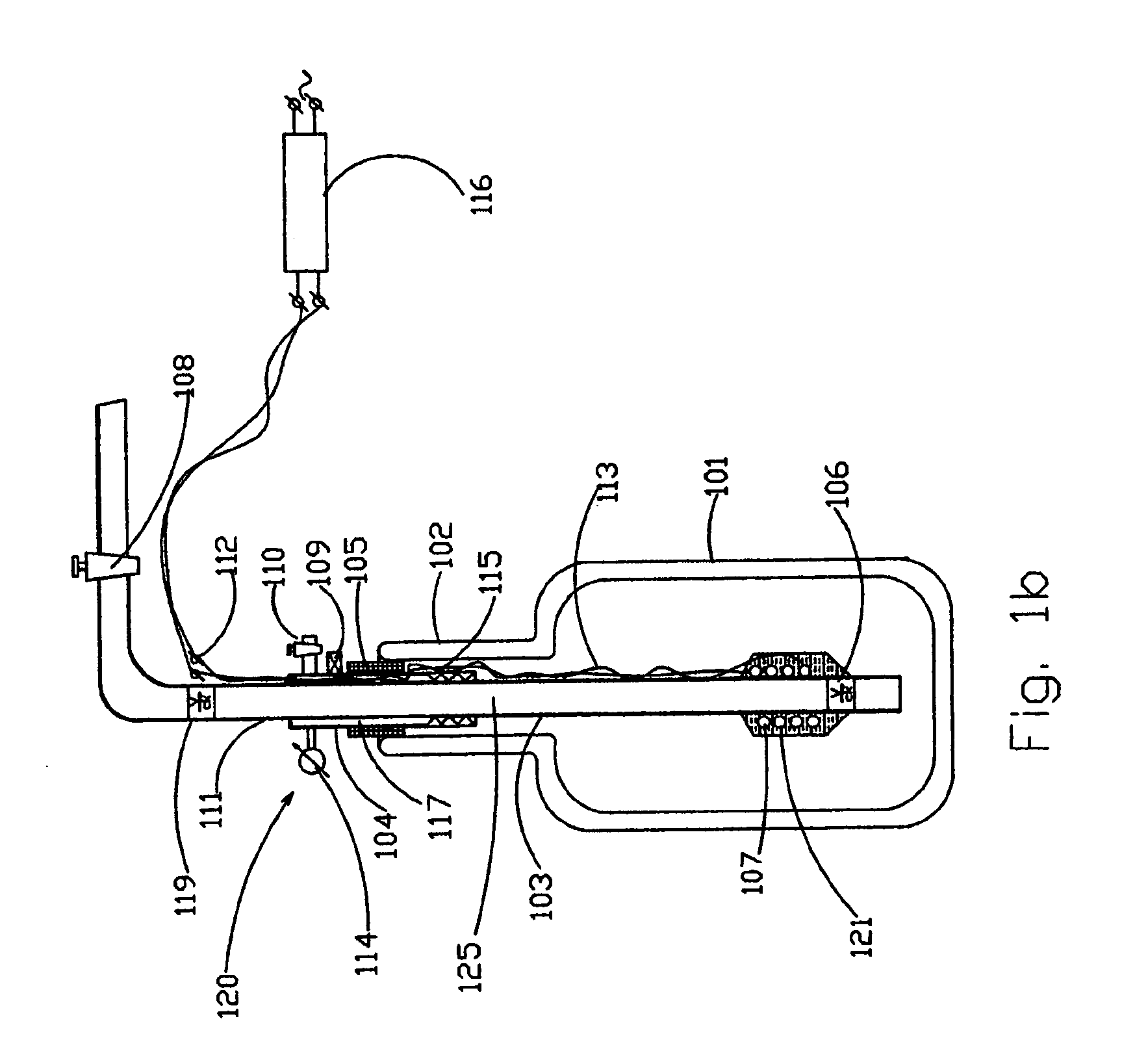

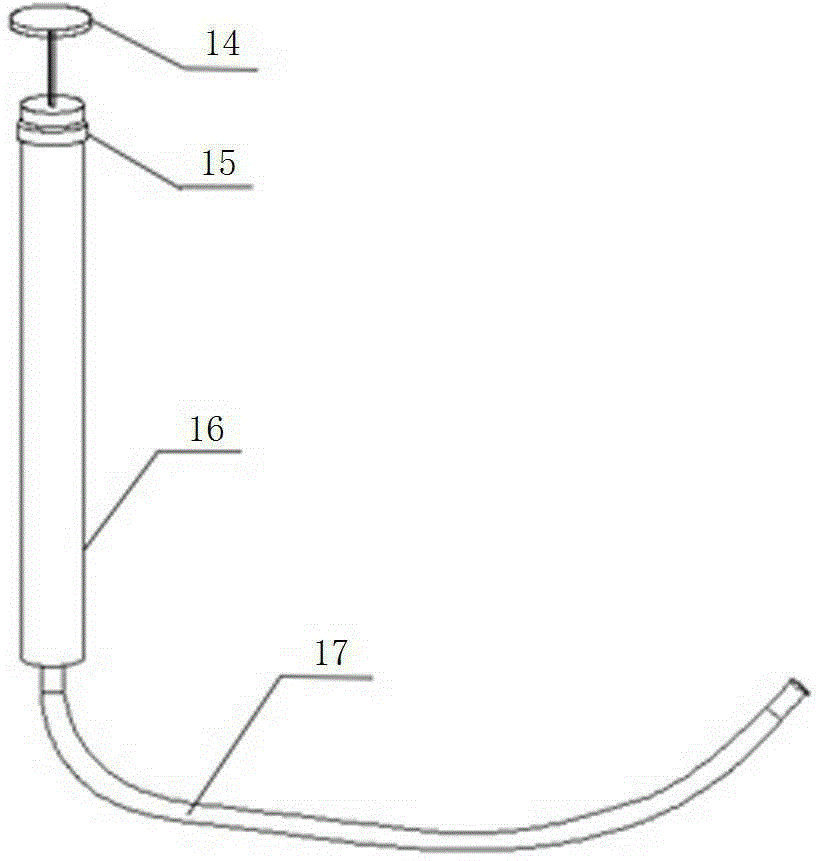

Pumping unit for delivery of liquid medium from a vessel

InactiveUS20090129946A1FlexibilityPromote boilingPressure pumpsPositive-displacement liquid enginesLiquid mediumEngineering

A pumping unit for delivering a liquid medium from a low pressure vessel such that the delivered medium has sufficiently high pressure, by providing the liquid medium in the form of separated pulses.

Owner:ICECURE MEDICAL

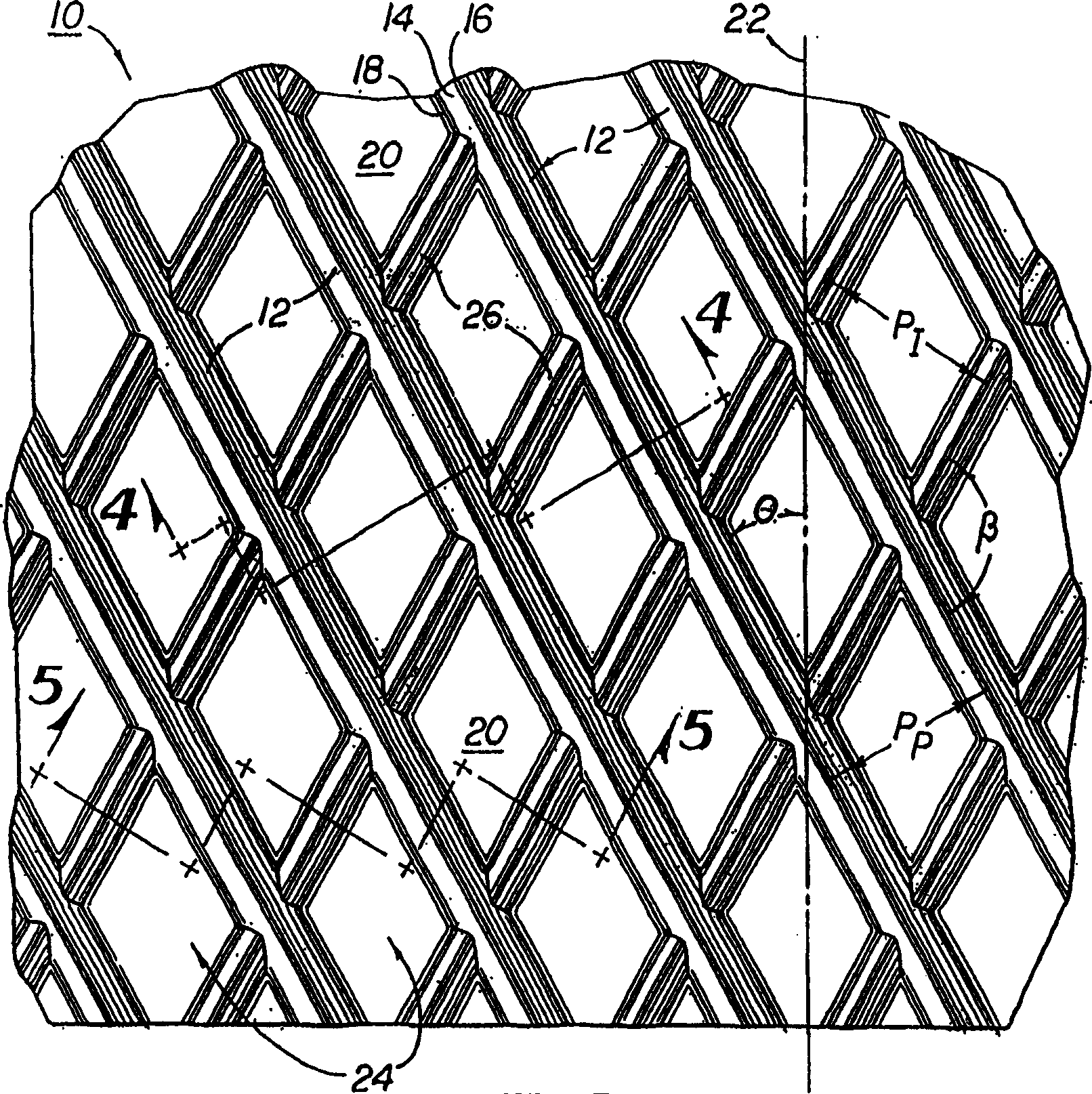

Improved heat transfer tube with grooved inner surface

InactiveCN1463353AReduce manufacturing costPromote boilingEvaporators/condensersMetal rolling arrangementsEngineeringHeat transfer tube

Owner:WOLVERINE TUBE INC +1

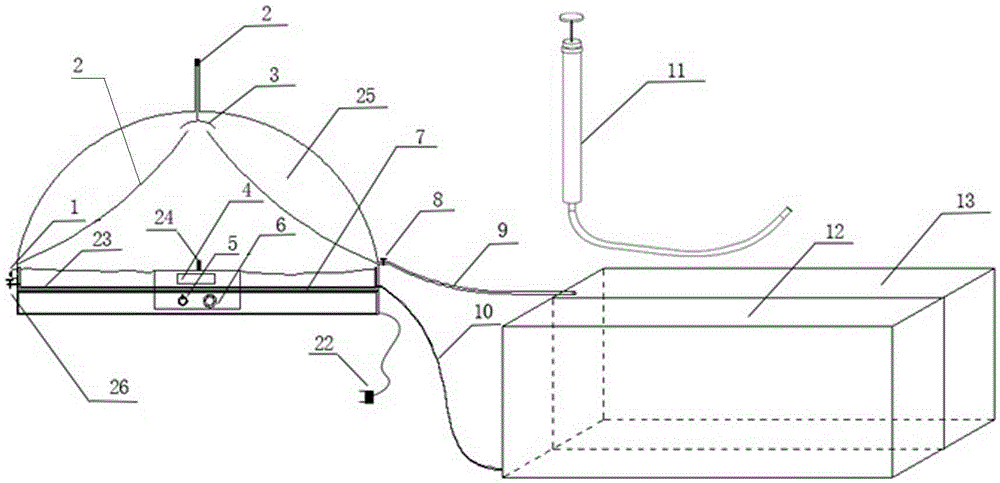

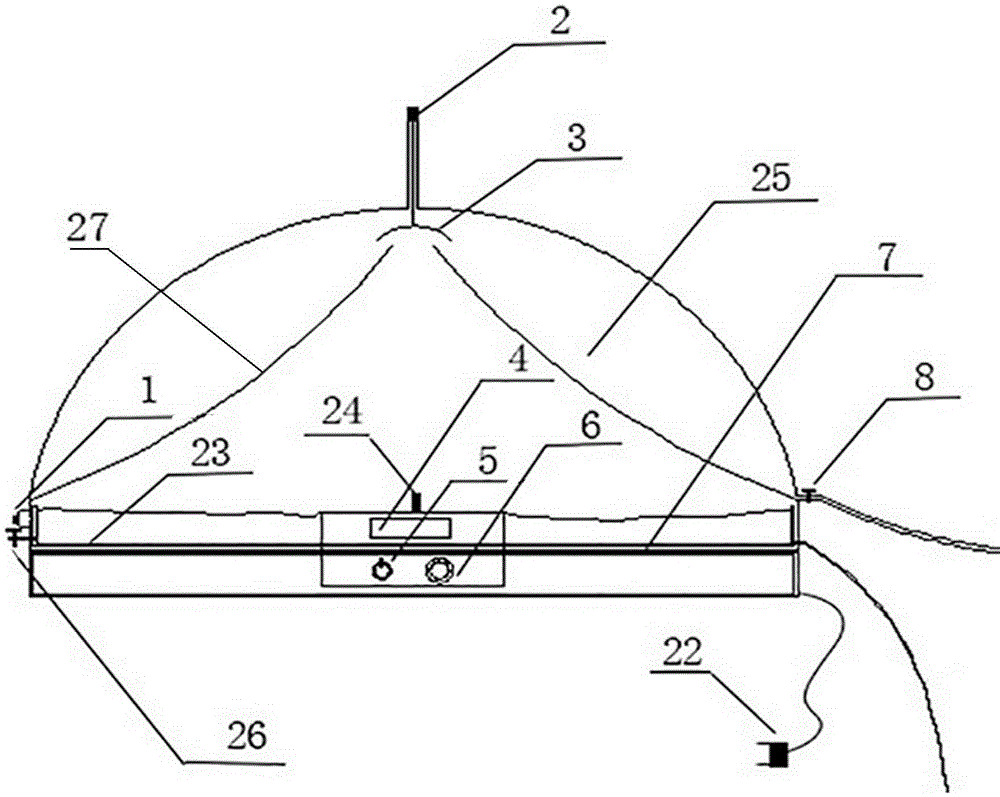

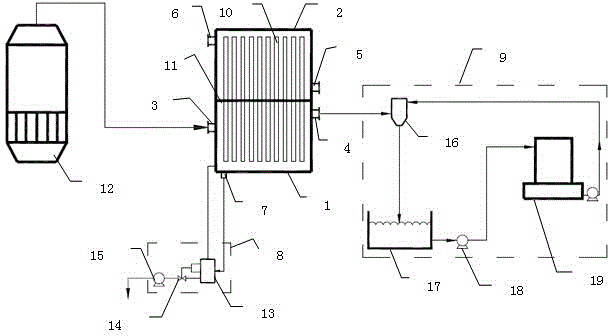

Seawater desalination plant applied to small ships

InactiveCN105347412AIncrease evaporation ratePromote boilingGeneral water supply conservationSeawater treatmentGlass coverEvaporation

The invention discloses a seawater desalination plant applied to small ships. The seawater desalination plant comprises a seawater storage case and a fresh water reception case, the seawater storage case is connected to a seawater evaporation plant by a seawater pipe, the seawater evaporation plant comprises a seawater evaporator and a glass cover in convex lens shape, and the glass cover seals and covers the whole seawater evaporator; the top part of the glass cover is provided with a condenser tube, and the lower end of the condenser tube is provided with an arc anti-falling cap whose opening is downward; the inner wall of the glass cover is circularly provided with a baffle plate, the baffle plate and the glass cover form a cavity for containing fresh water, and the cavity is connected to the fresh water reception case by a water valve and a fresh water pipe; the seawater evaporation plant is internally provided with a manometer, the manometer acquires the pressure in the glass cover, and transmits the data to a display screen for displaying; the glass cover is also provided with an air valve and a waste liquid outlet; the glass cover is connected to a suction pump; the lower part of the seawater evaporator is provided with an electric hot plate. The plant has the advantages of simple structure, low energy consumption and much produced fresh water.

Owner:WUHAN UNIV OF TECH

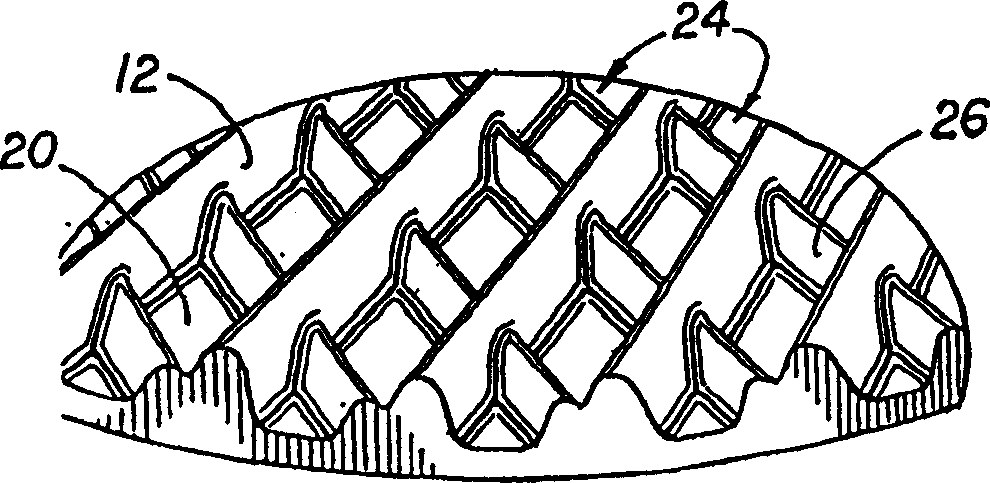

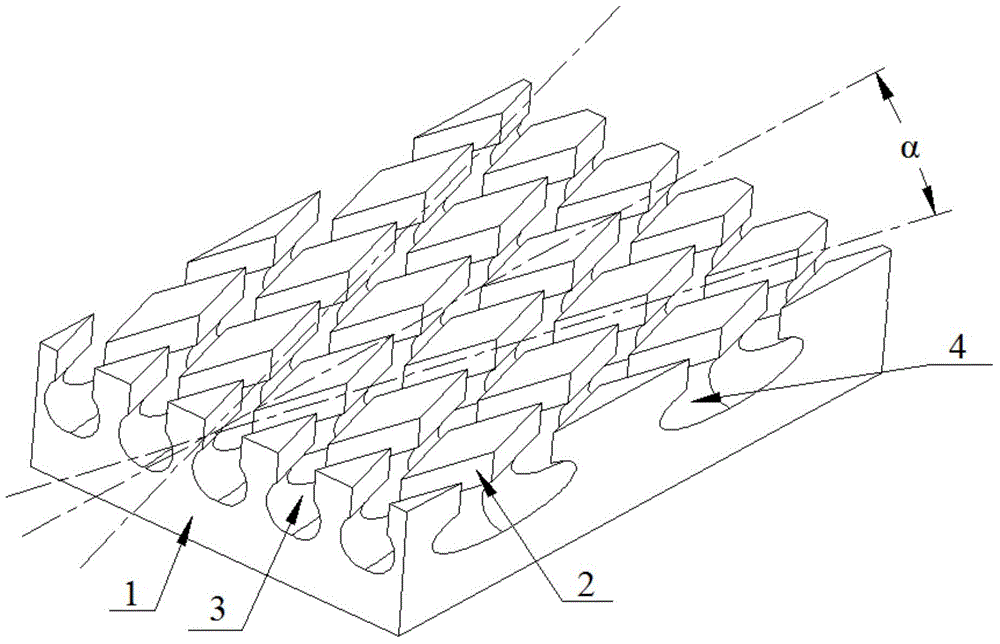

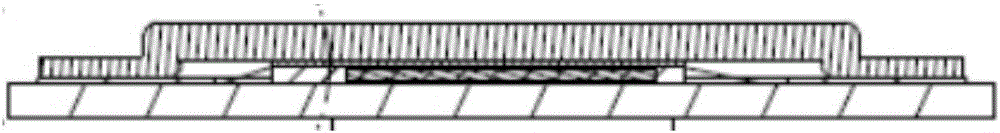

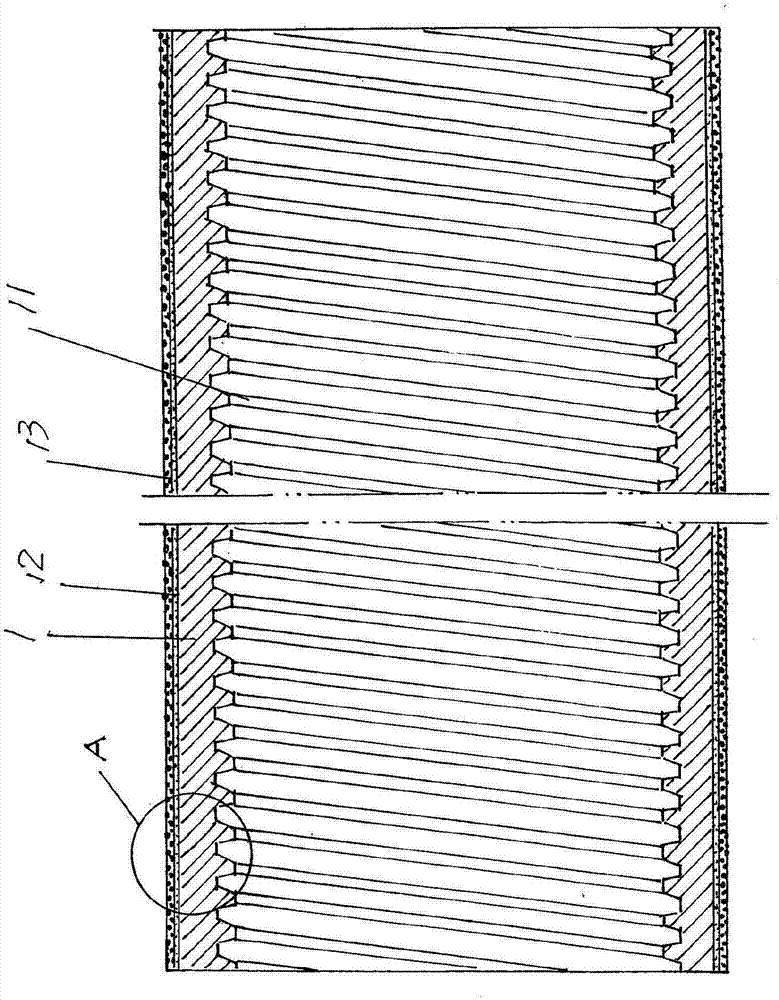

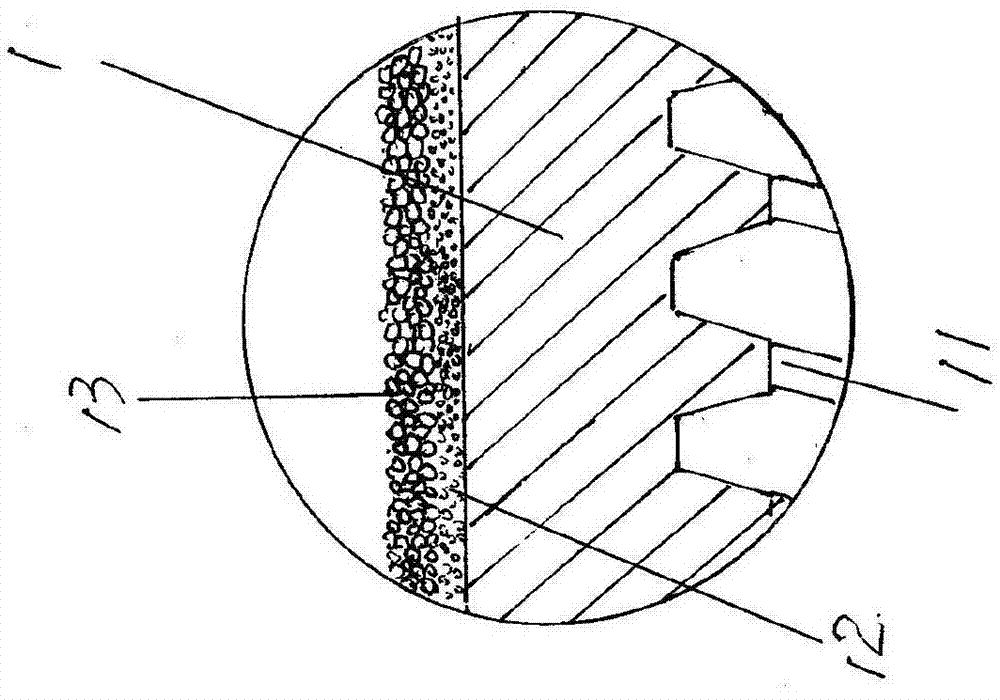

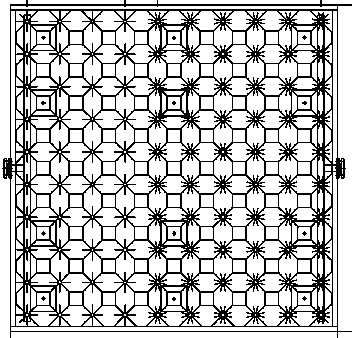

Flat heat pipe liquid suction core provided with fins and embedded grooves and manufacturing method thereof

