High-transmittance high-heat insulation energy-saving explosion-proof membrane and preparation process thereof

A preparation process and explosion-proof film technology, which is applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of insufficient attention to heat insulation performance, glass damage to surrounding personnel, temperature increase, etc. Achieving high visible light transmittance, significant thermal insulation effect, and improved molecular orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

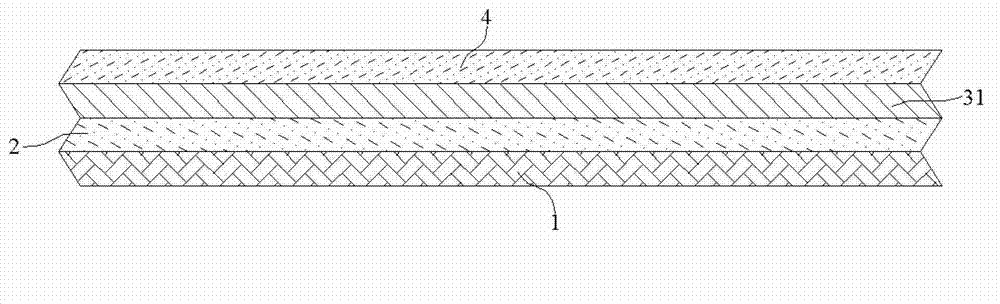

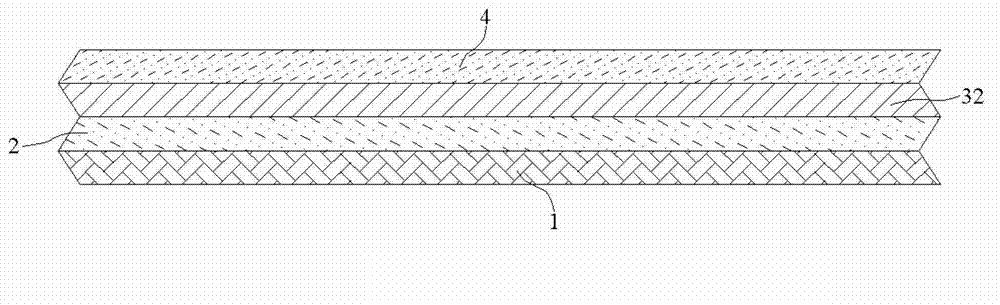

[0032] Embodiments 1 to 5: A high-transparency, high-heat-insulation, energy-saving and explosion-proof film, including a base material layer 1, a surface of the base material layer 1 is magnetron sputtered with a first metal indium layer 2, and the first metal indium layer 2 The other surface is magnetron sputtered with a metal silver layer 31 or a metal aluminum layer 32 as a heat insulating layer, and the other surface of the metal silver layer 31 or the metal aluminum layer 32 is magnetron sputtered with a second metal indium layer 4; The first metal indium layer has a thickness of 2-15 nm, the metal silver layer or metal aluminum layer has a thickness of 8-55 nm, and the second metal indium layer has a thickness of 5-20 nm.

[0033] Before magnetron sputtering of the above substrate layer, preheat shrinkage treatment is performed at 150-160°C.

[0034] An acrylic emulsion layer with a thickness of 0.5-5 μm is coated between the plastic base film and the first metal indium l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com