Patents

Literature

113results about How to "Achieving Corrosion Resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PVC foam wood/plastic composite material and manufacturing method thereof

The invention discloses a PVC foam wood / plastic composite material and relates to the technical field of composite materials. The PVC foam wood / plastic composite material is made from the following raw materials in parts by weight: 20-70 parts of PVC resin powder, 0-55 parts of wood flour, 5-40 parts of calcium carbonate powder, 0.1-0.5 part of sodium bicarbonate, 0.3-0.6 part of an azo-compound or hydrazine derivative, semicarbazide compound or nitroso-compound, 2-10 parts of a foaming regulator, 1.5-6 parts of a composite stabilizer, 0.7-2.1 parts of a lubricant, 0.5-1.2 part of soybean oil, 2.5-5.5 parts of an impact modifier, and 0.5-3 parts of a processing agent. The PVC foam wood / plastic composite material provided by the invention has the advantages of strong chemical stability, high strength, resistance to acid / alkaline corrosion, resistance to water seepage, flame retardancy and low cost.

Owner:山东宜群木塑科技有限公司

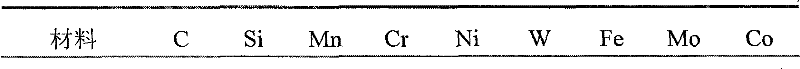

A kind of metal surface modification method

InactiveCN102268626AWide range of applicationsSave resourcesMolten spray coatingCoated surfaceState of art

The invention relates to a metal surface modification method. The invention first obtains a textured surface with a certain surface roughness value on the surface of a material by an electron beam texturing method, forms uniform tiny pits, and increases the bonding strength of the interface; then uses plasma The spraying process uses Co-based alloy or Ni-based alloy powder as the material to form a coating; finally, laser remelting technology is used to remelt the coating surface to improve the surface structure of the coating and improve the surface performance. Compared with the existing technology, this process can realize high temperature resistance, corrosion resistance, oxidation resistance, and fatigue resistance, and has high bonding strength, and the coating structure is uniform and compact, thereby greatly broadening the application range.

Owner:SHANGHAI UNIV OF ENG SCI

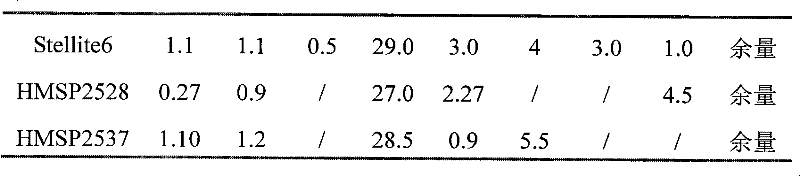

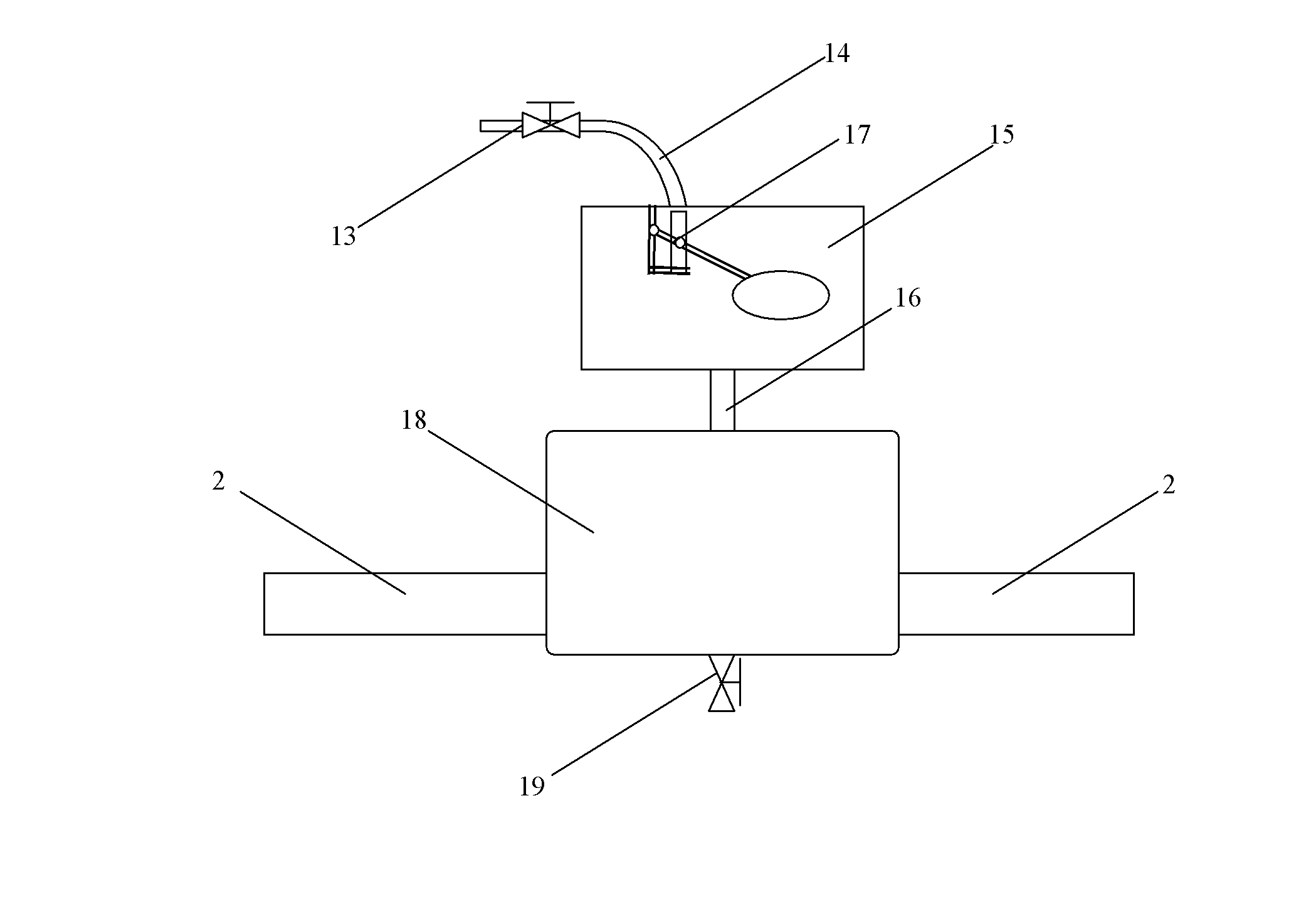

Direct-current electrolytic treatment process and equipment for circulating cooling water

InactiveCN103058336AGood environmental compatibilityGood effectWater/sewage treatmentEnvironmental chemistryCorrosion

The invention relates to a water direct-current electrolytic treatment process for circulating cooling and direct-current electrolytic treatment equipment for the circulating cooling, and shows the core concept that a bypass circulating system is arranged on a circulating cooling water system, and the direct-current electrolytic treatment equipment is arranged to treat the circulating cooling water. The direct-current electrolytic treatment equipment is used for scaling and separating out calcium and magnesium in the circulating water by utilizing cathodic hydrogen evolution reaction, and descaling and discharging the scale to continuously reduce the hardness of the system so as to preventing scale from generating; active materials separated from a specially dimensionally stable anode are utilized for exterminating bacteria and inhibiting the growth of bacteria, so that the problems due to blocking and corrosion are prevented; and simultaneously, the pH is increased by hydrogen evolution reaction, so that electrochemical corrosion can be effectively prevented. The direct-current electrolytic process realizes a plurality of functions in the same process, such as descaling, sterilizing and exterminating the bacteria. Compared with the conventional physical method and chemical method, the direct-current electrolytic treatment process has the advantages of being remarkable in effect, high in cleanability, capable of saving water source, low in energy consumption and low in cost, and can realize unattended operation.

Owner:沈阳瀚威科技有限公司

Multifunctional filter material for circulating water treatment and preparation method thereof

InactiveCN101857311AReduce scaleEfficient removalScale removal and water softeningBiological water/sewage treatmentSodium bicarbonateSludge

The invention discloses a multifunctional filter material for circulating water treatment, which is prepared from 1 to 10 weight percent of nano tourmaline powder, 55 to 80 weight percent of coarse tourmaline powder, 1 to 15 weight percent of kieselguhr, 1 to 15 weight percent of sepiolite powder, 1 to 15 weight percent of scallop powder, 1 to 10 weight percent of sodium bicarbonate and 0.5 to 1 weight percent of silver-carried zeolite powder. A preparation method comprises the following steps of: stirring and mixing raw materials uniformly, injecting the uniformly mixed powder into a turntable machine, and rotating the powder for 15 to 30 minutes with controlled humidity of 15 to 50 percent and rotational speed of 20 to 200 revolutions per minute by using attapulgite of 0.1 to 1 millimeter as a core; and finally sintering the powder for 4 to 8 hours at the temperature of between 400 and 600 DEG C in a muffle furnace to form a ceramic filter material with the diameter of 1 to 10 millimeters. The filter material can effectively remove Ca2+ and Mg2+ from the water and achieve the effects of inhibiting scales, preventing corrosion and removing biological sludge.

