Battery testing device and using method thereof

A technology for battery testing and testing units, applied in measuring devices, using liquid/vacuum for liquid tightness measurement, measuring electricity, etc., can solve problems affecting test accuracy, high and low temperature resistance, delaying research and development progress, etc., to achieve Realize high and low temperature variable temperature test, realize the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

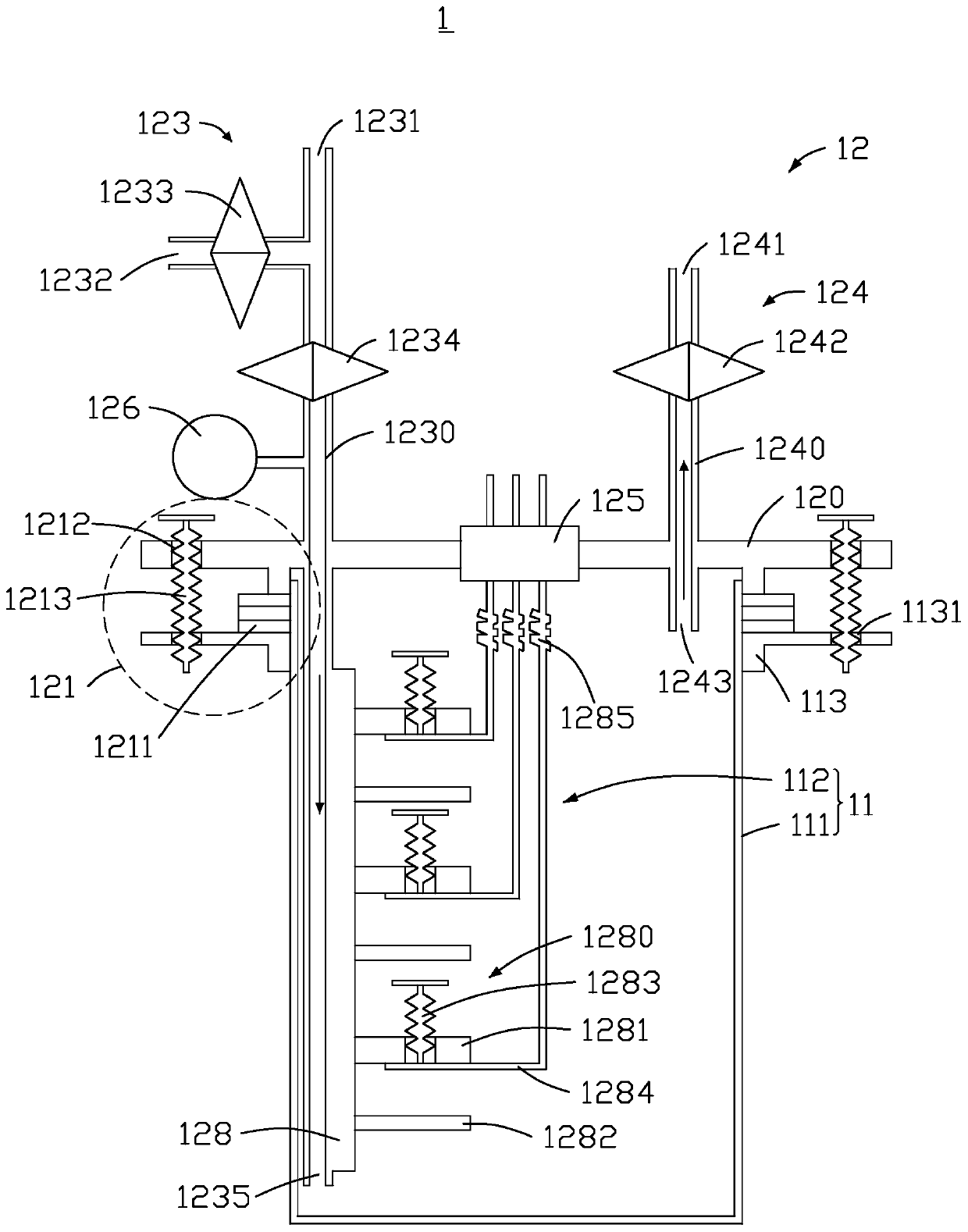

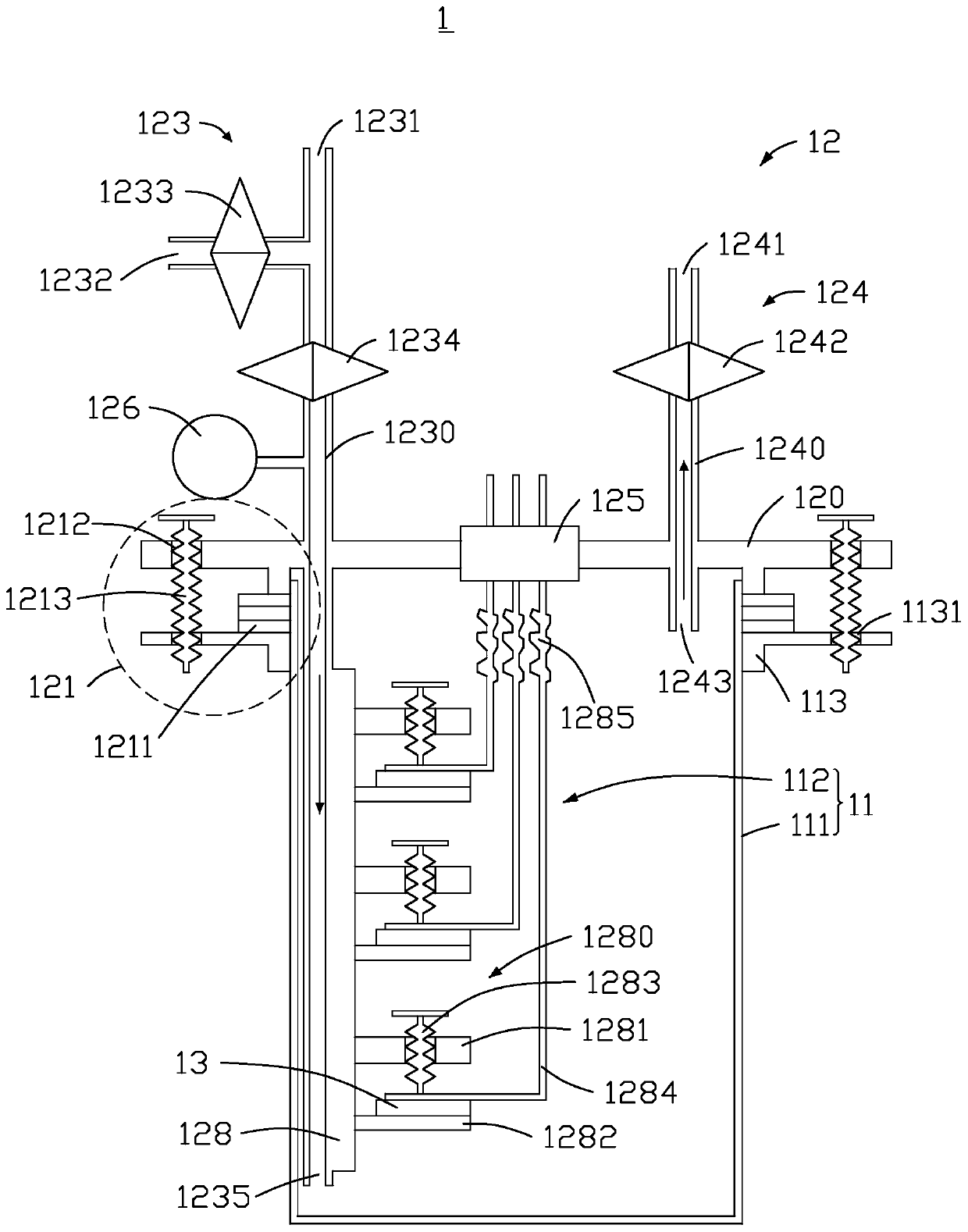

