Self-repairing non-phosphorus ceramic processing liquid for galvanized plate and ceramic process thereof

A technology for treating liquid and galvanized sheet, applied in the direction of metal material coating process, etc., can solve the problems of low corrosion resistance, the film layer does not have self-healing ability, etc., achieves low processing temperature, solves the problem of phosphorus pollution and raw material cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

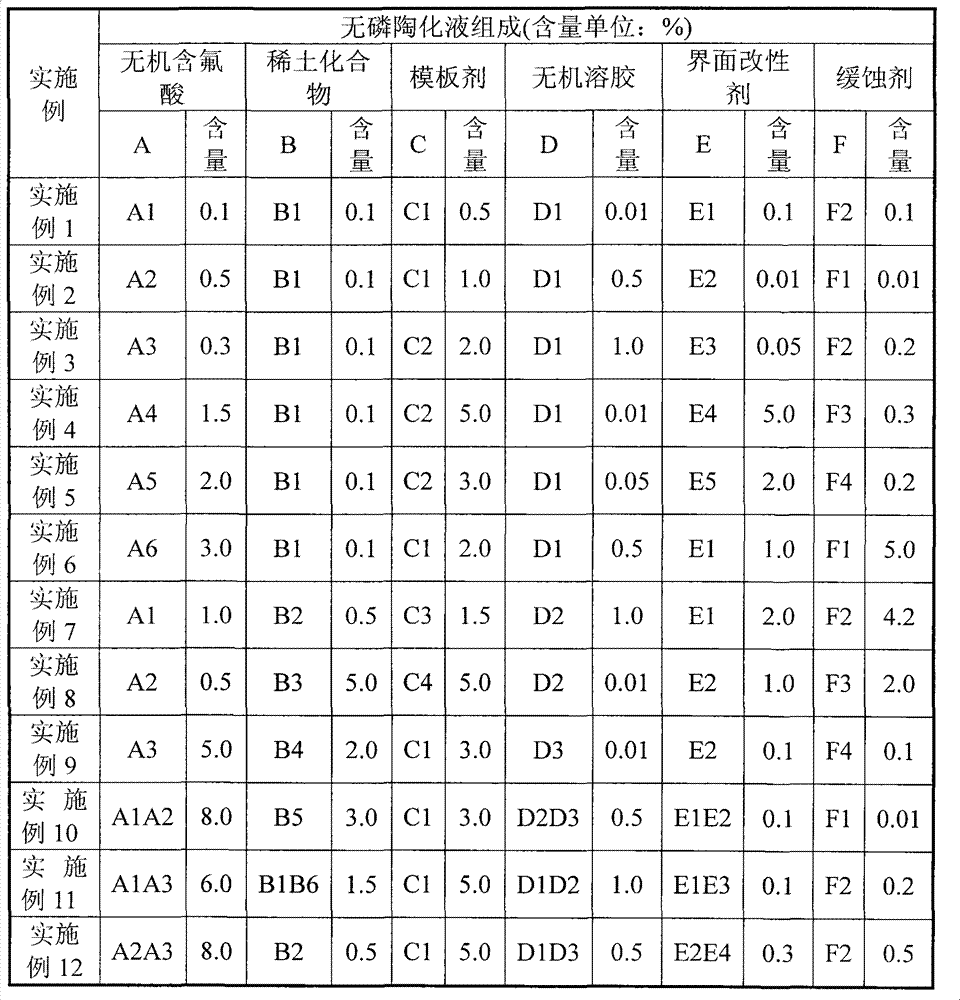

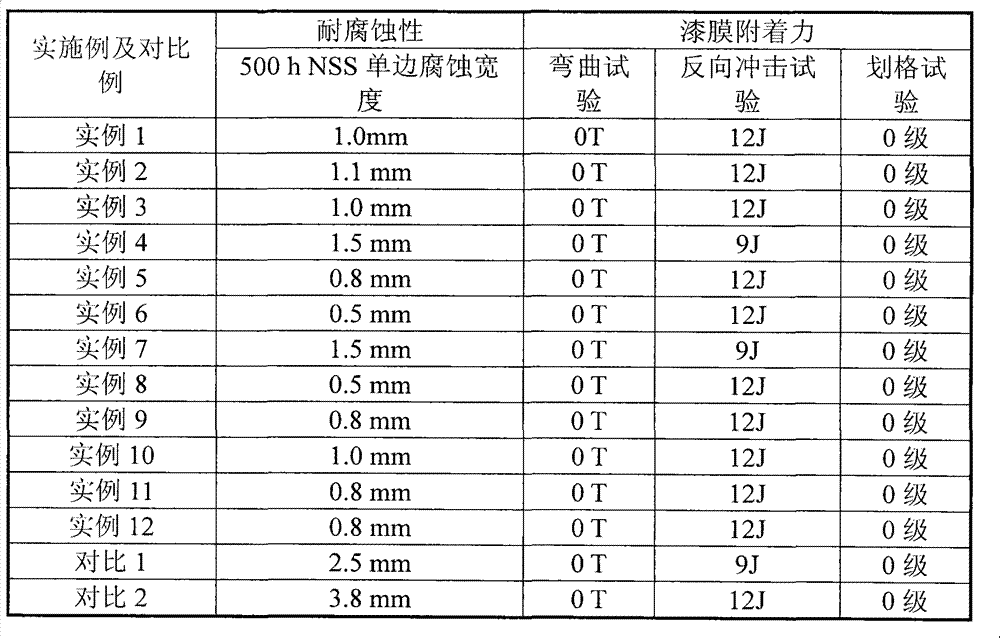

Examples

Embodiment 1

[0039] A kind of self-repairing phosphorus-free vitrification treatment solution for galvanized sheet comprises following components (by weight percentage):

[0040] h 2 TiF 6 0.1%, LaCl 3 0.1%, CTAC 0.5%, ZnO sol 0.01%, N-aminoethyl-γ-aminopropyltriethoxysilane 0.1%, H 3 BO 3 0.1%, the balance is water.

[0041] The optimum pretreatment temperature of the treatment solution is 25°C at room temperature, and the optimum treatment temperature after vitrification is 80°C.

Embodiment 2

[0043] A kind of self-repairing phosphorus-free vitrification treatment solution for galvanized sheet comprises following components (by mass percentage):

[0044] h 2 ZrF 6 0.5%, LaCl 3 0.1%, CTAC 1.0%, ZnO sol 0.5%, γ-glycidyl etheroxypropyl trimethoxysilane 0.01%, NaMoO 4 0.01%, the balance is water.

[0045] The optimum pretreatment temperature of the treatment solution is 25°C at room temperature, and the optimum treatment temperature after vitrification is 100°C.

Embodiment 3

[0047] A kind of self-repairing phosphorus-free vitrification treatment solution for galvanized sheet comprises following components (by mass percentage):

[0048] h 2 SiF 6 0.3%, LaCl 3 0.1%, SDS 2.0%, ZnO sol 1.0%, vinyltriethoxysilane 0.05%, H 3 BO 3 0.2%, the balance is water.

[0049] The optimum pretreatment temperature of the treatment liquid is 25°C at room temperature, and the optimum treatment temperature after vitrification is 110°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com