Owner:厦门柏斯顿智能科技有限公司

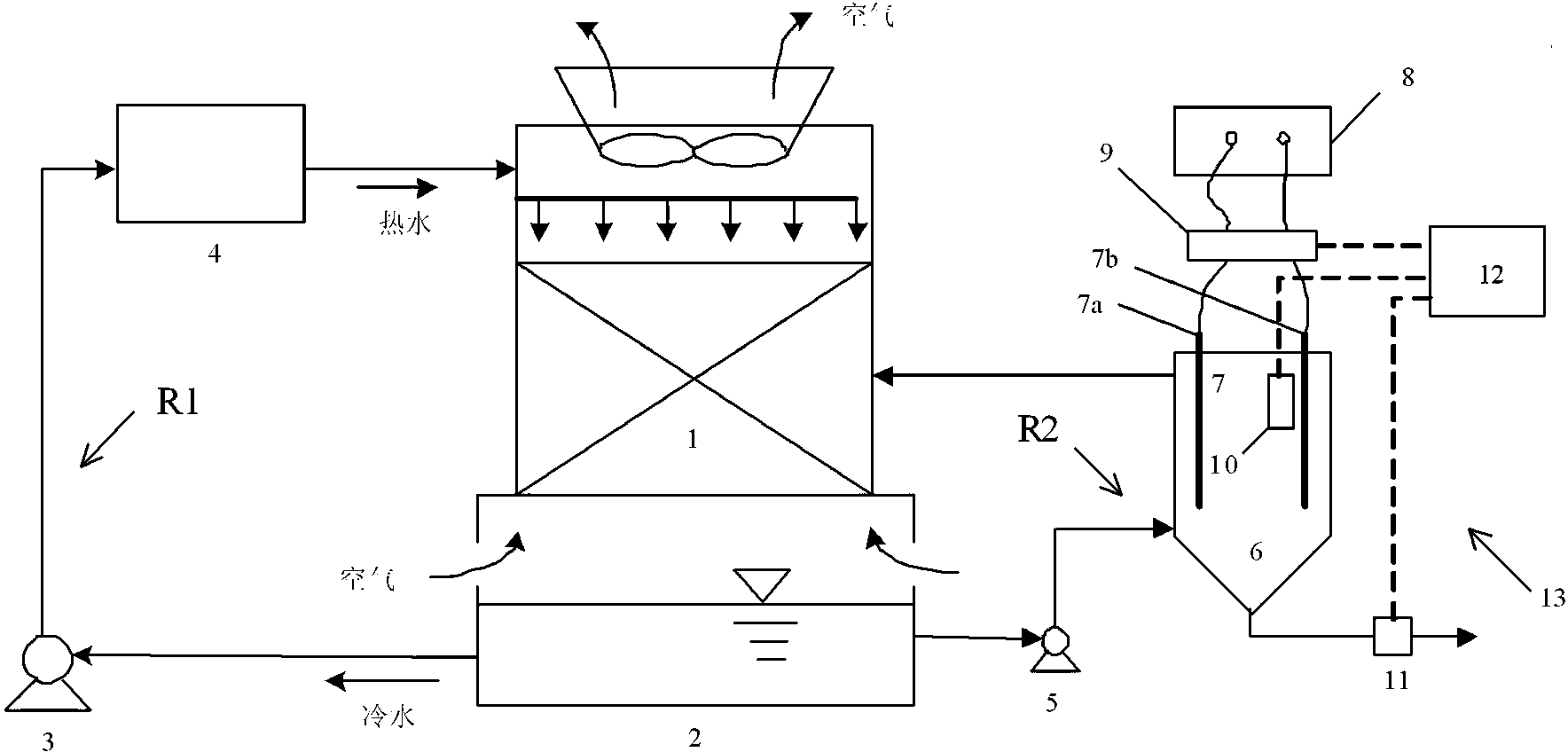

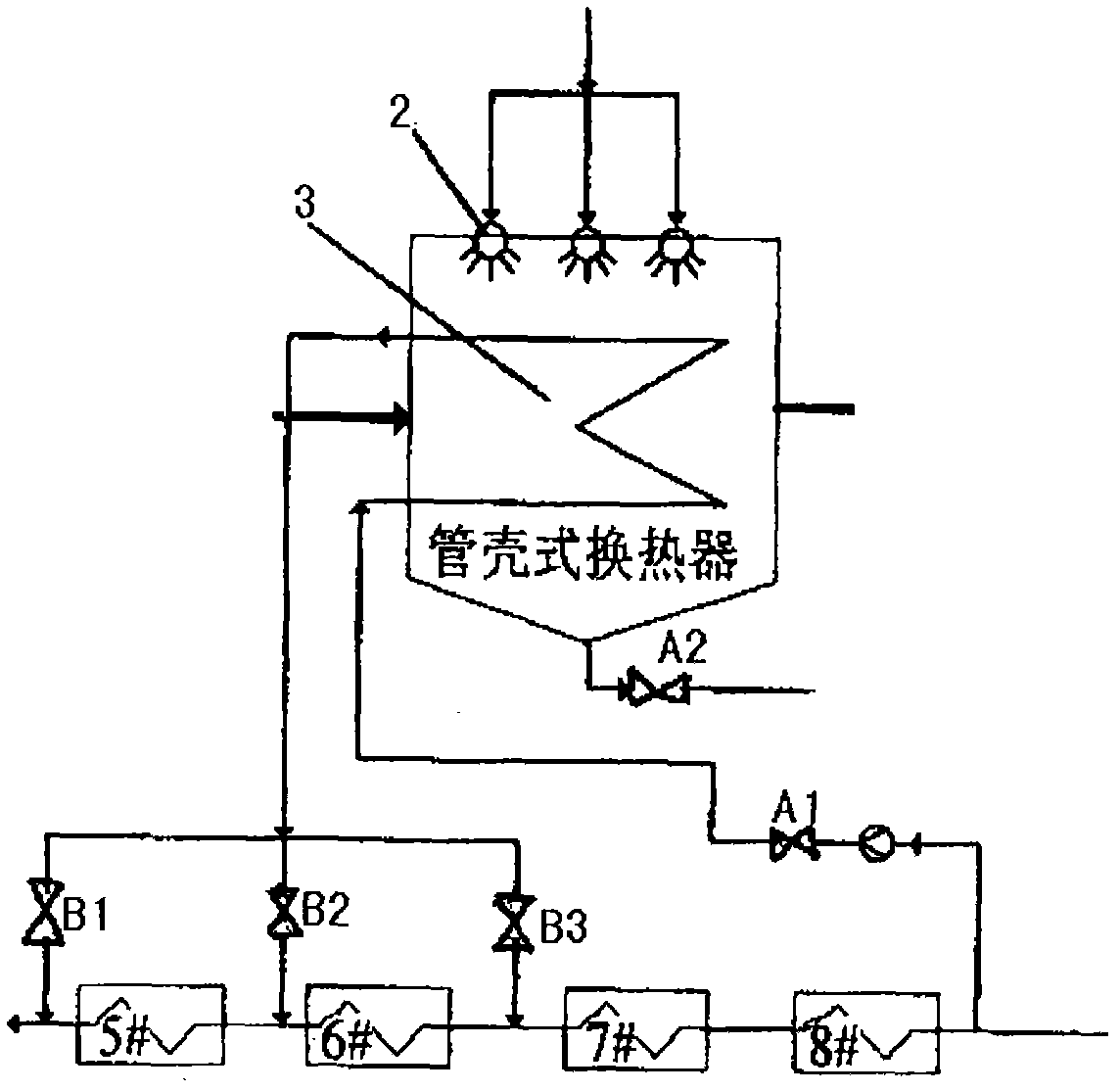

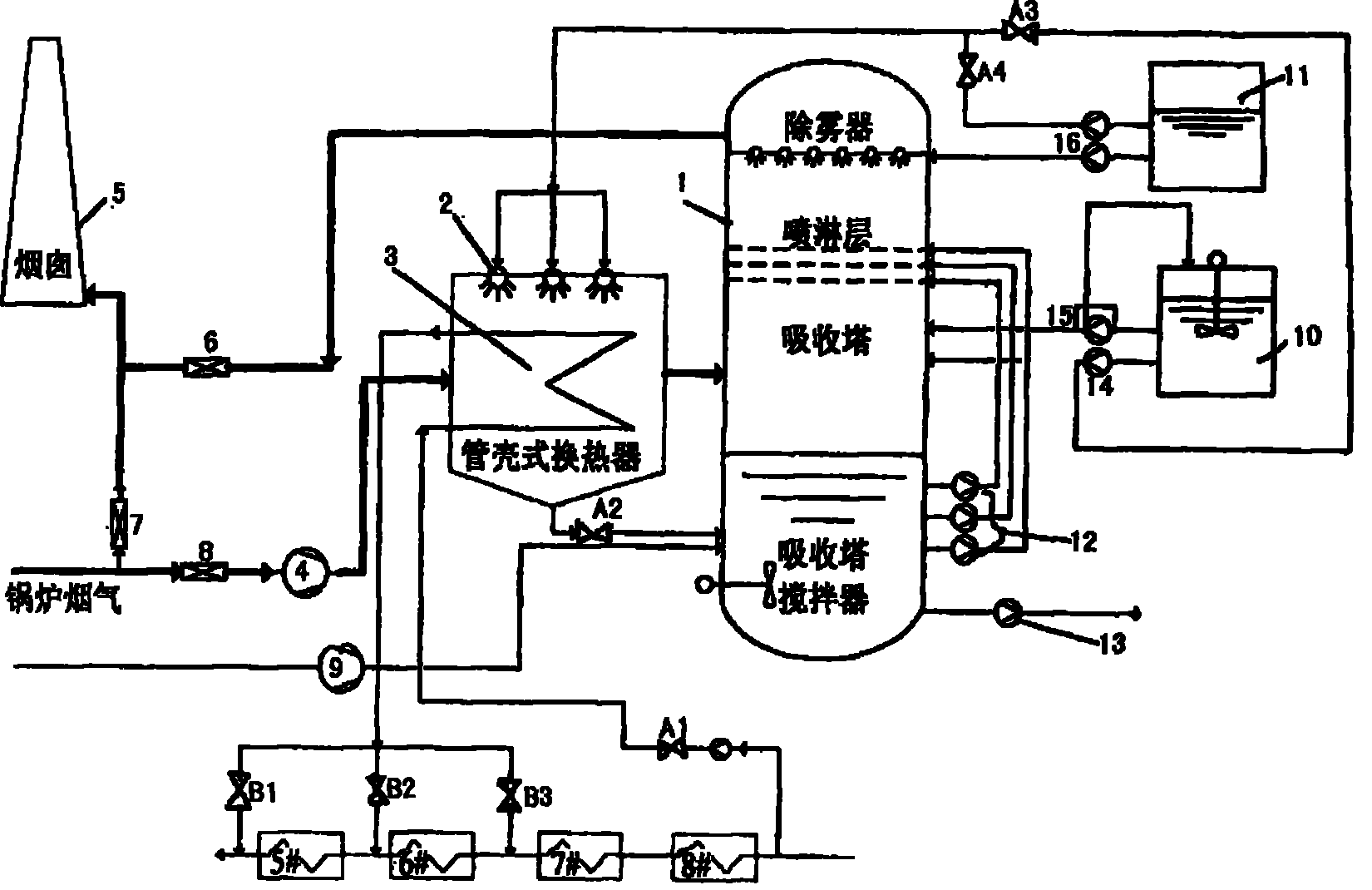

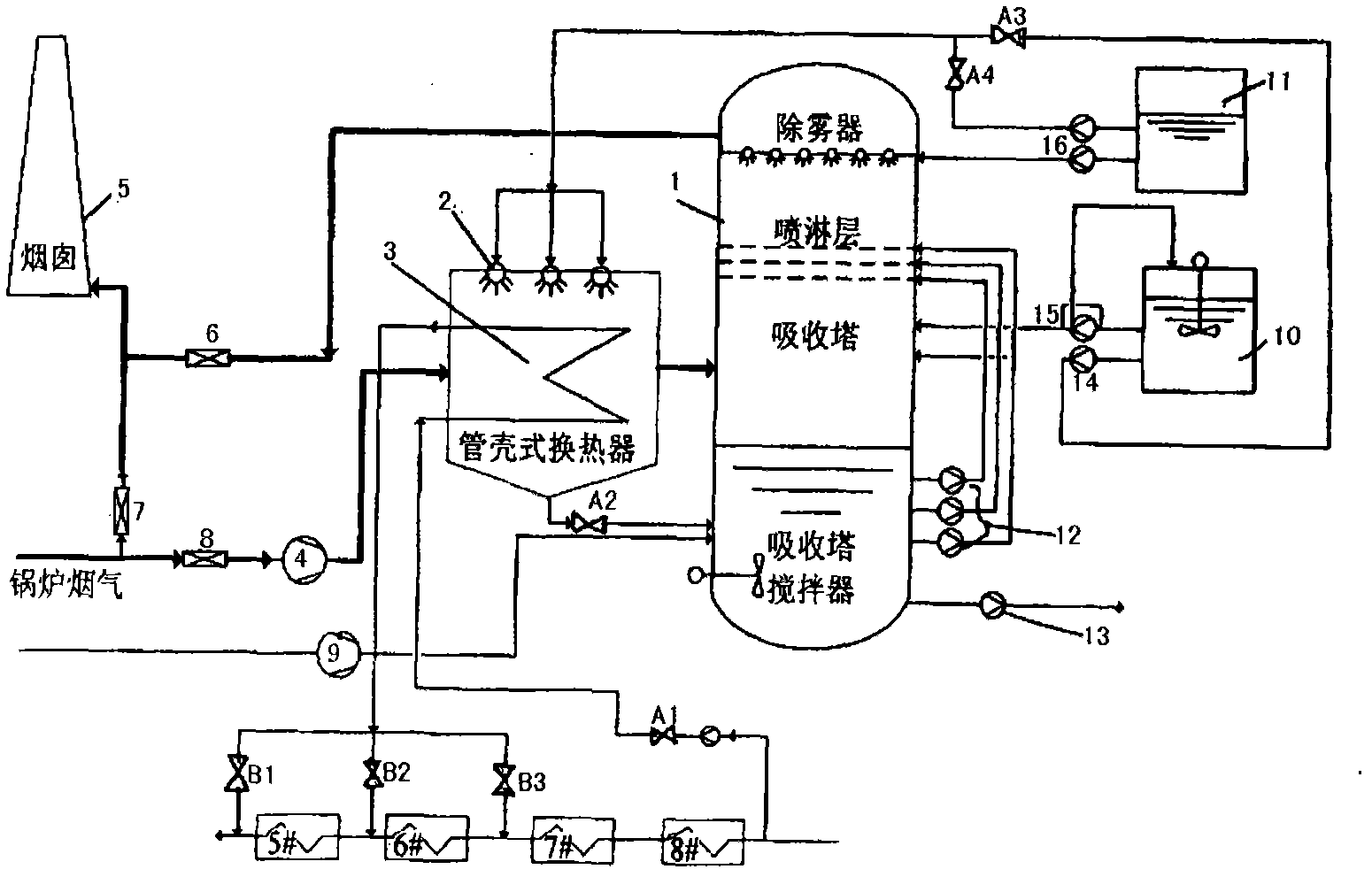

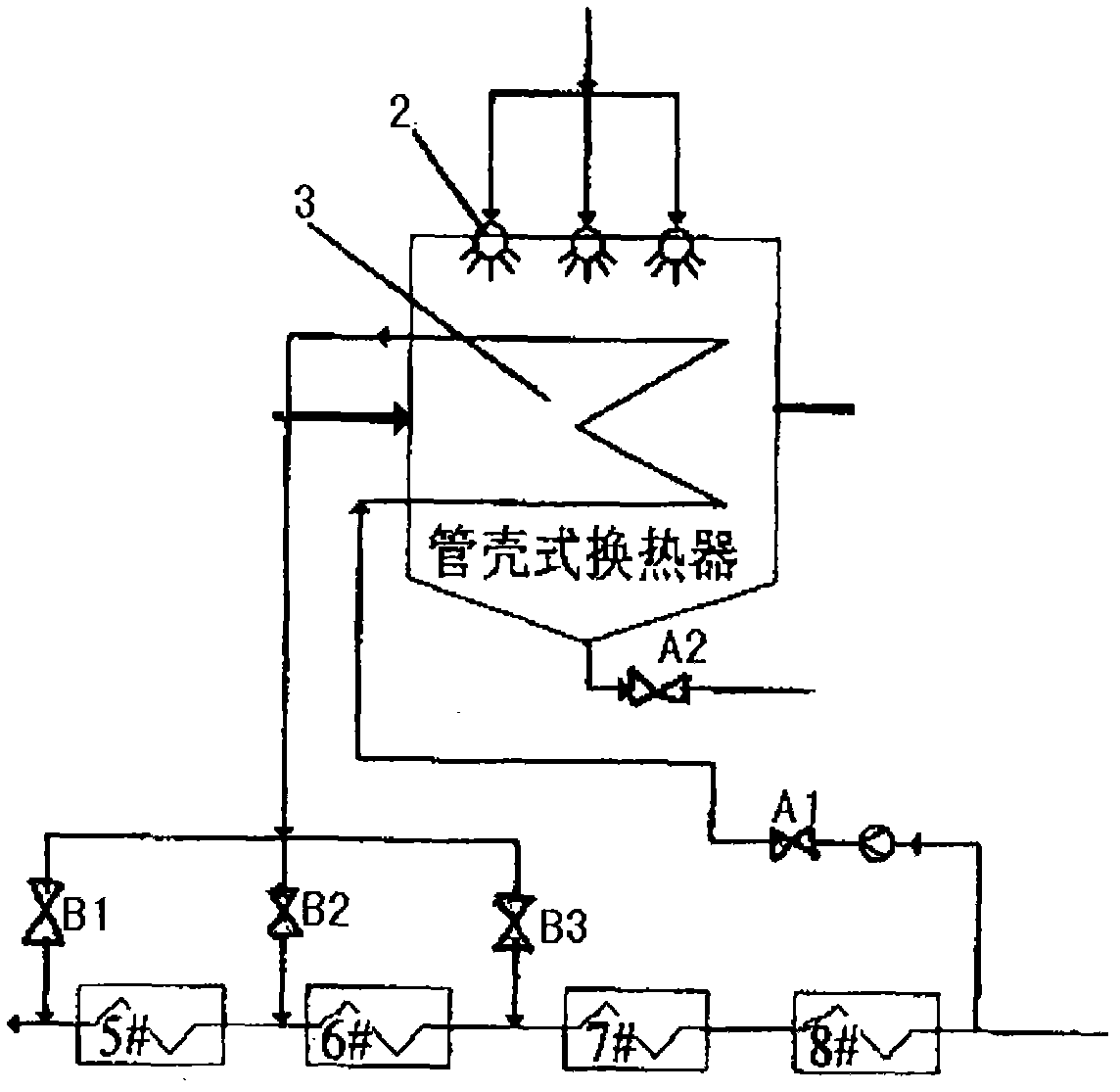

Integrated system for utilizing residual heat of boiler smoke and removing sulfur

InactiveCN102087021AImprove efficiencyReduce the temperatureDispersed particle separationEnergy industrySlurryIntegrated systems

The invention relates to an integrated system for utilizing residual heat of boiler smoke and removing sulfur. A tubular heat exchanger is used as a heat exchange main body of the system and is arranged on a tail flue between a booster fan and a desulfurization absorber, wherein the tubular heat exchanger is connected to a condensed water heating system; sets of nozzles are arranged in the heat exchanger for intermittently washing the inner tube wall of the heat exchanger and the wall of the flue; the processing water from a desulfurization system or limestone size or the mixture of the processing water and the limestone size are used as washing fluid for washing the walls; and the washing fluid is recovered and reused by returning to the desulfurization absorber after gathering on the bottom of the heat exchanger. By using the integrated system provided by the invention, the temperature of the smoke on the tail part of the boiler can be reduced to 50-70DEG C, thereby recovering the residual heat of boiler smoke and increasing the boiler efficiency. Meanwhile, the smoke within the temperature range which enters into the absorber of the desulfurization system on the tail part still meets the requirement of the temperature for desulfurization reaction, and the water consumption for desulfurization is reduced by 50-80%. Without designing a single size preparation and sewage treatment process, the water-saving and energy-saving properties, the anticorrosion property and reuse of the whole system are finally realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

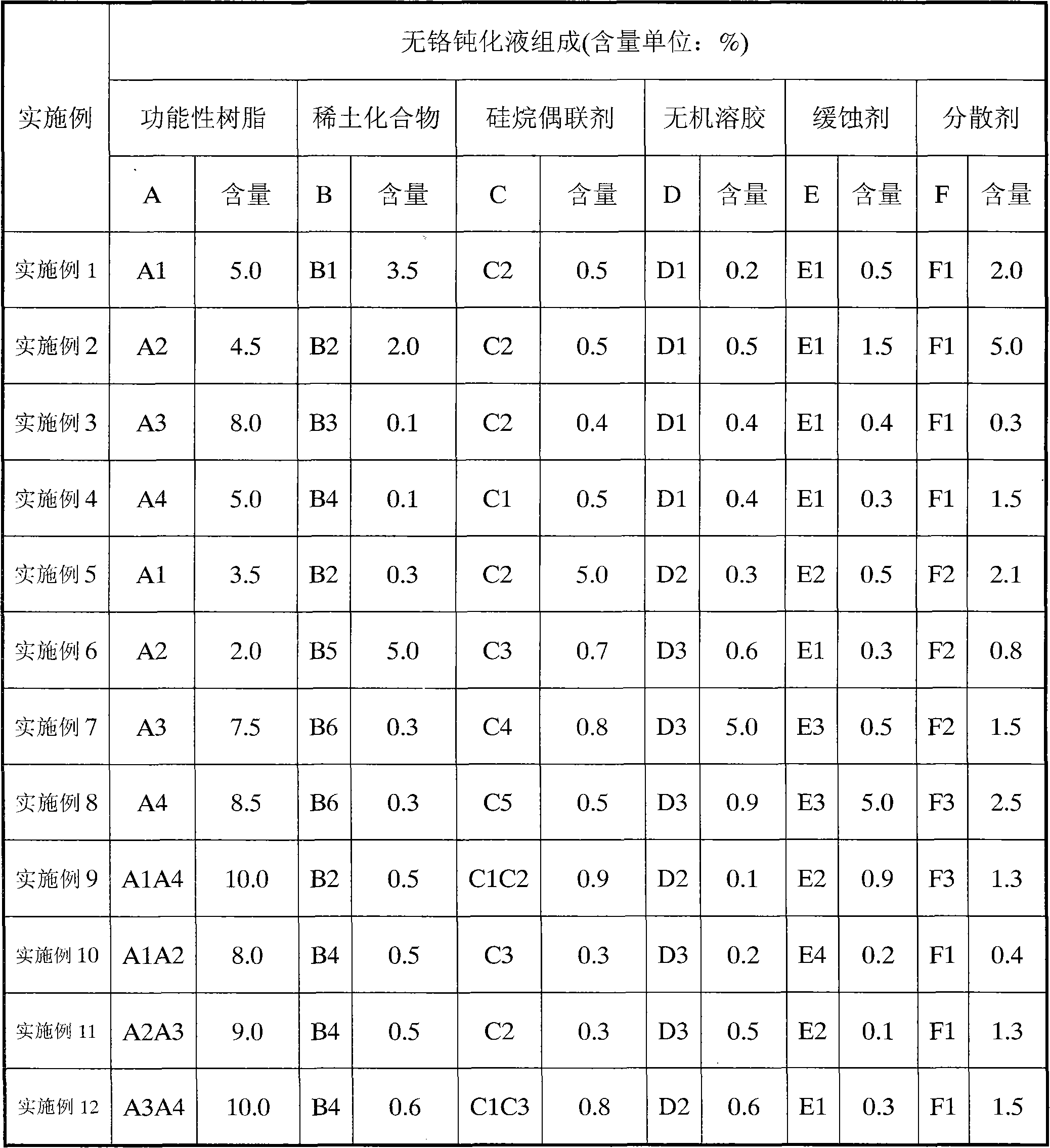

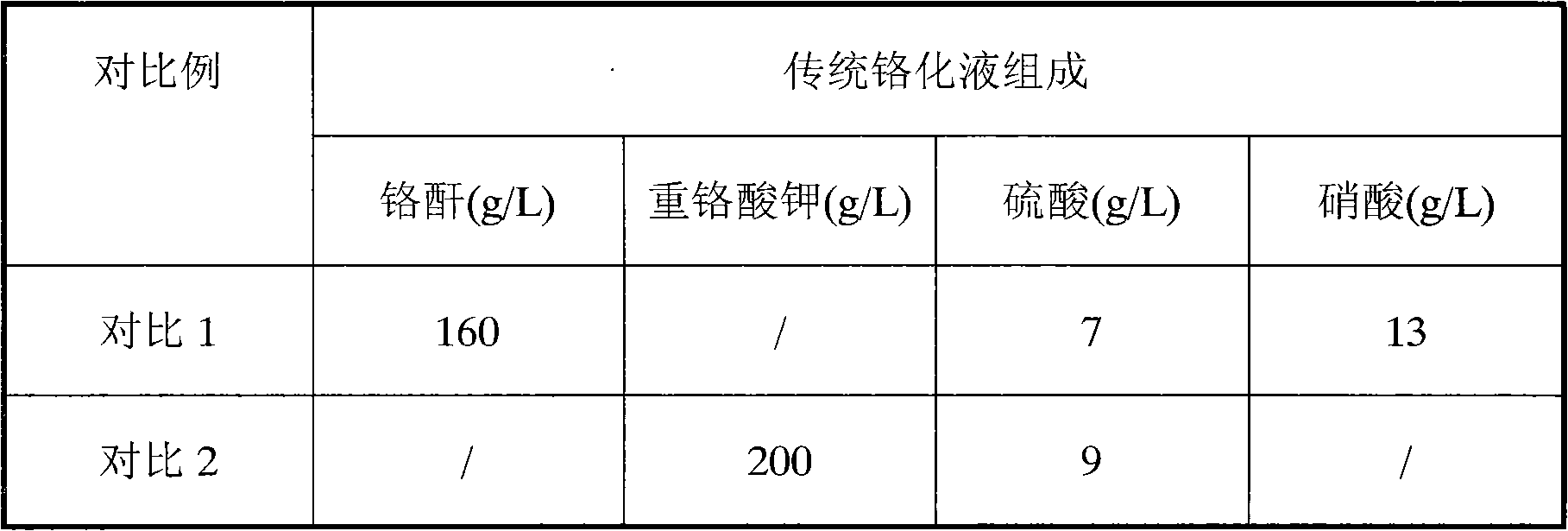

Self-repairing chromium-free passivation treatment fluid used for galvanized steel coil

InactiveCN102839367APrevent intrusionEnhances substrate surface adhesionMetallic material coating processesChromium freeSocial benefits

The invention relates to a self-repairing chromium-free passivation treatment fluid used for galvanized steel coil. The passivation treatment fluid comprises the following components of, by weight, 1-10% of a functional resin, 0.01-5% of a rare earth compound, 0.01-5% of a silane coupling agent, 0.01-5% of inorganic sol, 0.01-5% of a corrosion inhibitor, 0.01-5% of a dispersing agent, and the balance being water. The passivation treatment fluid provided by the invention can form a compact chromium-free passivation film having self-repairing capacity on the surface of the galvanized steel coil, so that corrosion resistance and adhesive force of a metal substrate are increased effectively; and the performance is superior to that of a conventional chromizing liquid passivation film. The passivation treatment fluid is low in cost and simple in process, and has small pollution to pollution, relatively high economic benefit and social benefit.

Owner:ANHUI WEILAI SURFACE TECH

Resin/silane compounded passivation liquid for galvanized coil steel and preparation method of resin/silane compounded passivation liquid