InactiveCN104864755AIncrease disturbanceIncrease the heat exchange areaIndirect heat exchangersCapillary pressureMarine engineering

The invention discloses a flat heat pipe liquid suction core provided with fins and embedded grooves and a manufacturing method thereof. The flat heat pipe liquid suction core comprises a metal evaporation plate, wherein multiple first embedded grooves and multiple second embedded grooves which are arranged at intervals and distributed in a staggered mode in the first direction and the second direction and multiple fins distributed in an array mode are arranged on the evaporation face of the metal evaporation plate, and each first embedded groove and each second embedded groove respectively comprises a groove body forming a groove cavity and a vertical gap forming a groove opening. Each fin comprises a fin body and a supporting boss and is formed by the gaps and internal groove bodies of the corresponding first embedded groove and the corresponding second embedded groove in a staggered mode. The liquid suction core can increase heat exchange area, promote boiling for nucleus formation, enhance boiling heat transfer, improve capillary pressure and reduce backflow resistance. During manufacture, a ball-end milling cutter is utilized to mill the embedded grooves in the first direction, and a base plate is turned to mill the embedded grooves in the second direction and meanwhile form a fin structure. The flat heat pipe liquid suction core is simple in manufacturing process and low in machining cost and can remarkably strengthen heat transfer.

Owner:XIAMEN UNIV

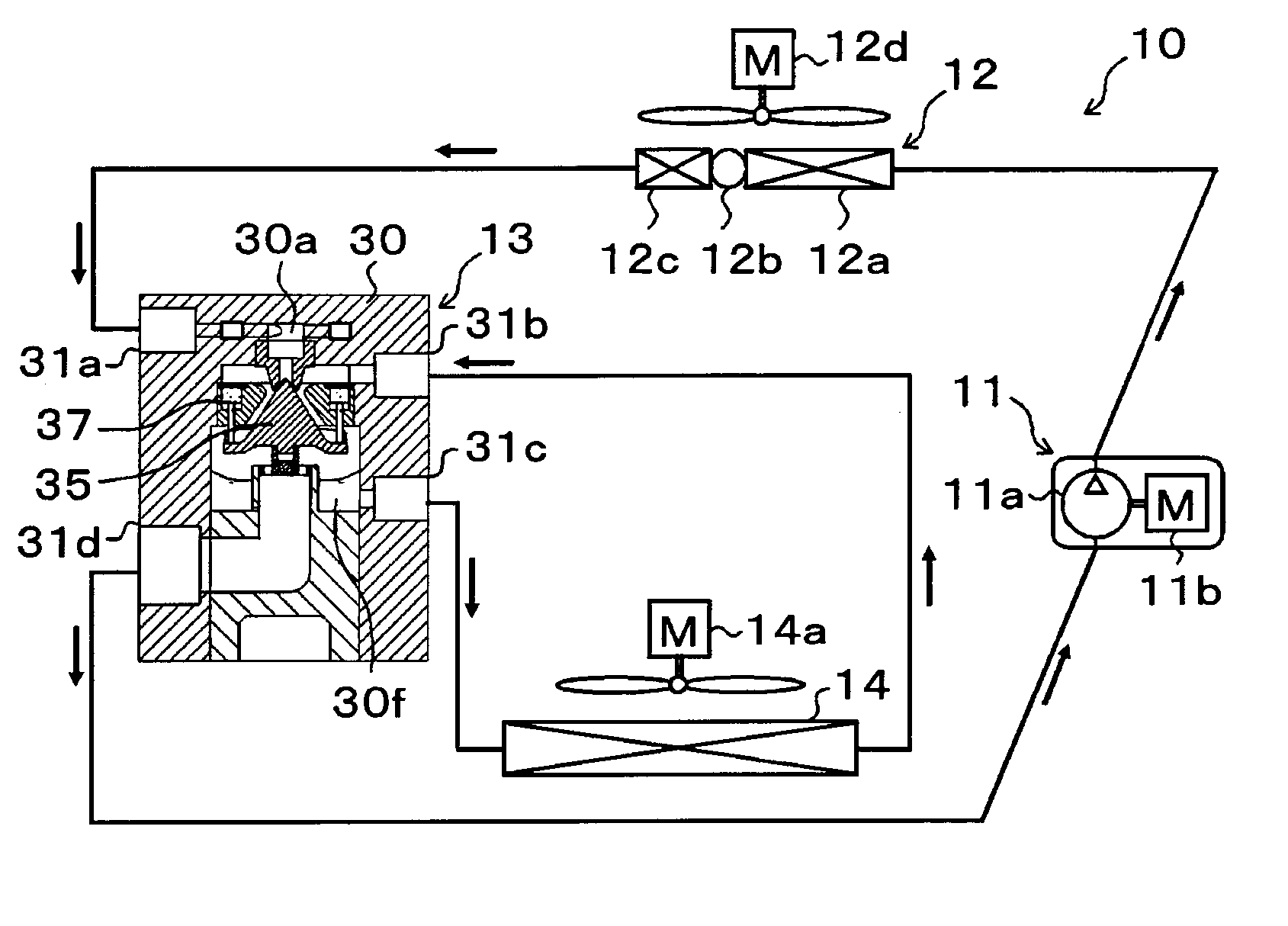

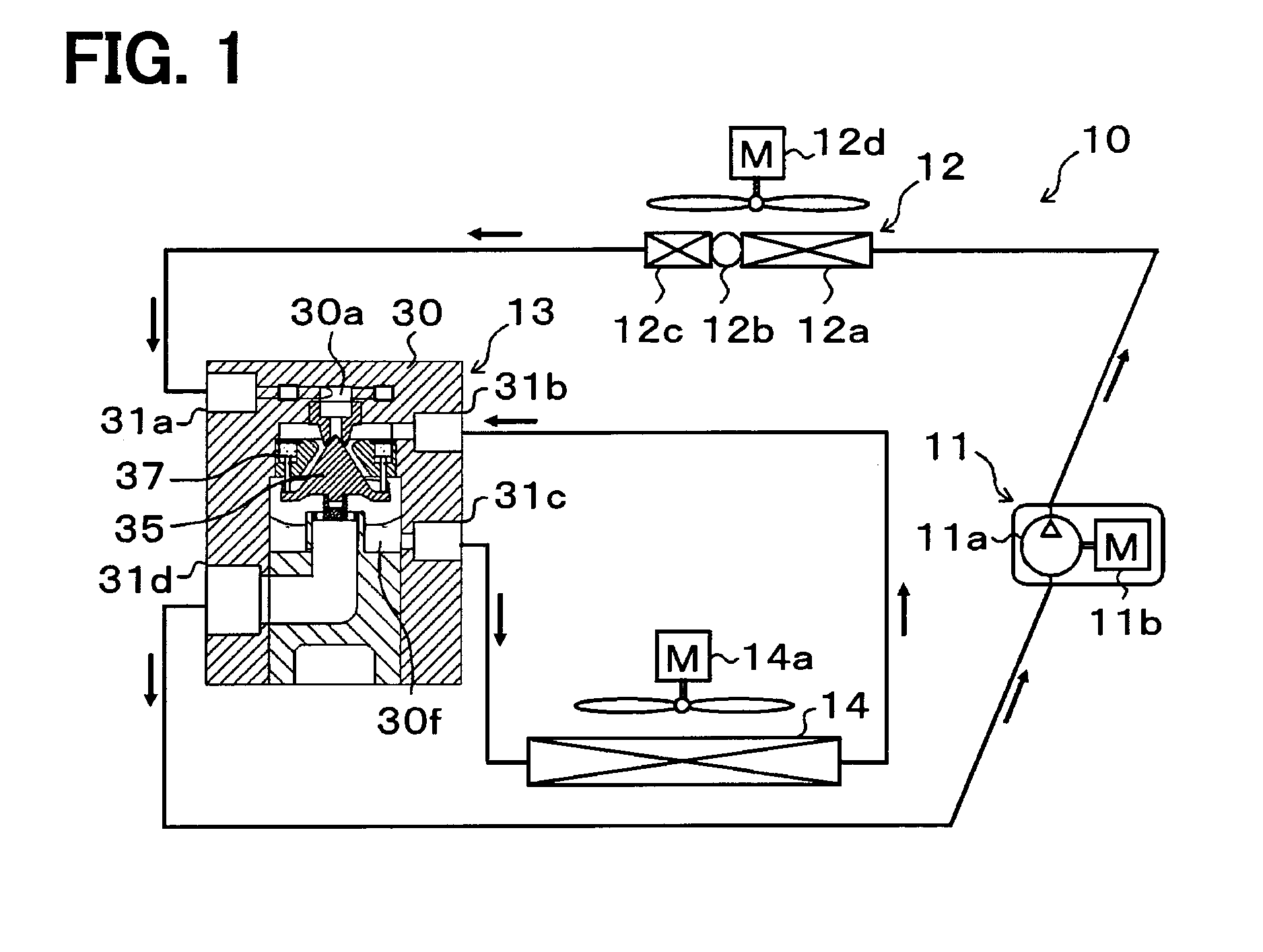

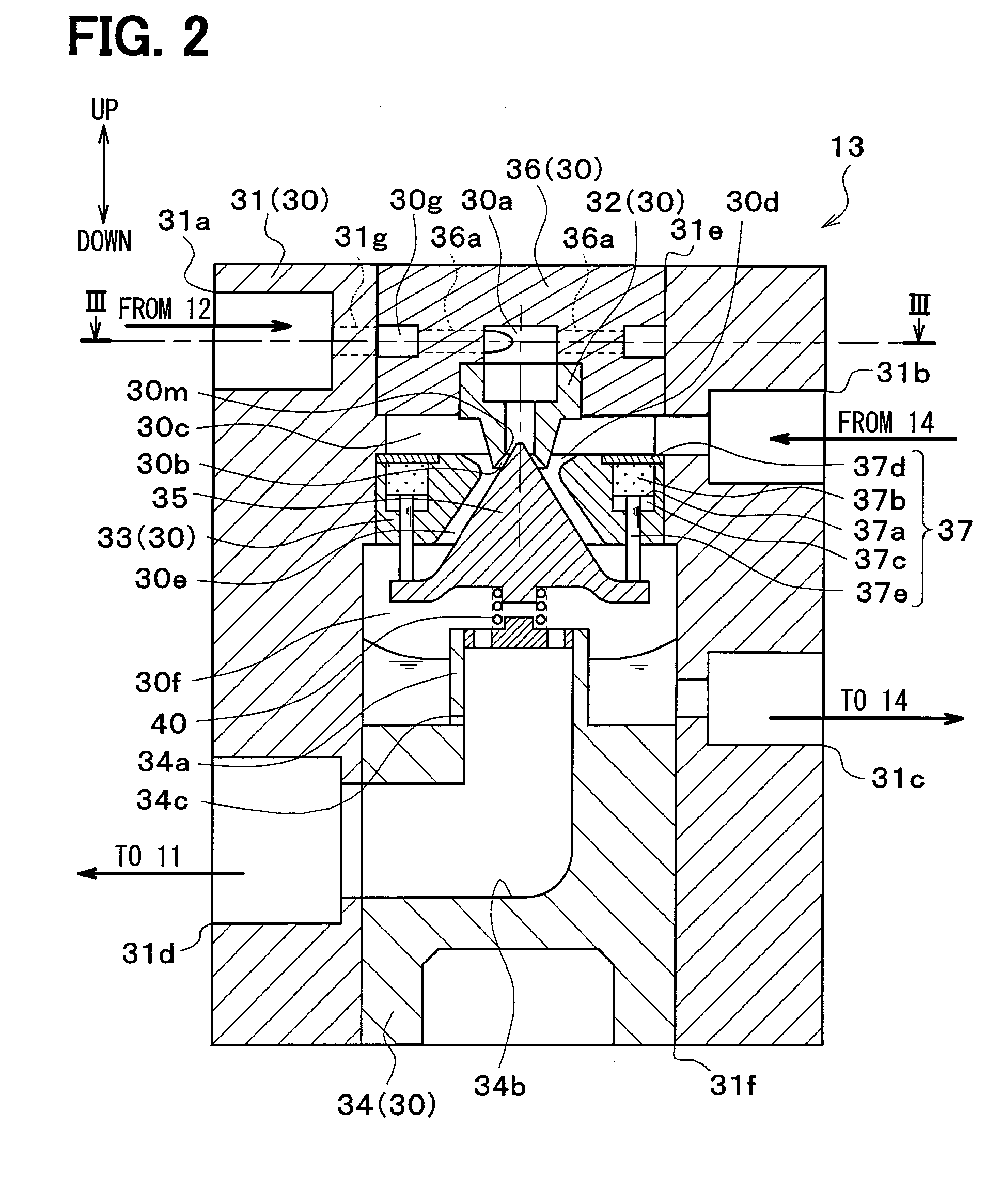

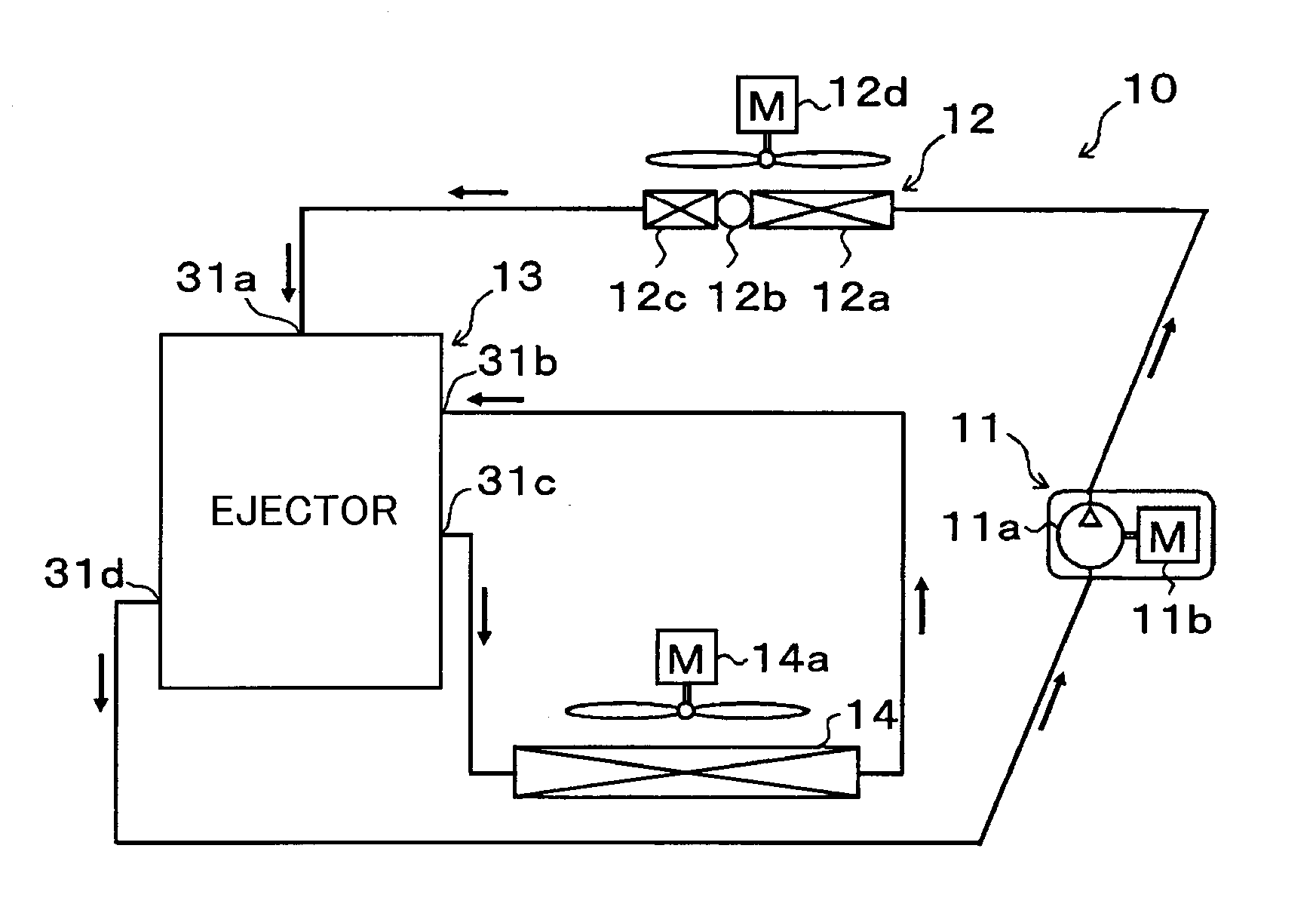

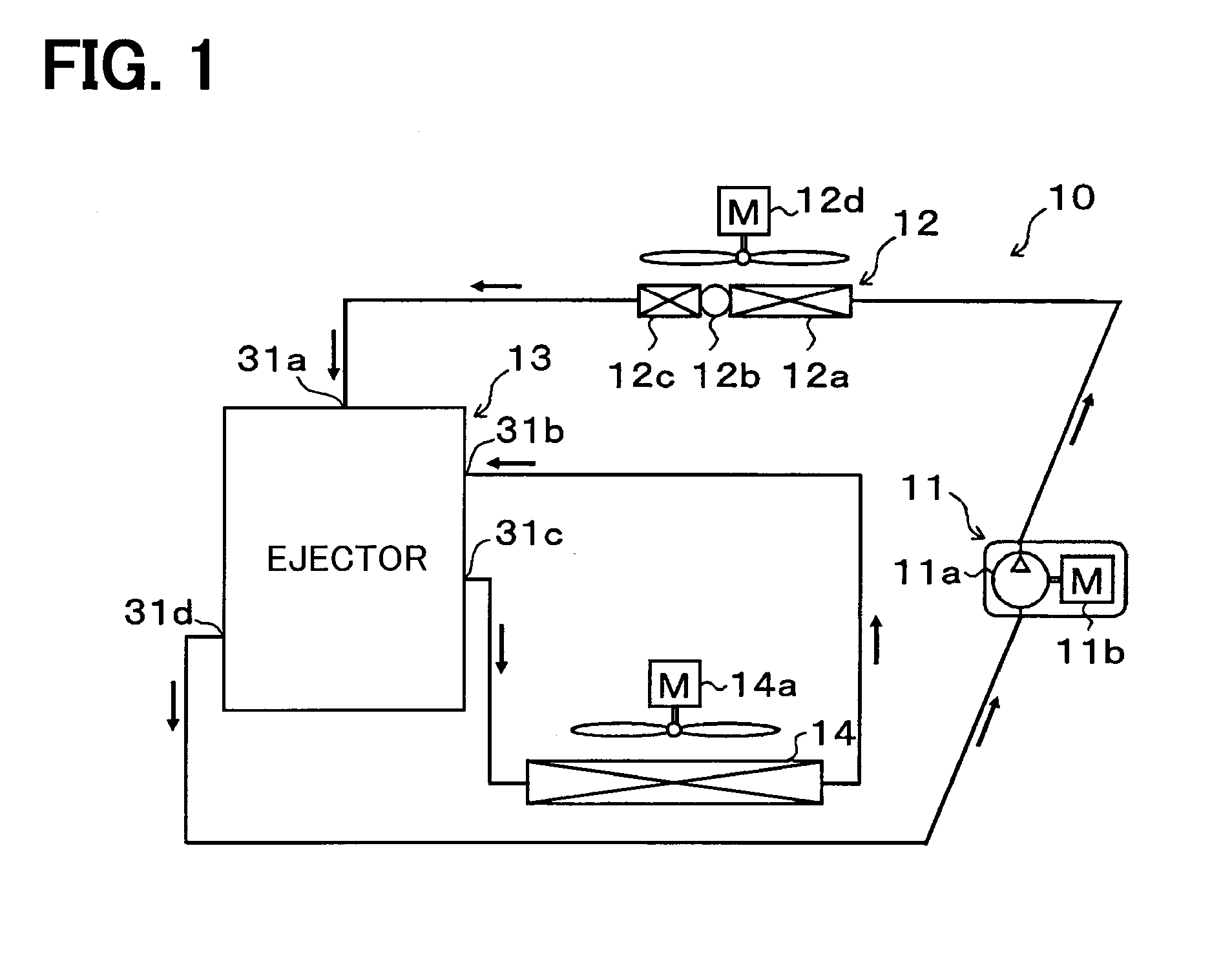

Ejector

InactiveUS20160169566A1Suppress large deviationImproves efficiency of nozzleCompression machines with non-reversible cycleJet pumpsRefrigerantPhysics

An approximately conical passage-forming member is disposed inside a body in which a swirling space for swirling a refrigerant is formed, and an ejector defines therein a nozzle passage that functions as a nozzle for depressurizing a refrigerant that has flowed out from the swirling space between an inner circumferential surface of the body and the passage-forming member, and a diffuser passage that pressurizes a mixed refrigerant obtained from a refrigerant sprayed from the nozzle passage and a refrigerant drawn from a suction-passage. A plurality of driving passages through which a refrigerant is introduced from a distribution space to the swirling space are formed in the body. In this case, the driving passages are formed in a manner such that a refrigerant flowing in from each driving passage into the swirling space flows along an outer circumference of the swirling space and flows in directions different from each other. Accordingly, nozzle efficiency is sufficiently improved.

