Manufacturing method of corrosion-resistance alloy hot-rolled steel pipe

A technology of corrosion-resistant alloys and manufacturing methods, applied in the direction of manufacturing tools, heat treatment furnaces, heat treatment equipment, etc., can solve problems such as poor corrosion resistance, lack of galvanizing equipment, and peeling off of the anti-corrosion layer, so as to avoid electrochemical corrosion and maintenance work The effect of ensuring corrosion resistance in a small amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

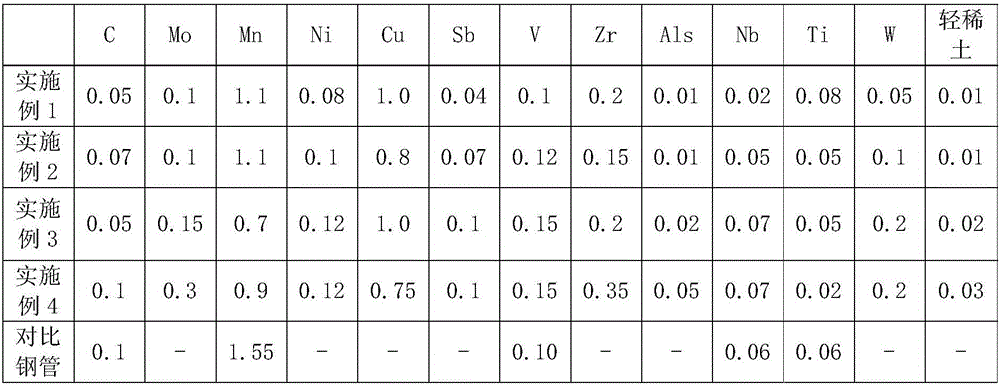

Embodiment 1

[0034] The composition of the steel pipe by weight percentage is: C 0.05%, Mo 0.1%, Mn: 1.1%, P≦0.02%, S≦0.002%, N≦0.005%, O≦0.001%, Ni 0.08%, Cu 1.0%, Sb 0.04%, V 0.1%, Zr 0.2%, Als 0.01%, Nb 0.02%, Ti 0.08%, W 0.05%, light rare earth LREE 0.01%, and satisfy 1.0%≤Cu+Zr+Als+Ti≤ 1.4%, the balance is Fe and unavoidable impurities;

[0035] The cooling step is to place the corrected steel pipe in a vacuum cooling furnace with a pressure of 10KPa and cool it to 850°C, then spray water on the surface of the steel pipe to cool it down to 650°C, and finally air-cool it. In the heating step, the steel pipe blank is heated to 1090°C, and then the piercing step is performed, the temperature of the steel pipe blank in the continuous rolling step is 1055°C, and the temperature of the steel pipe blank in the tension sizing step is 955°C.

Embodiment 2

[0037] The composition of the steel pipe by weight percentage is: C 0.07%, Mo 0.1%, Mn: 1.1%, P≦0.02%, S≦0.002%, N≦0.005%, O≦0.001%, Ni 0.1%, Cu 0.8%, Sb 0.07%, V 0.12%, Zr 0.15%, Als 0.01%, Nb 0.05%, Ti 0.05%, W 0.1%, light rare earth LREE 0.01%, and satisfy 1.0%≤Cu+Zr+Als+Ti≤ 1.4%, the balance is Fe and unavoidable impurities;

[0038] The cooling step is to place the corrected steel pipe in a vacuum cooling furnace with a pressure of 15KPa and cool it to 870°C, then spray water on the surface of the steel pipe to cool it down to 630°C, and finally air-cool it. In the heating step, the steel pipe blank is heated to 1090°C, and then the piercing step is performed, the temperature of the steel pipe blank in the continuous rolling step is 1055°C, and the temperature of the steel pipe blank in the tension sizing step is 940°C.

Embodiment 3

[0040] The composition of the steel pipe by weight percentage is: C 0.05%, Mo 0.15%, Mn: 0.7%, P≦0.02%, S≦0.002%, N≦0.005%, O≦0.001%, Ni 0.12%, Cu 1.0%, Sb 0.1%, V 0.15%, Zr 0.2%, Als 0.02%, Nb 0.07%, Ti 0.05%, W 0.2%, light rare earth LREE 0.02%, and satisfy 1.0%≤Cu+Zr+Als+Ti≤ 1.4%, the balance is Fe and unavoidable impurities;

[0041] The cooling step is to place the corrected steel pipe in a vacuum cooling furnace with a pressure of 30KPa and cool it to 900°C, then spray water on the surface of the steel pipe to cool it down to 600°C, and finally air-cool it. In the heating step, the steel pipe blank is heated to 1080°C, and then the piercing step is performed, the temperature of the steel pipe blank in the continuous rolling step is 1035°C, and the temperature of the steel pipe blank in the tension sizing step is 935°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com