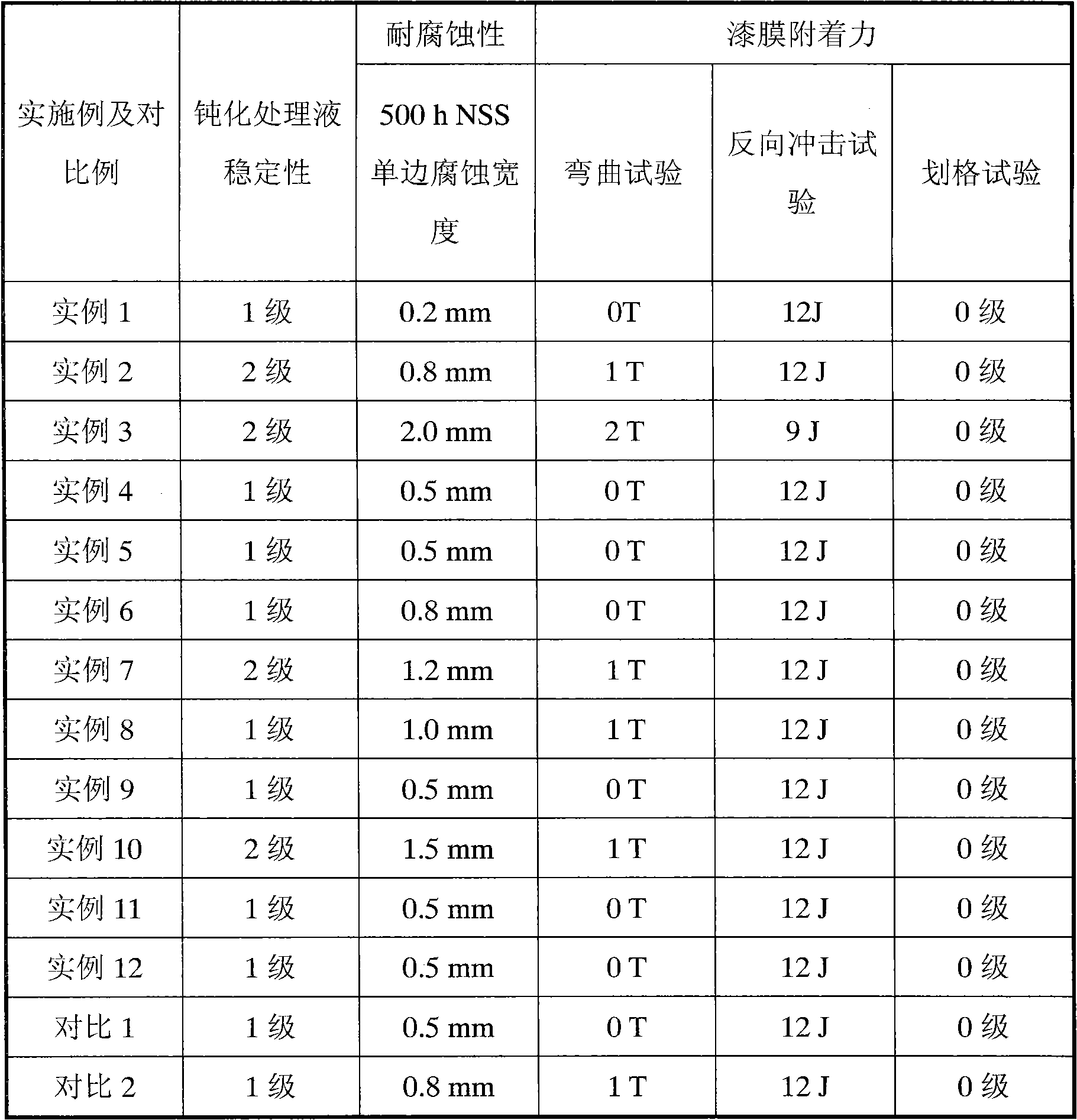

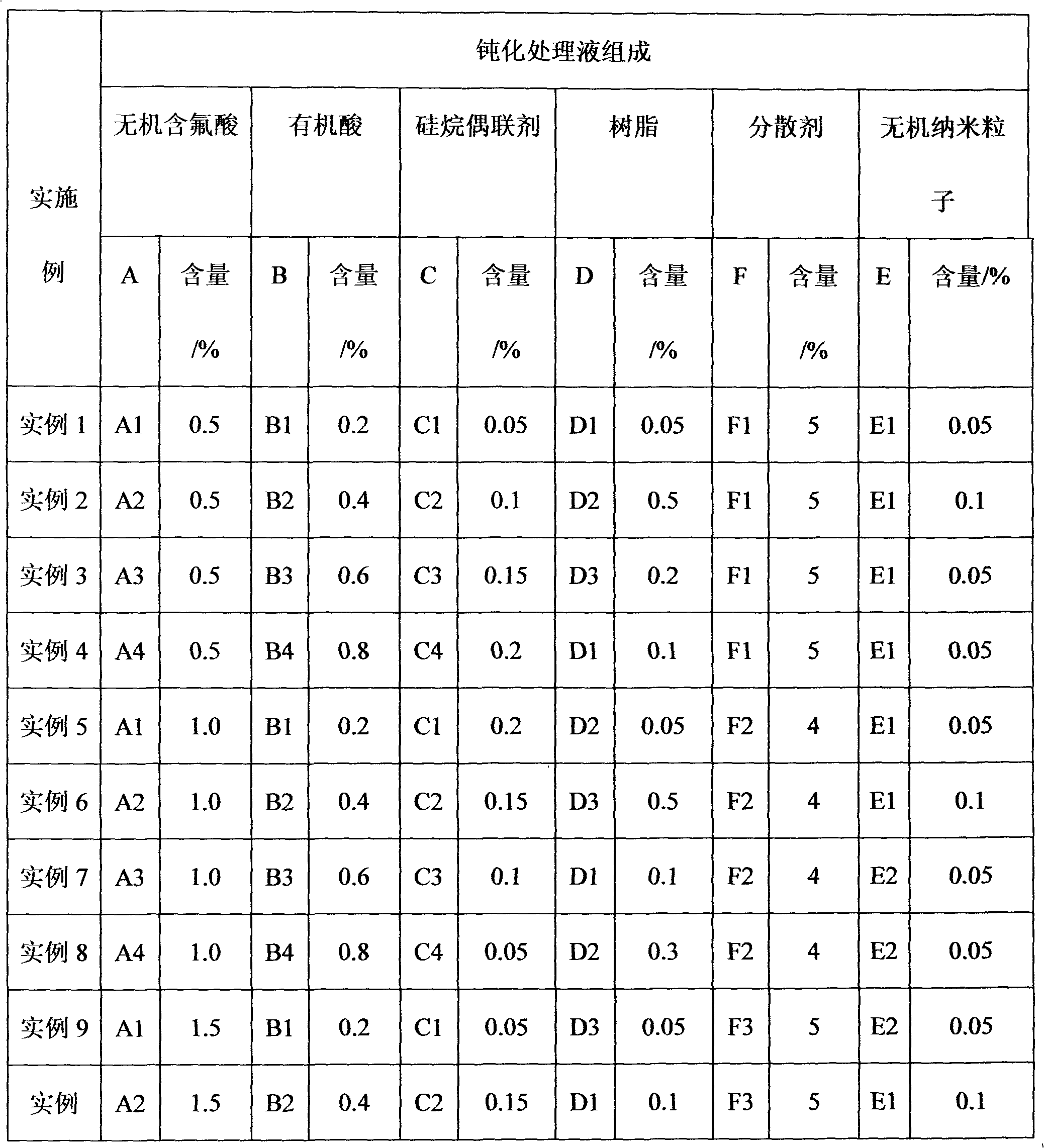

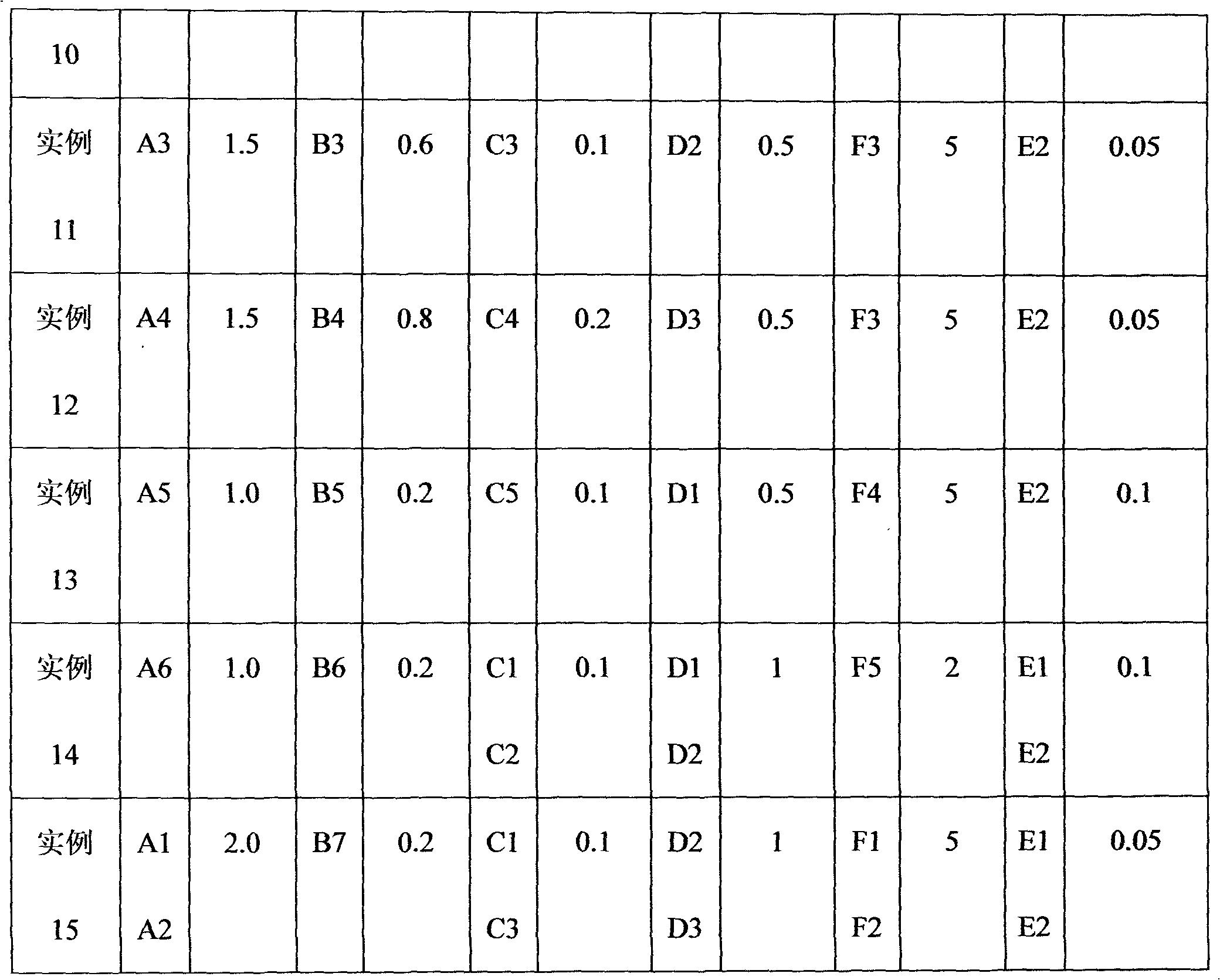

InactiveCN102534593AImprove stabilityLow costMetallic material coating processesSocial benefitsSilane compounds

The invention provides a resin / silane compounded passivation liquid for galvanized coil steel and a preparation method of the resin / silane compounded passivation liquid, and belongs to the technical field of chrome-free passivation of a galvanized plate. The passivation liquid comprises the following constituents by weight percent: 0.01 to 10 percent of inorganic fluorine-containing acid, 0.01 to 10 percent of organic acid, 0.01 to 5 percent of silane coupling agent, 0.01 to 5 percent of resin, 0.01 to 5 percent of inorganic nano particle, 0.01 to 5 percent of dispersing agent, and water in balancing amount. According to the method provided by the invention, a layer of organic / inorganic composite film can be formed on the surface of the galvanized coil steel, so that the corrosion resistance and the adhesive force are excellent, and the performance is superior to that of a passive film made of a chromizing liquid. The invention has the advantages that the cost is low; the process is simple; the stability is high; the environmental pollution is low; and the economic and the social benefits are higher.

Owner:ANHUI WEILAI SURFACE TECH

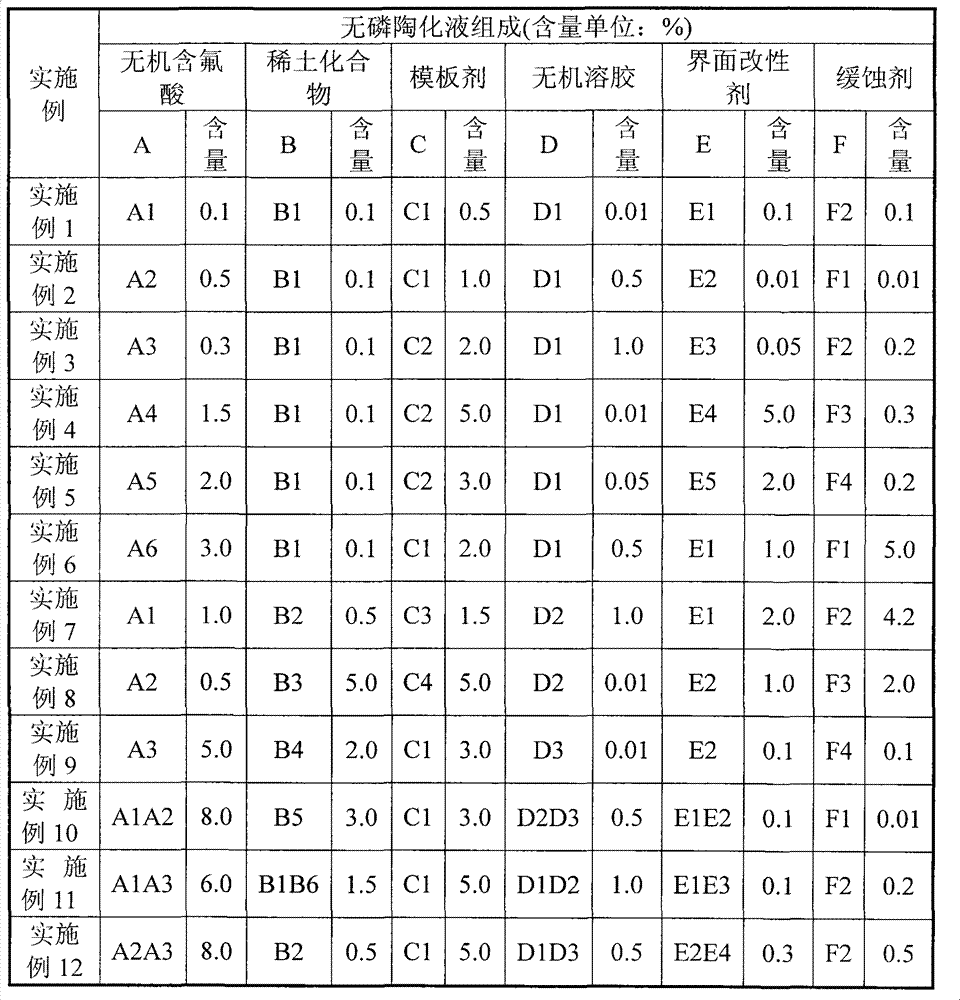

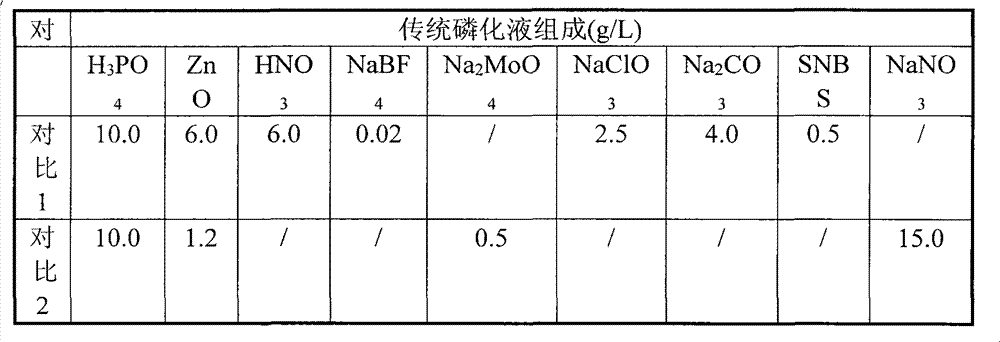

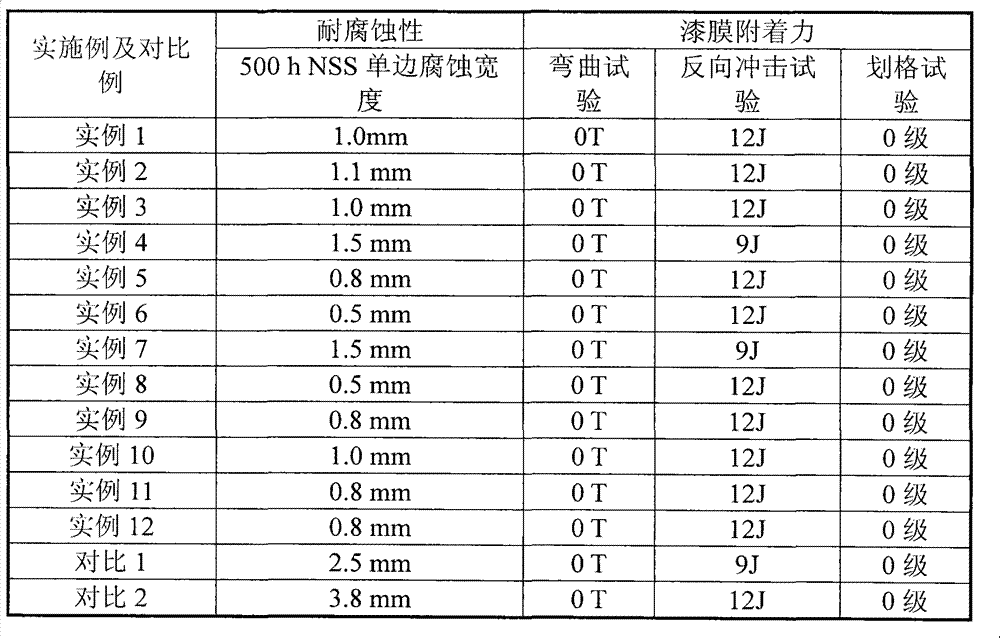

Self-repairing non-phosphorus ceramic processing liquid for galvanized plate and ceramic process thereof

InactiveCN102965653APrevent intrusionImprove adhesionMetallic material coating processesSocial benefitsRare earth

The invention discloses a self-repairing non-phosphorus ceramic processing liquid for galvanized plate and a ceramic process thereof. The processing liquid comprises the following components, by weight: 0.1-8% of inorganic fluorine-bearing acid, 0.01-5% of rare earth compounds, 0.5-5% of a template agent, 0.01-1% of an inorganic sol, 0.01-5% of an interfacial modifier, 0.01-5% of an inhibitor and the balance of water. The ceramic processing liquid provided by the invention can automatically assemble a layer of dense amorphous membrane on the galvanized plate surface through the template agent; breakage position on the membrane has self-repair ability, so that corrosion resistance and adhesion of the galvanized plate are effectively improved, and superior to those of a traditional phosphating film. The invention has the advantages of low cost, simple process, little pollution to the environment, high economic benefit and social benefit.

Owner:ANHUI WEILAI SURFACE TECH

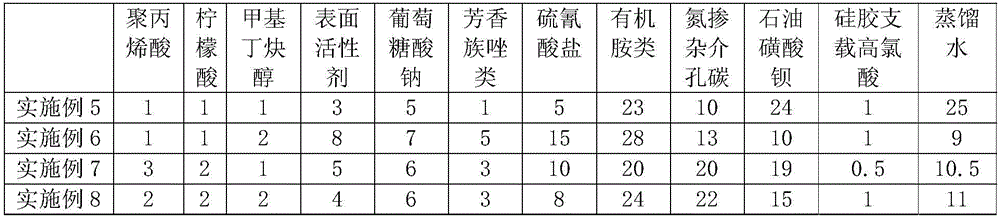

Corrosion inhibitor for oil-gas gathering and transportation pipeline and preparation method thereof

The invention discloses a corrosion inhibitor for an oil-gas gathering and transportation pipeline and a preparation method thereof. The corrosion inhibitor comprises the following components in parts by weight: 1-3 parts of polyacrylic acid, 2-10 parts of surface active agent, 5-8 parts of gluconic acid sodium salt, 1-5 parts of aromatic azole, 5-20 parts of carbonate, 20-40 parts of organic amine, 10-30 parts of carrier, 10-30 parts of barium mahogany sulfonate, 1-3 parts of liquid wax and 10-20 parts of distilled water. The corrosion inhibitor is used for inhibiting acidic erosion existing in liquid or natural gas oil field pipelines, especially the erosion caused by sulfureted hydrogen; an alkalescent liquid is formed by adding carbonate and a carrier to guarantee the absorption to acids; the addition of gluconic acid sodium salt in the components realizes the absorption of metal ions such as iron ions, aluminum ions, calcium ions and the like in the exploitation of petroleum pipelines by forming complexes of the ions, thereby avoiding electrochemical corrosion; moreover, no special equipment is needed during operation according to the preparation method, the materials are easily obtained, and the corrosion inhibitor has a good application prospect.

Owner:马杨洋 +9

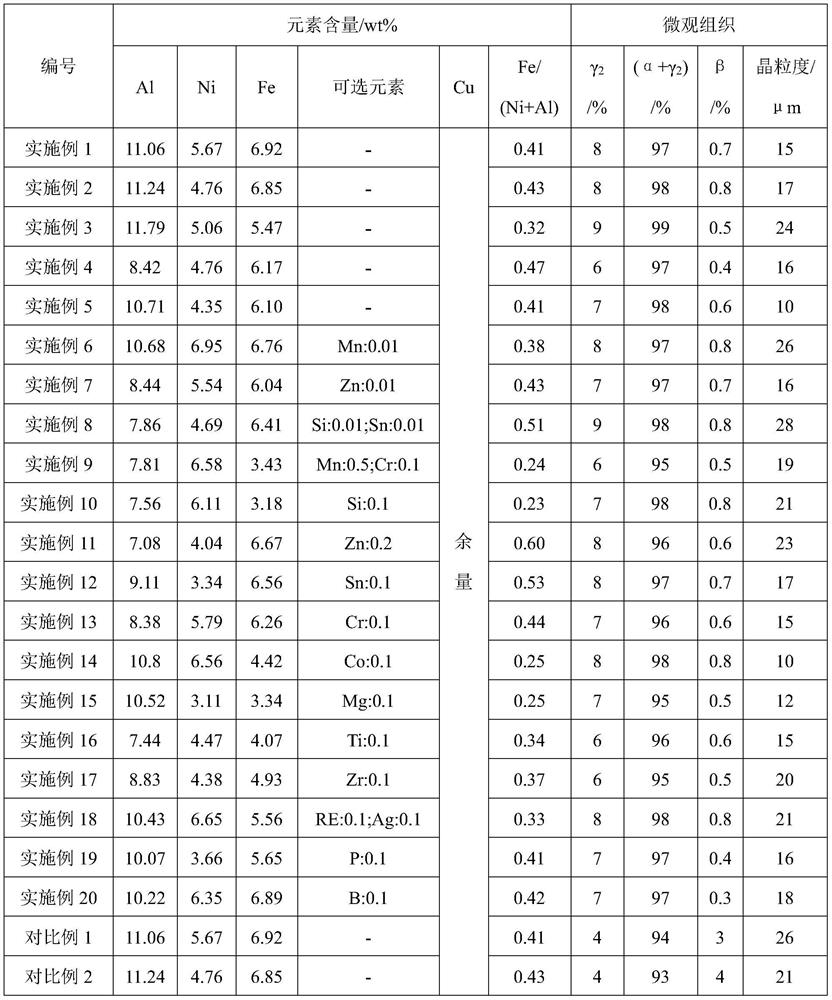

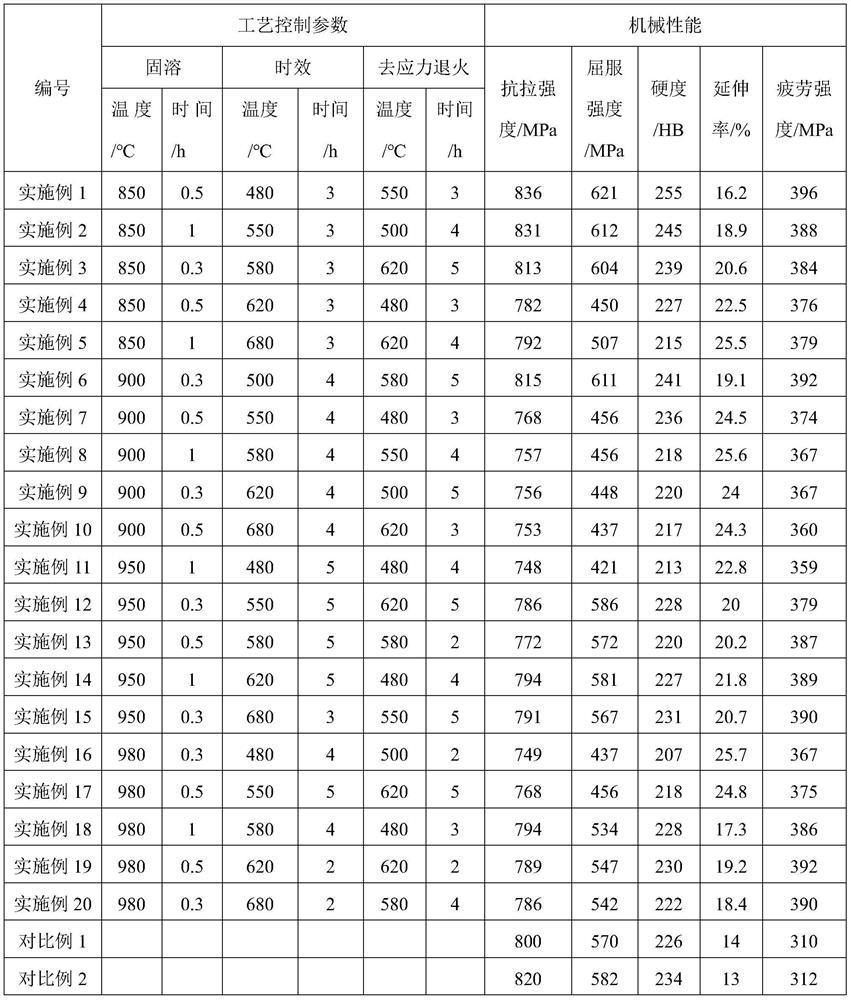

Aluminum bronze and preparation method thereof

The invention discloses aluminum bronze. The aluminum bronze is characterized by comprising the following components in percentage by mass: 7.0-12.0% of Al, 3.0-7.0% of Ni, 3.0-7.0wt% of Fe, 0-1.0wt%of Mn, 0-1.0wt% of Zn, 0-0.5wt% of Si, 0-0.5wt% of Sn, and the balance Cu and inevitable impurities; and a microstructure of the aluminum bronze contains an alpha phase and a gamma 2 phase. The aluminum bronze has the tensile strength of not less than 740MPa, the yield strength of not less than 400MPa, the ductility of not less than 15% and the hardness of not less than 200HB; when the stretchingcycle times are 107 times, the fatigue strength is 355-400MPa; and the aluminum bronze can satisfy the requirements of structural parts, wear resisting parts, corrosion resisting parts and the like working in such places as mechanical industry, ship and ocean industry, petrochemical industry and electric industry on comprehensive performances of the aluminum bronze.