Owner:DENSO CORP

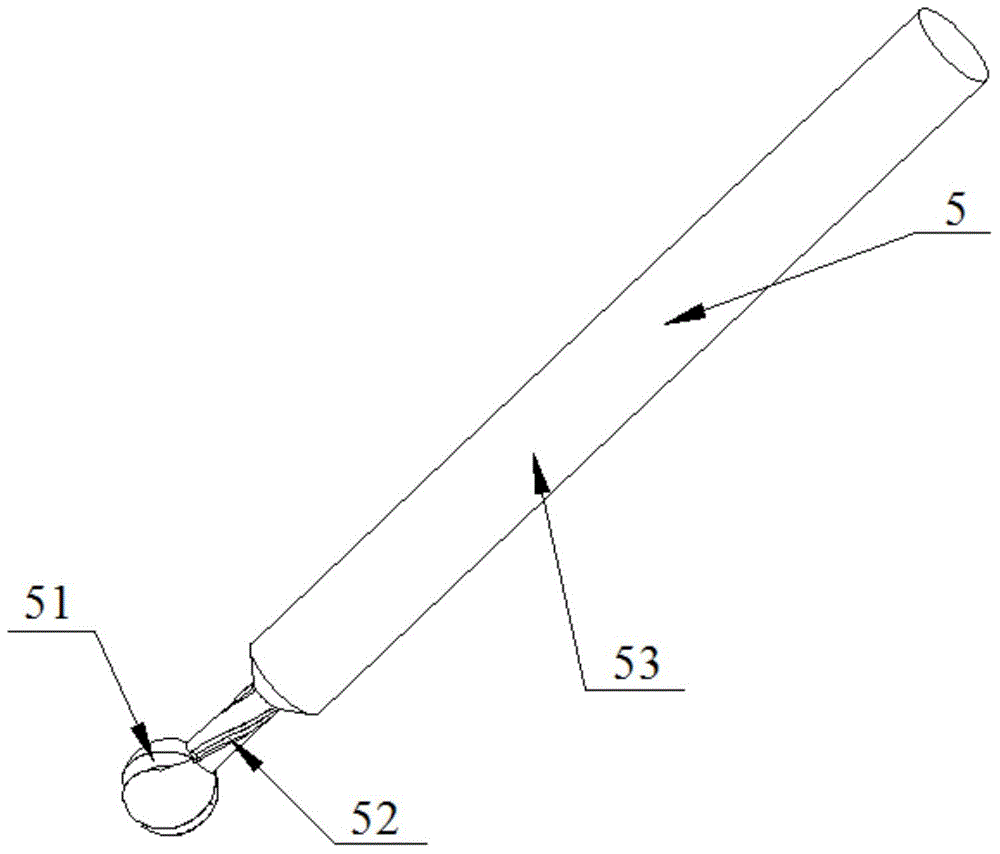

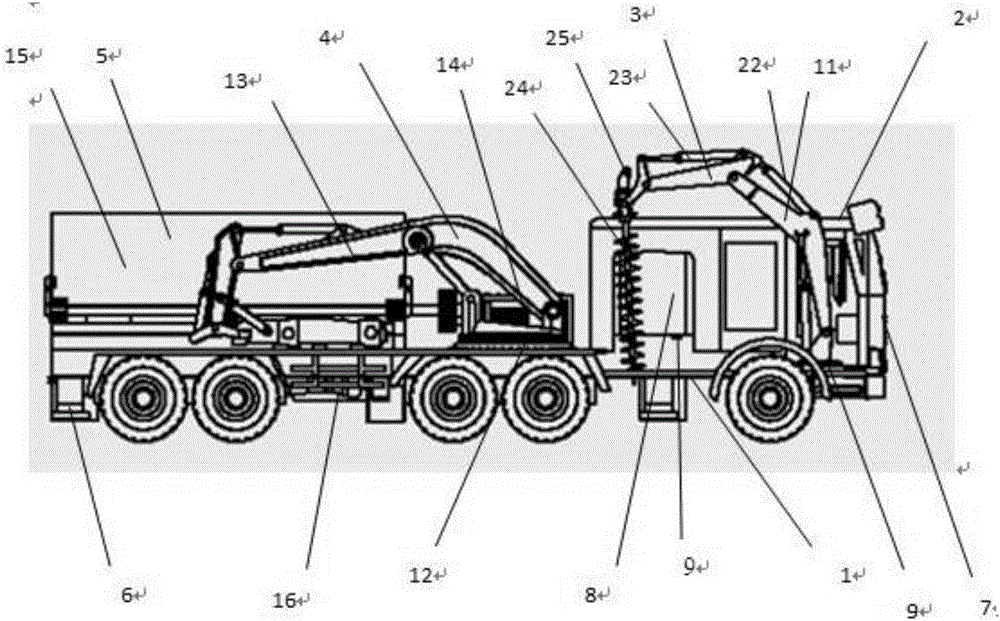

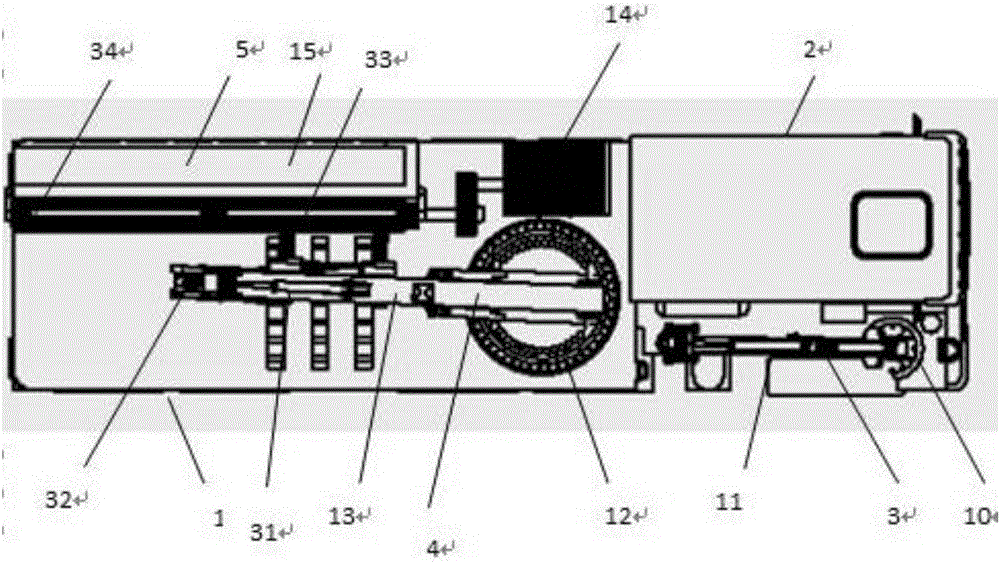

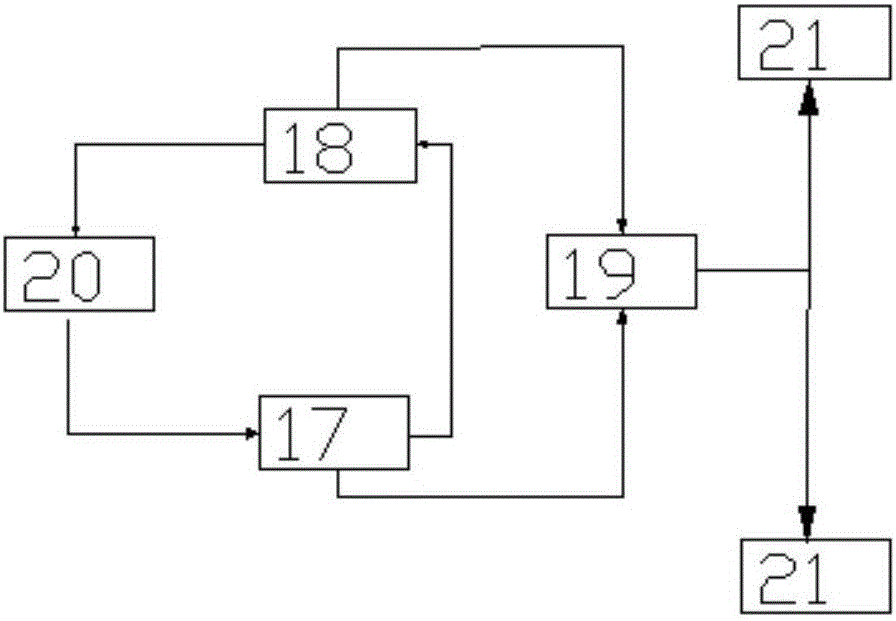

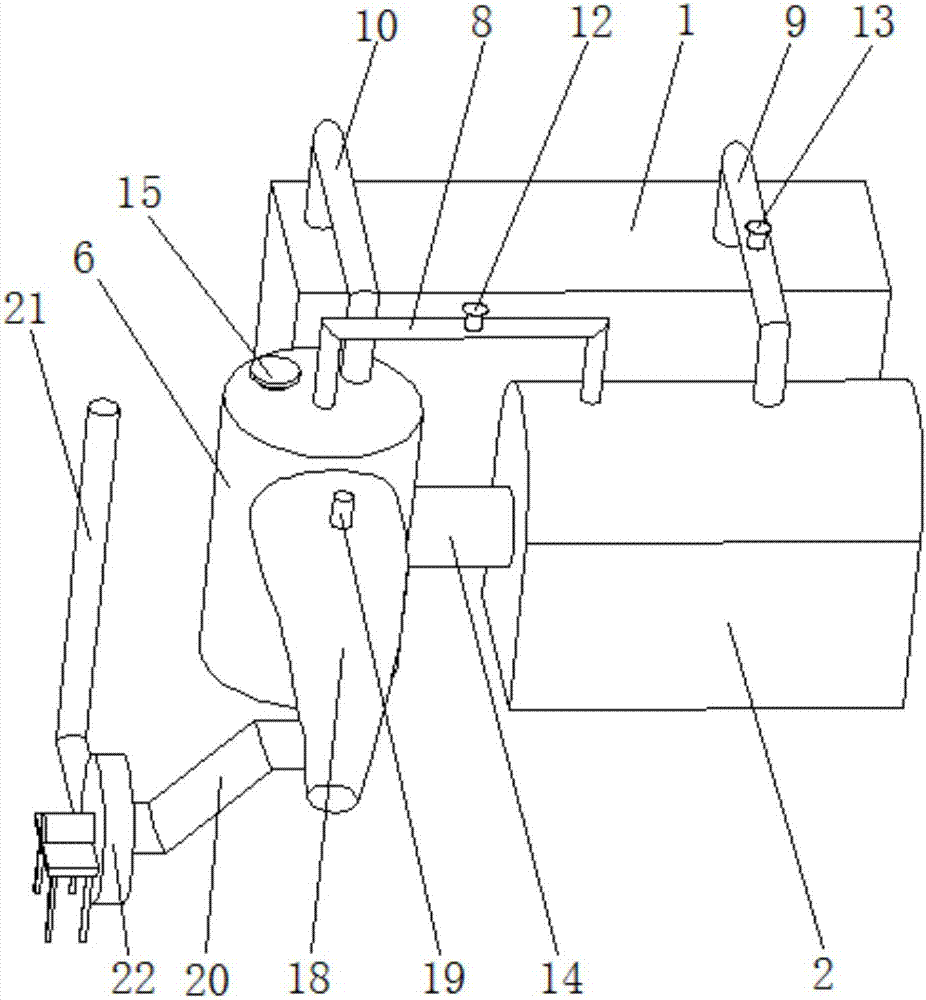

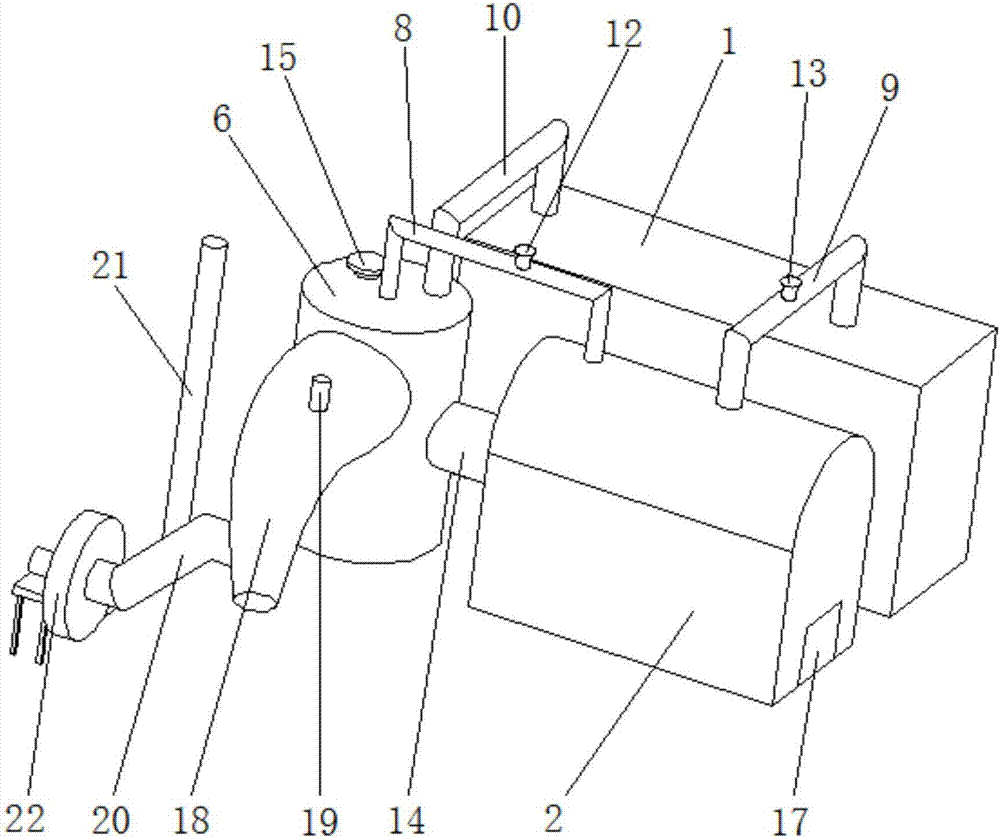

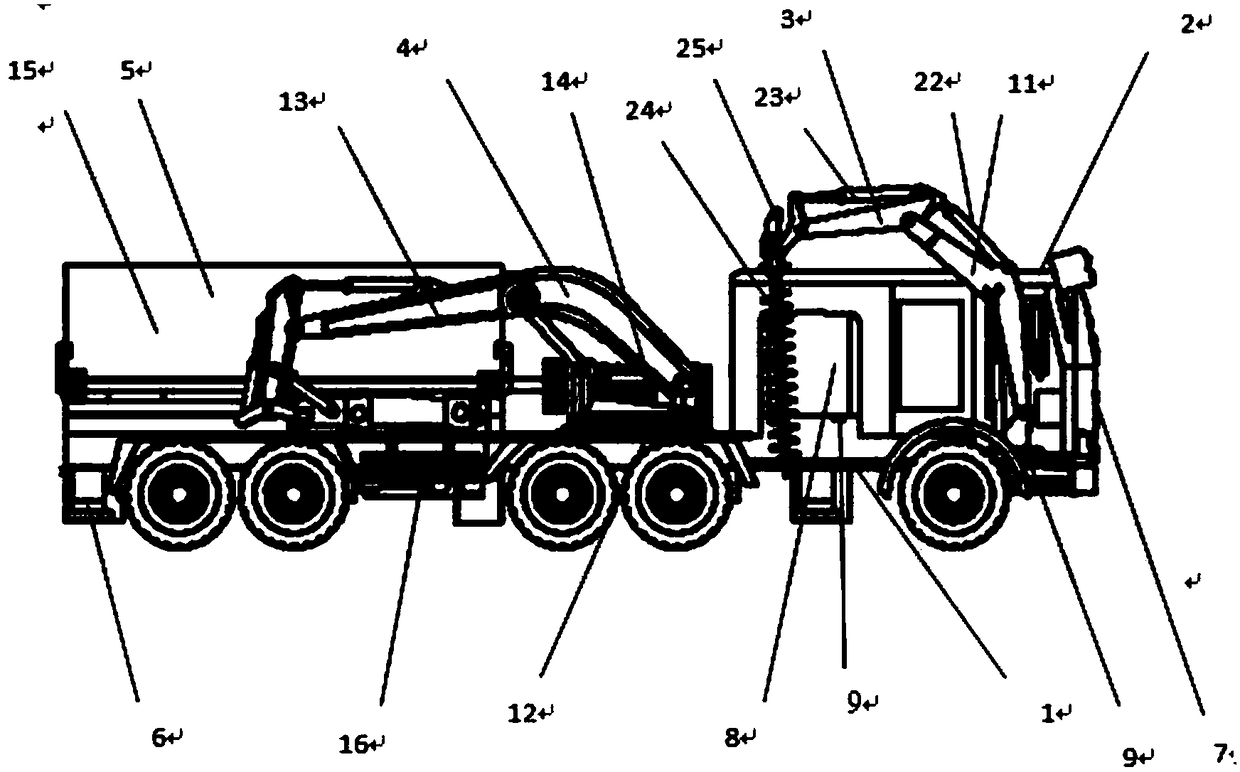

Automatic poling vehicle for transmission stringing engineering

The invention discloses an automatic poling vehicle for transmission stringing engineering and belongs to the technical field of electric power engineering. The automatic poling vehicle comprises a frame, a control chamber, a drilling device, a poling device and a rod-pulling device, wherein the control chamber, the drilling device, the poling device and the rod-pulling device are all arranged on the frame; a jack is arranged on the frame; the control chamber comprises a cab and a control room; a slide rail is arranged at the bottom of the control room; the drilling device comprises a rotating plate and a drilling arm; the poling device comprises a planet wheel and a mechanical arm; the rod-pulling device comprises a rod-pulling motor and a rod-storage box. The automatic poling vehicle for transmission stringing engineering provided by the invention can realize integrated drilling and poling; the working efficiency is increased; the improved link mechanism is adopted; the fixed point vertical poling is realized; the rotating is efficient and flexible; the automatic poling vehicle is efficient and environmentally friendly; the utilization ratio of energy is high.

Owner:LIAONING TECHNICAL UNIVERSITY

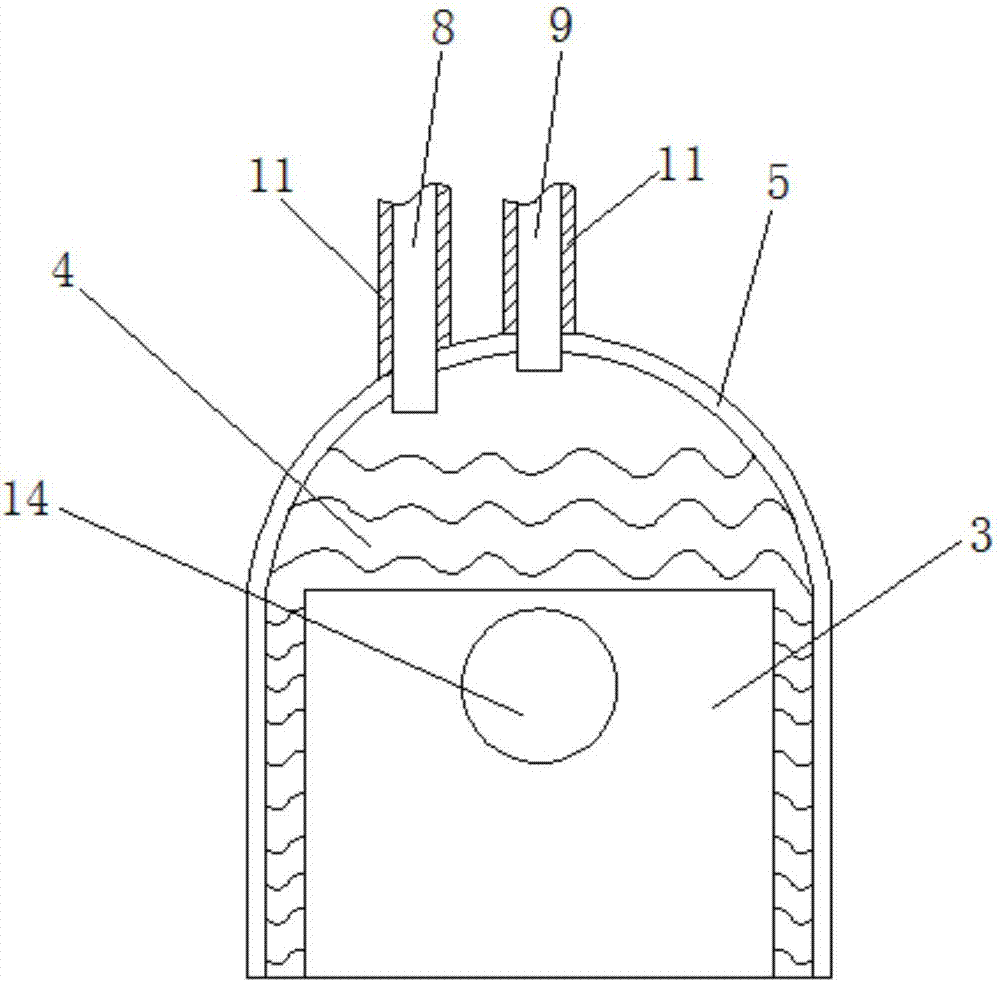

Boiler device for preparing steam

PendingCN107131492ASimple structureEasy to makeDrying gas arrangementsSteam boilersProcess engineeringCombustion chamber

The invention discloses a boiler device for preparing steam. The boiler device comprises a furnace body located at one side of a drying room, wherein a combustion chamber is arranged in the furnace body; a boiling water pond for completely covering the combustion chamber is arranged above the combustion chamber; an interlayer for covering the boiling water pond is arranged between the boiling water pond and the shell; an exhaust furnace communicating with the combustion chamber is arranged at one end of the furnace body; a preheating pond capable of utilizing afterheat of combustion tail gas for heating is arranged at the upper part of an inner cavity of the exhaust furnace; and a circulating pipe for communicating the preheating pond, the boiling water pond and a steam pipe of the drying room to form a moisture cycle is also arranged on the furnace body. The boiler device is simple in structure and convenient to prepare; the contact area of the boiling water pond and the combustion chamber is expanded; hot water is preheated by reasonably utilizing the tail gas and flows into the boiling water pond in cycle; the energy of combustion is fully utilized; the preparation efficiency and flow of the steam are improved; the production cost is reduced; and the requirements of energy conservation and environment protection are met.

