Waste activated carbon regeneration equipment

A technology for regeneration equipment and waste activated carbon, which is applied in filter regeneration, separation methods, combustible gas purification/transformation, etc. It can solve the problems of difficult material collection, high labor intensity, and large amount of dust flying, and achieve a uniform heating area , increase the firmness, the effect of large heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

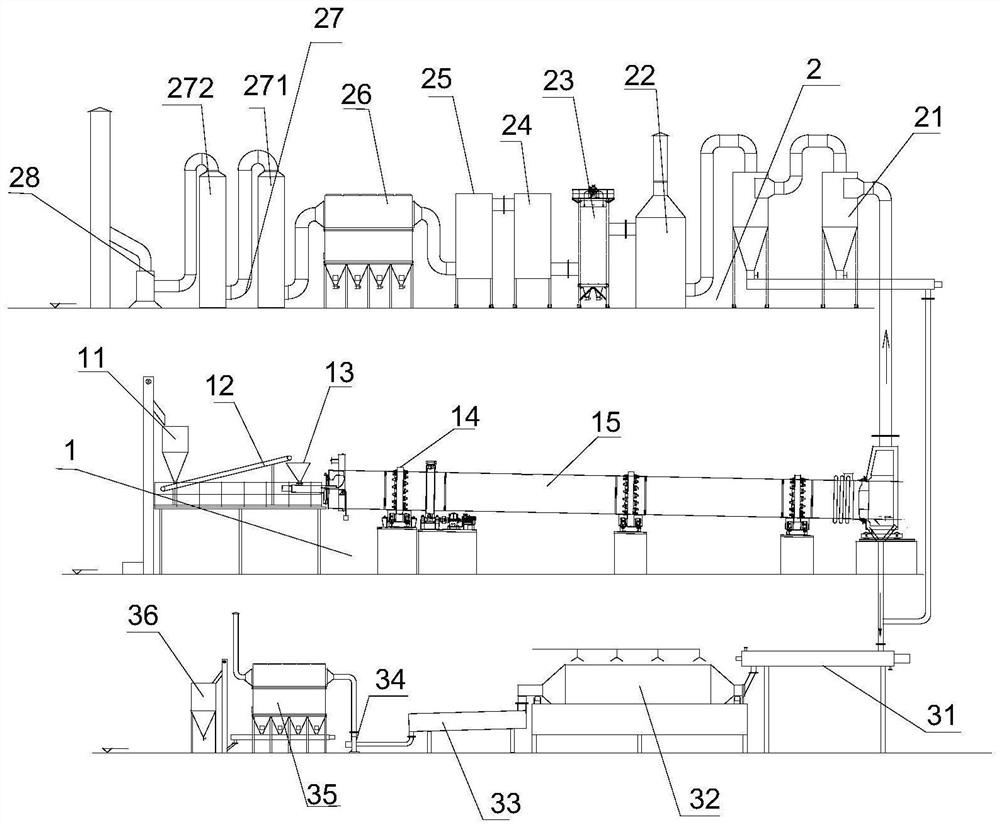

[0036] like figure 1 The waste activated carbon regeneration equipment shown, the whole set of waste activated carbon regeneration equipment is controlled by computer intelligently, and the whole equipment is controlled by the total electricity, which can be divided into lighting computer power control cabinet, waste activated carbon treatment device power control cabinet, environmental protection treatment device power control cabinet . The electric control cabinet of the cooling and receiving device realizes the independent control between the devices, and a series of operations can be completed manually on the external control panel. Waste activated carbon regeneration equipment: including waste activated carbon treatment device 1, environmental protection treatment device 2, cooling and receiving device 3, and the rotary furnace 1 is connected with the environmental protection treatment device 2 and the cooling and receiving device 3. The waste activated carbon treatment d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com