Owner:NINGBO POWERWAY ALLOY MATERIAL

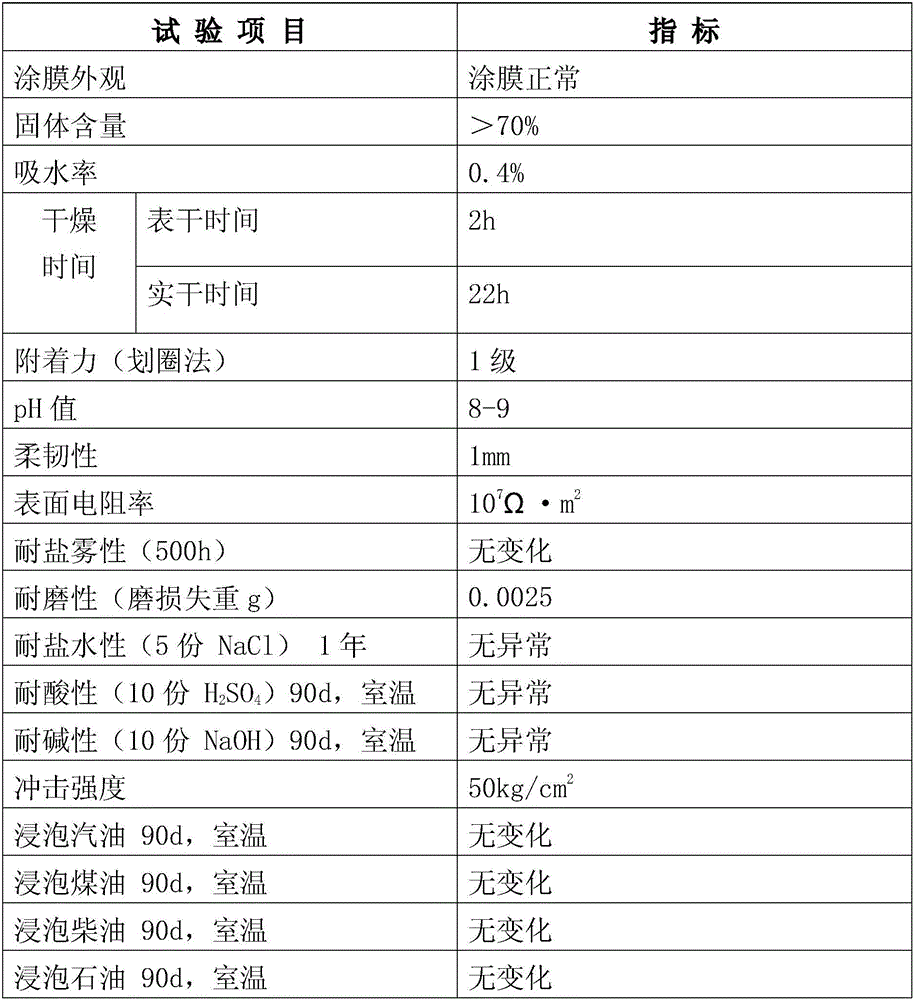

Anticorrosion antistatic coating and preparation method thereof

InactiveCN105778638AAvoid the defect that it is easy to aggregate and not easy to disperseAvoids the disadvantage of requiring larger volume fractionsAnti-corrosive paintsElectrically-conductive paintsZno nanoparticlesNetwork structure

The invention relates to coating and in particular relates to anticorrosion antistatic coating and a preparation method thereof. Raw materials of the anticorrosion antistatic coating comprise a film forming material, nano metal fibers, chemical antirust pigments, fillers and auxiliaries, wherein metal level of the nano metal fibers is lower than level of steel. The anticorrosion antistatic coating has the beneficial effects that nano zinc oxide fibers are adopted; the defect that nano zinc oxide can be easily agglomerated and is difficult to disperse is overcome; conductive fibers have small diameter and great length-diameter ratio, so that a small amount of conductive fibers can form a conductive network structure in coating, and influence on other properties of the coating can be reduced; and contradiction between static conductivity and corrosion prevention property of the coating in the traditional concept is surmounted, and the paint has two functions, namely corrosion prevention and static conduction.

Owner:SHENGYA TECH DALIAN

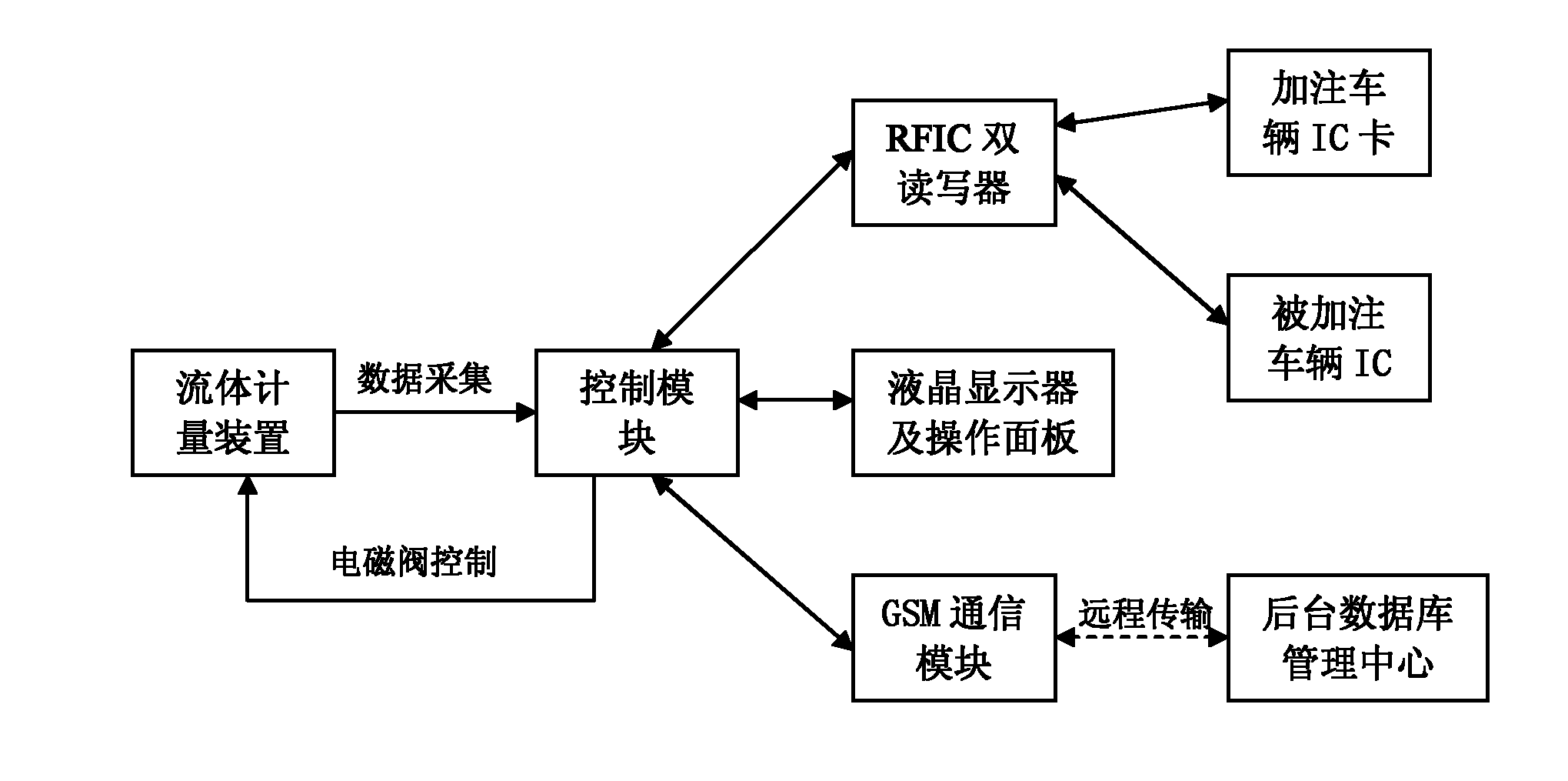

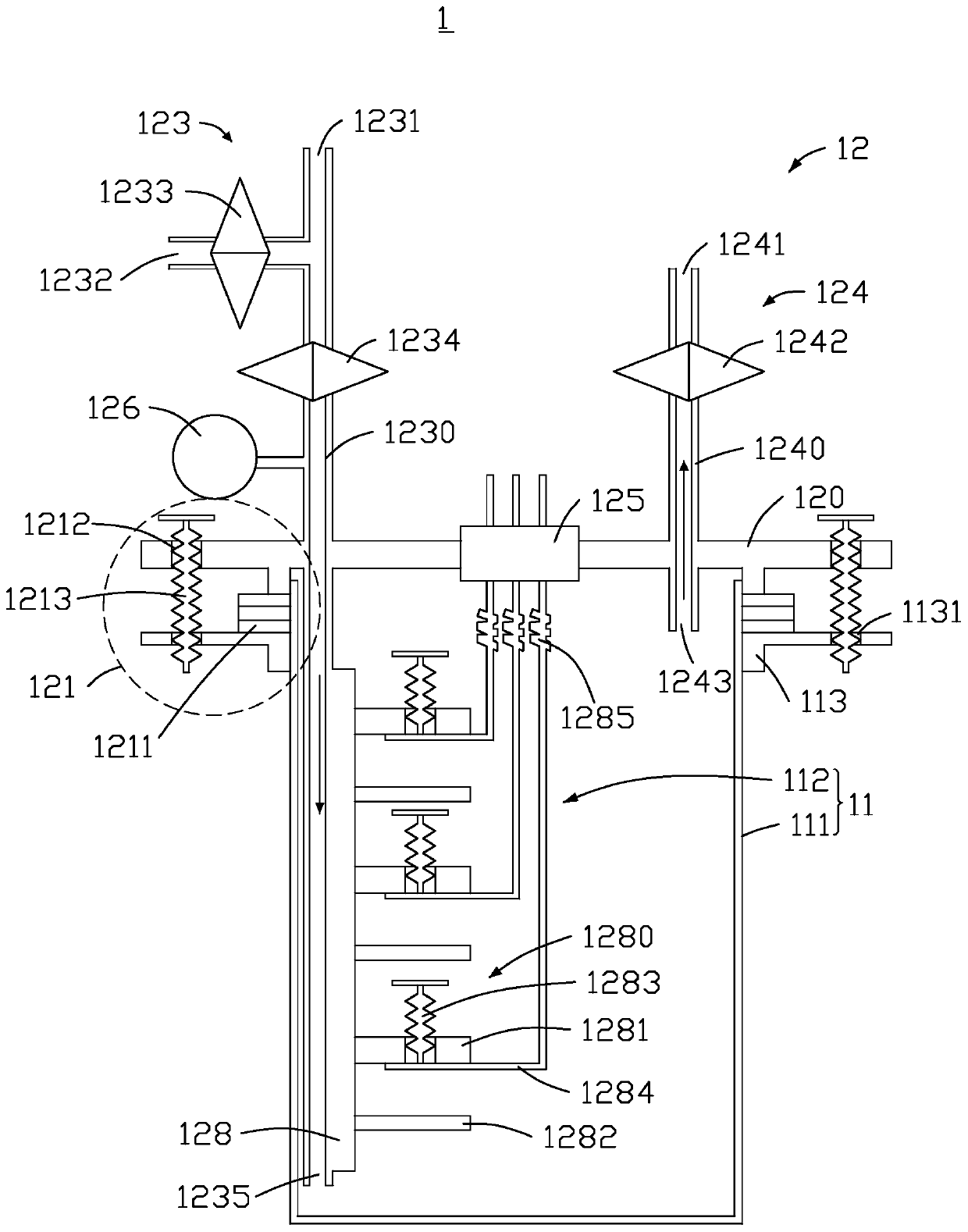

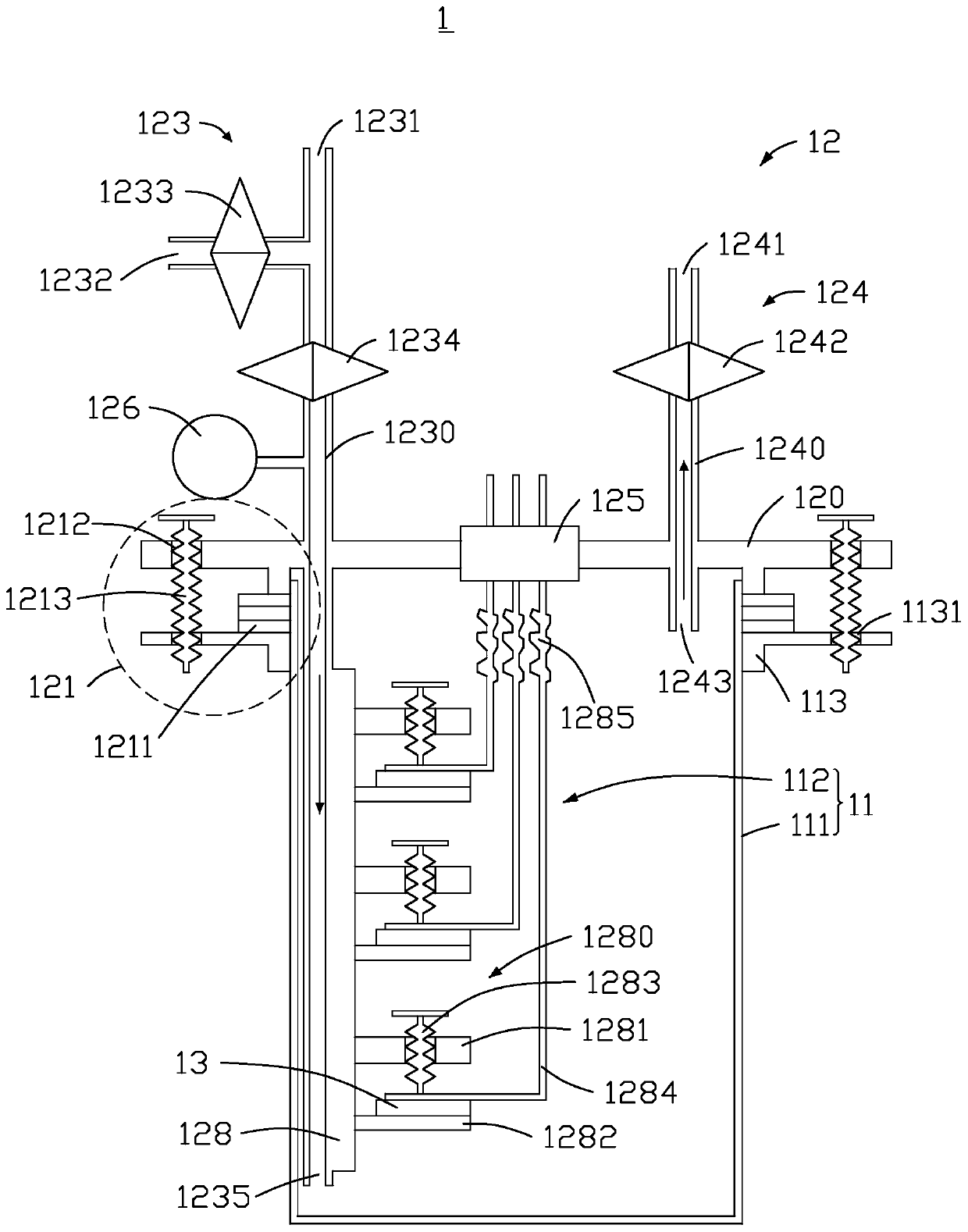

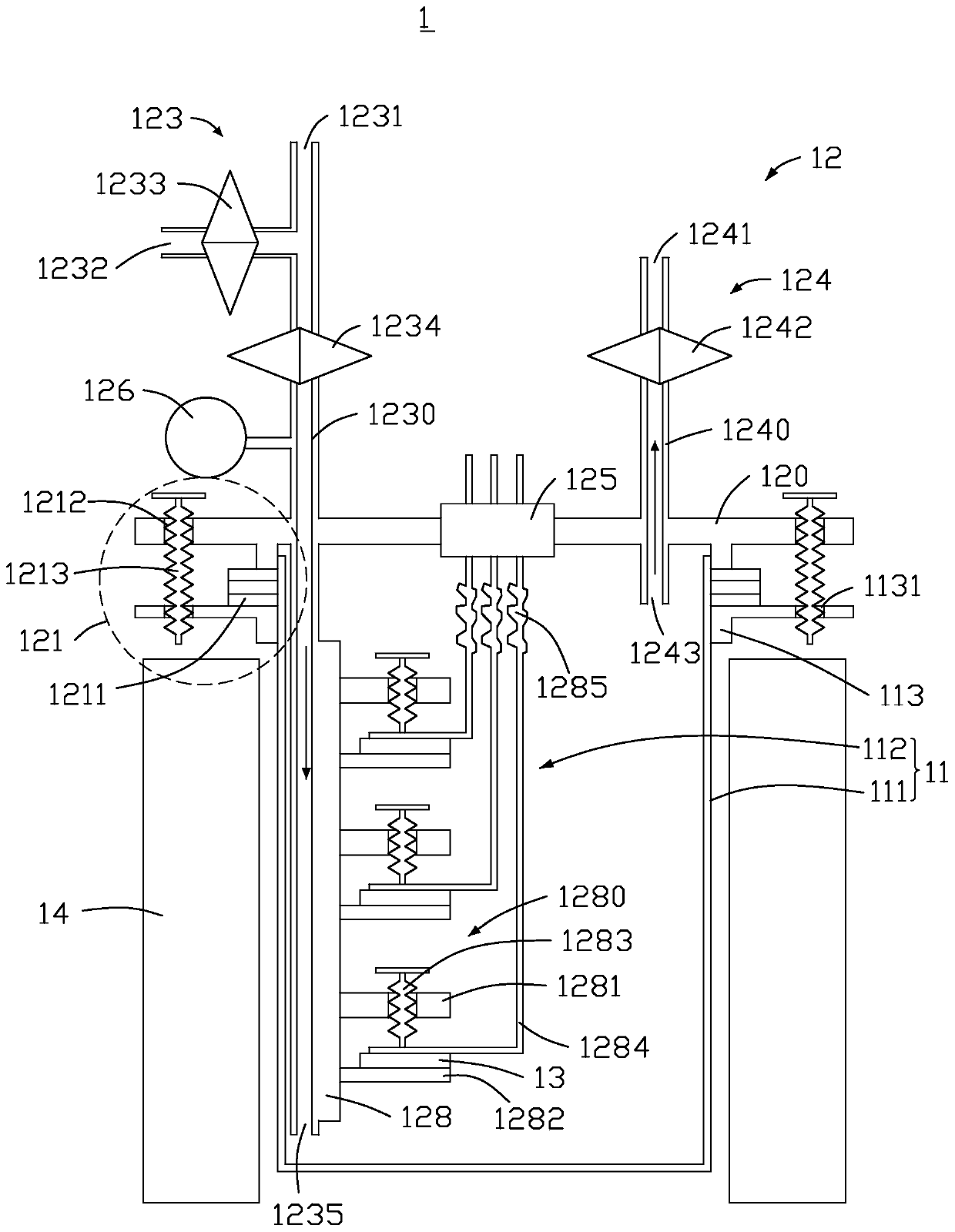

Vehicle-mounted high-precision fluid metering device and metering management system

InactiveCN102295260AShorten the lengthAchieving Corrosion ResistanceCo-operative working arrangementsVolume indication and recording devicesSolenoid valveEngineering

The invention discloses a vehicle-mounted high-precision fluid metering device and a metering management system, and relates to a vehicle-mounted accurate flow metering mechanism, and a vehicle-mounted flow metering real-time management system. The fluid metering device sequentially consists of a section of straight pipe (2), a solenoid valve (7), a section of filling flexible pipe (11) and a filling gun (12); the metering management system comprises a control module, a radio frequency integrated circuit (RFIC) double reader, a liquid crystal display, and an operation panel, a global system for mobile communication (GSM) communication module, a background database management center, a filling vehicle integrated circuit (IC) card, and a filled vehicle IC card. The flow metering device has the advantages of high metering precision, corrosion resistance, high repeatability and abrasive resistance and the like; the metering management system realizes the function of a mobile filling station, and provides a better management platform for a manager. The fluid metering device and the metering management system can accurately meter the flow of the fluid, and are suitable for metering of quantity acceptance and trade settlement of the media which are loaded by an oil tank carrier vehicle and other special liquid carrier vehicles.