Owner:容县润达家具有限公司

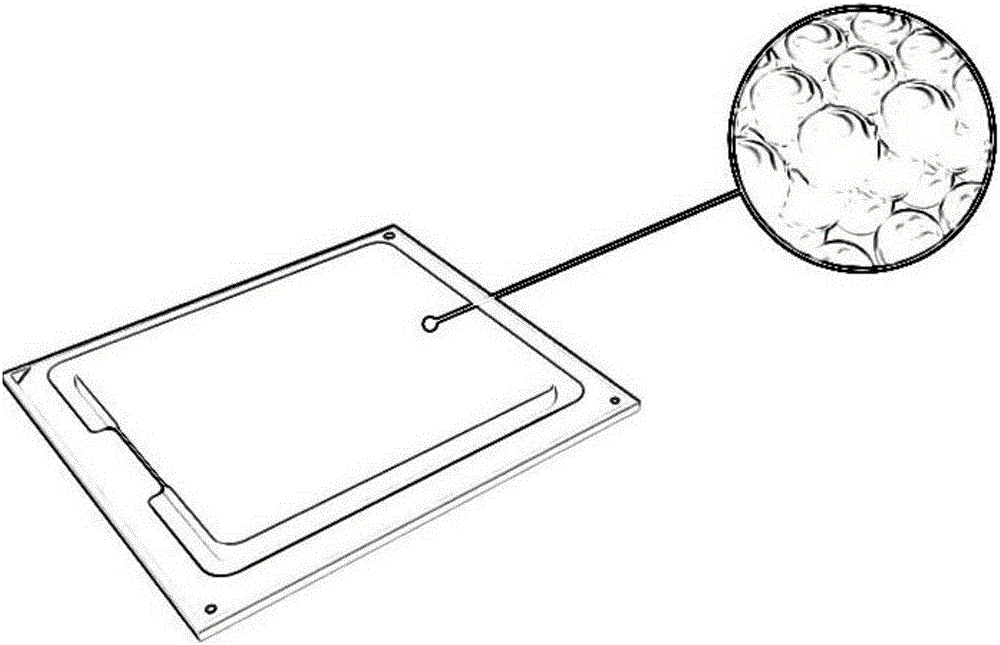

Surface treatment method for CPU cover

InactiveCN106637194AIncrease vaporization corePromote boilingMetallic material coating processesWelding apparatusHydrogenEvaporation

The invention discloses a surface treatment method for a CPU cover. The surface treatment method comprises the following steps of evenly adhering metal powder to the surface of a sheet metal; and sintering the surface of the sheet metal under the protection of hydrogen, so as to form a porous metal covering layer on the surface of the sheet metal. The metal powder is adhered to the surface of the sheet metal to be welded on the surface of the CPU cover, the metal powder is then sintered into an integrity so as to form the porous metal covering layer on the surface of the sheet metal, and the sheet metal is welded on the CPU cover, so that the evaporation core of the CPU cover is improved, the boiling property of the surface of the CPU cover is strengthened, the surface temperature of the CPU cover is reduced, and the purposes of strengthening boiling, saving energies and efficiently dissipating heat are fulfilled.

Owner:SUGON DATAENERGYBEIJING CO LTD

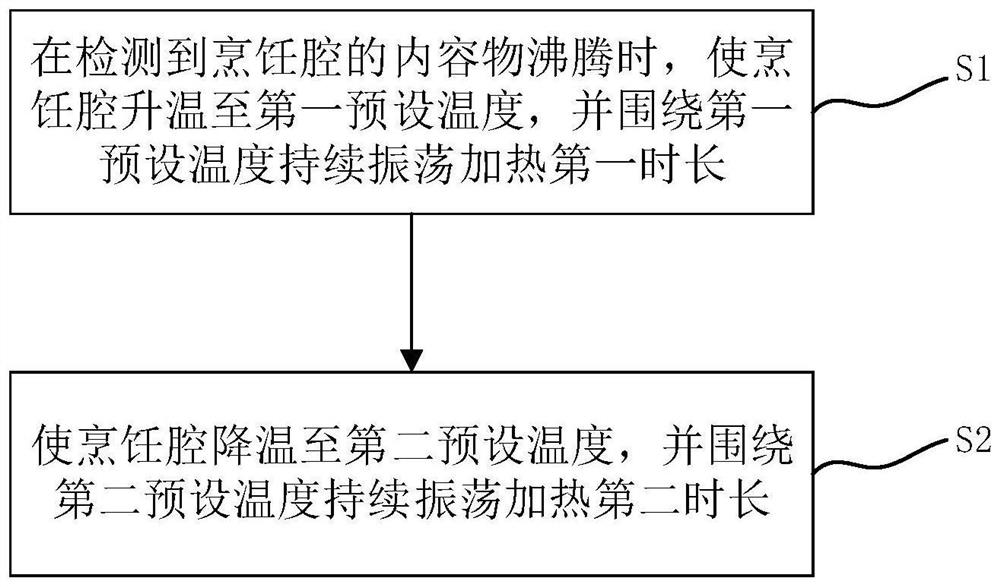

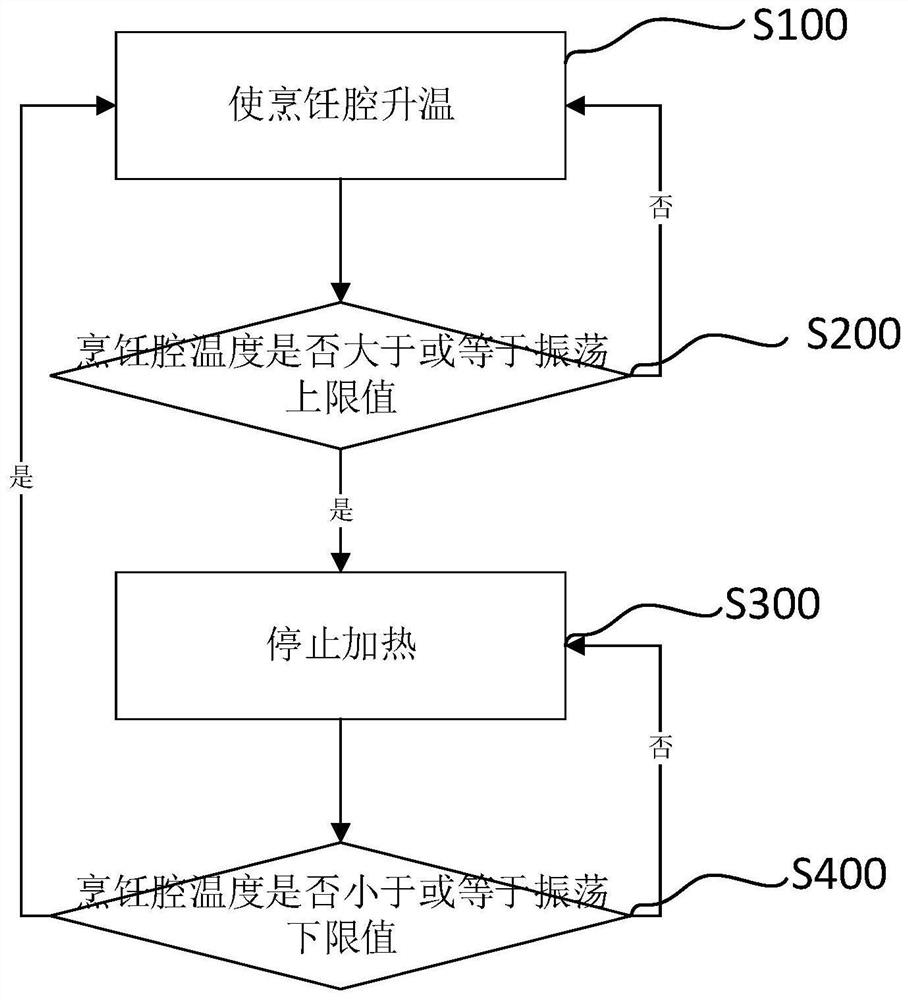

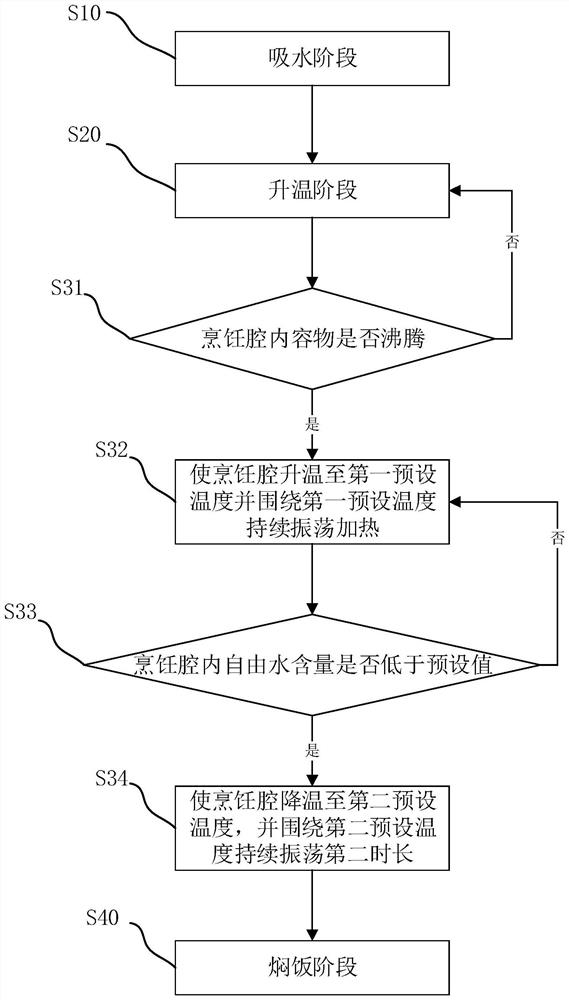

Cooking utensil, control method and device thereof, and storage medium

InactiveCN111938410AFully boiledPromote boilingTemperatue controlWarming devicesThermodynamicsProcess engineering

Owner:GREE ELECTRIC APPLIANCES INC

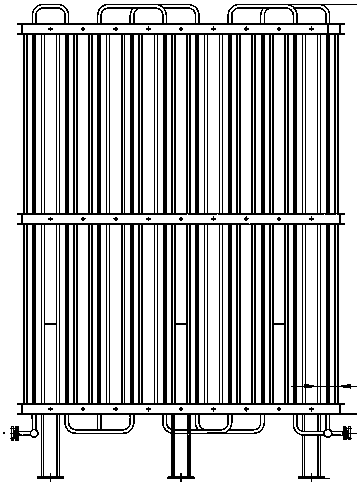

Heat pipe type heat energy recovery device

The invention discloses a heat pipe type heat energy recovery device which comprises a condensing box. A set of heat pipe assemblies is vertically arranged in the condensing box in a sleeved mode. Each heat pipe assembly comprises a U-shaped outer frame, a separation plate horizontally arranged on the inner wall of the outer frame and a gravity heat pipe vertically penetrating through the separation plate. The space below each separation plate forms a steam chamber, and the space above each separation plate forms a condensing chamber. A lower inlet, a lower outlet and a drain outlet are formed in the side wall of each steam chamber, and an upper inlet and an upper outlet are formed in the side wall of each condensing chamber. The lower inlets are connected with a tail effect evaporation tank, the lower outlets are connected with a cooling system, and the drain outlets are connected with an equipressure drainage assembly. Heat in juice steam is used for heating sugarcane juice at other procedures, vacuum is generated at the same time, sugarcane juice in the tail effect evaporation tank can conveniently boil, a large amount of cooling water is saved, and the problem that the gravity heat pipes are blocked is avoided.

Owner:韦华全 +1

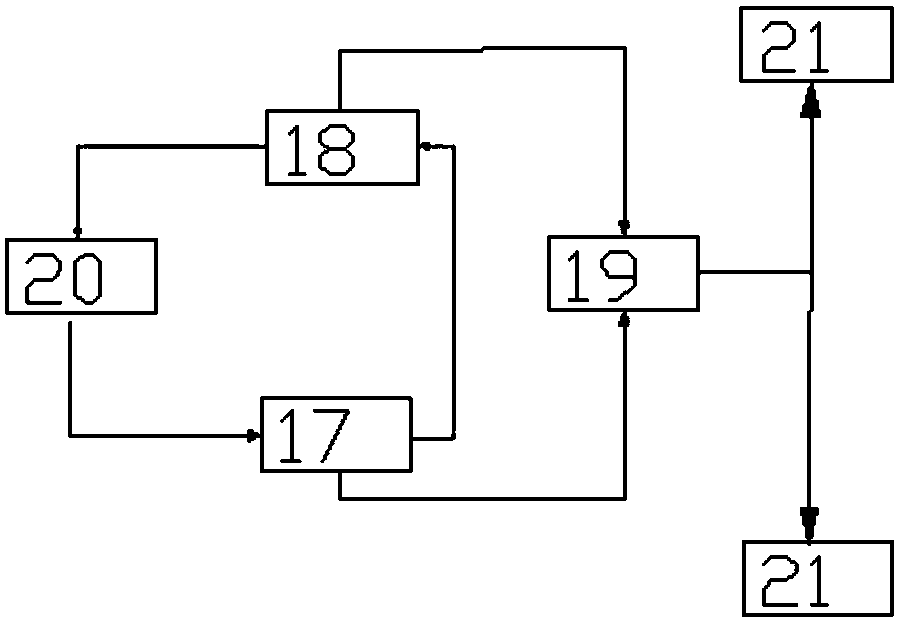

Micro loop heat pipe and method

PendingCN107687783AEasy reunionDoes not significantly deteriorate heat transferIndirect heat exchangersThermodynamicsMicro-loop heat pipe

The invention discloses a micro loop heat pipe and a method. The micro loop heat pipe comprises an evaporation chamber. One end of the evaporation chamber is connected with an inlet of a condensing chamber through a steam pipe. The other end of the evaporation chamber is connected with an outlet of the condensing chamber through a liquid backflow pipe. The interior of the evaporation chamber is partitioned into an evaporation space and a backflow liquid storage space communicating with the evaporation space through a thermal insulating partition plate made of a thermal insulating material. A plurality of layers of capillary cores with different hole diameters are arranged in each of the evaporation space and the backflow liquid storage space. When external heat is input through the wall surface of the evaporation space, a nano fluid working medium in the evaporation space is heated and evaporated to generate steam; and the steam enters the condensing chamber through the steam pipe andis condensed, then flows back to the backflow liquid storage space along the liquid backflow pipe, and then returns to the evaporation space through the bottom of the evaporation chamber, namely a bottom channel of the thermal insulating partition plate; and circulation is achieved in this way.

Owner:SOUTH CHINA UNIV OF TECH

Ejector

InactiveUS20160090995A1Reduction in nozzle efficiencyLow efficiencyJet pumpsVehicle heating/cooling devicesEngineeringNozzle

A swirling space in which a refrigerant is swirled into a gas-liquid mixing state includes an upstream swirling space in which the refrigerant flowing from an external is swirled, and a downstream swirling space in which the refrigerant flowing from the upstream swirling space is introduced into a nozzle passage while swirling. Further, a cross-sectional shape of an outlet part of the upstream swirling space is formed into an annular shape along an outer peripheral shape of the upstream swirling space.