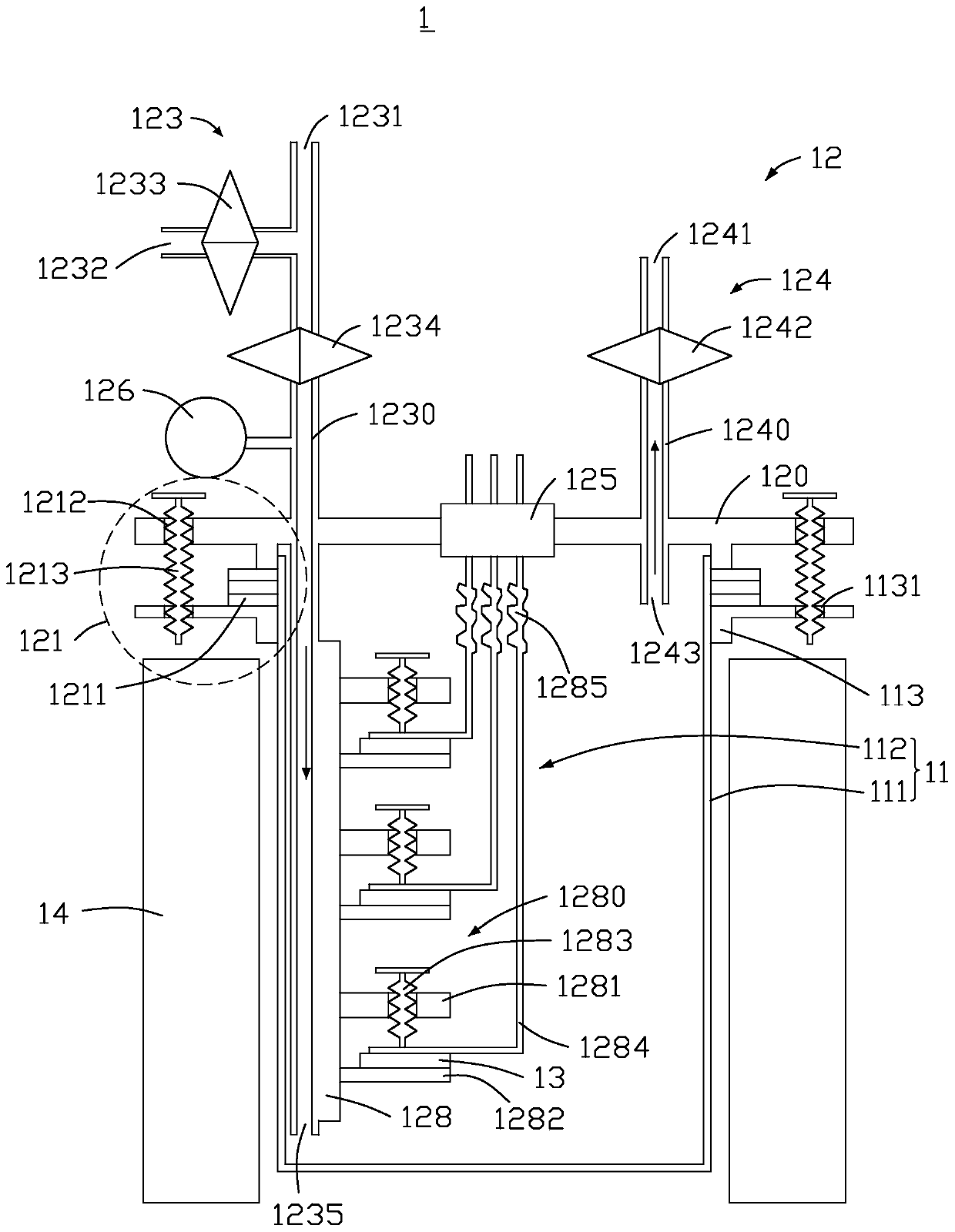

Image

Examples

Embodiment 1

[0069] First assemble the lithium-oxygen button cell in the glove box. Specifically: a commercial Li sheet (diameter 16mm, thickness 1mm) is used as the negative electrode, Super P (SP) carbon material is used as the conductive agent, La0.85Ca0.15Cr0.85O3@Ru (LCC@R) is used as the positive electrode catalyst, Whatman GF / D Glass fiber as diaphragm, CF 3 SO 3 Li / TEGDME is the electrolyte to assemble the battery. Among them, Super P, La 0.85 Ca 0.15 Cr 0.85 o 3 @Ru and the binder PVDF are coated on the nickel foam according to the ratio of 6:3:1 to prepare the positive electrode sheet. The assembled lithium-oxygen battery is tested with a battery testing device 1, Figure 4 The lithium-oxygen battery measured for an embodiment of the present invention is at room temperature charge and discharge electrochemical performance diagram, SP+La 0.85 Ca 0.15 Cr 0.85 o 3 The discharge platform of a lithium-oxygen battery with @Ru as the positive electrode is around 2.6V, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com