Owner:侯振岐

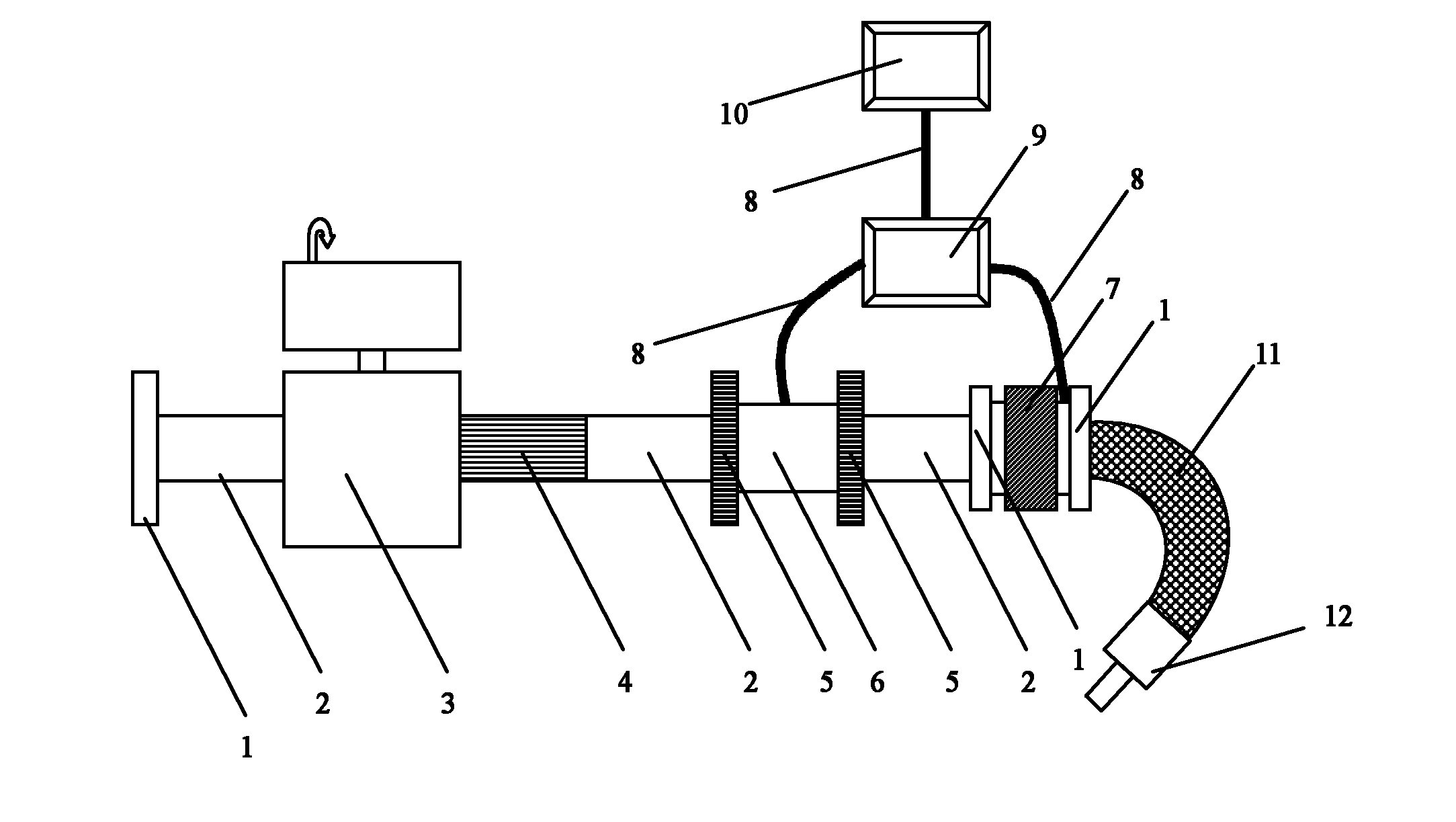

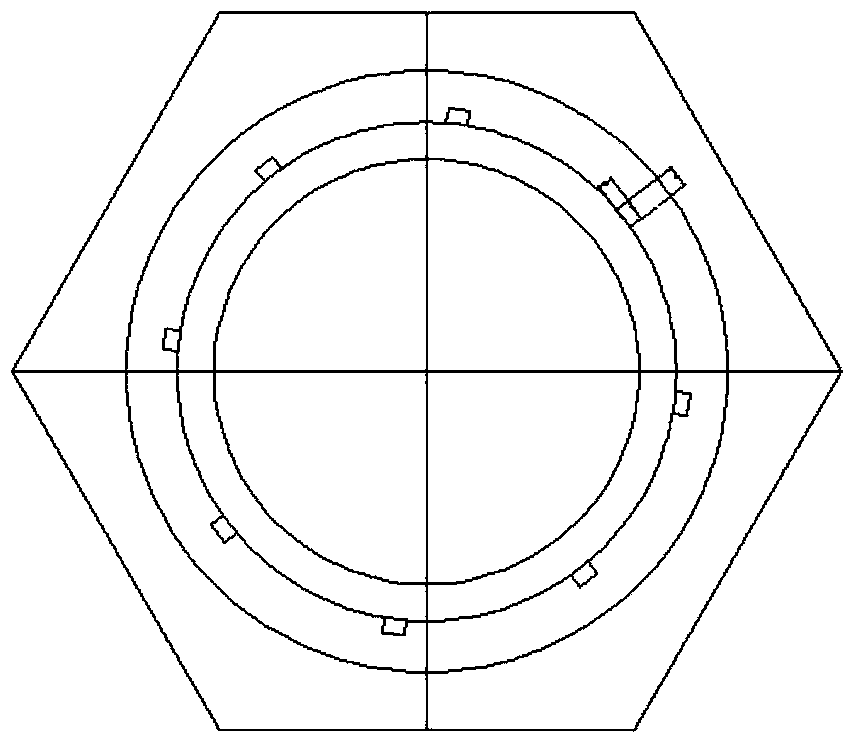

Spiral nozzle used in controlled rolling and controlled cooling technology and spiral type water feeding method

InactiveCN104107767AFast heat exchangeImprove wear resistanceSpray nozzlesWork cooling devicesSpray nozzleEngineering

The invention relates to a spiral nozzle used in controlled rolling and controlled cooling technology and a spiral type water feeding method. A water feeding chamber and a turbulence pipe are matched for use. The spiral nozzle comprises a nozzle body and an adjustable spiral type circular seam which is arranged in the periphery direction of the outer wall of the nozzle body. Cooling media are sprayed into the turbulence pipe in the adjustable spiral type circular seam direction through fixed tangent kinetic energy. Through the adjustable spiral type circular seam, the cooling media enter the turbulence pipe under large pressure in the adjustable spiral type circular seam direction through large tangent kinetic energy. By tangent flowing of the cooling media, heat exchanging speed of the cooling media and high-temperature rolled pieces is greatly improved, steel surfaces and core part grain growth can be effectively avoided, the strength is improved, and meanwhile other performance is obviously improved. Meanwhile, the spiral nozzle is small, energy consumption is lowered, cooling capacity is improved, a corrosion resistant coating layer is sprayed on the surface of the nozzle, and the corrosion resistance of the nozzle is improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

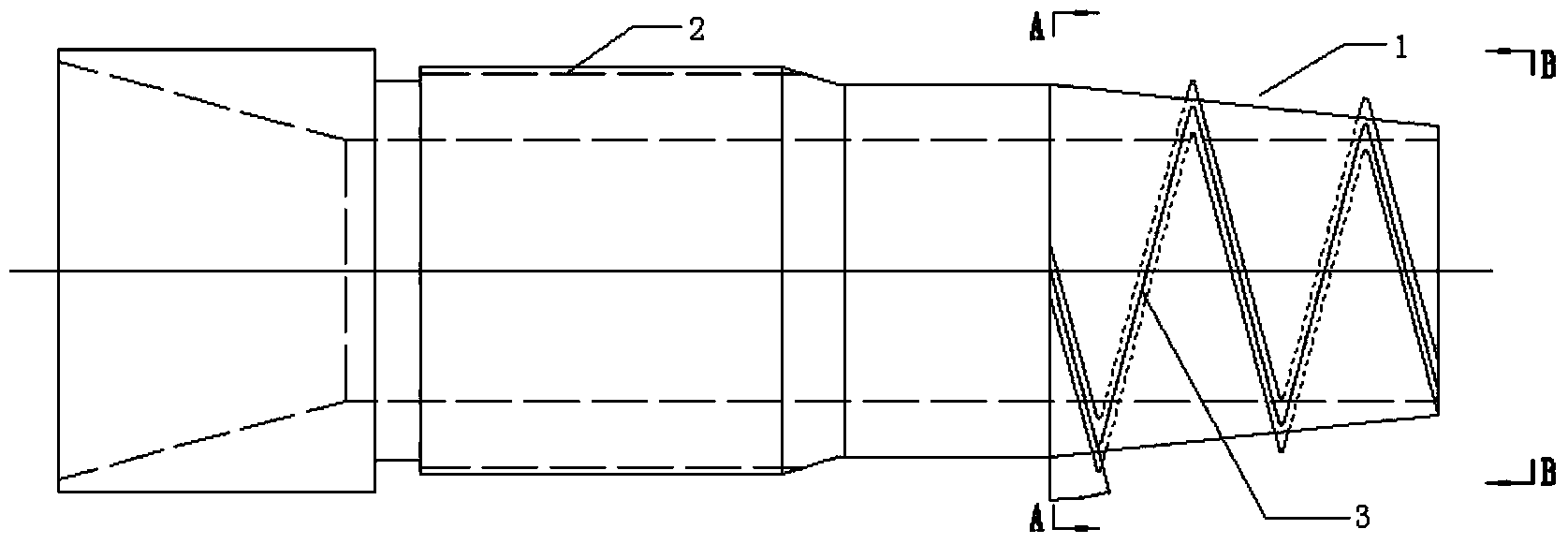

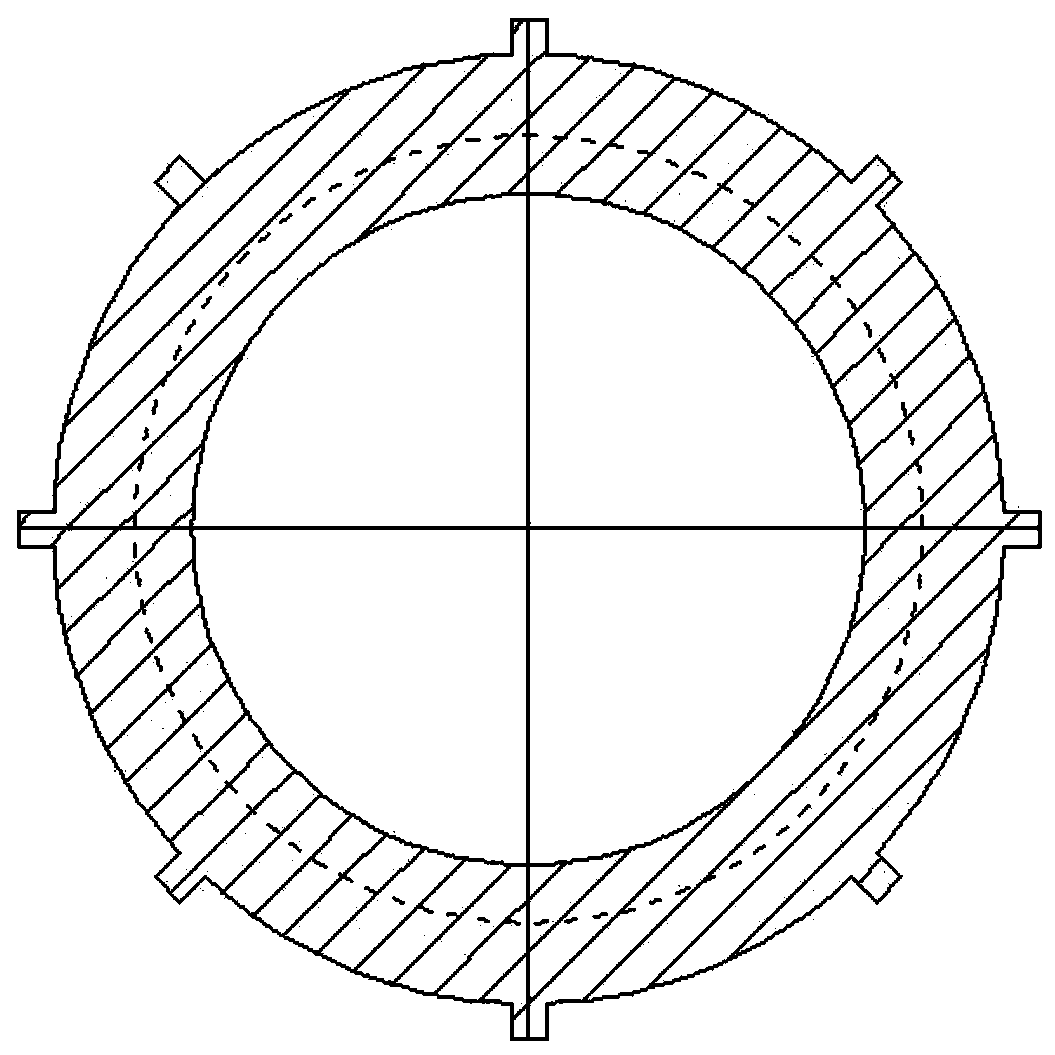

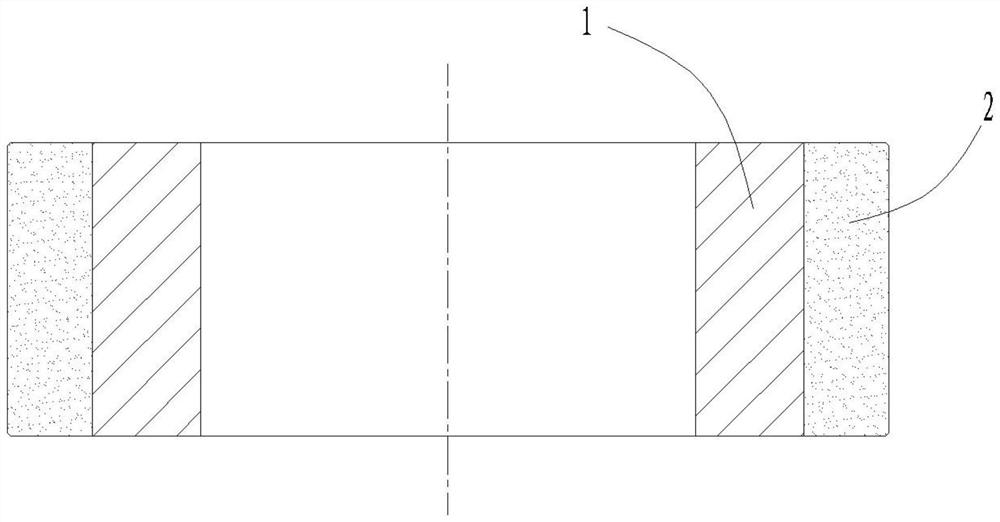

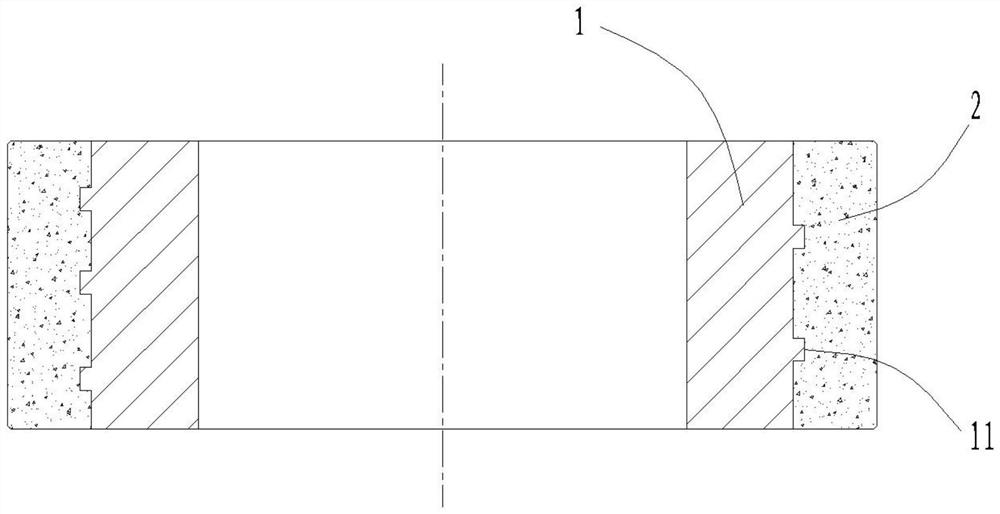

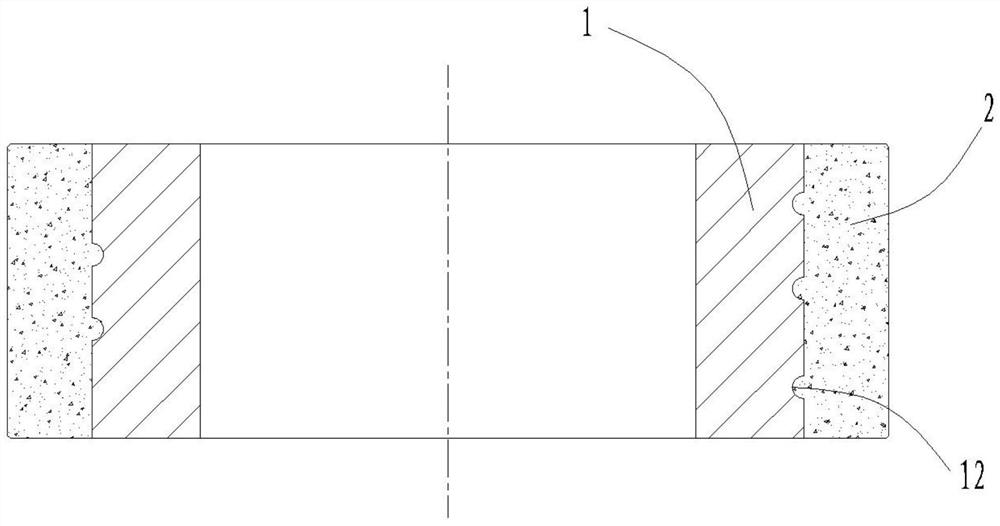

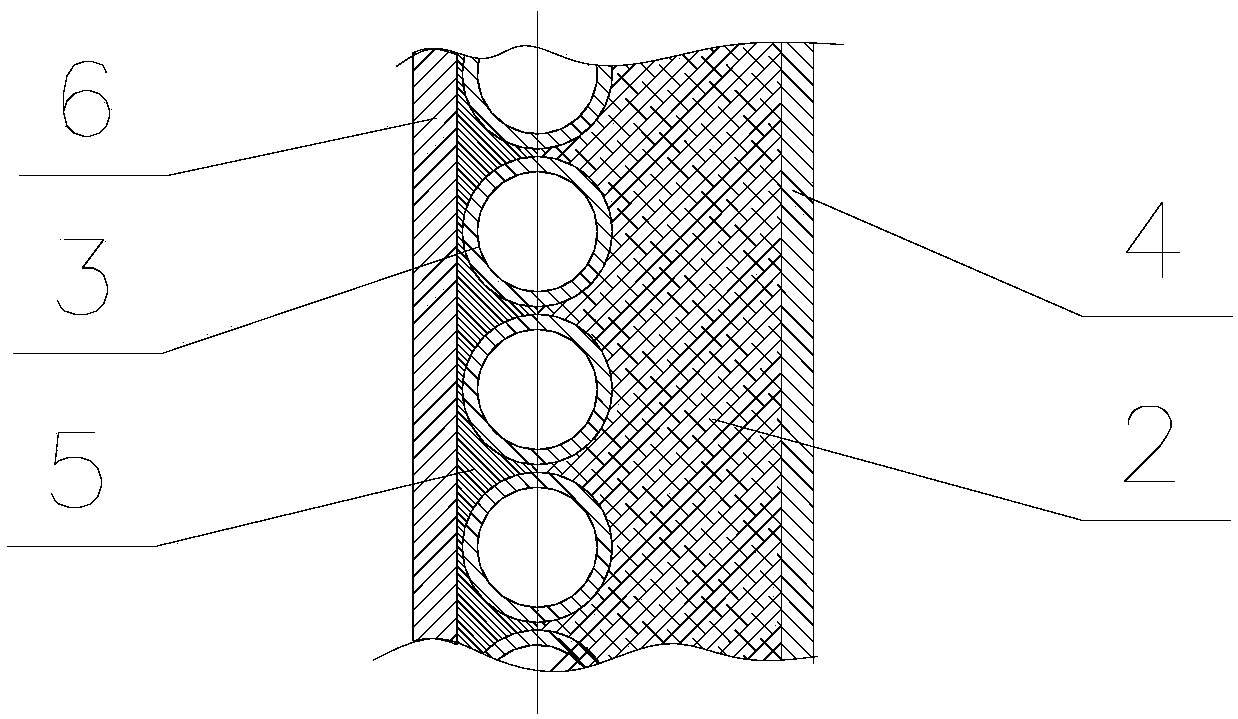

High-carbon high-vanadium powder high-speed steel composite roll collar and manufacturing method thereof

InactiveCN112247151AImprove bindingImprove performanceFurnace typesHeat treatment furnacesManufacturing cost reductionPipe

The invention discloses a high-carbon high-vanadium powder high-speed steel composite roll collar. The high-carbon high-vanadium powder high-speed steel composite roll collar comprises an inner-layersteel pipe (1) and outer-layer powder high-speed steel (2), wherein the inner-layer steel pipe (1) is a prefabricated cylindrical inner steel pipe, and the outer-layer powder high-speed steel (2) is acylindrical high-speed steel pipe which wraps the periphery of the inner-layer steel pipe (1) through a hot isostatic pressing method; and the ratio of the thickness of the inner-layer steel pipe (1)to the thickness of the outer-layer powder high-speed steel (2) is 1: (0.6-1.5). The high-carbon high-vanadium powder high-speed steel composite roll collar has high wear resistance, good red hardness and high compressive strength of powder metallurgy high-speed steel, and the manufacturing cost can be effectively reduced. The invention further discloses a manufacturing method of the high-carbonhigh-vanadium powder high-speed steel composite roll collar.