Owner:DENSO CORP

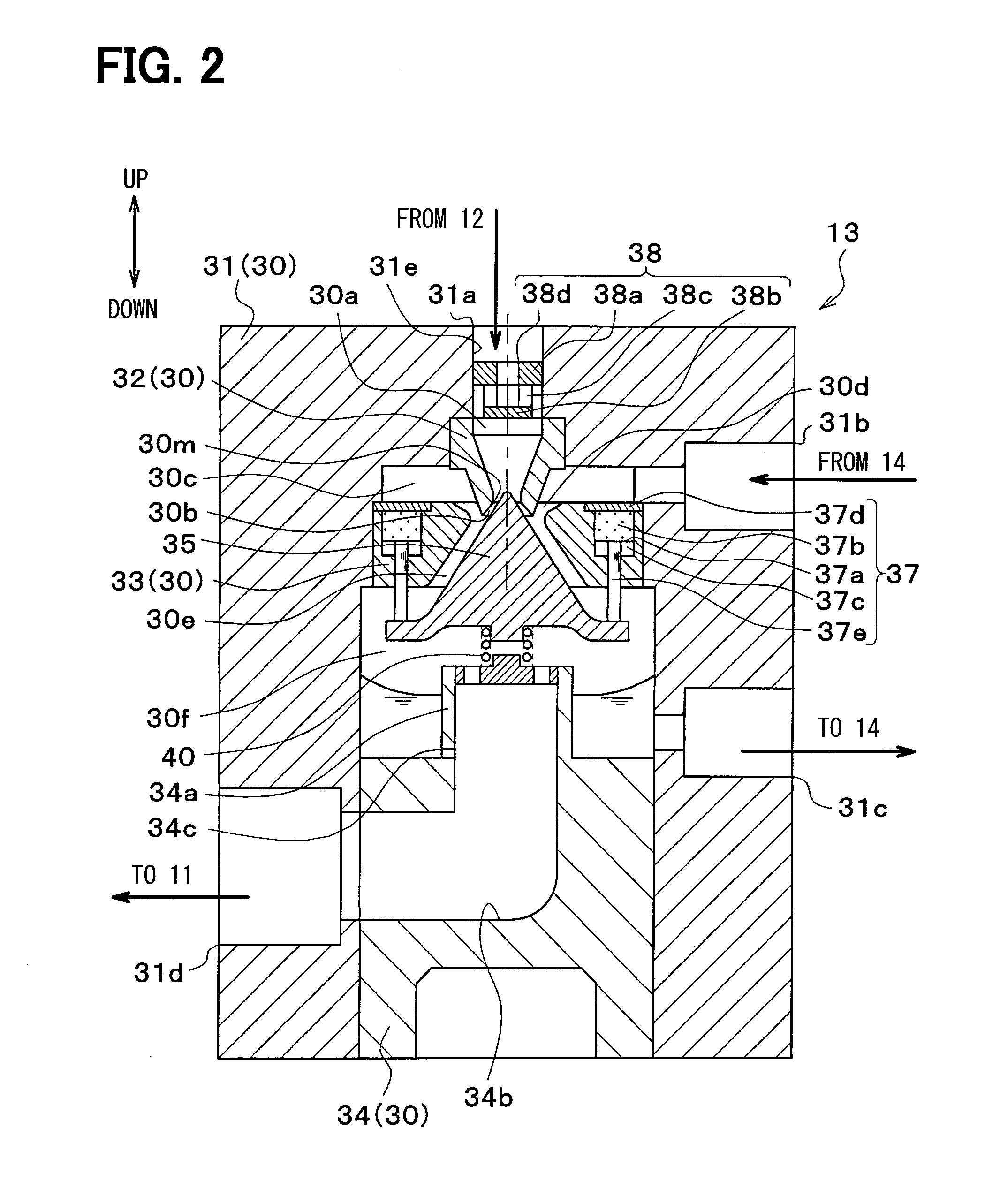

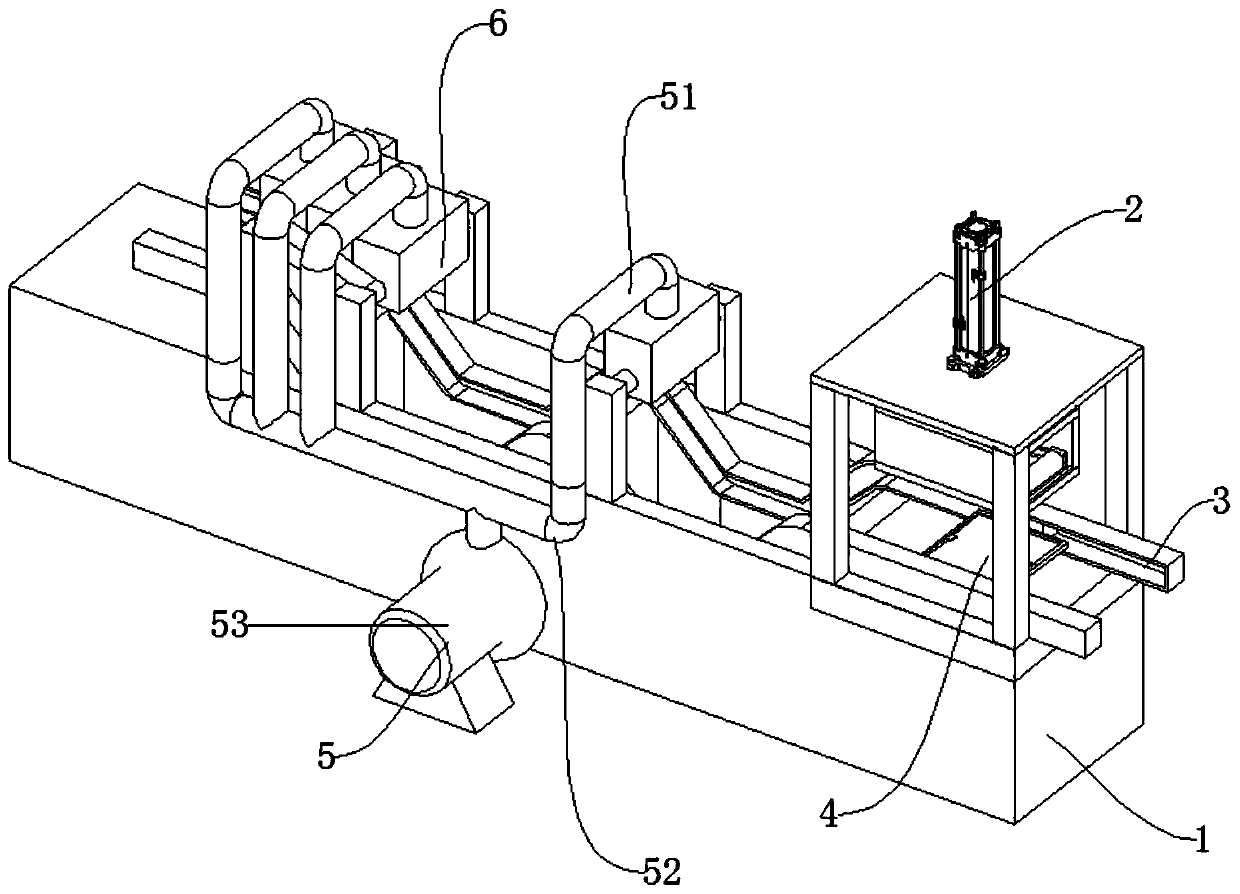

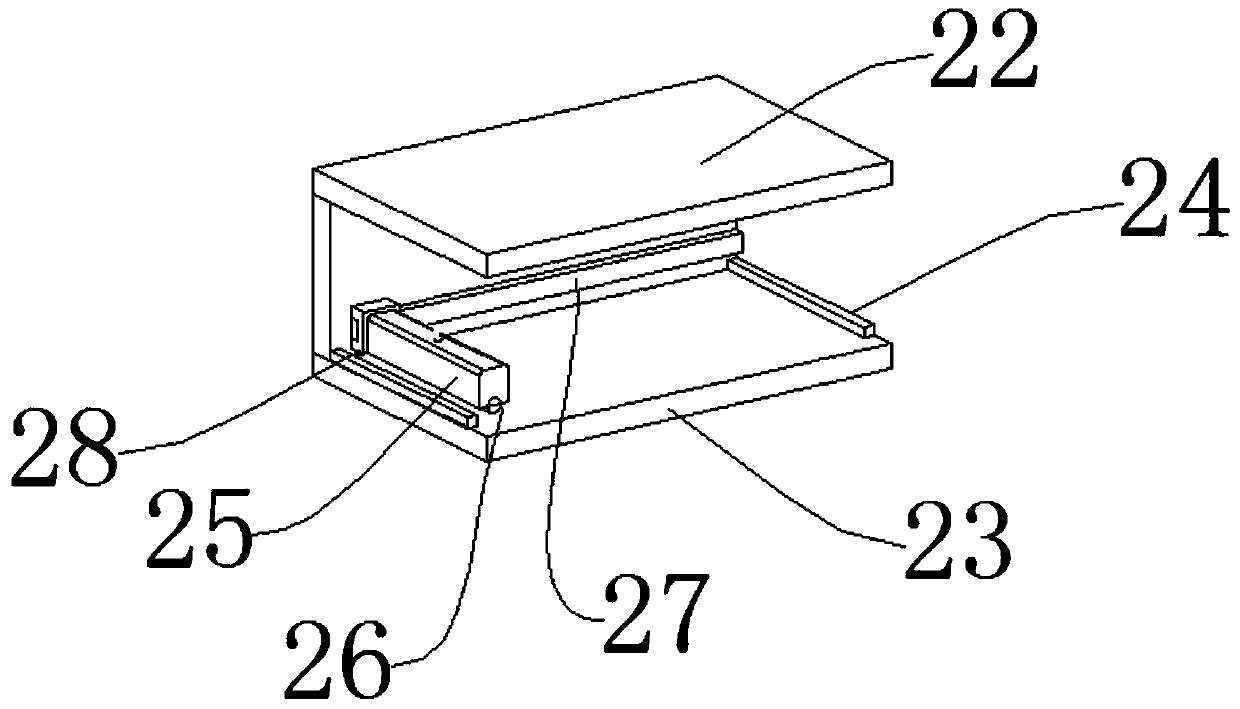

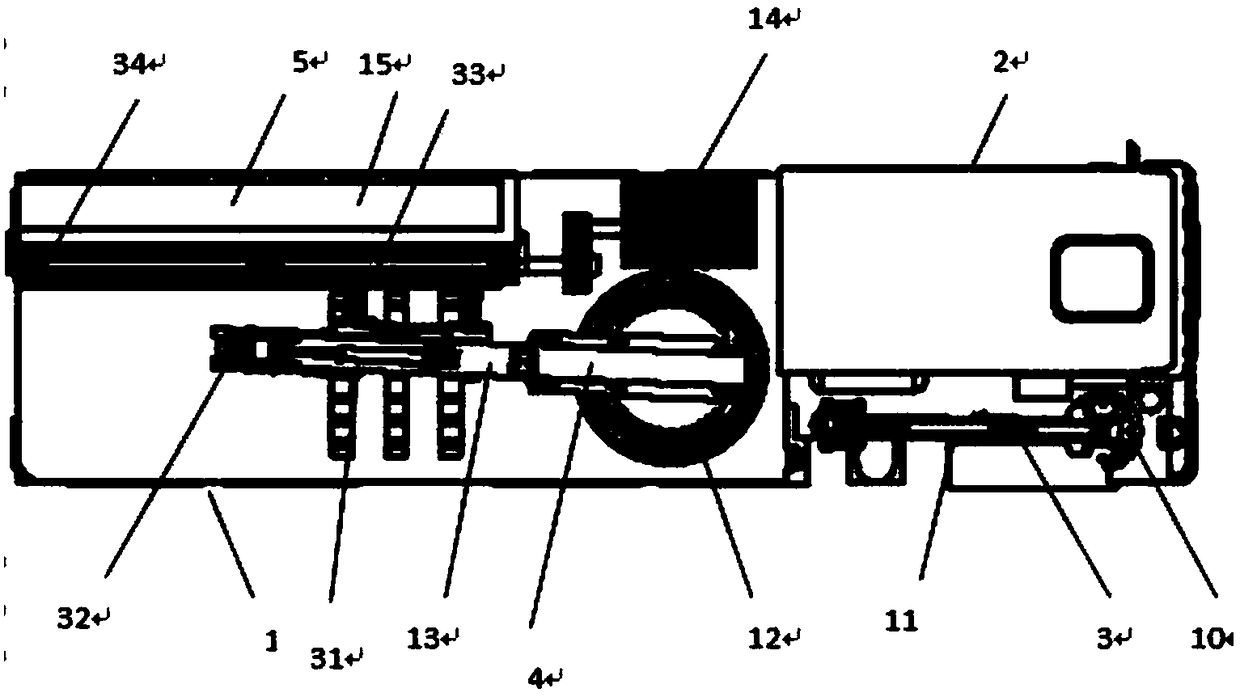

Etching device for manufacturing semiconductor chip and use method thereof

PendingCN110416133AAvoid overetchingReasonable structureSemiconductor/solid-state device manufacturingConveyor partsEtchingSemiconductor chip

The invention discloses an etching device for manufacturing a semiconductor chip and a use method thereof. The etching device comprises a supporting mechanism, a transporting mechanism, a printing mechanism, a gas supply mechanism and a reaction mechanism. The transporting mechanism is connected with the supporting mechanism and used for driving a circuit board to be etched to move along a presettrajectory. The printing mechanism, the gas supply mechanism and the reaction mechanism are sequentially arranged, and are all arranged above the transporting mechanism. The output end of the gas supply mechanism is connected with the input end of the reaction mechanism. When the circuit board moves below the reaction mechanism, the gas supply mechanism supplies high pressure gas to the reaction mechanism, and the reaction mechanism blows gas to the circuit board. According to the invention, the transporting mechanism is used to drive the circuit board to move along the preset trajectory; thecircuit board is printed by using the printing mechanism; the gas supply mechanism supplies high pressure gas to the reaction mechanism; when the circuit board moves to the reaction mechanism, the circuit board is cleaned by the high pressure gas; excessive etching of reaction liquid is avoided; and the yield is greatly improved.

Owner:NANJING COLLEGE OF INFORMATION TECH

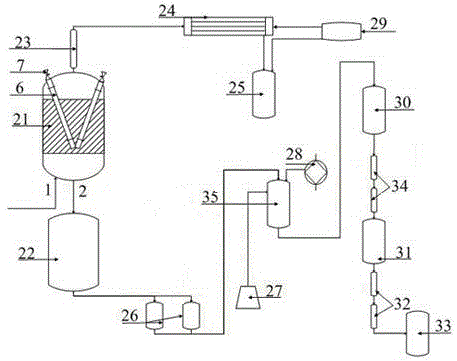

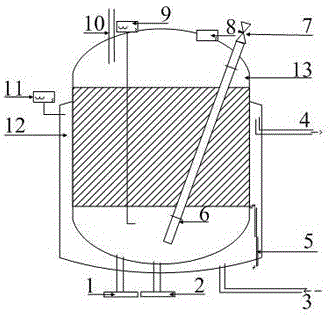

Purifying system and process for 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane

InactiveCN105541689AShorten distillation timeImprove permeabilityOrganic compound preparationPeroxy compound preparationDistillationMaterial consumption

The invention discloses a purifying system for 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane. The system comprises a distillation kettle and a decoloring kettle; the distillation kettle is connected with the decoloring kettle through a material conveying pipeline; the distillation kettle comprises a casing; an air inlet pipe is arranged in the casing; the distance between one end of the air inlet pipe and the bottom of the casing is 10 to 200 mm; the other end of the air inlet pipe is connected with the top wall of the casing; the arrangement of the air inlet pipe is favorable to introduce air into liquid to assist the boiling of the liquid; the decoloring kettle is arranged, so that the product quality is improved. The invention further provides a purifying process for the 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane. Distillation is performed under the conditions of 61 to 68 DEG C and -0.093 to 0.098 MPa; the air is introduced into the liquid for distilling; the product is decolored after the distilling is completed; the distilling time is shortened; the purity and the chromaticity of a target product are improved; the energy consumption and material consumption for purifying are reduced.

