A device and method for oil-water demulsification separation of heavy oil

A technology for oil-water separation and separation equipment, which is applied in the fields of hydrocarbon oil dehydration/demulsification, electrical/magnetic dehydration/demulsification, mechanical dehydration/demulsification, etc. It can improve the stability of crude oil, avoid secondary emulsification and improve separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

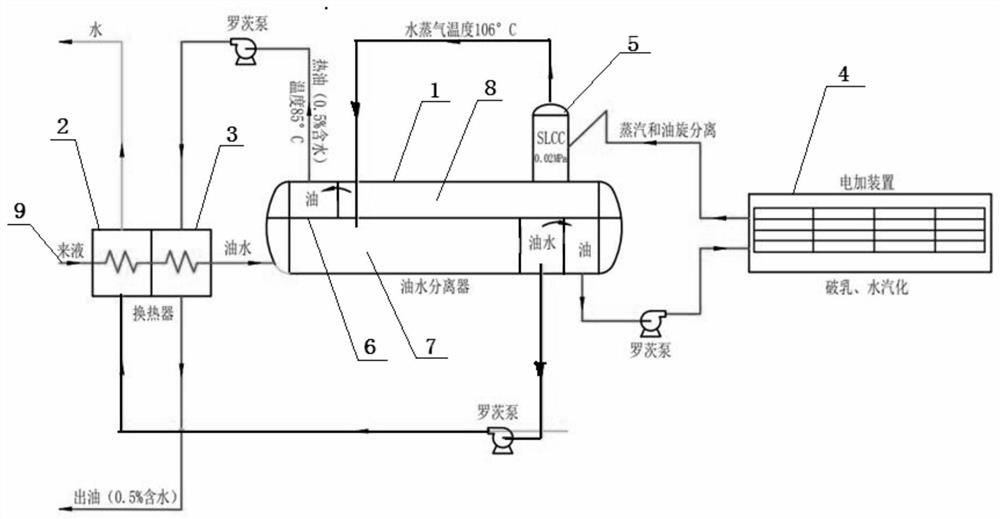

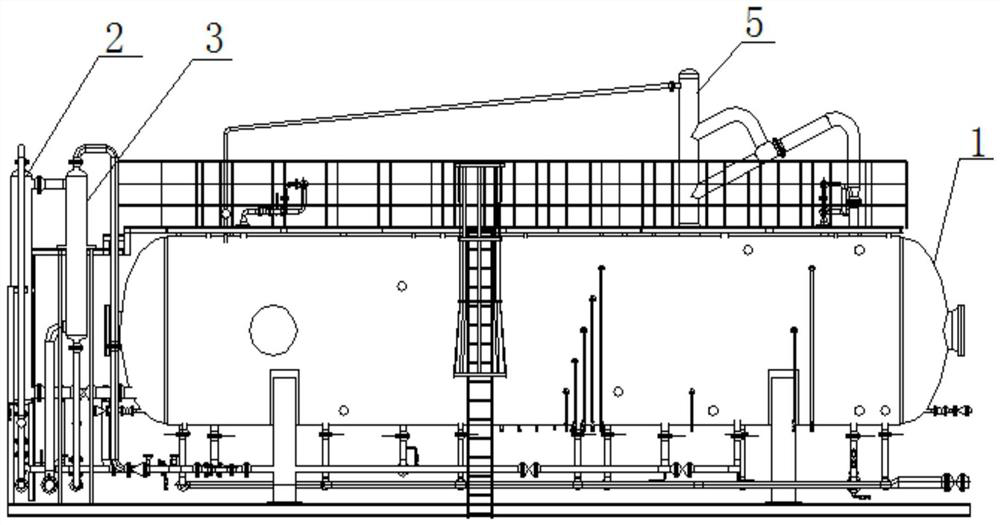

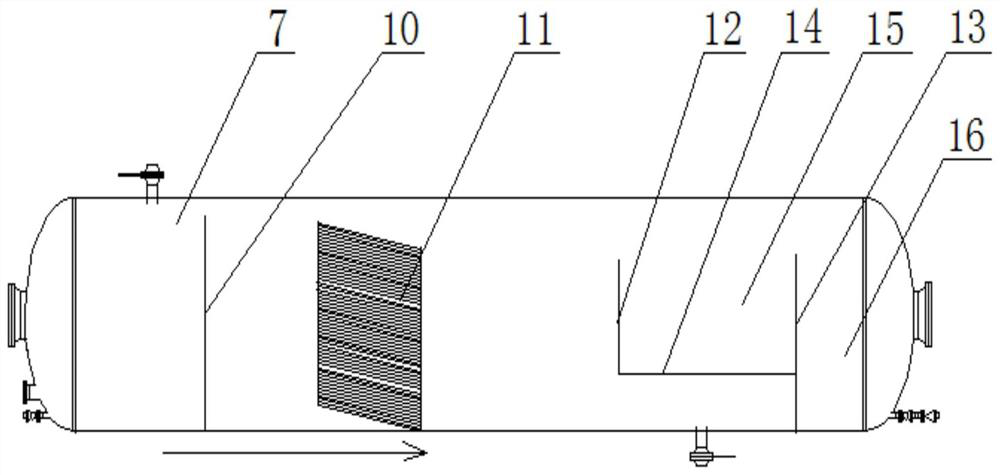

[0038] A heavy oil oil-water demulsification separation equipment, such as figure 1 As shown, it includes an oil-water separation tank 1, and also includes an electromagnetic induction heater 4 (such as Figure 11 shown) and a vapor-liquid cyclone separator 5 for effective separation of water vapor and liquid phase, the oil-water separation tank 1 is divided into a primary oil-water separation chamber 7 and a secondary oil-water separation chamber 8, a primary oil-water separation chamber 7 It is connected with the secondary oil-water separation chamber 8 through the electromagnetic induction heater 4 and the vapor-liquid cyclone separator 5 in sequence.

specific Embodiment 2

[0040] With above-mentioned specific embodiment 1, its difference is: as figure 2 As shown, the oil-water separation tank 1 is arranged horizontally, the primary oil-water separation chamber 7 and the secondary oil-water separation chamber 8 are separated by the longitudinal partition 6 along the axial direction of the oil-water separation tank 1, and the oil-water inlet ports of the primary oil-water separation chamber 7 are sequentially connected There is a second heat exchanger 3 and a first heat exchanger 2, the first heat exchanger 2 is provided with an incoming liquid inlet 9, and the water phase outlet of the primary oil-water separation chamber 7 is connected to the shell side of the first heat exchanger 2 The oil phase outlet of the primary oil-water separation chamber 7 is connected with the liquid inlet of the electromagnetic induction heater 4, and the liquid outlet of the electromagnetic induction heater 4 is connected with the feed inlet of the vapor-liquid cyclo...

specific Embodiment 3

[0045] A method for demulsifying and separating heavy oil from oil and water using a heavy oil and oil-water demulsification separation device according to the above specific embodiment, comprising the following steps:

[0046] The oil-water mixed liquid is sent to the first-stage oil-water separation chamber 7 of the oil-water separation tank 1 for oil-water separation, and the oil phase separated in the first-stage oil-water separation chamber 7 is sent to the electromagnetic induction heater 4 for processing, and the electromagnetic induction heater The heating temperature of 4 is controlled at 106°C, the electromagnetic field is controlled at 300A / M, the oil-water mixture treated by the intermediate frequency heater enters the vapor-liquid cyclone separator 5 at a constant temperature of 106°C, and the water vapor and liquid in the vapor-liquid cyclone separator 5 The cyclone rapid separation is formed, and the liquid mixture obtained after the cyclone separation enters the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com