Owner:HUNAN 3T NEW MATERIAL

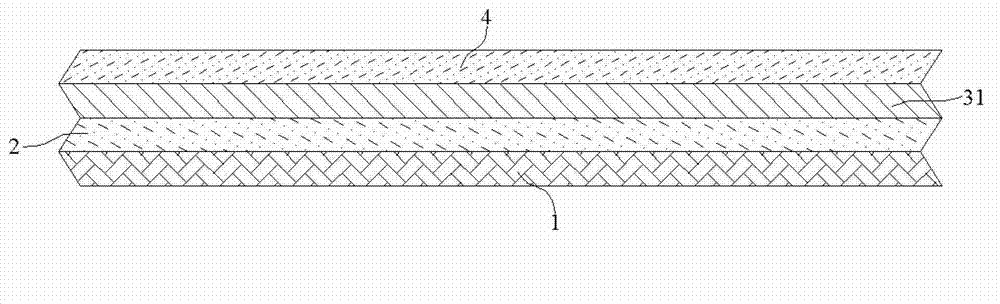

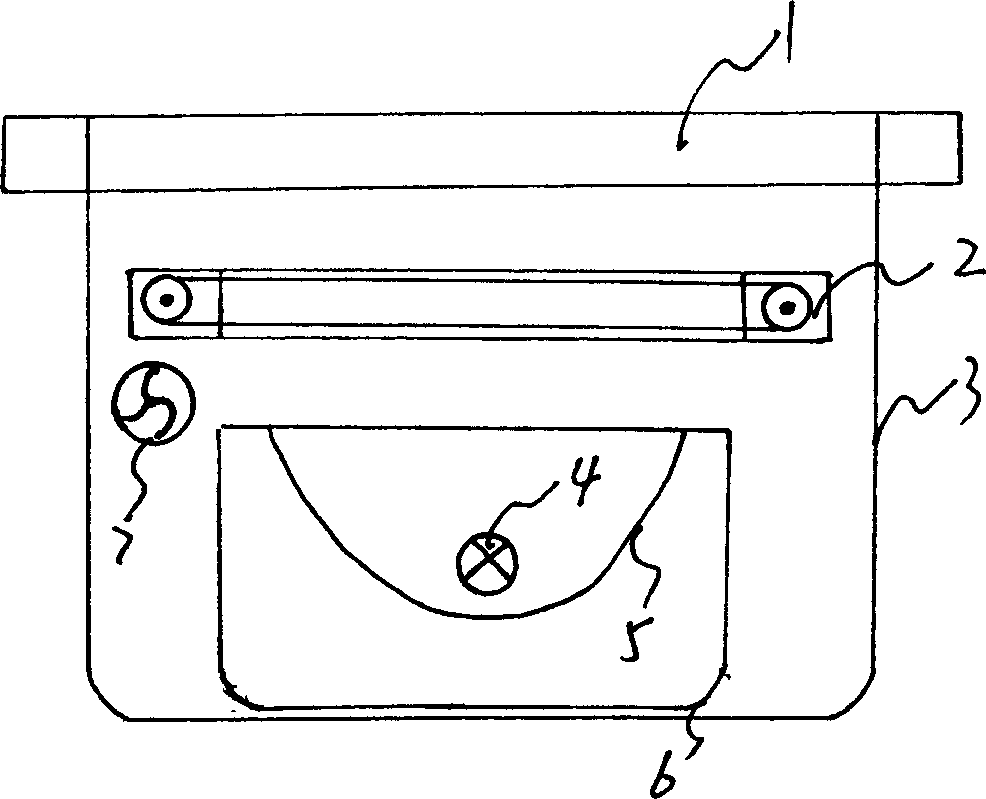

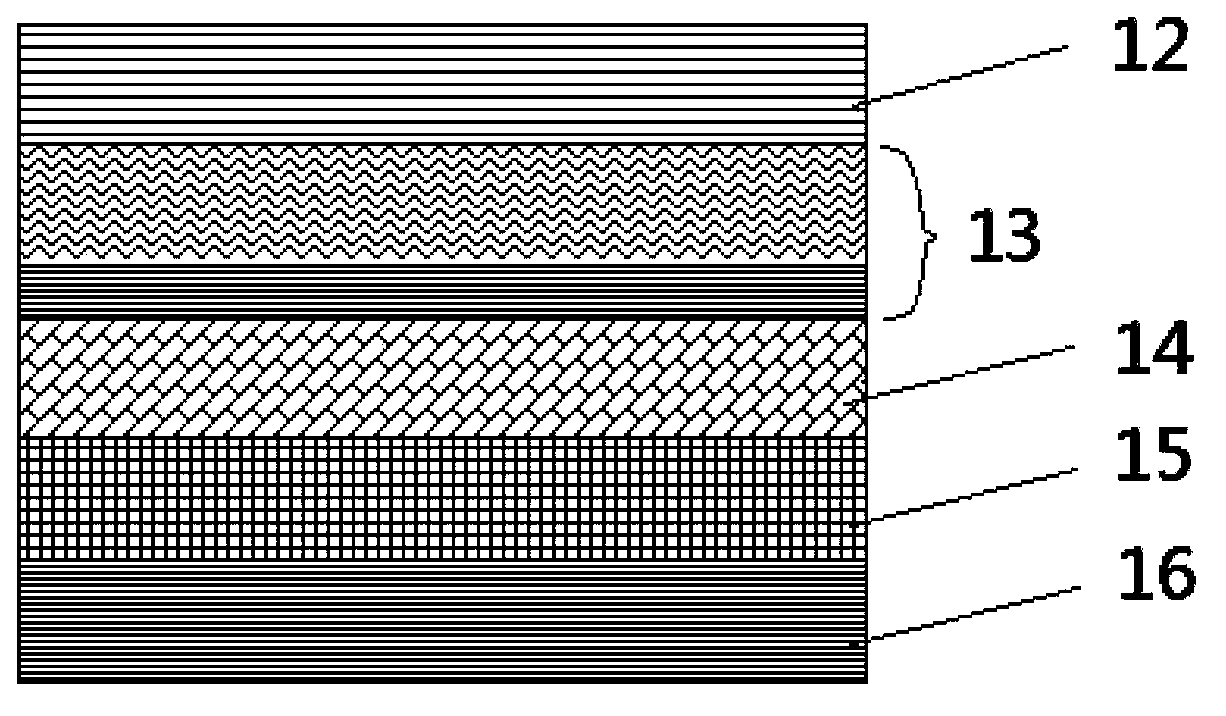

High-transmittance high-heat insulation energy-saving explosion-proof membrane and preparation process thereof

ActiveCN103042766AImprove protectionPrevent oxidationVacuum evaporation coatingSputtering coatingIndiumInsulation layer

The invention discloses a high-transmittance high-heat insulation energy-saving explosion-proof membrane and a preparation process thereof. The membrane comprises a substrate layer, wherein a first metal indium layer is magnetron-sputtered on one surface of the substrate layer; a metal silver layer or a metal aluminum layer as a heat insulation layer is magnetron-sputtered the other surface of the first metal indium layer; a second metal indium layer is magnetron-sputtered on the other surface of the metal silver layer or the metal aluminum layer; and the preparation process comprises the following steps: preparing a plastic-based membrane; magnetron-sputtering and depositing the first metal indium layer for oxidation protection on the plastic-based membrane in the step one; magnetron-sputtering and depositing the heat insulation layer on the other surface of the first metal indium layer; and magnetron-sputtering and depositing the second metal indium layer on the other surface of the heat insulation layer in the step three. According to the invention, the high-transmittance high-heat insulation energy-saving explosion-proof membrane is beneficial to reflecting and blocking infrared rays in solar rays and significant in heat insulation effect, and can preferably protect the magnetron-sputtered metal layers, prevent the metals from oxidation, and improve and ensure the performance and service life of products, thereby being applicable to places with higher requirements; and meanwhile, the invention provides the preparation process of the above high-transmittance high-heat insulation energy-saving explosion-proof membrane.

Owner:斯迪克新型材料(江苏)有限公司

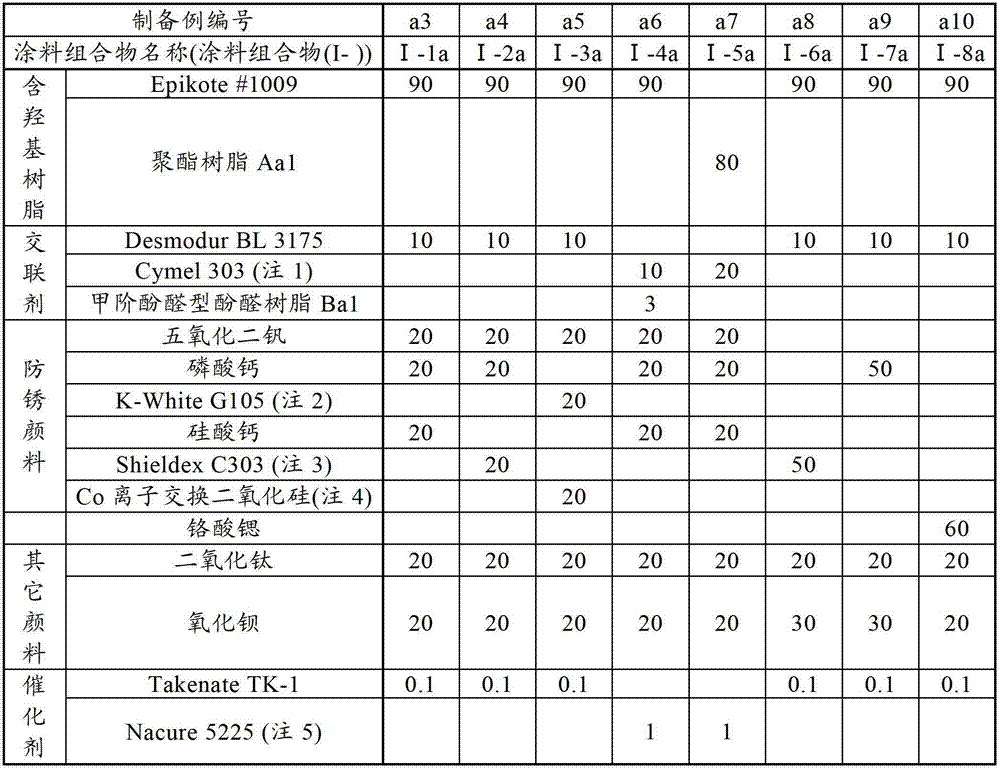

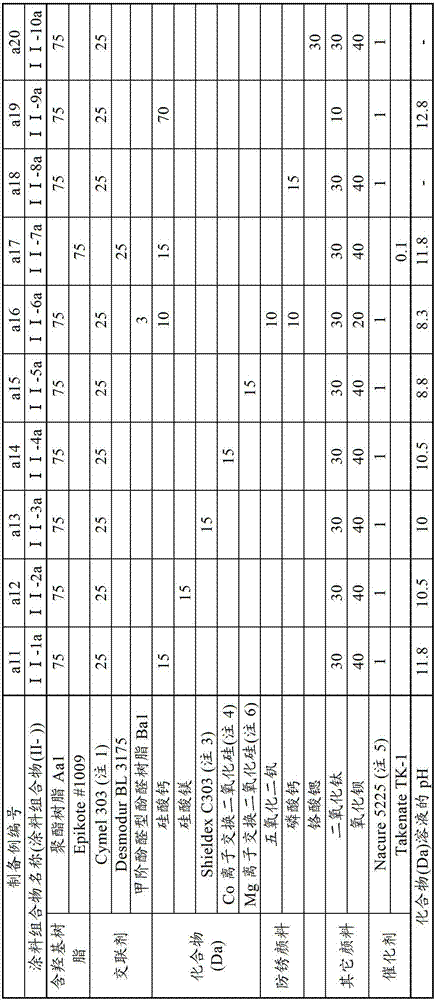

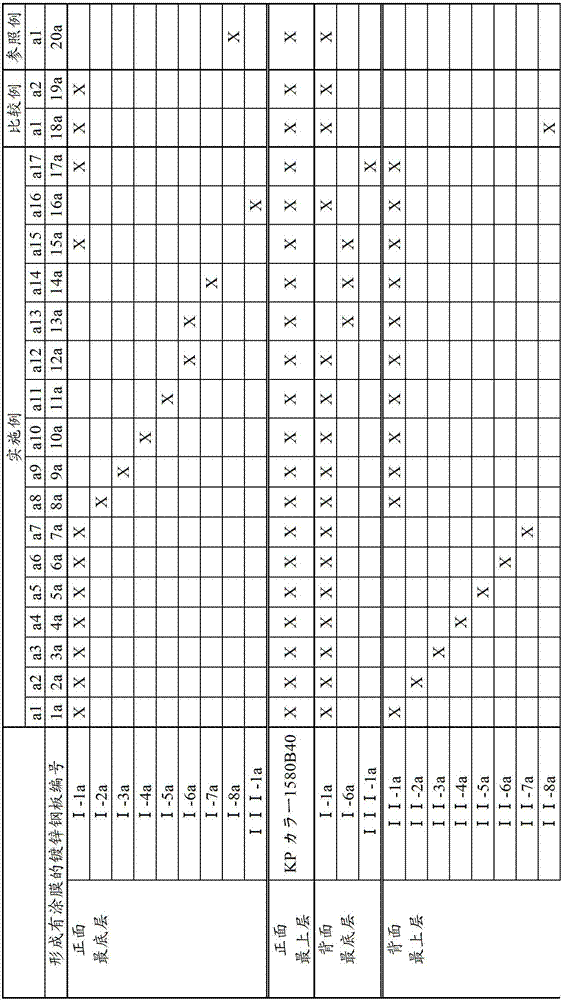

Zinc-plated steel sheet having coating film formed thereon and having excellent white rust resistance

ActiveCN102791483AImprove corrosion resistanceExcellent white rust resistanceHot-dipping/immersion processesLiquid surface applicatorsSilicic acidPhosphoric acid

Disclosed is a zinc-plated steel sheet having a coating film formed thereon, in which a multi-layered coating film composed of a non-chromium coating composition is formed on both the front surface and the rear surface thereof, and which has excellent corrosion resistance in a flat area and excellent resistance to white rust in a processed part and an edge part (which is highly visible particularly in the initial stage in use). Specifically disclosed is a zinc-plated steel sheet having a coating film formed thereon, in which a multi-layered coating film is formed on the front surface thereof and a one-layered or multi-layered coating film is formed on the rear surface thereof. In the steel sheet, a coating film composed of a coating composition that comprises a hydroxy-group-containing coating-film-forming resin and contains a predetermined amount of an anti-corrosion pigment is formed on the lowermost layer of at least one of the front and rear surfaces thereof, and a coating film composed of a coating composition that contains a predetermined amount of a silicic acid ion of a metal silicate salt and a metal ion exchange silica, a phosphoric acid group and / or a phosphate salt group of a phosphoric-acid-group-containing coating-film-forming resin and / or a phosphate-salt-group-containing coating-film-forming resin, and / or an azole compound is formed on the uppermost layer of at least one of the front and rear surfaces.

Owner:KANSAI PAINT CO LTD

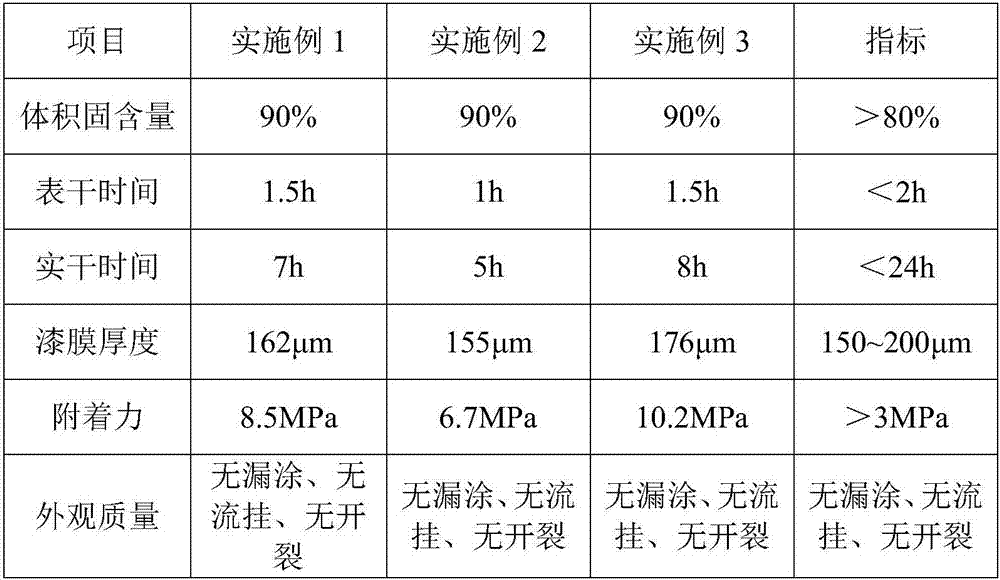

Coating process for preparing waterborne heavy corrosion protection coating based on single-way thick film technology

ActiveCN106994436AReduce the content of solvent waterReduce moisture evaporationPretreated surfacesCoatingsSolventMicrometer

The invention provides a coating process for preparing a waterborne heavy corrosion protection coating based on the single-way thick film technology. The high-pressure no-air manner is adopted to spray a corrosion protection coating with the solid content in volume being 80% or above, accordingly, in the process, the content of solvent water is reduced, the water volatilization amount in the paint film drying process is reduced, the thickness and the coating compactness of a single-way spraying construction coating dry film are improved, the coating combination strength is improved, the single-way construction coating dry film with the thickness ranging from 150 micrometers to 200 micrometers can be manufactured, only through single-way coating, the corrosion protection capacity, with 10 years or above, of the coating in the industrial or coastal regions with the brinishness can be achieved, and compared with multi-way coating process in the prior art, the production efficiency is greatly improved.

Owner:SHANGHAI ZHENHUA HEAVY IND

Environmentally-friendly solvent-free anticorrosive graphene coating and preparation method thereof

InactiveCN110358407ALarge specific surface areaImprove thermal conductivityAnti-corrosive paintsEpoxy resin coatingsEnvironmental resistanceSolvent free

The invention discloses an environmentally-friendly solvent-free anticorrosive graphene coating and a preparation method thereof. The coating of the invention is prepared from, by weight, 30-40 partsof epoxy resin, 15-20 parts of a reactive diluent, 0.15-0.2 part of graphene, 5-10 parts of an assistant, 20-25 parts of iron oxide red, 10-15 parts of mica powder, 0.4-0.8 part of fumed silica, 4-6 parts of barite, 6-10 parts of tripolyphosphate, 0.5-1.5 parts of a silane coupling agent and 7-15 parts of a phenolic amine epoxy resin curing agent. The product of the invention is a solvent-free coating, does not contain volatile organic solvents, has a solid content of 100% and a VOC content of zero, and is green and environmentally friendly; and the super large specific surface area, excellentbarrier property, high chemical stability and good electrical conducting property of the graphene are utilized, so the comprehensive properties of the anticorrosive composite coating are greatly improved.

Owner:四川芯美科技有限公司

Computer controlled underwater color-variable spotlight

InactiveCN1664439ASolve the problem of single colorAchieve varietyLighting heating/cooling arrangementsGas-tight/water-tight arrangementsLight beamOptoelectronics

The invention relates to a under water color alterable high brightness shooting light that belongs to under water shooting light manufacturing field. The reflection shield is installed in the case of the shooting light, and the high brightness light emit source is in the reflection shield. And the computer color vary machine is located on the top of the reflection shield and in the waterproof case of the shooting light. The light translucidus cover is located on the port of the under water waterproof shooting light case and is sealed to the port. The design of the computer color alter machine solves the problem of the color singleness of the under water shooting light and realizes the polychrome of the under water shooting light. And the color would be changed following the music of the computer.

Owner:杭州亿奥光电有限公司

Preparation method for BOPET high-imitation metal wiredrawing VCM film

ActiveCN103692722ASave production costSave manufacturing costSynthetic resin layered productsMetal layered productsUltravioletBoPET

The invention discloses a preparation method for a BOPET (biaxially oriented polyester) high-imitation metal wiredrawing VCM film. The method includes: conducting surface wiredrawing treatment on one side of a transparent BOPET film; coating one surface without surface wiredrawing treatment by a polyurethane UV curable paint, carrying out UV photo-curing and heat curing, and performing natural cooling to obtain a surface hardened coating; coating the surface subjected to surface wiredrawing treatment with a model SC-400 pre-aluminizing prime coat to obtain a fastness enhanced coating; conducting vacuum aluminizing processing on the fastness enhanced coating to obtain a vacuum aluminized layer; and coating the aluminized surface of the vacuum aluminized layer with a model SC-500 topcoat, thus obtaining an antioxidant protective coating. Single-layer BOPET is adopted as a film main material, thus reducing the dosage of a raw material film, saving the production cost, prolonging the product life and improving the tolerance to various adverse conditions. The film obtained by the method has the visual effects of an imitated metal wire drawing board, thus realizing the purpose of high simulation of different material wiredrawing metal boards.