Owner:宜宾高县钧恒新材料有限公司

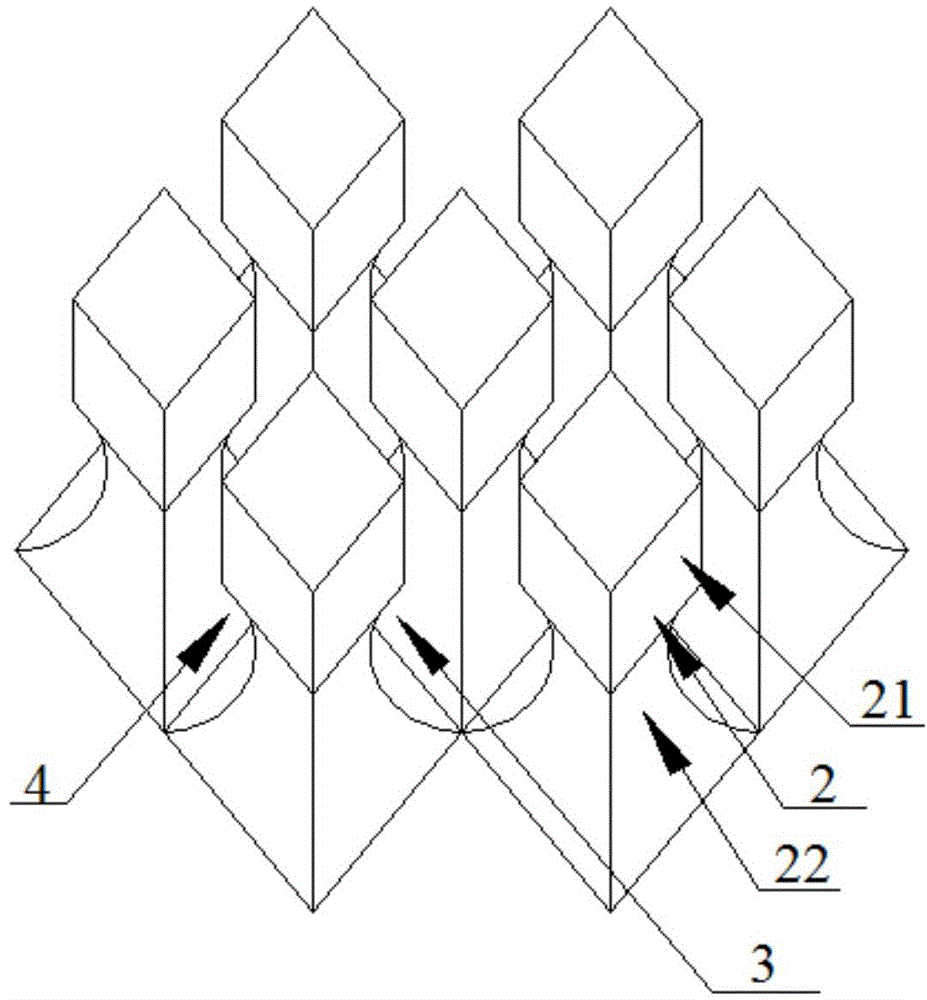

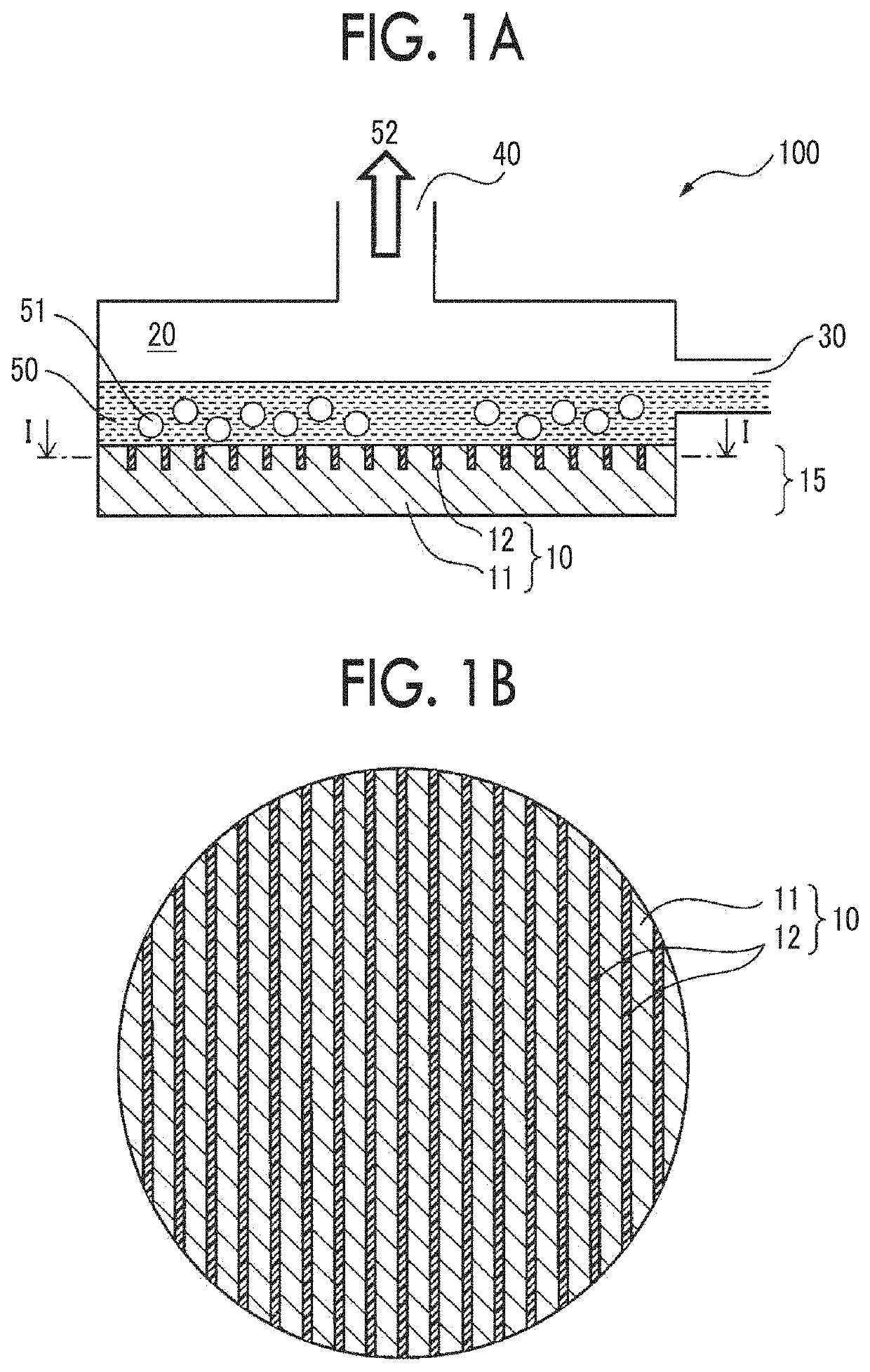

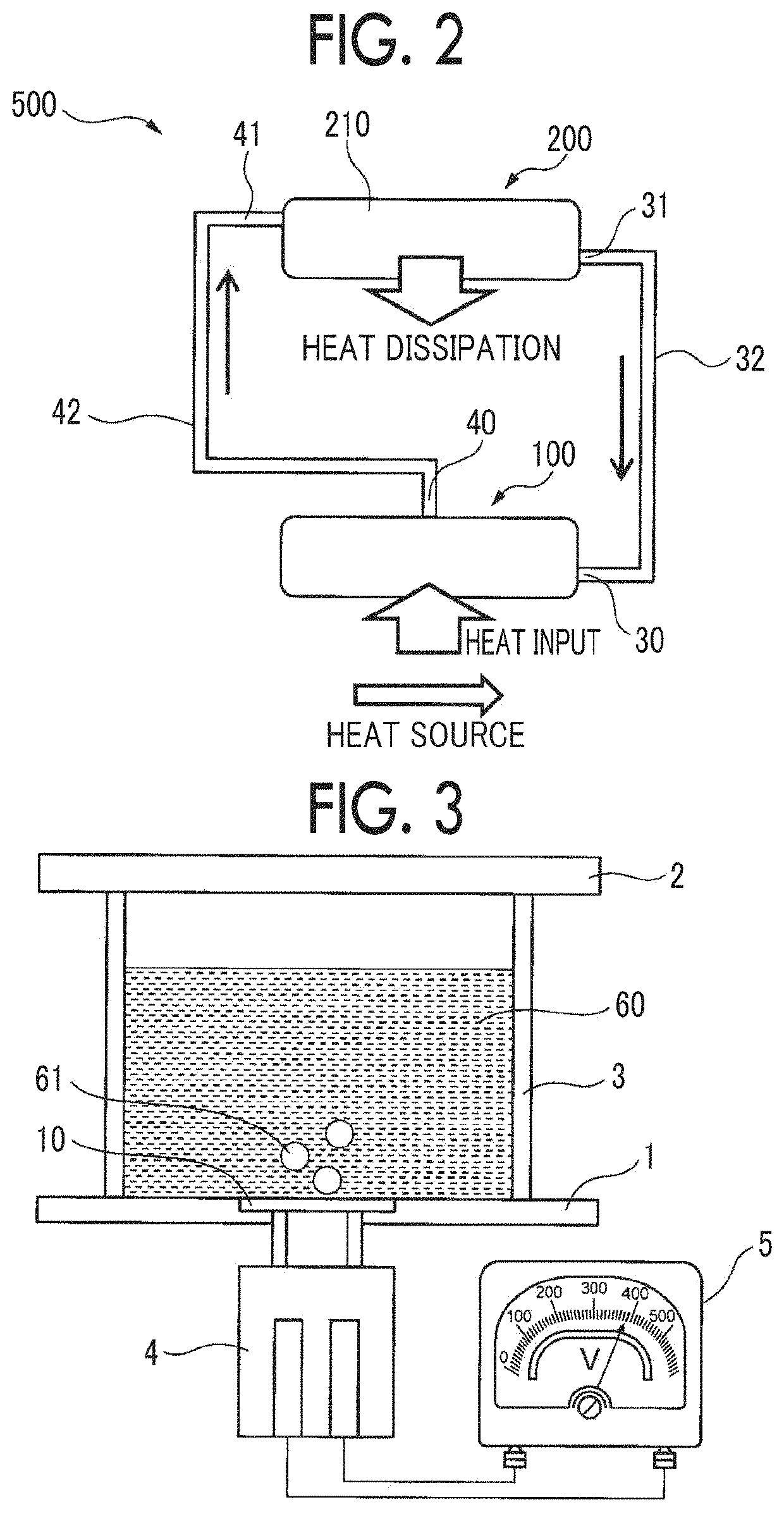

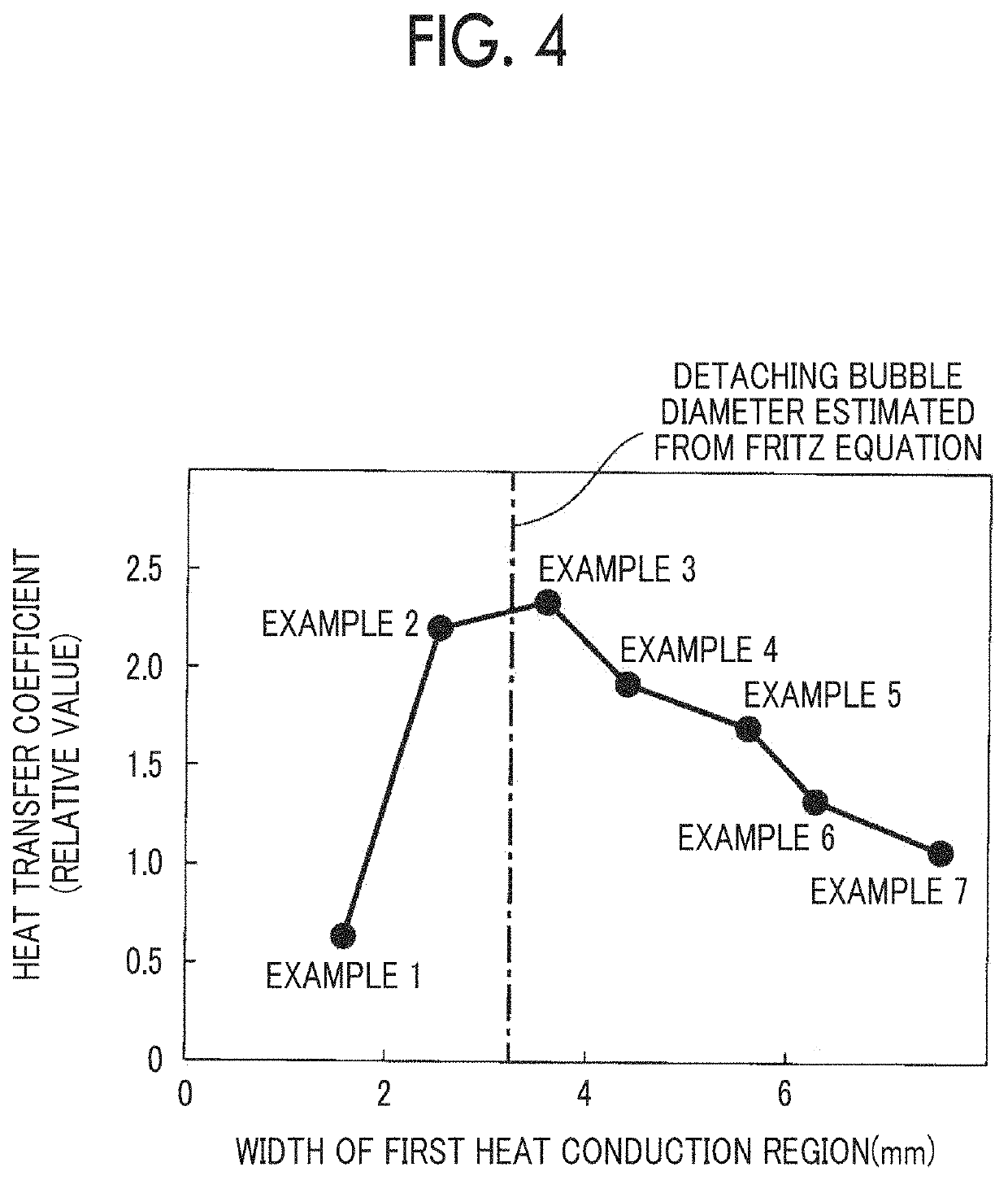

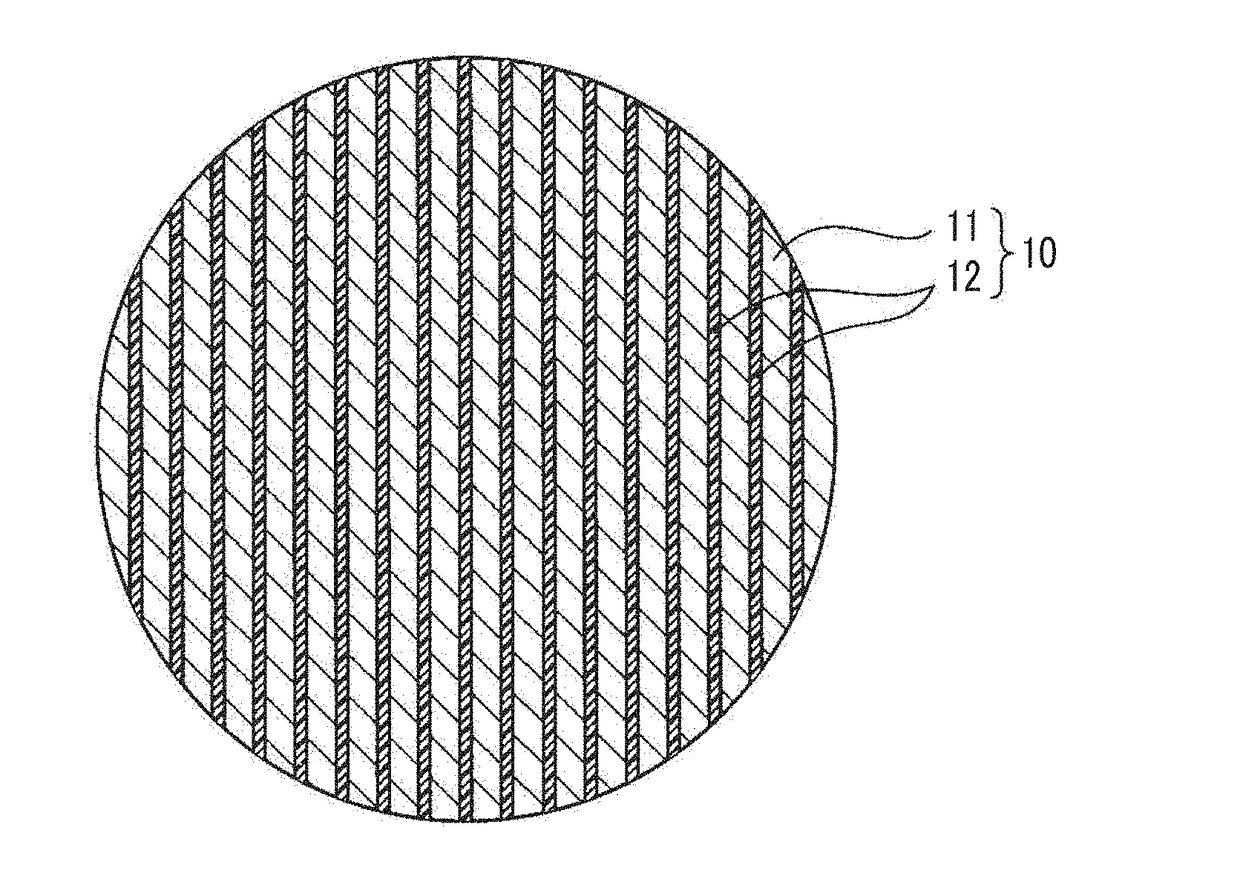

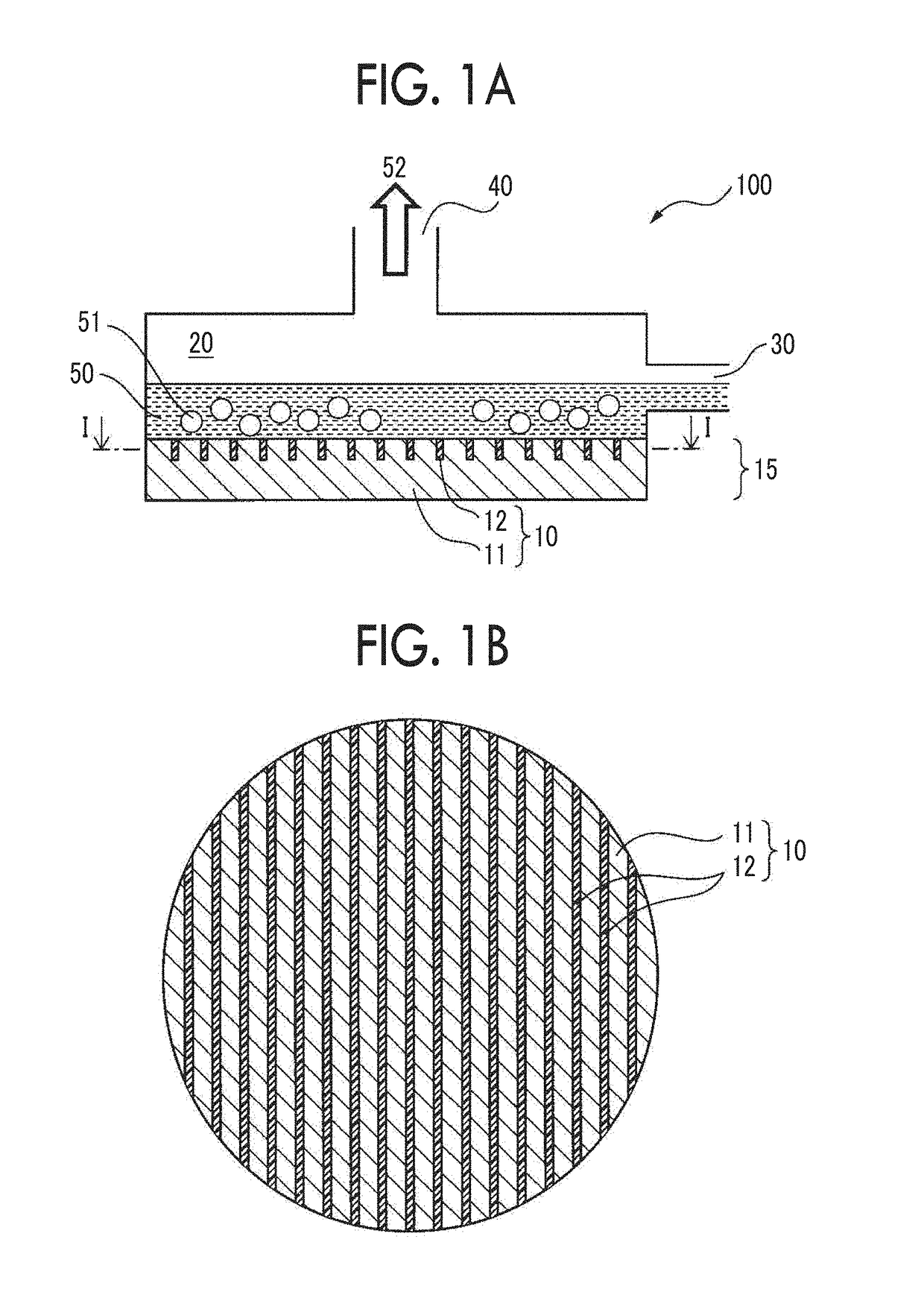

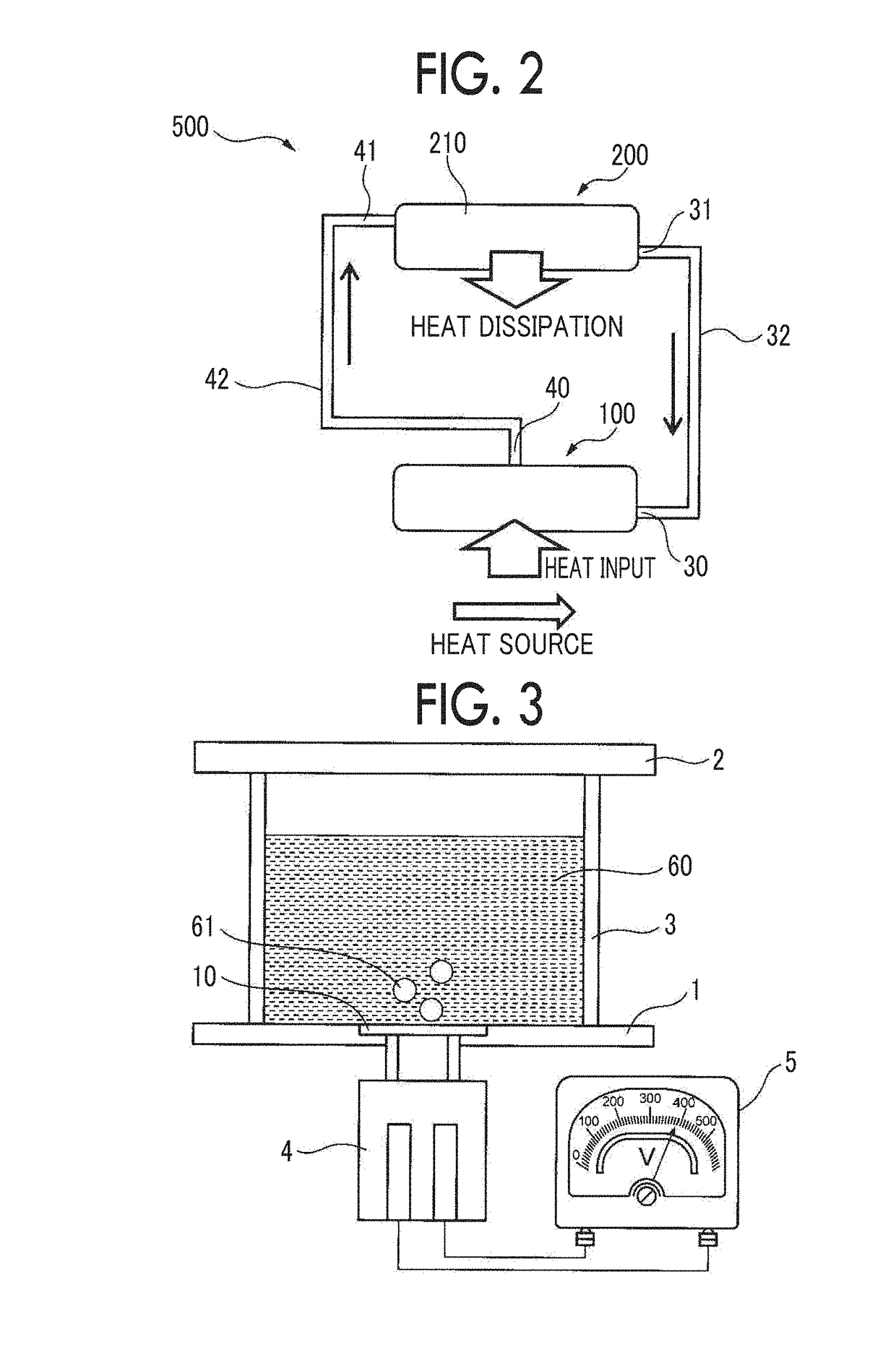

Heat exchanger, heat exchange method using heat exchanger, heat transport system using heat exchanger, and heat transport method using heat transport system

ActiveUS10816283B2Promote generationImprove the overall coefficientRecuperative heat exchangersHeat transfer modificationHeat transmissionEngineering

A heat exchanger is configured to perform heat exchange by boiling a liquid by heat transfer from a heat source to the liquid through a heat transfer member. In the heat exchanger, a first heat conduction region and a second heat conduction region are alternately provided in a form of stripes on a surface on a side that contacts the liquid such that the liquid boils via a heat transfer member.

Owner:TOYOTA JIDOSHA KK

heat exchanger

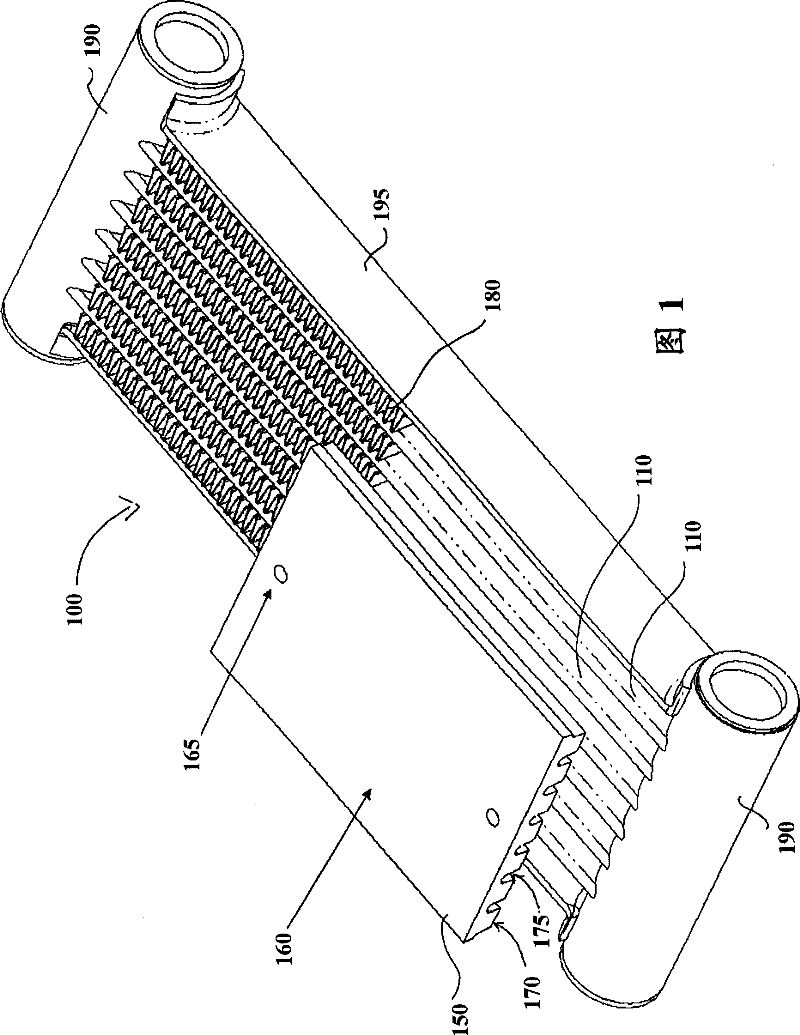

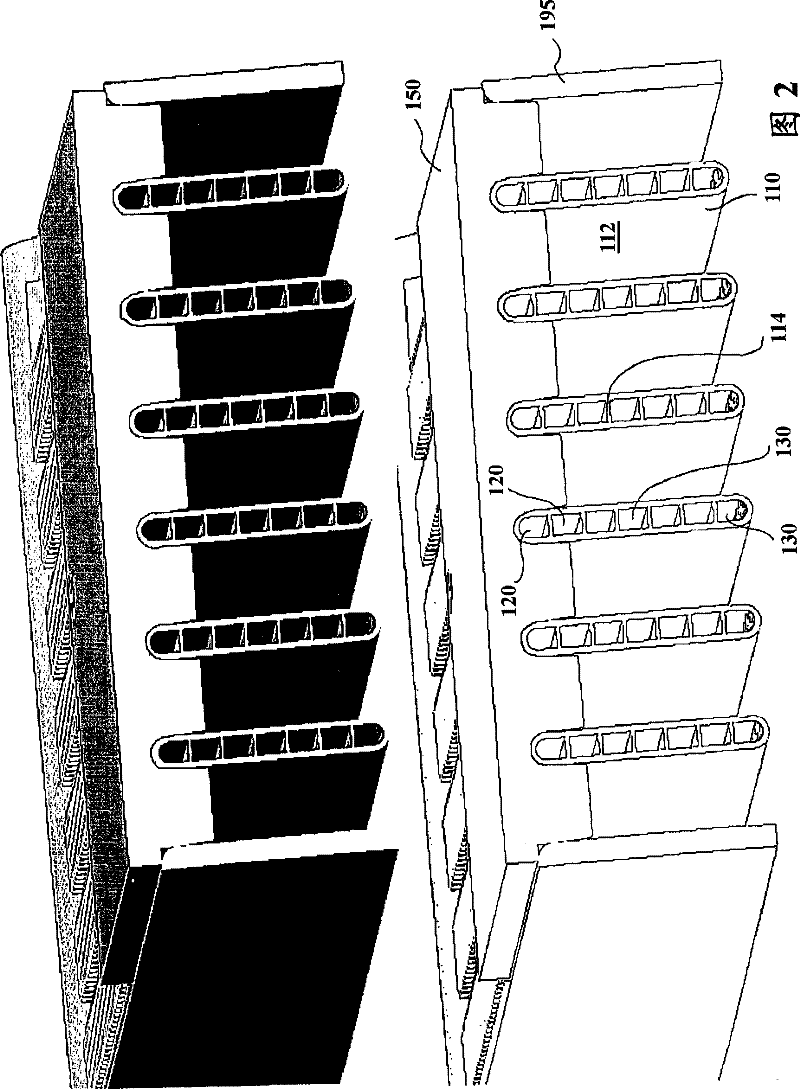

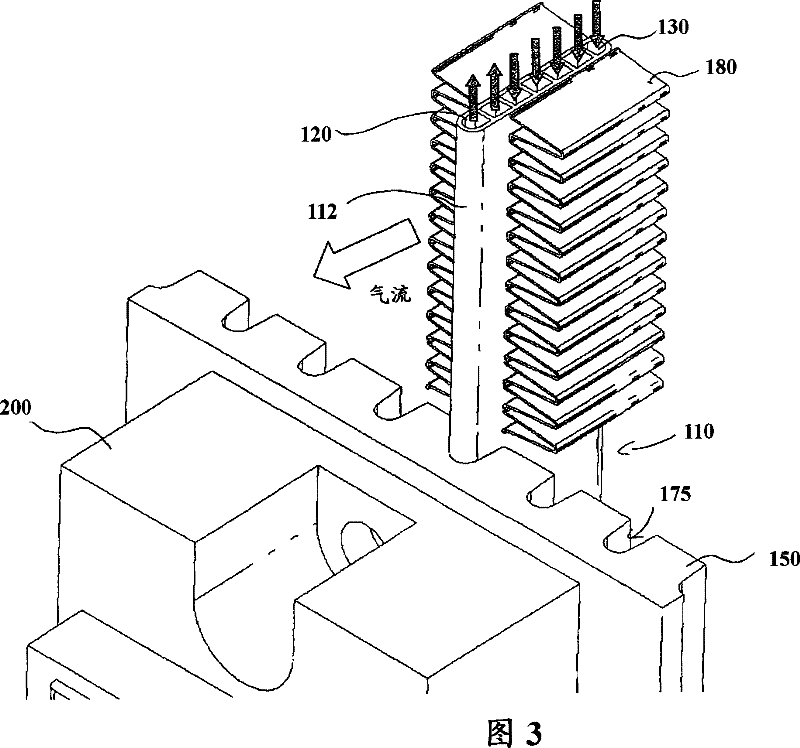

ActiveCN101377392BEfficient removalLow costStationary conduit assembliesHeat transfer modificationWorking fluidEngineering

The present invention provides a heat exchanger (100) for removing heat energy from a heat generator (200), comprising at least one conduit (110) for a working fluid, which is arranged in an upright position of at least 45°, each conduit having an exterior wall (112) and at least one interior wall (114) for forming at least one evaporator channel (120) and at least one condenser channel (130) within the conduit (110). Furthermore, the heat exchanger (100) comprises a first heat transfer element (150; 183) for transferring heat into the evaporator channel (120) and a second heat transfer element (180) for transferring heat out of the condenser channel (130).

