Zinc-plated steel sheet having coating film formed thereon and having excellent white rust resistance

A galvanized steel sheet and coating technology, which is applied in the direction of plating, coating, anti-corrosion coating, etc. of superimposed layers, can solve the problems of white rust on the end face and cannot fully suppress white rust, and achieve excellent white rust resistance, Inhibits the formation of zinc oxide, excellent corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example a1

[0222] Preparation example a1: Synthesis of polyester resin Aa1 solution

[0223] The starting material mixture shown below was placed in a reaction vessel equipped with a stirrer, thermometer, reflux condenser, etc., and heated from 160°C to 230°C over 3 hours. The produced water was distilled off by a rectification column, and the resulting product was kept at 230° C. for 1 hour. Thereafter, xylene was added thereto, dehydration was performed under reflux of xylene at 230° C., and esterification reaction was performed.

[0224] Ethylene glycol: 0.9mol

[0225] Neopentyl glycol: 0.1mol

[0226] Isophthalic acid: 0.95mol

[0227]When the acid value reached about 0, the resulting product was cooled to 140°C for 2 hours. After cooling, Swasol 1500 (high-boiling aromatic petroleum solvent, produced by Maruzen Petrochemical Co., Ltd.) was added thereto to thereby obtain a polyester resin Aa1 solution having a solid content of 35%. The obtained resin had a number average molec...

preparation example a2

[0229] Preparation example a2: Resole phenolic resin Ba1 solution

[0230] 100 parts of bisphenol A, 178 parts of 37% aqueous formaldehyde solution, and 1 part of sodium hydroxide were placed in a reaction vessel, and a reaction was performed at 60° C. for 3 hours. Thereafter, the reaction product was dehydrated under reduced pressure at 50 °C for 1 h. 100 parts of n-butanol and 3 parts of phosphoric acid were successively added thereto, and the reaction was performed at 110° C. to 120° C. for 2 hours. After the reaction was completed, the resulting solution was filtered, and the resulting sodium phosphate was filtered off to obtain a resole phenolic resin Ba1 solution with a solid content of 50%. The obtained resin had a number average molecular weight of 880, and had an average of 0.4 methylol groups and 1.0 alkoxymethyl groups per benzene nucleus.

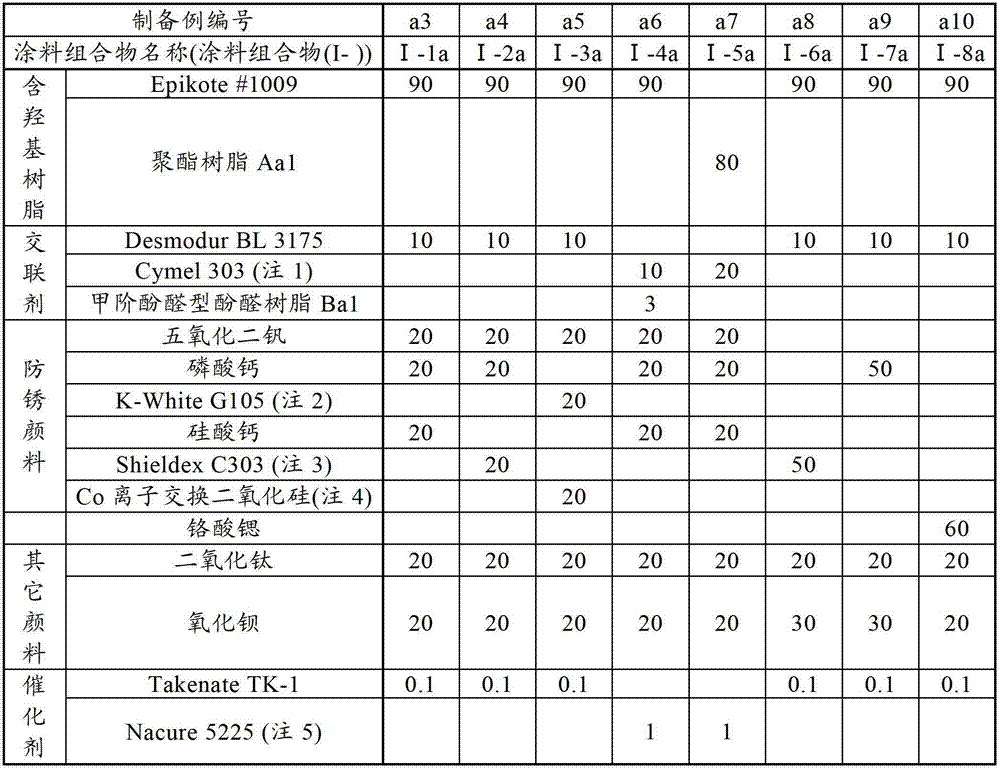

[0231] Coating composition (I) preparation 1

preparation example a3

[0233] Dissolve 90 parts of Epikote#1009 (manufactured by Japan Epoxy Resin Co., Ltd., bisphenol A type epoxy resin, hydroxyl-containing resin) in 135 parts of mixed solvent 1 (containing cyclohexanone / ethylene glycol monobutyl Ether / Solvesso 150 (manufactured by Esso Sekiyu K.K., high-boiling aromatic hydrocarbon solvent)=3 / 1 / 1 (mass ratio)) to obtain an epoxy resin solution. Then, 225 parts of this epoxy resin solution and 20 parts of vanadium pentoxide, 20 parts of calcium phosphate, 20 parts of calcium silicate, 20 parts of titanium dioxide, 20 parts of barium oxide and an appropriate amount of mixed solvent 2 (comprising Solvesso 150 (by Esso Sekiyu K.K. production, high-boiling aromatic hydrocarbon solvent) / cyclohexanone=1 / 1 (mass ratio)) mixing. Then, pigment dispersion is performed until the particles (particle diameter of pigment coarse particles) become 20 μm or less. Thereafter, 13.3 parts (solid content: 10 parts) of Desmodur BL 3175 (manufactured by Sumika Bayer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com