Owner:SHANGHAI RADIX VACUUM METALIZING

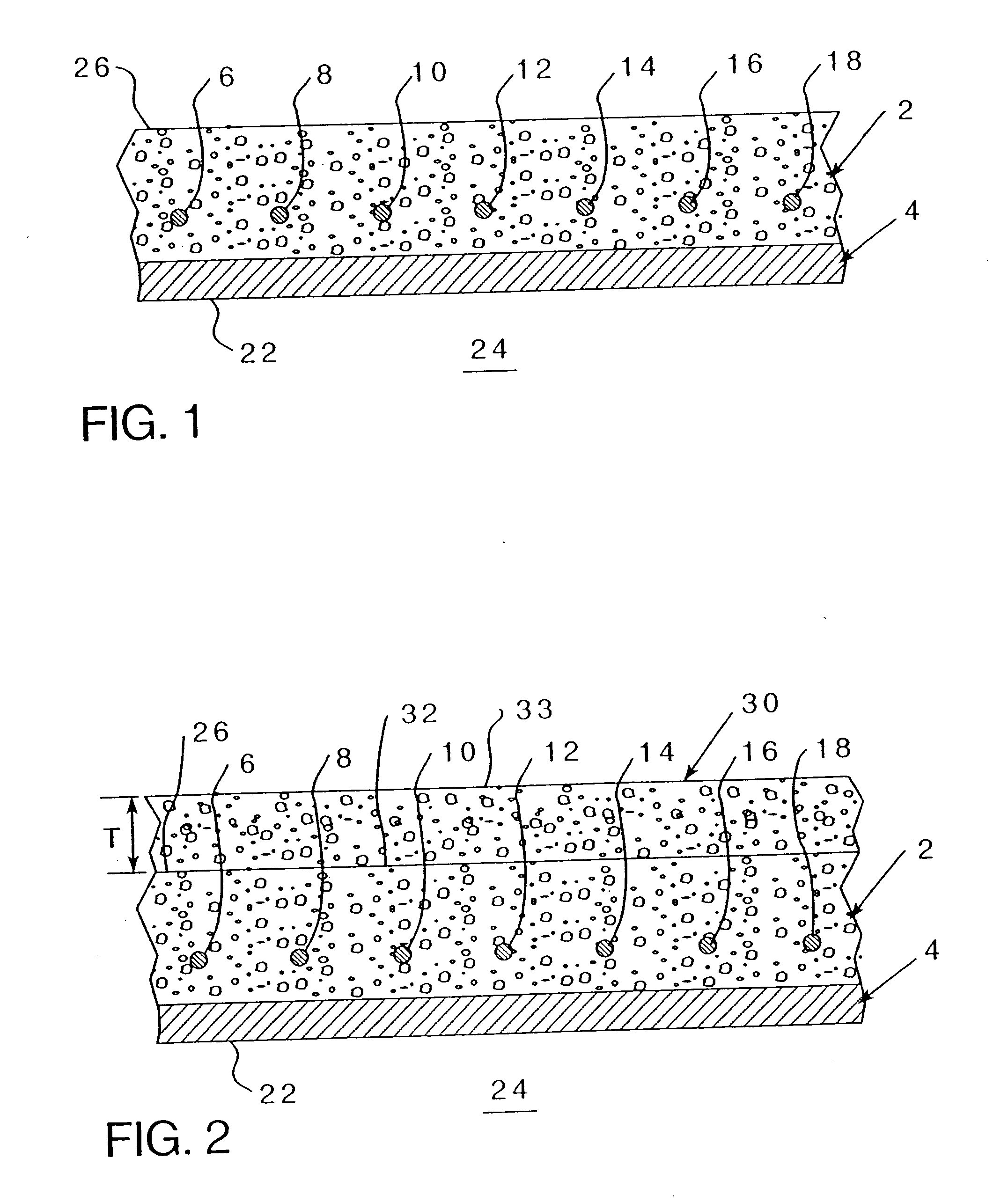

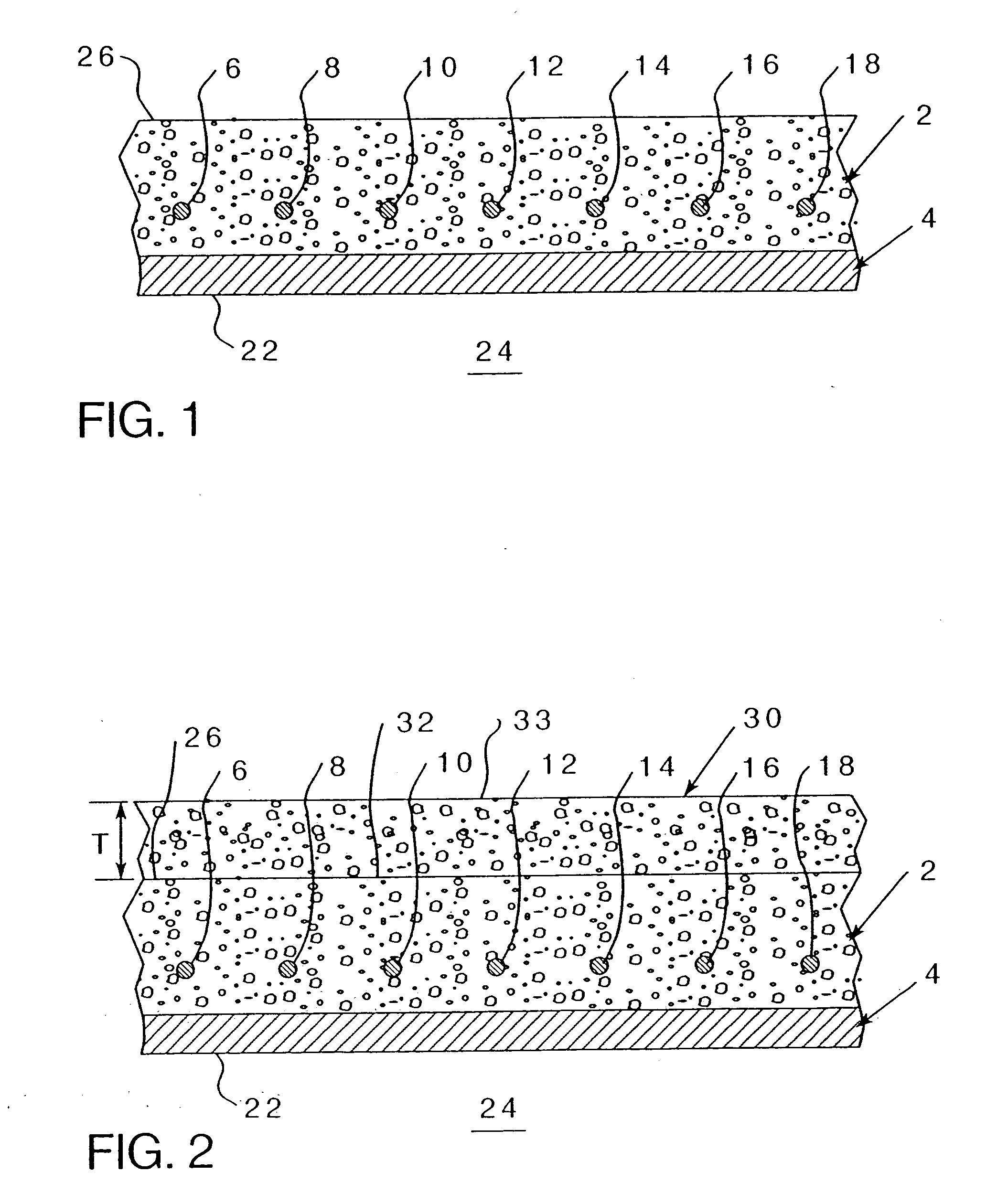

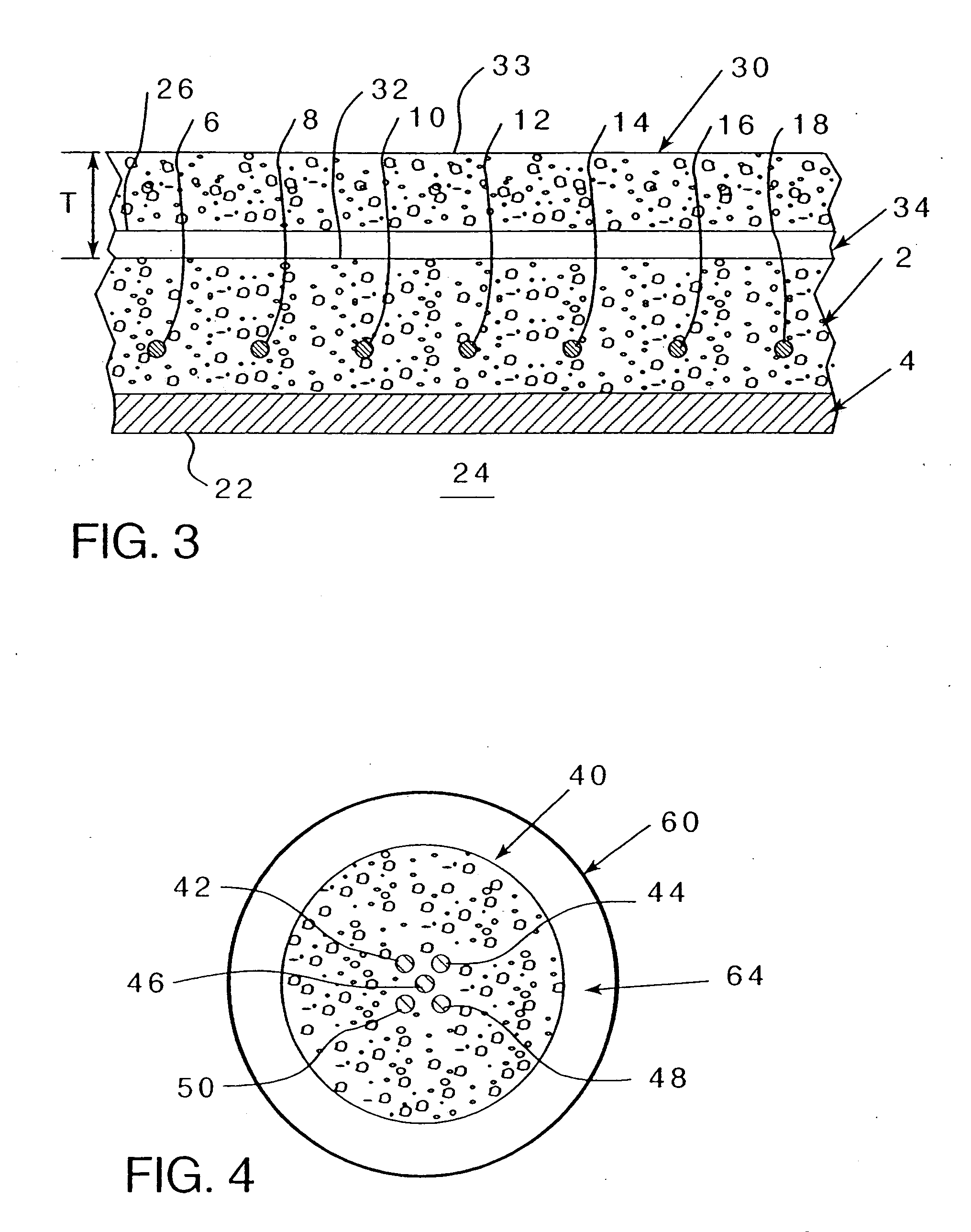

Direct sequestration of chloride ions

InactiveUS20050211137A1Corrosion resistanceAchieving Corrosion ResistanceOther chemical processesSolid waste managementSolubilityNitrite

The present invention provides methods and compounds for the direct sequestration of chloride ions without requiring the addition of a source of anion such as nitrite or nitrate. A direct sequestration additive is introduced to fresh concrete or hardened concrete where the additive reacts with incoming chloride ions to form a low solubility, chloride-containing compound which captures or sequesters chloride ions. In a preferred embodiment, the chloride-containing compound comprises 3CaO.Fe(2-x)AlxO3.CaCl2.nH2O, where x ranges from about 0 to 1.4, and n ranges from about 8 to 24. The chloride ions may be provided in the form of deicing salt or sea water. Because chloride-containing compounds such as 3CaO.Fe(2-x)AlxO3.CaCl2.nH2O are formed directly without requiring the addition of a source of anion (e.g. nitrite or nitrate), the process is referred to as “direct sequestration.”

Owner:BROWN PAUL W

Preparation and water treatment application of super-hydrophobic stainless steel-carbon nanotube composite membrane

ActiveCN111514764AEnhanced anti-pollution and anti-corrosion propertiesAchieve anti-pollution and anti-corrosion propertiesSemi-permeable membranesMembranesElectrically conductiveCorrosion

The invention provides preparation and water treatment application of a super-hydrophobic stainless steel-carbon nanotube composite membrane, and aims to provide a preparation method of a stainless steel-carbon nanotube composite membrane with high strength, flexibility, super-hydrophobicity and conductivity and a water treatment application technology. With application of a surface activation strategy and an autocatalytic chemical vapor deposition technology, a carbon nanotube functional layer grows on a stainless steel carrier in situ, the stainless steel-carbon nanotube composite membrane is constructed, the treatment performance of high-salinity wastewater and high-organic wastewater is remarkably improved through a micro-electric field assisted membrane distillation process, and in-situ membrane pollution resistance and corrosion resistance are achieved. The membrane preparation method and the membrane application strategy are expected to be expanded to preparation of other conductive metal matrix-carbon nanotube composite membranes and other water treatment separation applications such as separation and purification of high-salt wastewater, antibiotic wastewater and organic dye wastewater.

Owner:DALIAN UNIV OF TECH

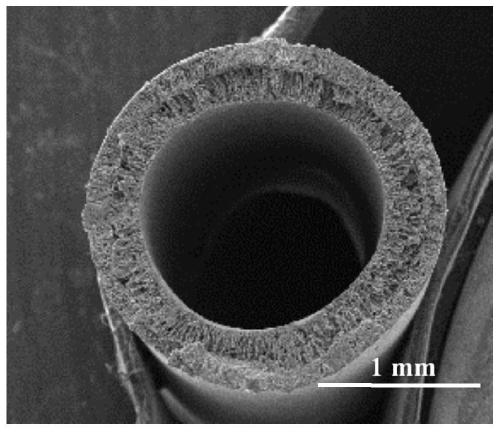

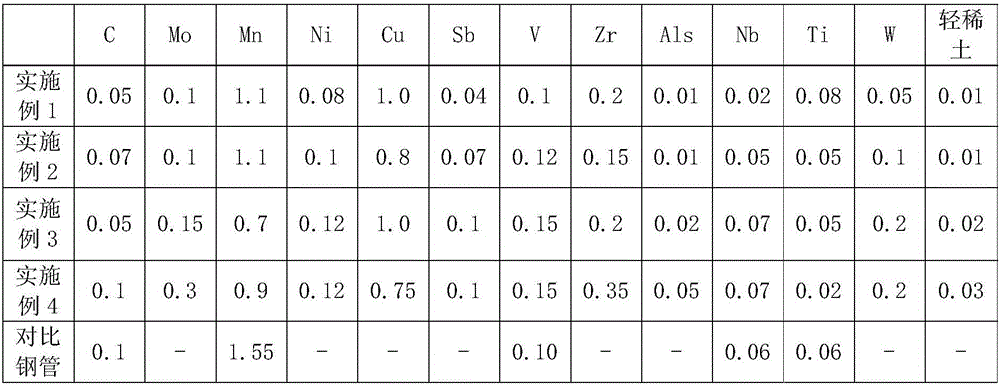

Manufacturing method of corrosion-resistance alloy hot-rolled steel pipe

InactiveCN106555137AGuaranteed corrosion resistanceAchieve absorptionFurnace typesHeat treatment furnacesPipeline transportElectrochemical corrosion

The invention aims to provide a manufacturing method of a corrosion-resistance alloy hot-rolled steel pipe with high acid resistance and excellent comprehensive corrosion resistance. The manufacturing method of the steel pipe comprises the steps of: iron smelting by a blast furnace, predesulfurization of molten steel, converter top-bottom compound blowing, LF furnace refining, continuous casting of a steel pipe blank, heating, perforation, continuous rolling, tension diameter determination, correction, cooling and prewashing; the prewashing is performed for the inner wall of the steel pipe by a corrosion inhibitor; after the corrosion inhibitor is contacted with the inner wall of the steel pipe, a layer of uniform protective film is formed on the inner wall of the steel pipe, so that the corrosion resistance of the inner wall of the steel pipe is improved; sodium gluconate preferably realizes absorption of such metal ions as aluminum and copper in the steel pipe to form ion complex compounds to prevent electrochemical corrosion; the corrosion inhibitor has multiple slow release mechanisms to preferably realize the corrosion resisting effect; and when the pipe conveys crude oil, the corrosion inhibitor has no need to continuously feed, so that the maintenance workload is low.