Owner:ABB (SCHWEIZ) AG

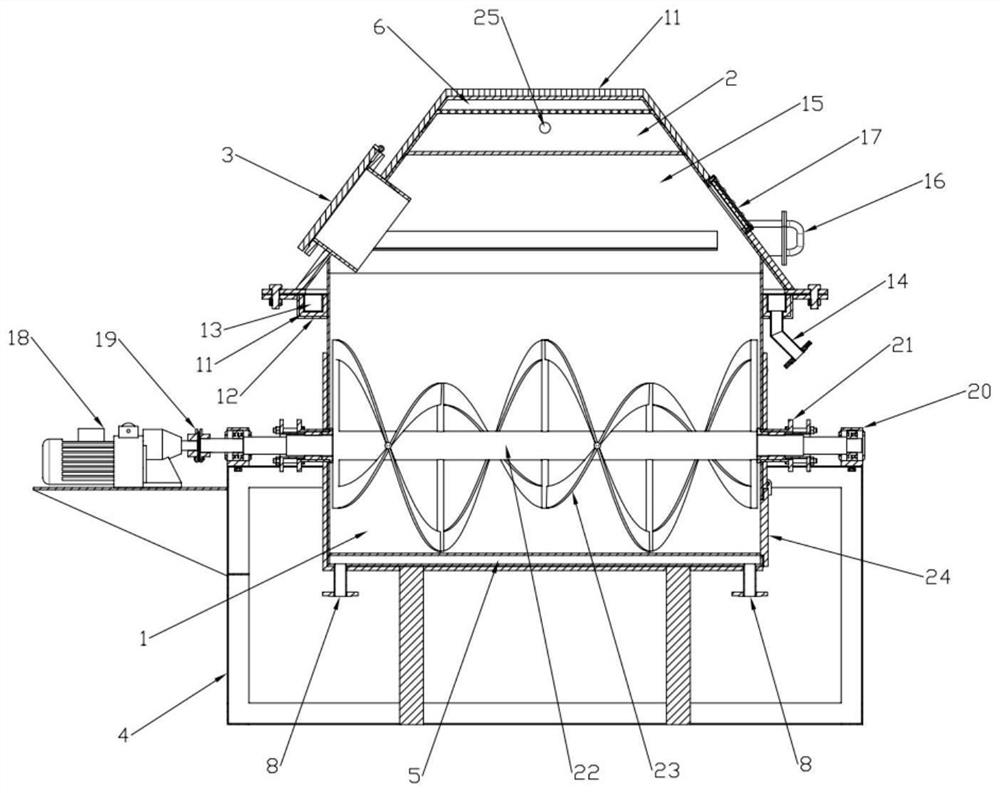

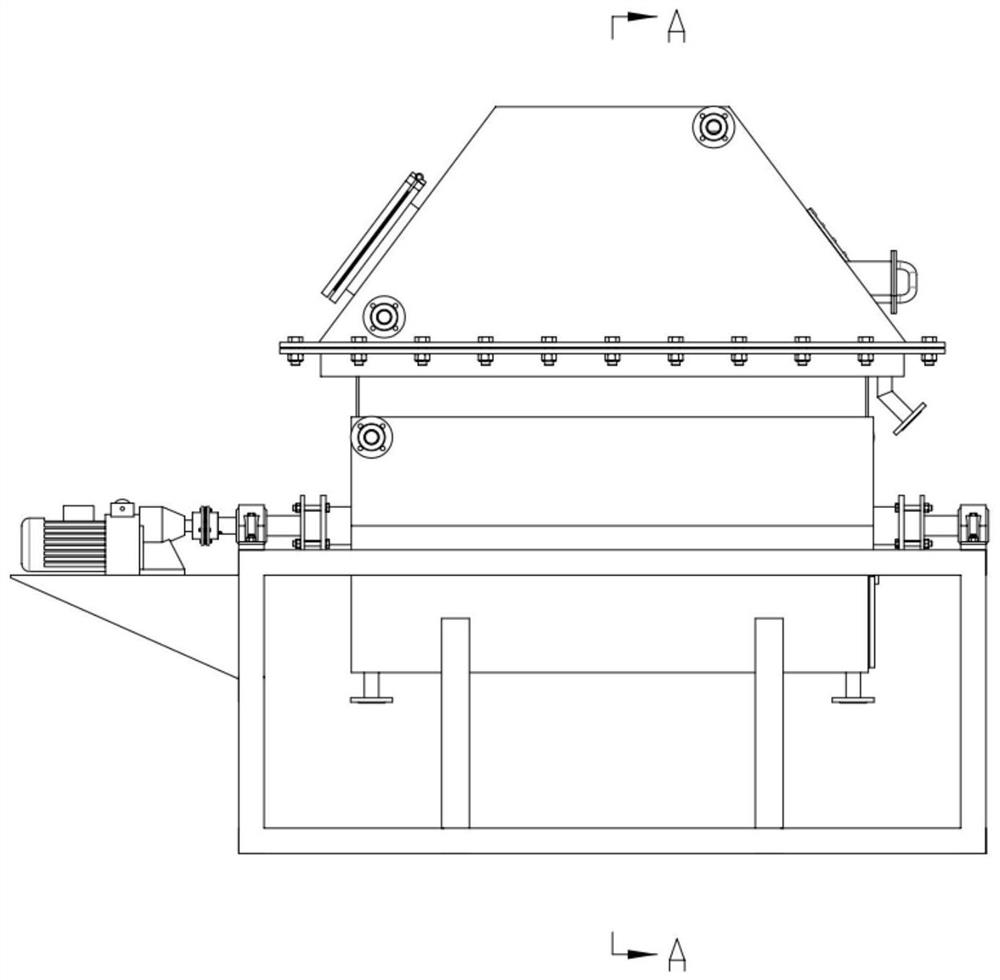

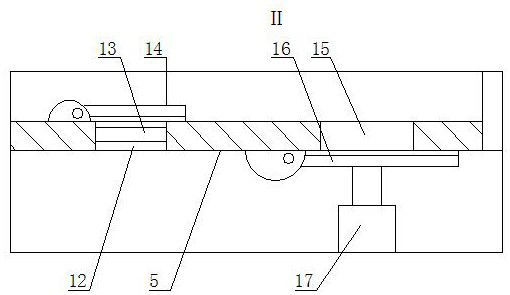

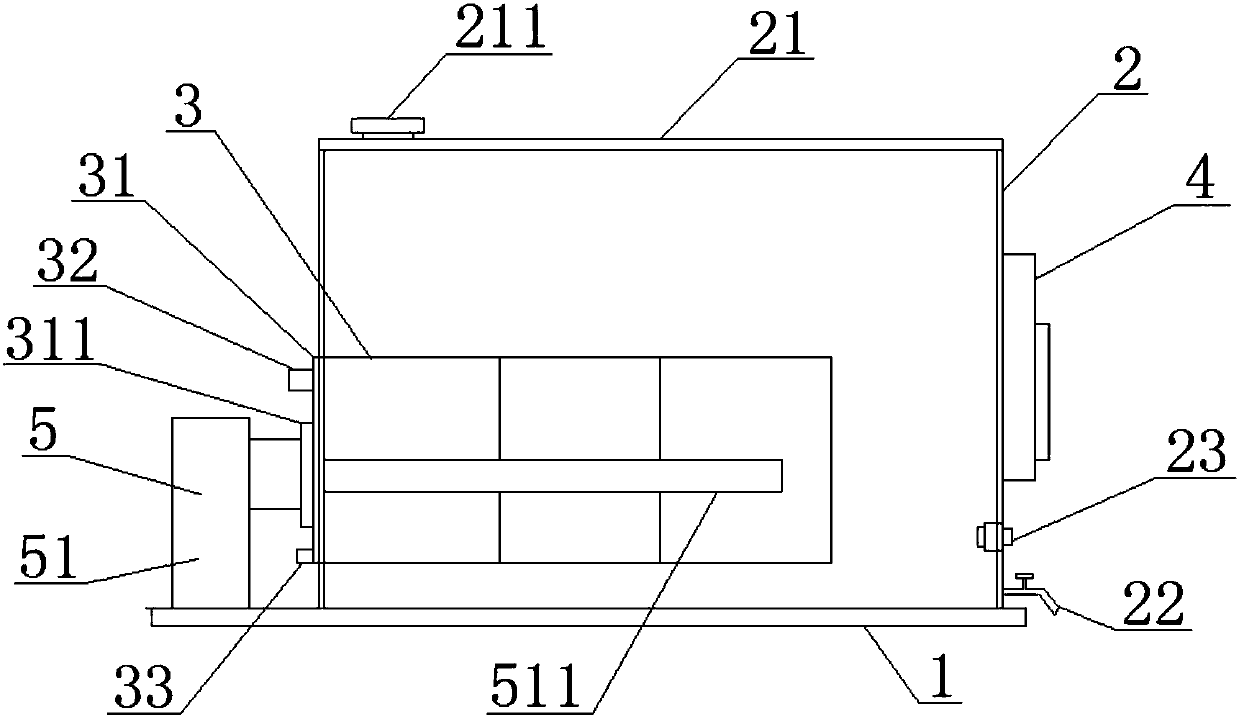

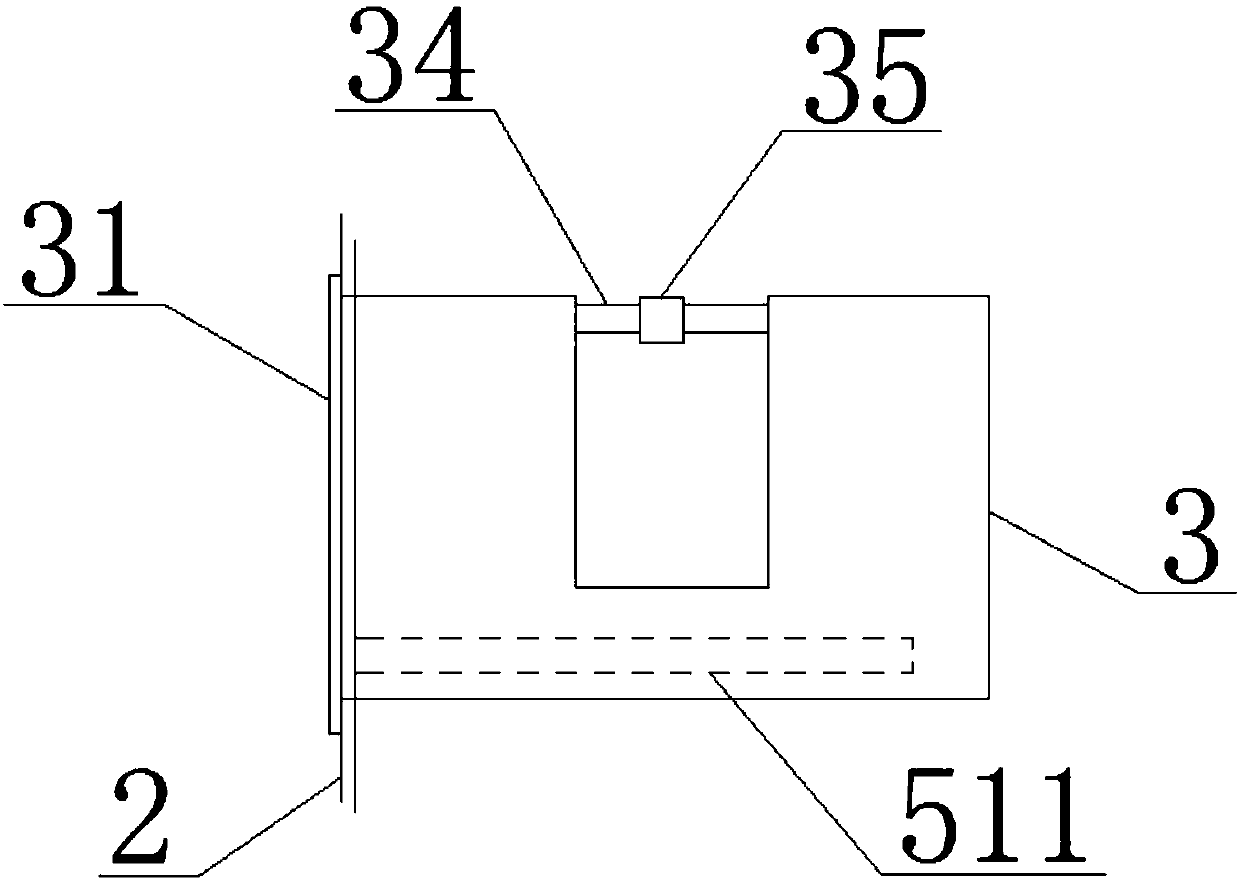

Horizontal drying device and system

PendingCN113606877AImprove the heating effectFacilitate heat exchangeDrying solid materials without heatSteam/vapor condensersWater vaporGravity center

The invention relates to a horizontal drying device and system. The horizontal drying device comprises a heating box, a condensing box and a stirring mechanism, the condensing box is arranged at the upper portion of the heating box, the condensing box and the heating box are connected and communicated with each other to form a working cavity, and one end of the stirring mechanism extends into the heating box from the side wall of one side of the heating box and extends out of the side wall of the other side of the heating box; and the stirring mechanism can stir heating materials in the heating box, a feeding port is formed in the side wall of the condensing box, and a discharging port is formed in the heating box in a communicating manner. The materials in the heating box are heated through the heating box, and the materials in the heating box are stirred through the transversely-arranged stirring mechanism, so that the materials are evenly heated, water vapor generated in the heating process of the materials upwards enters the condensing box and then is condensed, a certain vacuum degree is formed in the working cavity, boiling and evaporation of the materials are facilitated, the drying efficiency is improved, the material water removal efficiency is improved, the structure is simple and compact, the whole structure is efficient and energy-saving, the gravity center is lower, and the working stability is good.

Owner:广州坤域能源环保科技有限公司

Device and method for detecting residual chlorine in water for heat treatment of tire bead wire

PendingCN114684990ABig spaceImprove sealingWater treatment parameter controlWater treatment compoundsTire beadWater use

A residual chlorine detection device for tire bead wire heat treatment water comprises a tank, a heating wire is wound on the periphery of the tank, a drain hole and a water inlet are formed in the tank, a valve is arranged at the drain hole, a residual chlorine probe is fixedly installed in an exhaust hole, and an upper box and a lower box are arranged in the tank in a sliding mode. And the periphery of the upper box body and the periphery of the lower box body are respectively in airtight sliding contact fit with the inner periphery of the tank body. The device is simple in structure and ingenious in conception, scales on the side wall of the tank body are scraped and the inner wall of the tank body is cleaned through the upper box body and the lower box body which continuously move up and down, and in the up-down moving process of the upper box body, the space between the upper box body and the lower box body can be increased, so that negative pressure is formed, tap water can be boiled conveniently, residual chlorine in the tap water can overflow conveniently, and the service life of the tank body is prolonged. And meanwhile, the scraped scaling slag can be collected between the upper box body and the lower box body, the market requirement can be met, and the device is suitable for popularization.

Owner:SHANDONG DAYE

Water-oil integrated water tank

The invention relates to heating water tank equipment, in particular to a water-oil integrated water tank. The water-oil integrated water tank comprises a base, a water tank body, a heating oil tank,a control box and an electric heating device. The water tank body is fixedly installed on the base. A tank cover is installed at the top of the water tank body and is further provided with a water inlet cover. A water outlet valve is arranged at the outer side of the lower portion of the water tank body. A tank body connecting plate is arranged on the side portion of the heating oil tank and is further fixedly connected to the side face of a water tank main body. The heating oil tank is fixedly installed inside the water tank body through the tank body connecting plate arranged on the side portion of the heating oil tank. The electric heating device is fixedly installed on the base. The water-oil integrated water tank has the advantages that the independent heating oil tank is arranged inside the water tank body, water in the water tank body can be heated indirectly, microbubbles in the water are restrained, and the mute heating effect is good; and the mode of water heating can be achieved indirectly by means of oil heating, the heating area of the water is increased, and the heat conversion efficiency is improved.

Owner:SHANDONG RONGAN ELECTRONICS SCI & TECH CO LTD

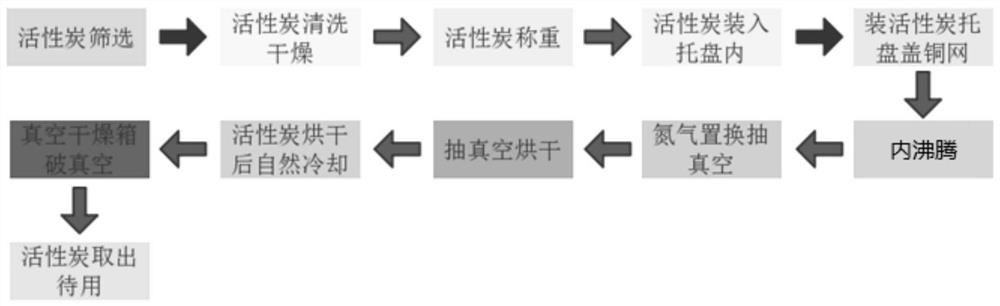

An internal boiling activated carbon treatment process

ActiveCN112076736BBoiling achievedPromote boilingCarbon compoundsOther chemical processesActivated carbonMicrowave - action

The invention relates to an activated carbon recovery processing technology and belongs to the field of activated carbon processing. An internal boiling activated carbon treatment process, the activated carbon is soaked in an alcohol-water solution; then the soaked activated carbon is heated in microwave radiation; finally, the activated carbon is dried in a vacuum system to obtain a recovered activated carbon product. The process uses the activated carbon internal boiling process, under the action of microwaves, combined with the control of air pressure, to regulate the internal boiling of the solution in the internal voids of the activated carbon, and promote the efficient discharge of harmful substances adsorbed inside the activated carbon. After testing, the specific surface area of activated carbon prepared by this process reaches more than 99.5% of that of the original activated carbon, and the adsorption capacity is almost the same as that of the original activated carbon.

Owner:中科富海(中山)低温装备制造有限公司

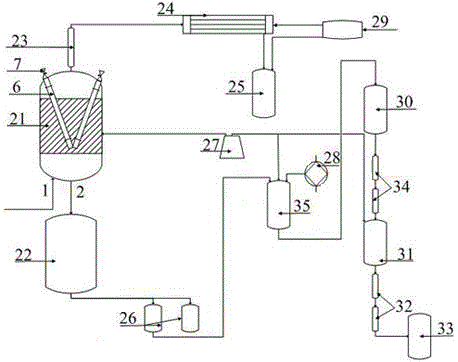

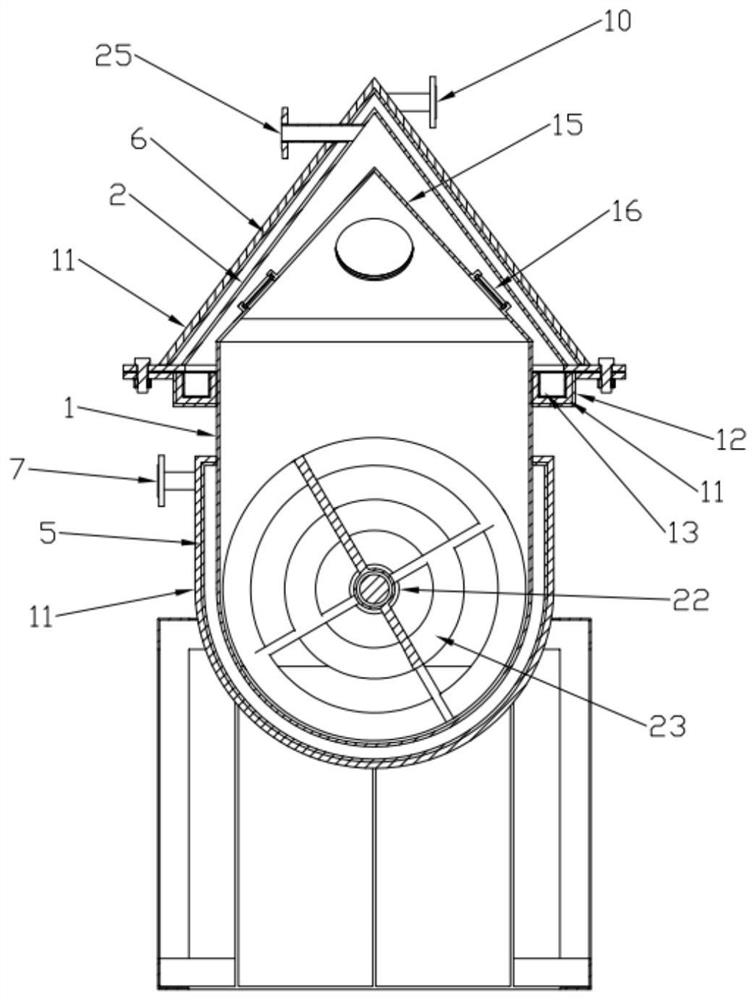

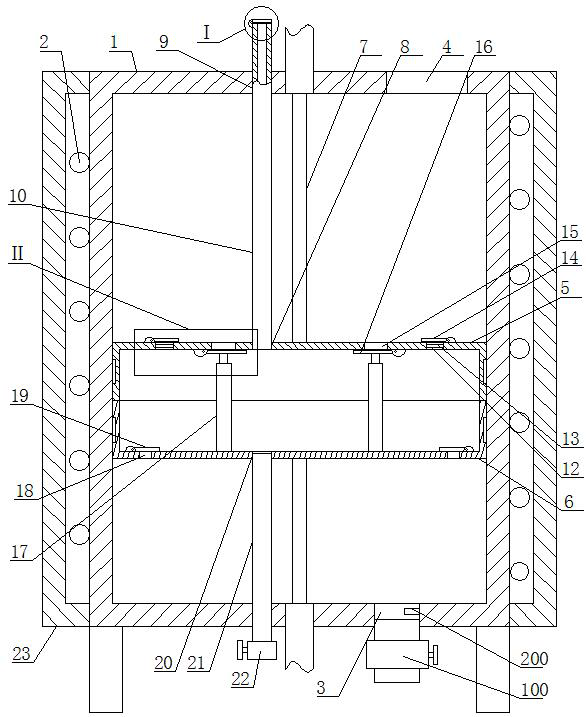

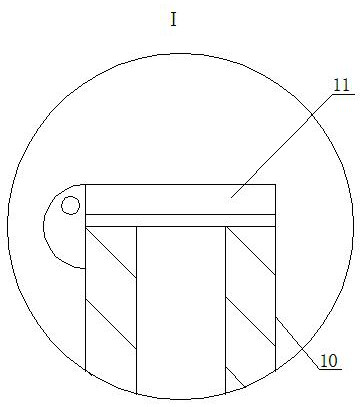

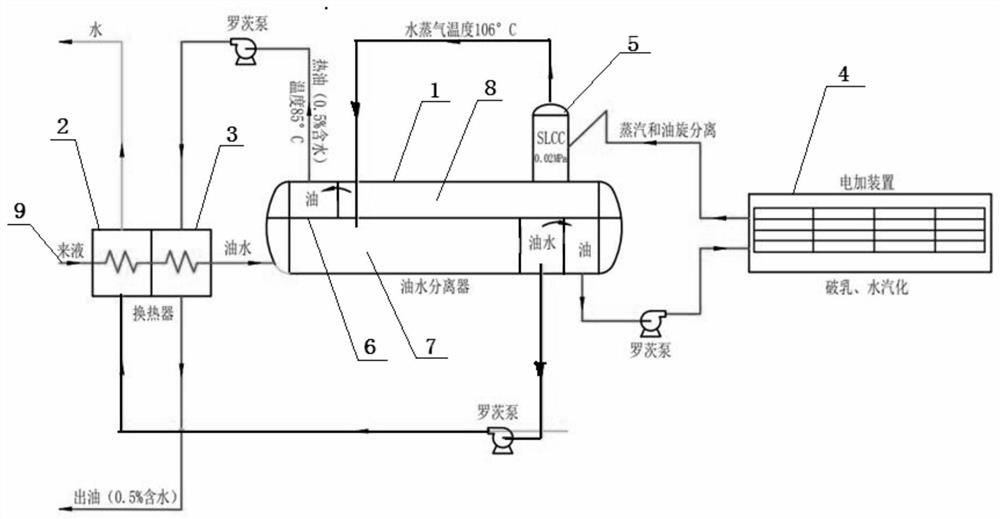

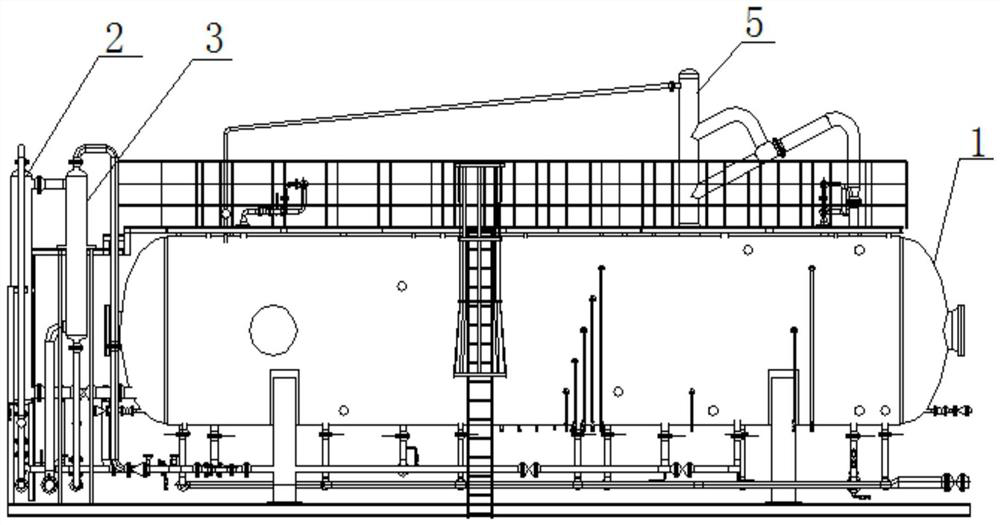

A device and method for oil-water demulsification separation of heavy oil

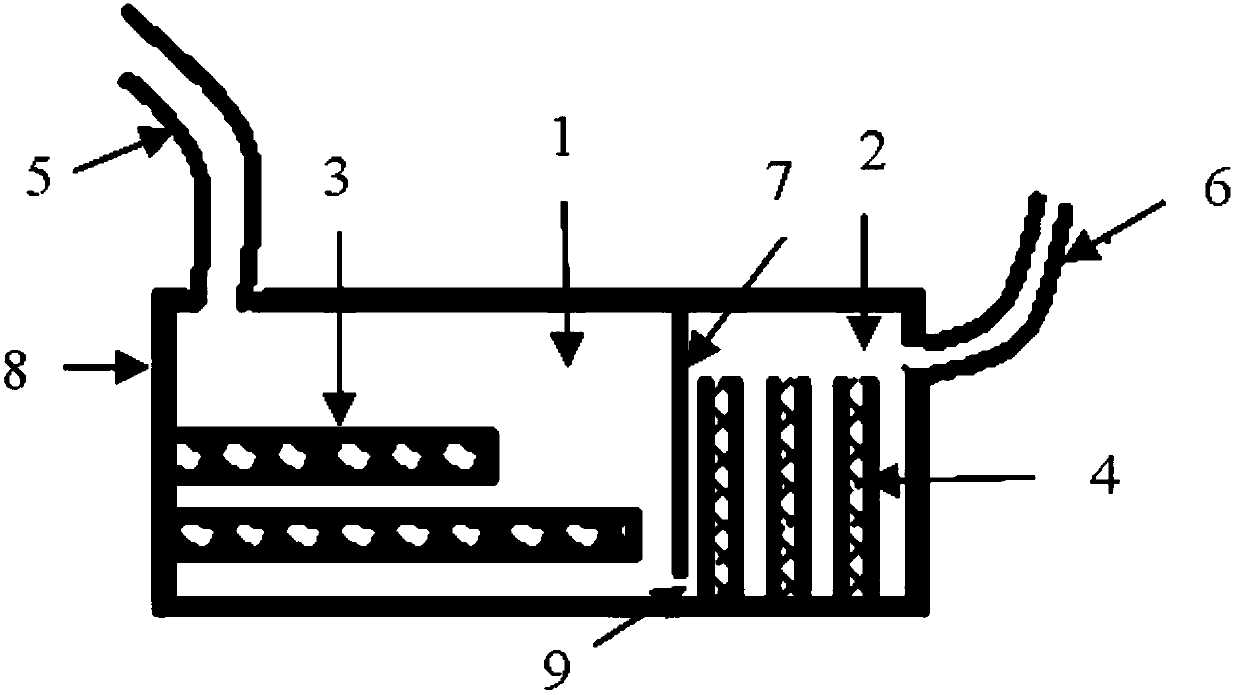

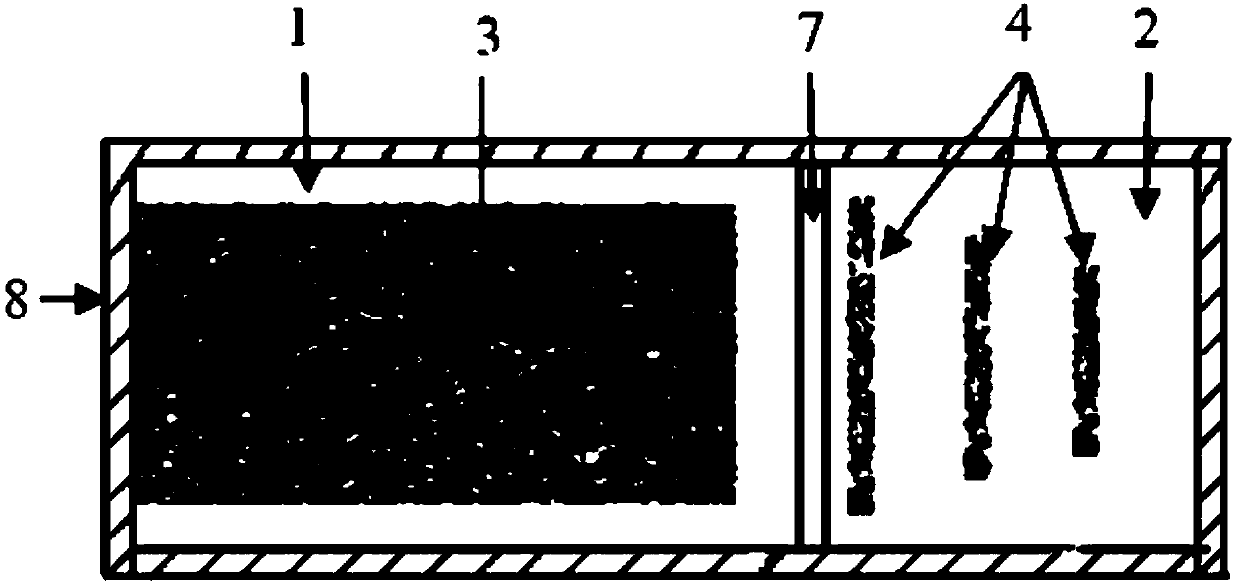

ActiveCN110643387BPromote boilingEfficient vaporizationDewatering/demulsification with mechanical meansDewatering/demulsification with electric/magnetic meansPhysical chemistryOil separation