Owner:XI'AN PETROLEUM UNIVERSITY

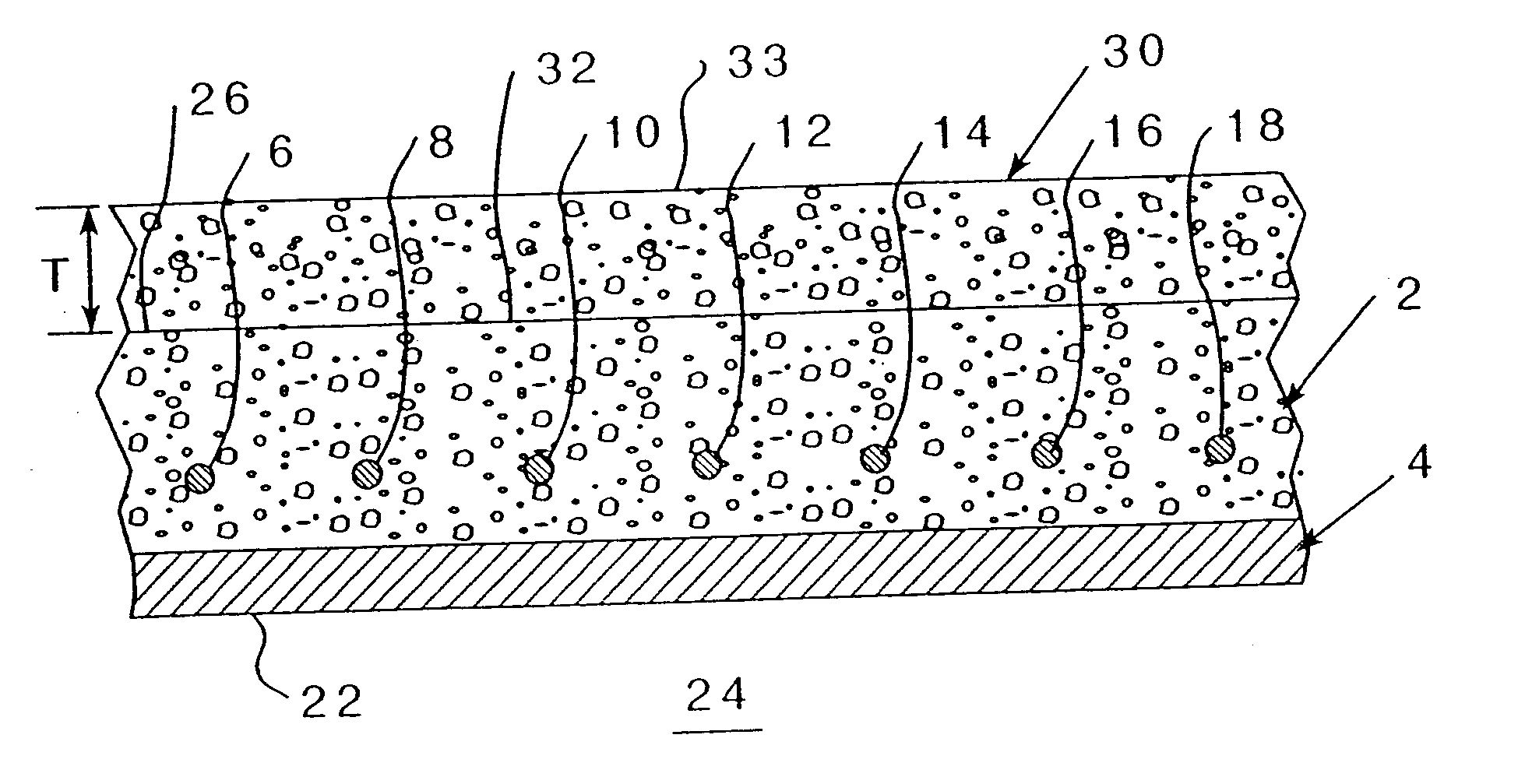

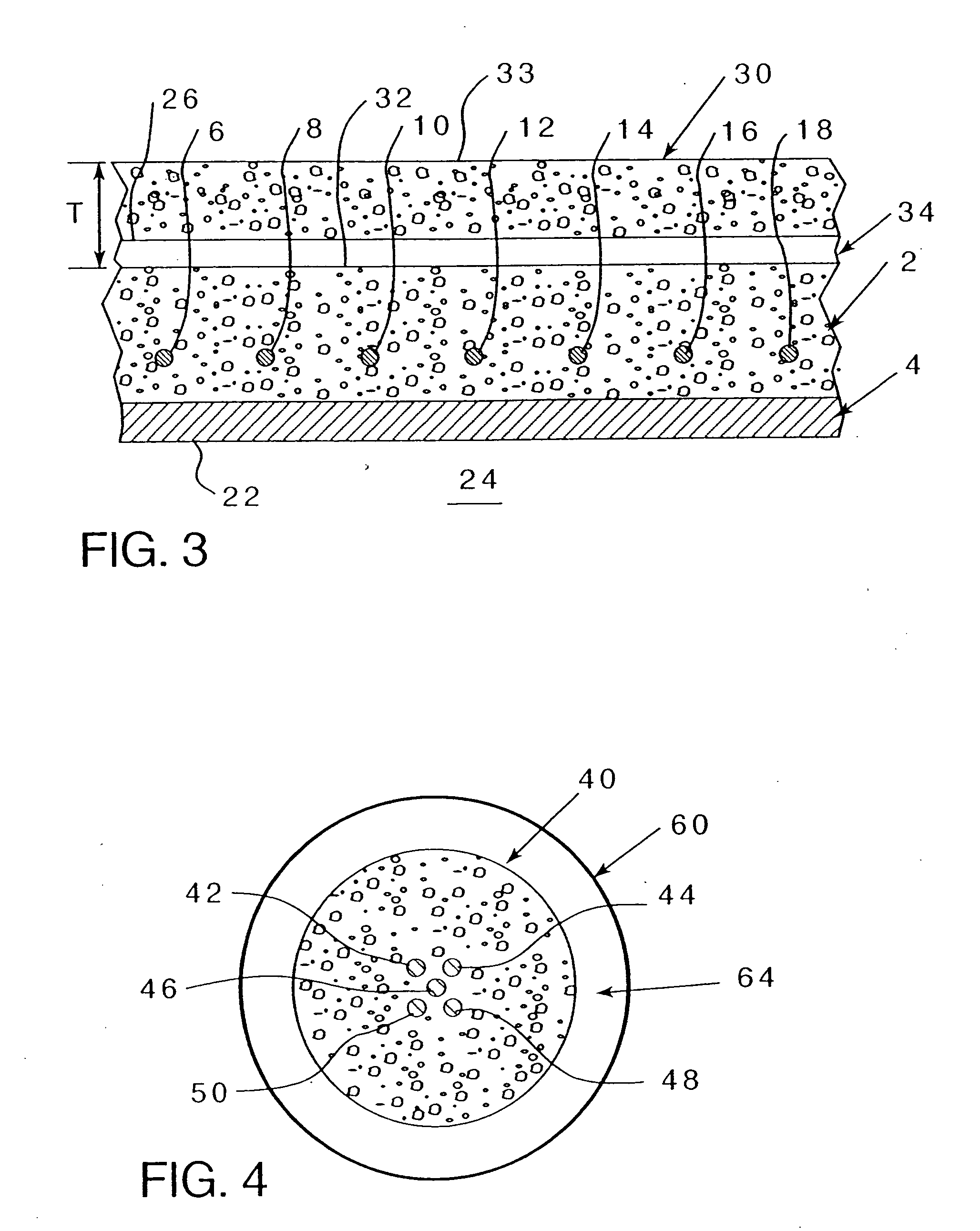

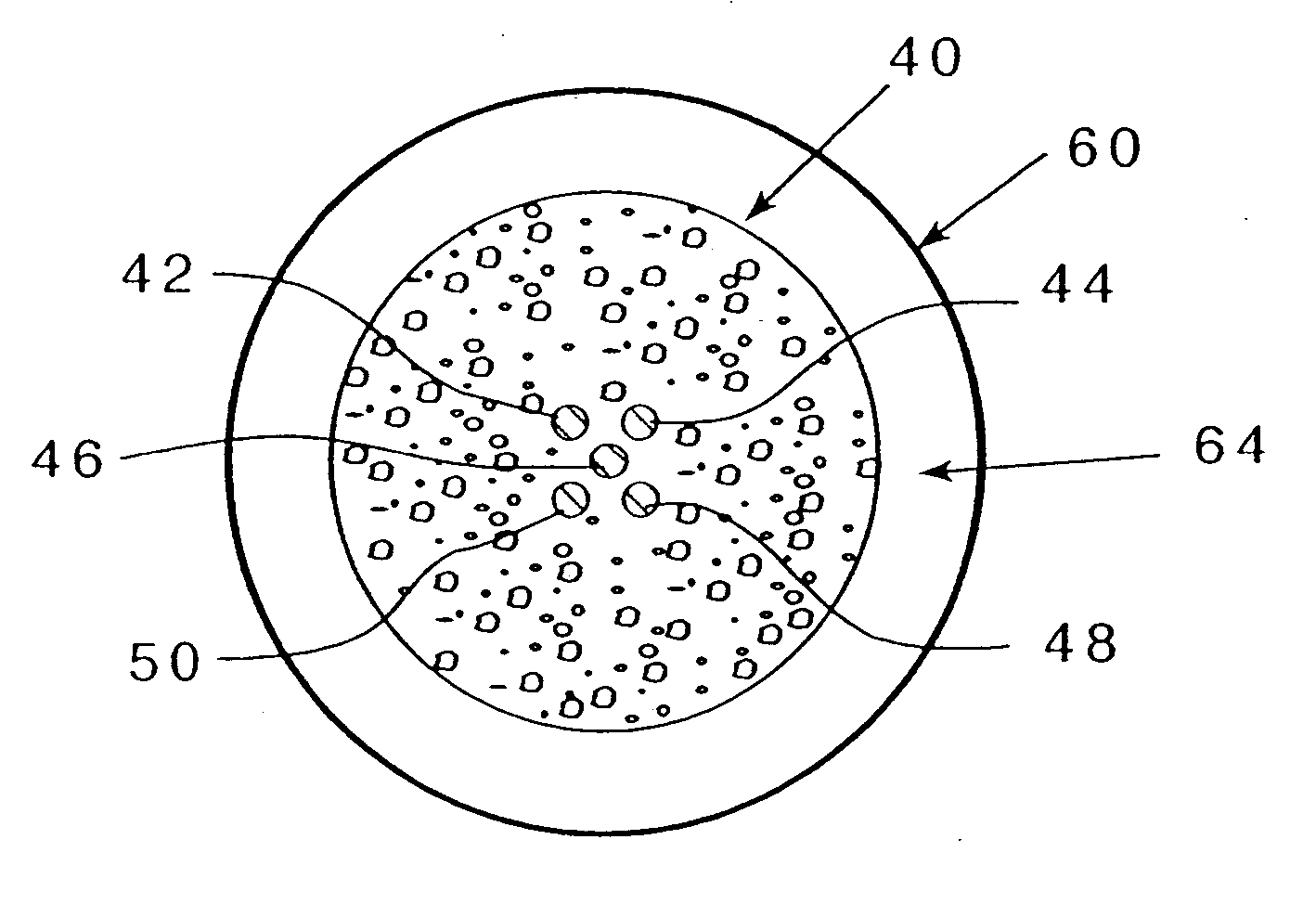

In situ formation of chloride sequestering compounds

InactiveUS20050235881A1Corrosion resistanceAvoid corrosionOther chemical processesChlorideMaterials science

The present invention provides methods and compounds for the in situ formation in concrete of chloride sequestering compounds that resist corrosion of metals contained within the concrete. These chloride sequestering compounds may include, but are not limited to, compounds having the formula 3CaO.Fe(2-x)AlxO3.Ca(NO2)2.nH2O and 3CaO.Fe(2-x)AlxO3.Ca(NO3)2.nH2O, where x ranges from about 0 to 1.4 and n ranges from about 8 to 24. In one embodiment, at least one Fe-containing additive is introduced into cement, and at least one anion-containing additive is introduced into mixing water. When the cement and mixing water are combined to create fresh concrete, the additives react to form chloride sequestering compounds. In another embodiment, the additives are introduced or mixed directly into fresh concrete that has already been formed, where they react to create chloride-sequestering compounds. “In situ” formation refers to the creation of a chloride sequestering compound within concrete.

Owner:BROWN PAUL W

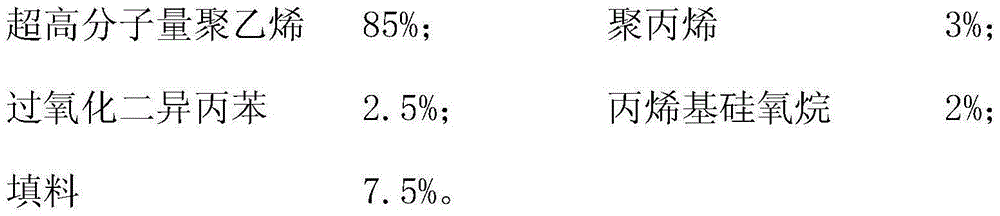

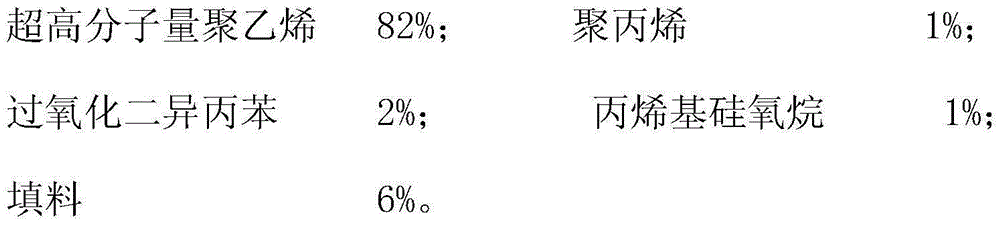

Ultra-high molecular weight polyethylene lining pipe

InactiveCN105199204AImprove liquidityExcellent thermal decompositionPolymer sciencePlastic materials

The invention discloses an ultra-high molecular weight polyethylene lining pipe. Raw materials including ultra-high molecular weight polyethylene, polypropylene, dicumyl peroxide, allyl siloxane and fillers are proportioned according to formula requirements, the raw materials are crushed and mixed by a mixing type particle crusher, then the grain size of powder materials is determined through a vibrating screen, and finally the proportioned raw materials are extruded to form the lining pipe through a plastic material extruding machine. By adding the dicumyl peroxide, the polypropylene and the allyl siloxane, the raw materials can be better decomposed under heating during injection molding, the flowability of plastic injection can be improved and the impact strength can be improved; by adding needle-shaped siliceous lime, the thermal deformation temperature can be improved; thereby through the combination of the raw materials, the effects of corrosion resistance, wear resistance and high temperature resistance are realized.

Owner:胜利油田金岛实业有限责任公司

CIPP hose for repairing trenchless underground pipe network, and preparation method and application of CIPP

InactiveCN108192182AAchieving wear resistanceAchieving Corrosion ResistancePipe elementsFiberEngineering

The invention relates to the technical field of pipeline engineering, and discloses a CIPP (cured in place pipe) for repairing a trenchless underground pipe network, and a preparation method and application of the CIPP. The CIPP for repairing the trenchless underground pipe network disclosed by the invention comprises a tubular fiber fabric, resin and a curing agent or a reactive diluent, whereinthe resin, the curing agent and the reactive diluent or the reactive diluent fill the fiber fabric; and the CIPP also comprises ultra-high-molecular-weight polyethylene, wherein the ultra-high-molecular-weight polyethylene is ultra-high-molecular-weight polyethylene particles or ultra-high-molecular-weight polyethylene fibers. The ultra-high-molecular-weight polyethylene has high impact strength,high wear resistance and low friction coefficient, so that the ultra-high-molecular-weight polyethylene is adopted as a single filler, then the CIPP can meet various repair performance requirements such as wear resistance, corrosion resistance, impact resistance, self-lubrication and the like, and meanwhile, the effects of simplifying formula, facilitating stirring and saving construction time areachieved. The ultra-high-molecular-weight polyethylene is safe and nontoxic, so that the CIPP provided by the invention can be used for repairing underground pipelines, and can also be used for repairing drinking water pipelines.

Owner:FUDAN UNIV +1

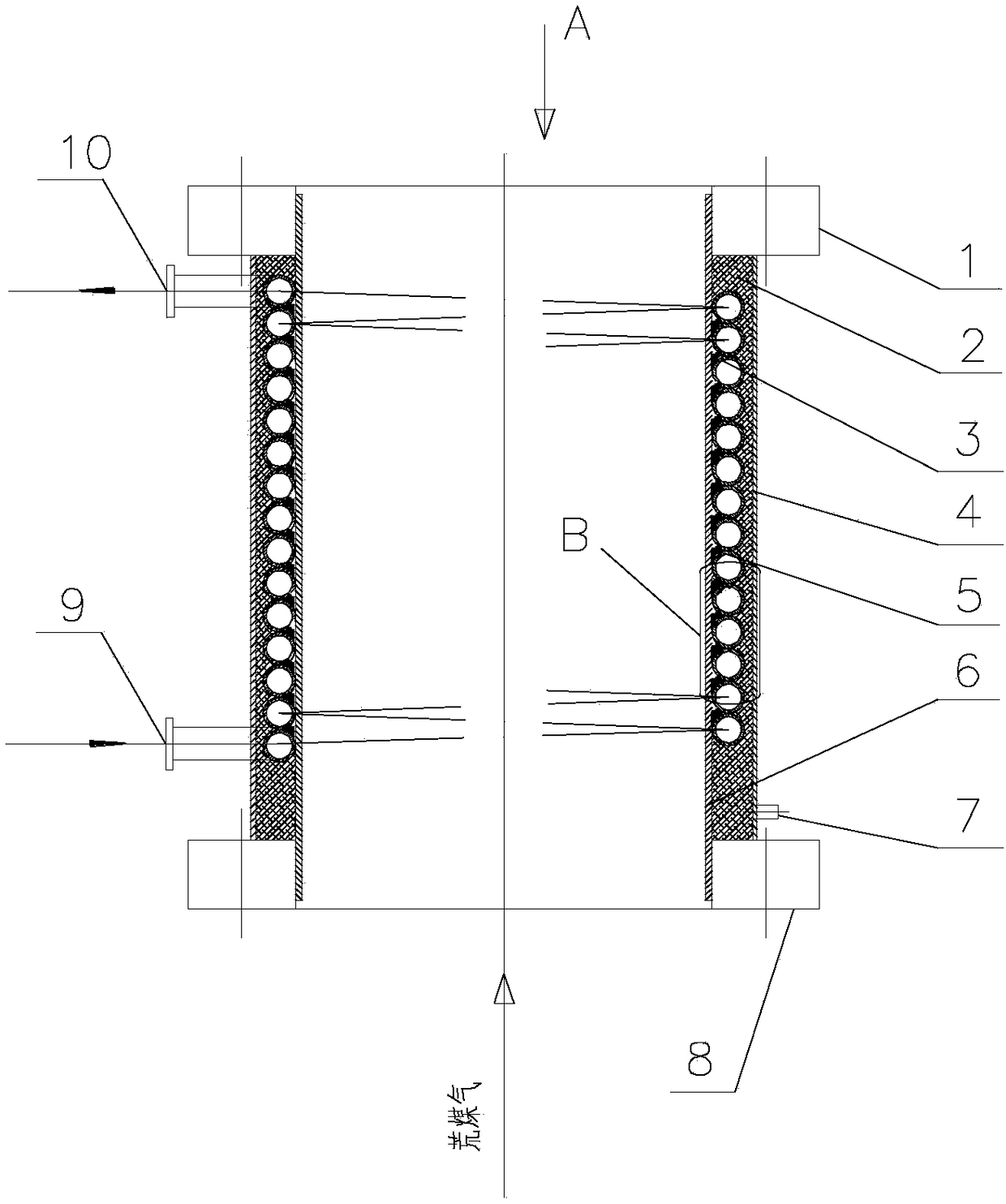

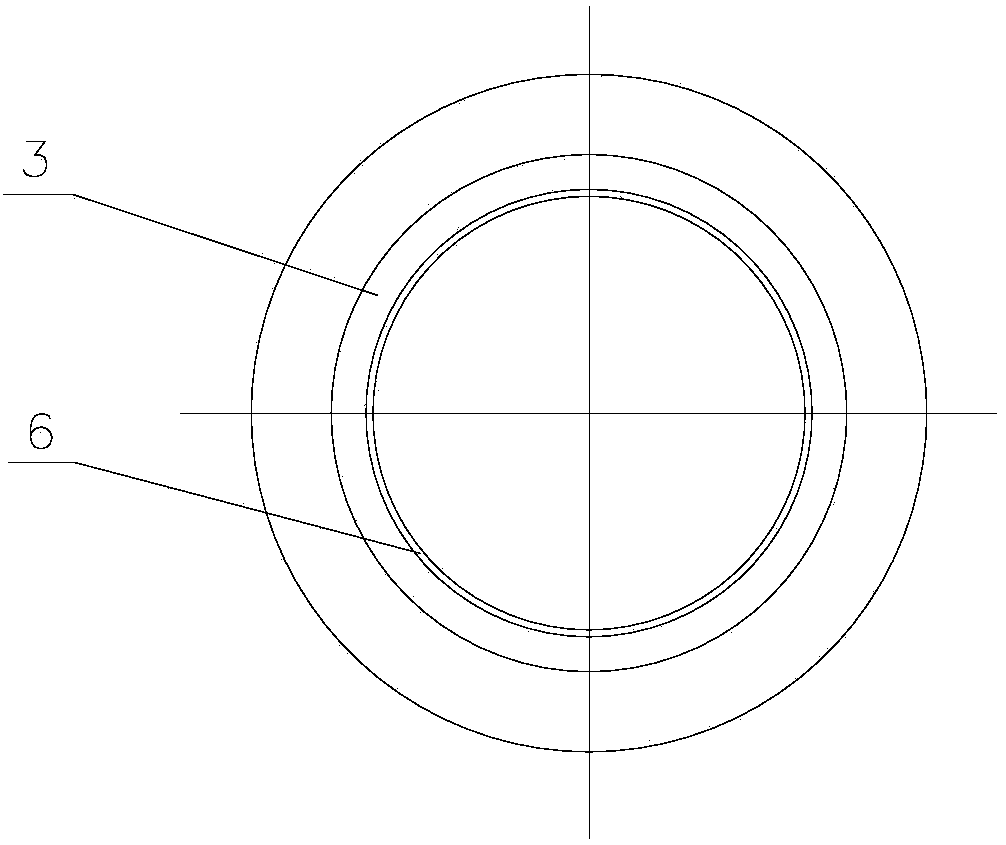

Spiral coil conduction type raw coke oven gas waste heat recovery equipment

PendingCN108467737AImprove securityFacilitate production operation managementEnergy inputIndirect heat exchangersWaste heat recovery unitTar

The invention discloses spiral coil conduction type raw coke oven gas waste heat recovery equipment. The spiral pipe conduction type raw coke oven gas waste heat recovery equipment comprises an ascending pipe inner barrel, an ascending pipe outer barrel and a heat transfer coil, wherein connecting flanges are arranged at the upper end and the lower end of the ascending pipe inner barrel and the ascending pipe outer barrel, the heat transfer coil is spirally wound on the outer side of the ascending pipe inner barrel, a heat transfer base plate is arranged between the heat transfer coil and theascending pipe inner barrel, the inner wall of the heat transfer base plate is tightly fitted with the outer wall of the ascending pipe inner barrel, the shape of the outer wall of the heat transfer base plate is matched with that of the heat transfer coil spirally wound on the heat transfer base plate, an insulating layer fills between the heat transfer coil and the ascending pipe outer barrel, and a vent nozzle is arranged at the bottom of the ascending pipe outer barrel. Compared with the prior art, the spiral coil conduction type raw coke oven gas waste heat recovery equipment has the beneficial effects that the heat transfer condition between the heat transfer coil and the ascending pipe inner barrel is improved, and the recovery rate of the heat of the raw coke oven gas is increased;the phenomenon that the tar in the raw coke oven gas is condensed on the cold wall is avoided; and the manufacturing cost of the waste heat recovery equipment is reduced.

Owner:樊晓光

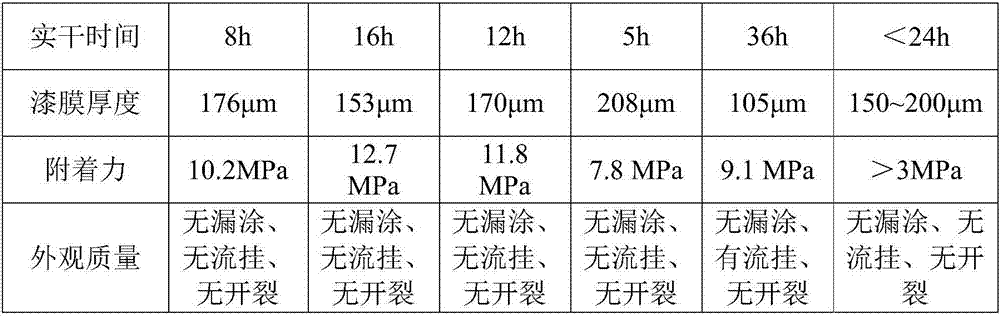

Battery testing device and using method thereof

ActiveCN110146821AAccurate detectionAchieving Corrosion ResistanceMeasurement of fluid loss/gain rateElectrical testingAviationComputer module

The invention discloses a battery testing device, which comprises a casing and a function module, wherein the casing comprises a shell and an accommodating cavity; one end of the shell is provided with an opening; the shell is internally provided with the accommodating cavity; the function module comprises a supporting frame, a first pipeline assembly, a second pipeline assembly, an aviation jointand multiple testing units; the supporting frame is buckled at the opening; the aviation joint is arranged on the supporting frame; the first pipeline assembly and the second pipeline assembly pass through the supporting frame; at least part of the first pipeline assembly and the second pipeline assembly is located in the accommodating cavity; the first pipeline assembly comprises a first metal valve and a second metal valve; the second pipeline assembly comprises a third metal valve; the first metal valve, the second metal valve and the third metal valve are arranged outside the accommodating cavity; the supporting frame, the first pipeline assembly and the second pipeline assembly are used as common electrodes of the battery testing device; and the multiple testing units are arranged inside the accommodating cavity. The invention also provides a using method for the battery testing device,.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

BOPET high-simulation metal wire drawing VCM film, use thereof, and VCM

ActiveCN103692725ASave production costSave manufacturing costSynthetic resin layered productsMetal layered productsBoPETCase hardening

The invention discloses a BOPET high-simulation metal wire drawing VCM film, a use thereof, and a VCM. The VCM film sequentially comprises a surface hardening coat, a transparent BOPET film with one surface subjected to surface wire drawing treatment, a fastness enhancing coat, a vacuum aluminum coat and an anti-oxidation protection coat; the surface hardening coat is an ultraviolet-curable polyurethane coating layer; the fastness enhancing coat is a polyurethane coating layer, and the above polyurethane coating is a primer with the model of SC-400 before aluminizing; and the anti-oxidation protection coat is a polyurethane coating layer, and the above polyurethane coating a top coating with the model of SC-500. The VCM film adopts single-layer BOPET as a film main material, so the consumption of a raw film is reduced, the production and making cost is saved, the life of a product is prolonged, and the tolerances of various bad conditions are improved. The VCM film has a best visual sense effect of a simulation metal wire drawing plate, and truly realizes the high simulation purpose of wire drawing metal plates of different materials.

Owner:SHANGHAI RADIX VACUUM METALIZING

Integrated system for utilizing residual heat of boiler smoke and removing sulfur

InactiveCN102087021BImprove efficiencyReduce the temperatureDispersed particle separationEnergy industrySlurryEngineering

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com