The invention discloses a heavy oil oil-water demulsification separation equipment and method, comprising an oil-water separation tank, and is characterized in that it also includes an electromagnetic induction heater and a vapor-liquid cyclone separator. The oil-water separation tank is divided into a first-stage oil-water separation chamber and a second-stage oil-water separation chamber. The first-stage oil-water separation chamber is connected to the second-stage oil-water separation chamber through an electromagnetic induction heater and a vapor-liquid cyclone in turn. The separation method includes the following steps to mix the oil-water and send the liquid to the first-stage oil-water separation tank. The oil-water separation chamber is used for oil-water separation, and the oil phase separated in the first-stage oil-water separation chamber is sent to the electromagnetic induction heater for treatment. The liquid mixture obtained after flow separation enters the secondary oil-water separation chamber for oil-water separation again to obtain refined oil with a water content of less than 0.5%. The advantages are high oil-water separation efficiency, low energy consumption and high product purity.

Owner:新疆中亚石油天然气有限公司

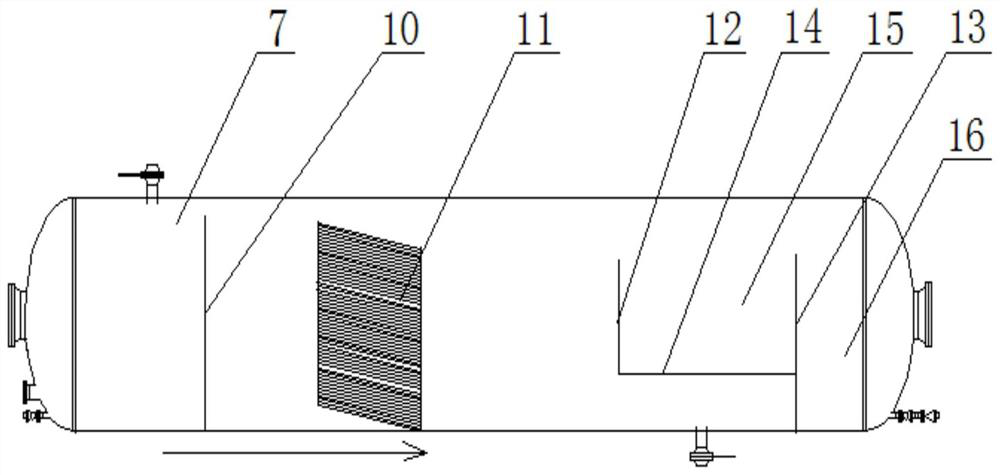

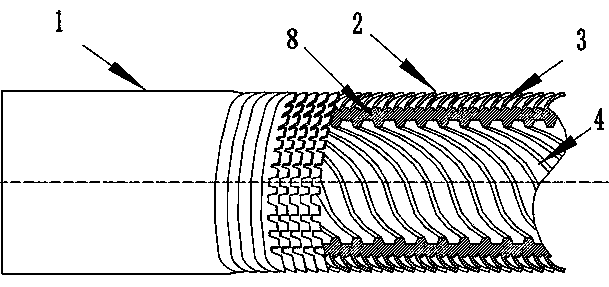

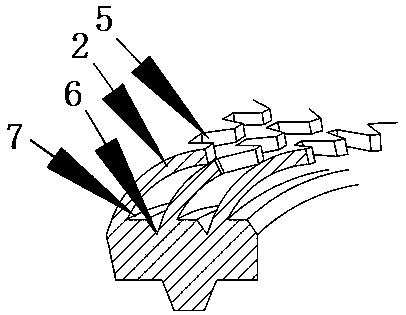

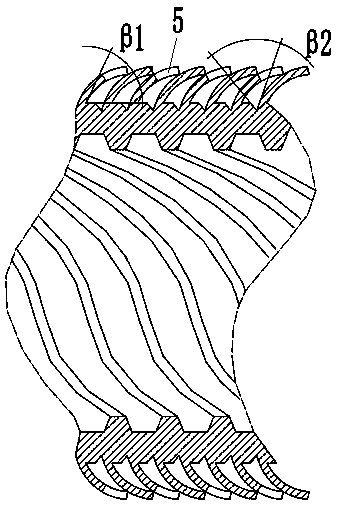

Novel flooded type evaporating heat exchange tube

ActiveCN109307389AIncrease boiling heat transfer coefficientPromote growthEvaporators/condensersHeat transfer modificationEngineeringExchange coefficient

The invention discloses a novel flooded type evaporating heat exchange tube. The novel flooded type evaporating heat exchange tube comprises a light section and an evaporating surface section, whereinthe evaporating surface section comprises a heat exchange tube body (8). The novel flooded type evaporating heat exchange tube is characterized in that inclined bent fins (2) which are spirally distributed along the axis of the heat exchange tube are arranged on the outer surface of the heat exchange tube body (8), wherein the surfaces of the fins (2) are in the shapes of curved surfaces, and thefins tilt in the same direction; the tops of adjacent fins (2) are in tight contact with each other without a seam, and the fins (2) cover a channel between the fins to define a triangular cavity (3); a trapezoidal notch (5) is formed in the top of each fin (2) as a steam discharge hole / liquid inlet of the cavity; and bulged ribs which are uniformly distributed in the peripheral direction are arranged on the inner surface of the heat exchange tube body (8), and a spiral channel is formed between every two adjacent ribs. The novel flooded type evaporating heat exchange tube is simple in processing, and is high in yield; and within a practical common wall surface superheat degree range, a heat exchange coefficient is slightly affected by the wall surface superheat degree, and is kept stable, so that variable working conditions of a heat exchanger are adapted.

Owner:山东恒辉节能技术集团有限公司

Heat exchanger, heat exchange method using heat exchanger, heat transport system using heat exchanger, and heat transport method using heat transport system

ActiveUS20180245863A1Promote boilingImprove the overall coefficientRecuperative heat exchangersHeat transfer modificationTransport systemPlate heat exchanger

A heat exchanger is configured to perform heat exchange by boiling a liquid by heat transfer from a heat source to the liquid through a heat transfer member. In the heat exchanger, a first heat conduction region and a second heat conduction region are alternately provided in a form of stripes on a surface on a side that contacts the liquid such that the liquid boils via a heat transfer member.

Owner:TOYOTA JIDOSHA KK

Automatic pole car for power transmission and wiring engineering

The invention discloses an automatic vertical pole vehicle for power transmission and strenuous engineering, which belongs to the technical field of electric power engineering. It includes a vehicle frame, a control room, a drilling device, a pole device and a rod pulling device. The control room, the drilling device, the pole device and the lever device are all arranged on the vehicle frame. Jack, the control room includes a cab and a control room, the bottom of the control room is provided with a slideway, the drilling device includes a rotating disk and a drilling arm, and the vertical rod device includes a planetary wheel and a mechanical arm. The rod pulling device comprises a rod pulling motor and a rod storage box. The automatic vertical pole car for power transmission and wiring engineering of the present invention can realize integrated drilling and vertical poles, improve work efficiency, adopt an improved connecting rod mechanism, realize fixed-point vertical poles, rotate efficiently and flexibly, be efficient and environmentally friendly, and have high energy utilization rate .

Owner:LIAONING TECHNICAL UNIVERSITY

Preparation method for evaporating pipe of flooded evaporator

The invention discloses a preparation method for an evaporating pipe of a flooded evaporator. The preparation method comprises the steps that spiral internal teeth are rolled on the inner wall of a copper pipe, and then the inner surface and the outer surface of the copper pipe are cleaned and dried; the copper pipe is sleeved with a fine copper powder particle limiting pipe, introduced into a sintering furnace to be sintered with protective gas, discharged out of the sintering furnace and cooled, the fine copper powder particle limiting pipe is pulled away, and a fine copper powder particle capillary-structure layer is combined with the outer wall of the copper pipe; the fine copper powder particle capillary-structure layer is sleeved with a coarse copper powder particle limiting pipe, introduced into the sintering furnace to be sintered with protective gas, discharged out of the sintering furnace and cooled, the coarse copper powder particle limiting pipe is pulled away, a coarse copper powder particle capillary-structure layer is combined with the outer side of the fine copper powder particle capillary-structure layer, and a pipe blank is obtained; and the pipe blank is introduced into the sintering furnace to be sintered with protective gas, discharged out of the sintering furnace and cooled, and the evaporating pipe of the flooded evaporator is obtained. Thermal contact resistance between the copper pipe and the fine powder particle capillary-structure layer as well as between the copper pipe and the coarse powder particle capillary-structure layer is avoided, and the heat exchange performance is good; a heat transfer coefficient is increased; and the maximum effect of the thermal conductivity is achieved.

Owner:JIANGSU CUILONG PRECISION COPPER TUBE CORP

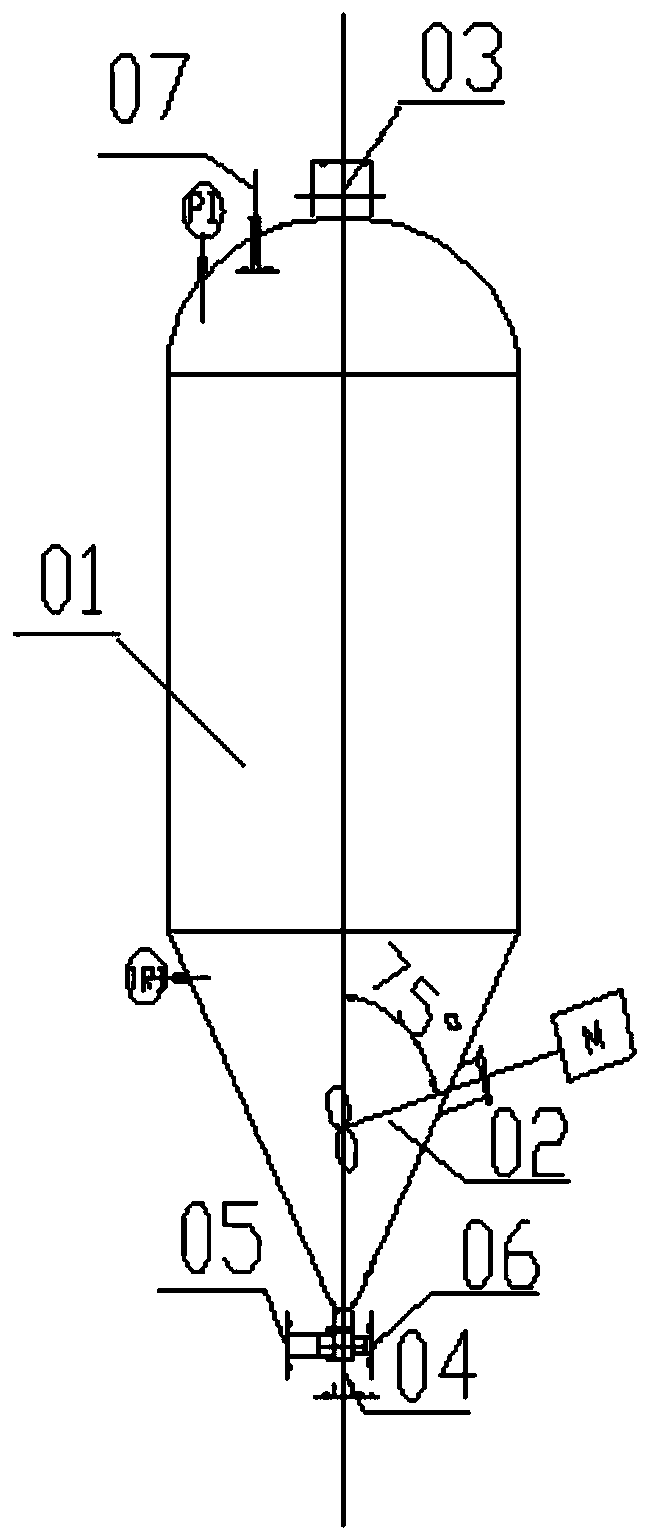

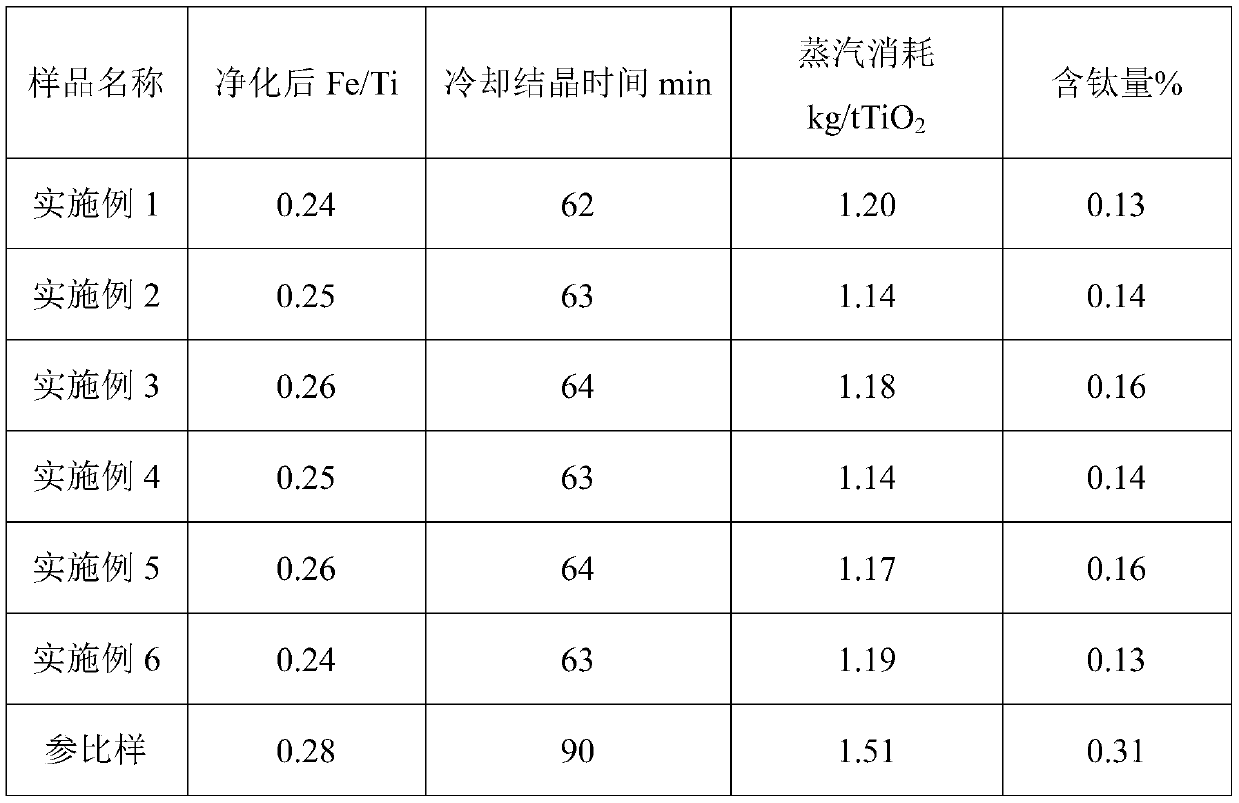

A purification method for raw materials for production of decorative base paper titanium dioxide

ActiveCN107935029BReduce consumptionReduce titanium contentTitanium and titanyl sulfatesIron sulfatesPurification methodsSulfate

The invention discloses a purification method of a decorative base paper titanium dioxide production material, and belongs to the technical field of sulfuric acid method titanium dioxide production. The method is performed in a crystallizing tank with a stirrer, and comprises the following steps: A, feeding titanium sulfate solution into the crystallizing tank, and starting the stirrer; B, controlling pressure in the crystallizing tank to cool down a material; C, leading auxiliary steam into the crystallizing tank, meanwhile leading auxiliary circulation water into the crystallizing tank, andcontrolling tank feeding temperature and tank discharging temperature of the auxiliary circulation water, pressure in the tank and material temperature in the tank; D, leading main steam into the crystallizing tank, meanwhile leading main circulation water into the crystallizing tank, and controlling tank feeding temperature and tank discharging temperature of the main circulation water, pressurein the tank and material temperature in the tank; E, stopping the leading of auxiliary steam, main steam, auxiliary circulation water and main circulation water, emptying till pressure in the tank isequal to environment pressure, and filtering. The method realizes purification of the titanium sulfate solution, and improves the crystallization efficiency of ferrous sulfate in the titanium sulfatesolution.

Owner:HEBEI MILSON TITANIUM DIOXIDE

Air temperature type LNG gasifier

InactiveCN109780432APromote generationAvoid formingStationary conduit assembliesPressure vesselsEngineeringSpiral flow

The invention relates to an air temperature type LNG gasifier. The air temperature type LNG gasifier comprises a frame and finned tubes, the finned tubes are arranged in parallel to form arrays, the finned tubes are divided into two arrays including eight-fin fin tubes and 12-fin finned tubes, and spiral flow guide parts are arranged in the finned tubes. The gasifier is good in heat exchange effect and small in size.

Owner:江苏凯德翎能源科技有限公司

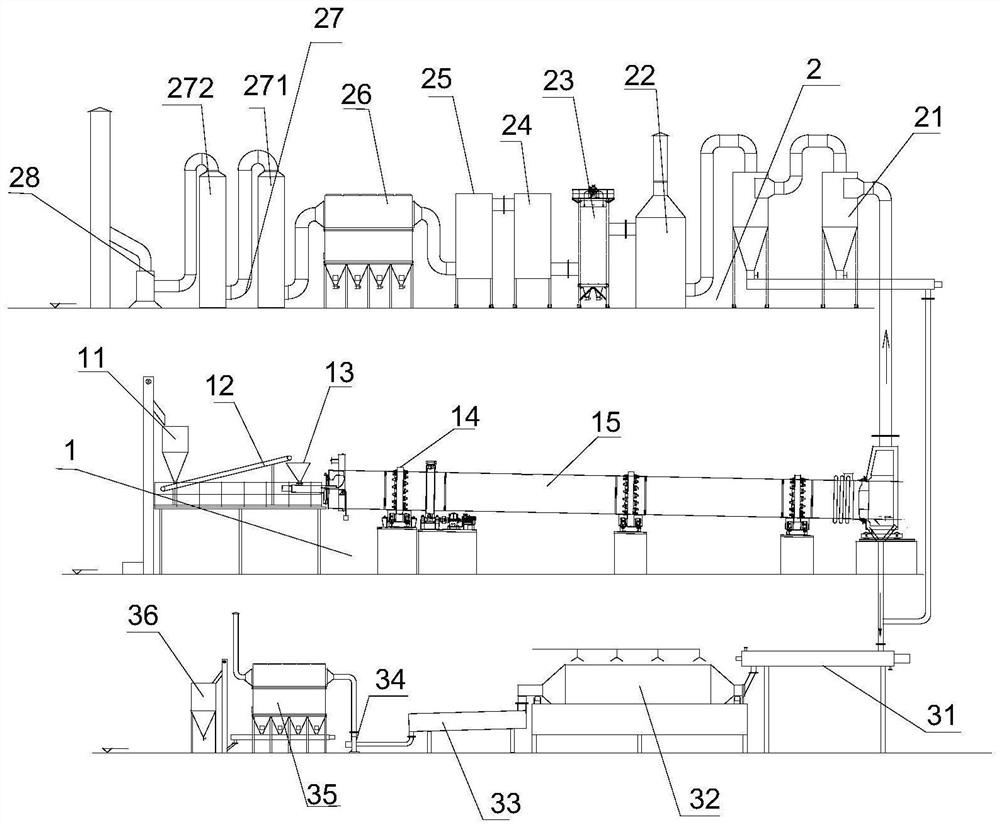

Waste activated carbon regeneration equipment

The invention discloses waste activated carbon regeneration equipment. The device consists of a waste activated carbon treatment device, an environment-friendly treatment device and a cooling and receiving device. And the waste activated carbon treatment device is used for screening, lifting and feeding waste activated carbon and regenerating the waste activated carbon at high temperature. The environment-friendly treatment device is used for purifying waste gas and waste water generated by high-temperature regeneration of waste activated carbon. And the cooling and receiving device reduces the temperature of the regenerated activated carbon and solves the problem of difficulty in cooling, receiving and storing. The first-stage, second-stage and third-stage lifting plate sections are arranged in the rotary furnace, so that waste activated carbon is boiled in the furnace, and the heating area is enlarged. And the castable and the fixing device in the rotary furnace have corrosion resistance, so that the rotary furnace is durable. The regeneration equipment provided by the invention solves the problems of poor waste activated carbon regeneration effect, high labor intensity, dust flying, environmental pollution and the like. Production equipment and environment-friendly equipment are integrated, mechanical and clean production is achieved, the capacity is large, the yield is high, and the regeneration effect is good.

Owner:天能炭素(江苏)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com